1986 California F350 with 460 won't pass smog

#1

<< Moderator's Note - This thread is a bunch of posts broken out of Uno's thread dealing with starters & solenoids that transitioned to not passing the California emissions tests.

He's also got a thread in the Carburetor forum that gives useful information.... >>

hey 87-250-

I must have missed your post but just read it and wanted to thank you.

It appears for the time being that my issue is fixed or at the WORST dormant again.

I took back the new ignition switch and a new ignition lock cylinder cause it was NOT those things. It seems that in my particular situation it was the negative battery cable and connector that was causing the issue. I checked out all the other helpful suggestions but they all appeared to be in ok condition.

I have now moved on to trying to pass smog because of a CO reading that is 4 times what is acceptable here in CA. I started a thread relating to the problem in the Carb section but Im thinking I should have done it here in this forum..

I hope Im not committing some sort of crime by mention the problem here since I have another thread in another section but if so Im sorry.

Thanks again for everyone's input.

He's also got a thread in the Carburetor forum that gives useful information.... >>

hey 87-250-

I must have missed your post but just read it and wanted to thank you.

It appears for the time being that my issue is fixed or at the WORST dormant again.

I took back the new ignition switch and a new ignition lock cylinder cause it was NOT those things. It seems that in my particular situation it was the negative battery cable and connector that was causing the issue. I checked out all the other helpful suggestions but they all appeared to be in ok condition.

I have now moved on to trying to pass smog because of a CO reading that is 4 times what is acceptable here in CA. I started a thread relating to the problem in the Carb section but Im thinking I should have done it here in this forum..

I hope Im not committing some sort of crime by mention the problem here since I have another thread in another section but if so Im sorry.

Thanks again for everyone's input.

#2

18 lashes with a wet noodle!

J/K, you're fine.

I don't know that I've ever been to the carb forum in my life.

There's nothing saying you can't copy the text of your post and repost it over here....

#3

Thanks I appreciate the offer. Im beat for tonight gonna have at it again tomorrow..Ahhh one of my favorite things to do when I have no work...work on my truck.. Not that I dont enjoy working on things thats the story of my life I LOVE working on things but there is about 50,000 other things that need done around here and although they may be much more "work"... that work pales in comparison to the *&#%$ frustration of trying to find and fix something your cant find and therefor cant fix.

Not that I dont enjoy working on things thats the story of my life I LOVE working on things but there is about 50,000 other things that need done around here and although they may be much more "work"... that work pales in comparison to the *&#%$ frustration of trying to find and fix something your cant find and therefor cant fix.

Whew.. I feel a little better getting that rant out. So I would like to pull some of that thread over here but I want the most productive information in hopes of helping others as well.. Its a good thread and has some very common issues with this truck year and carb. Vacuum questions, Mixture adjustment questions, Float adjustments, the infamous PV (Power Valve) There are so many common issues with this year and model im surprised that there are not a whole series of stickies for each subject.

So I would like to pull some of that thread over here but I want the most productive information in hopes of helping others as well.. Its a good thread and has some very common issues with this truck year and carb. Vacuum questions, Mixture adjustment questions, Float adjustments, the infamous PV (Power Valve) There are so many common issues with this year and model im surprised that there are not a whole series of stickies for each subject.

Thanks again. Oh I almost forgot. I wasn't joking about it being a crime, seriously, Some forums are crazy about things like that and I just didn't want to ruffle any feathers off. But Im glad this is NOT one of them. THanks again.

Not that I dont enjoy working on things thats the story of my life I LOVE working on things but there is about 50,000 other things that need done around here and although they may be much more "work"... that work pales in comparison to the *&#%$ frustration of trying to find and fix something your cant find and therefor cant fix.

Not that I dont enjoy working on things thats the story of my life I LOVE working on things but there is about 50,000 other things that need done around here and although they may be much more "work"... that work pales in comparison to the *&#%$ frustration of trying to find and fix something your cant find and therefor cant fix. Whew.. I feel a little better getting that rant out.

So I would like to pull some of that thread over here but I want the most productive information in hopes of helping others as well.. Its a good thread and has some very common issues with this truck year and carb. Vacuum questions, Mixture adjustment questions, Float adjustments, the infamous PV (Power Valve) There are so many common issues with this year and model im surprised that there are not a whole series of stickies for each subject.

So I would like to pull some of that thread over here but I want the most productive information in hopes of helping others as well.. Its a good thread and has some very common issues with this truck year and carb. Vacuum questions, Mixture adjustment questions, Float adjustments, the infamous PV (Power Valve) There are so many common issues with this year and model im surprised that there are not a whole series of stickies for each subject. Thanks again. Oh I almost forgot. I wasn't joking about it being a crime, seriously, Some forums are crazy about things like that and I just didn't want to ruffle any feathers off. But Im glad this is NOT one of them. THanks again.

#4

Ok Im bringing some of the post info from the other forum and hope that someone can help me. My main issue facing is my CO reading after smog test (CA) is 4 times higher than acceptable readings. I need to get this down to pass.

The smog tec said there is a vacuum issue but it may not be all that is contributing to the high reading. He suggested that it may also be the float level. During the test he pulled off the line leading to the EGR valve and determined that what ever was supposed to control vacuum to this line was not working. He said the line is not plugged but something controlling vacuum to that line is not functioning properly. He clearly said that the EGR valve was functioning.

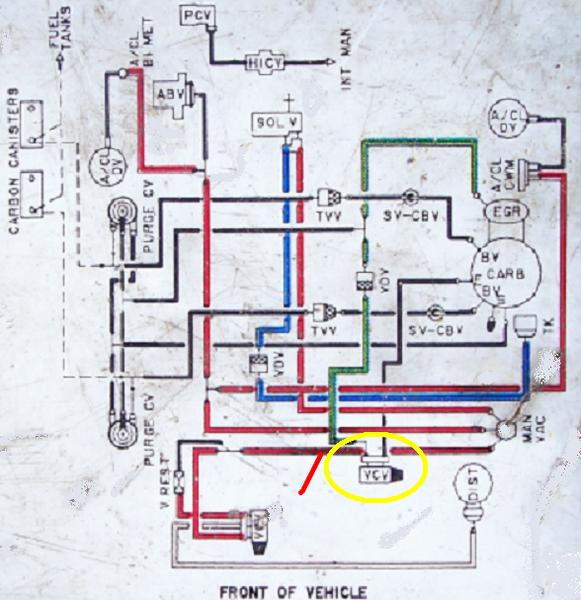

Now the GREEN line in the diagram below the best I can see is that it goes DIRECTLY into one of the 2 ports on that VCV valve. This is the line he pulled off and said it was not functioning properly he pulled it off at the EGR valve and now since I change them I dont remember if at the time it was going into the VCV valve or into a T or into the other 3 port VCV valve. At any rate it NOW is going directly into the 2 port VCV valve. If some one could tell me if it is in the correct place I would appreciate it.

What I have done so far:

In this pic I have been unable to find the specific names for the yellow port/valve and the whitish port/valve (both connected to the thermostat housing). I do not know how to check if these are working properly.

I have not changed any settings on the carb relating to mixture. Honestly I cant even find the darn things. I do have yet to change the harmonic balancer. In another unrelated post I determined by the responses that it has in fact slipped because I could not time it. HOWEVER I did adjust the timing by ear about 6 months ago because I was trying to time it and after not being able to get the mark anywhere close to where it should be I had to do it by ear because I had no way of knowing where it was before I started. It idles just fine I mean it only has 83,000 orig miles on it so its not PUUURRR fect but its not idling like the timing is way out of whack or even slightly out just nice and steady. Could the high reading be related to the timing being off as well?

Ok thats just about everything up to date..I will wait and hope patiently for some help.

Oh one more quick thing in the vac diagram where the blue line terminates at the valve mounted to the valve cover (on the diagram it looks like its labeled 90Lv) my valve has 3 ports. One is currently has a plug on it. Im assuming thats right cause the diagram only shows 2 lines going in. Thanks again.

The smog tec said there is a vacuum issue but it may not be all that is contributing to the high reading. He suggested that it may also be the float level. During the test he pulled off the line leading to the EGR valve and determined that what ever was supposed to control vacuum to this line was not working. He said the line is not plugged but something controlling vacuum to that line is not functioning properly. He clearly said that the EGR valve was functioning.

Now the GREEN line in the diagram below the best I can see is that it goes DIRECTLY into one of the 2 ports on that VCV valve. This is the line he pulled off and said it was not functioning properly he pulled it off at the EGR valve and now since I change them I dont remember if at the time it was going into the VCV valve or into a T or into the other 3 port VCV valve. At any rate it NOW is going directly into the 2 port VCV valve. If some one could tell me if it is in the correct place I would appreciate it.

What I have done so far:

- I changed the orientation of the vacuum lines from the way they were to the way I assume this diagram reads they should be. which for the most part is that the red vac line does NOT go into the VCV valve (circled in yellow) but UNDER it then on to the VCV valve on the left

- I have adjusted the float level so that fuel is just barely at the threads of the window.

- I took the Power Valve out and check it by sucking on it and the piston WENT IN which another member told me was the way to check it.

In this pic I have been unable to find the specific names for the yellow port/valve and the whitish port/valve (both connected to the thermostat housing). I do not know how to check if these are working properly.

I have not changed any settings on the carb relating to mixture. Honestly I cant even find the darn things. I do have yet to change the harmonic balancer. In another unrelated post I determined by the responses that it has in fact slipped because I could not time it. HOWEVER I did adjust the timing by ear about 6 months ago because I was trying to time it and after not being able to get the mark anywhere close to where it should be I had to do it by ear because I had no way of knowing where it was before I started. It idles just fine I mean it only has 83,000 orig miles on it so its not PUUURRR fect but its not idling like the timing is way out of whack or even slightly out just nice and steady. Could the high reading be related to the timing being off as well?

Ok thats just about everything up to date..I will wait and hope patiently for some help.

Oh one more quick thing in the vac diagram where the blue line terminates at the valve mounted to the valve cover (on the diagram it looks like its labeled 90Lv) my valve has 3 ports. One is currently has a plug on it. Im assuming thats right cause the diagram only shows 2 lines going in. Thanks again.

#5

What I have done is to remove them from the engine...

Put some short pieces of vacuum hose on all the nipples...

Put the assembly into a pan of water and heat it up on the stove; as it warms up, you will be able to blow/not blow through the various hoses.

This is real easy with 2- and 3-port valves as they're basically just like on/off switches, you can look at a diagram and figure out which nipple always has vacuum and which one gets vacuum when the thing warms up.

Same principle applies with the multi-port switches but it's just a bit more complicated is all as there are multiple ports to try and blow through.

Put some short pieces of vacuum hose on all the nipples...

Put the assembly into a pan of water and heat it up on the stove; as it warms up, you will be able to blow/not blow through the various hoses.

This is real easy with 2- and 3-port valves as they're basically just like on/off switches, you can look at a diagram and figure out which nipple always has vacuum and which one gets vacuum when the thing warms up.

Same principle applies with the multi-port switches but it's just a bit more complicated is all as there are multiple ports to try and blow through.

#7

Trending Topics

#8

#10

So, uno....

I read through your thread in the Carb forum, you haven't mentioned a VERY important point here (at least not that I remember) so I'm gonn ask you to go to User CP and finish filling out your profile so we can all see that you're in California.

What you enter (I believe in the 3rd pane) will show up on each post you make.

It sounds like you handled your starter solenoid problems?

High CO is generally a result of "incomplete combustion."

This can mean too little air in the fuel/air mixture, and/or too much gas, and/or incorrectly-set ignition timing.

A backfire out the exhaust can be caused by unburnt fuel coming into contact with hot exhaust valves and igniting.

The EGR valve induces air into the catalytic converter to promote burning of excess, unburnt fuel in the exhaust.

You said your vacuum delay valves (the white & yellow things) are working? Yet your EGR valve isn't being actuated?

This tells me that problem could very well be because of incorrect vacuum hose installation.

As I remember it, vacuum to the distributor switches between ported (from the carb) & manifold (from the intake manifold) vacuum dependent on engine temperature... the dist would normally get its vacuum from the carb unless the engine is running "too warm" at which time it switches to manifold vacuum, this advances the ignition timing which raises the idle speed which draws more air through the fan and across the radiator.

Ported (carb-supplied) vacuum doesn't exist at idle, manifold vacuum always exists.

The red will be connected to the red (in the yellow circle on your sticker).

That sticker bothers me... from the 3-port valve, the top red line connects to a restrictor device (V REST) which then connects to NOTHING! Orange arrow

It evaporates into the ether, I don't think that's right, but....

What you are calling 9OL V is "SOL V" which is a computer-controlled solenoid valve, possibly related to the EVAP system (Evaporative Emissions, traps gasoline fumes in a charcoal canister (one per tank) and later injects them back into the engine for combustion).

TK is a Throttle Kicker, bumps up the idle speed in certain situations. (air conditioning turned on, for example).

VDV is Vacuum Delay Valve, slows down the initiation of vacuum to a device.

The EGR is only supposed to operate at cruising speeds (2,000 or so RPM and above) and only when the engine is warmed up.

Get your engine warmed up, start it up, look at the EGR valve as you raise the engine speed with your hand, you should be able to see the diaphragm moving as it opens & closes.

If it doesn't, what you could do is first mark where everything is at right now so it can be put back to how it was if you need to.

If you are confident that 2-port white vacuum switch is working correctly, connect one nipple to the carb, the other nipple to a VDV, then from there to the EGR.

It looks like that's how the factory had it set up to begin with (according to that diagram, with the one hose disappearing into the ether).

I read through your thread in the Carb forum, you haven't mentioned a VERY important point here (at least not that I remember) so I'm gonn ask you to go to User CP and finish filling out your profile so we can all see that you're in California.

What you enter (I believe in the 3rd pane) will show up on each post you make.

It sounds like you handled your starter solenoid problems?

High CO is generally a result of "incomplete combustion."

This can mean too little air in the fuel/air mixture, and/or too much gas, and/or incorrectly-set ignition timing.

A backfire out the exhaust can be caused by unburnt fuel coming into contact with hot exhaust valves and igniting.

The EGR valve induces air into the catalytic converter to promote burning of excess, unburnt fuel in the exhaust.

You said your vacuum delay valves (the white & yellow things) are working? Yet your EGR valve isn't being actuated?

This tells me that problem could very well be because of incorrect vacuum hose installation.

As I remember it, vacuum to the distributor switches between ported (from the carb) & manifold (from the intake manifold) vacuum dependent on engine temperature... the dist would normally get its vacuum from the carb unless the engine is running "too warm" at which time it switches to manifold vacuum, this advances the ignition timing which raises the idle speed which draws more air through the fan and across the radiator.

Ported (carb-supplied) vacuum doesn't exist at idle, manifold vacuum always exists.

The red will be connected to the red (in the yellow circle on your sticker).

That sticker bothers me... from the 3-port valve, the top red line connects to a restrictor device (V REST) which then connects to NOTHING! Orange arrow

It evaporates into the ether, I don't think that's right, but....

What you are calling 9OL V is "SOL V" which is a computer-controlled solenoid valve, possibly related to the EVAP system (Evaporative Emissions, traps gasoline fumes in a charcoal canister (one per tank) and later injects them back into the engine for combustion).

TK is a Throttle Kicker, bumps up the idle speed in certain situations. (air conditioning turned on, for example).

VDV is Vacuum Delay Valve, slows down the initiation of vacuum to a device.

The EGR is only supposed to operate at cruising speeds (2,000 or so RPM and above) and only when the engine is warmed up.

Get your engine warmed up, start it up, look at the EGR valve as you raise the engine speed with your hand, you should be able to see the diaphragm moving as it opens & closes.

If it doesn't, what you could do is first mark where everything is at right now so it can be put back to how it was if you need to.

If you are confident that 2-port white vacuum switch is working correctly, connect one nipple to the carb, the other nipple to a VDV, then from there to the EGR.

It looks like that's how the factory had it set up to begin with (according to that diagram, with the one hose disappearing into the ether).

#11

Thanks for the reply

Ok so here is another bizzar recent twist. I recently adjustd the float levelas front and back (just below the threads in site glass/hole) I did the front one first and then yeaterday did the second one. After adjusting the FRONT float but BEFORE adjusting the BACK float I drove the truck and it was stuttering all over the place after resuming to drive after coming to a stop sign or slowing way down as if to anticipate a stop. IT ONLY does it when trying to accelerate after slowing down or resuming after a stop. cold or hot. It does not do it while driving at a regular consistent speed driving down freeway or large cross streets through town.

Ok now here is the twist. As I was doing the second one (Back) the idle speed increased slightly. I have not driven the truck since adjusting the second float level so I dont know if that got rid of the hesitating/back firing?

I have not driven the truck since adjusting the second float level so I dont know if that got rid of the hesitating/back firing?

Im going to warm it up chech the EGR operation then dirve it around the block this moring to see if anything new has changed.

Thanks again and any and all continued help is greatly appreciated.

So, uno....

I read through your thread in the Carb forum, you haven't mentioned a VERY important point here (at least not that I remember) so I'm gonn ask you to go to User CP and finish filling out your profile so we can all see that you're in California.

Done

It sounds like you handled your starter solenoid problems?

Well it seems that way we shall see.

This can mean too little air in the fuel/air mixture, and/or too much gas, and/or incorrectly-set ignition timing.

I have yet to replace the Harmonic Balancer and there fore cannot time it with light I was going to try the vacuum gauge method but have not done so yet.

I cant seem to remember which I should tackle first. I think that is the real problem here SEQUENCE. I mean I know I have to address the vacuum lines which by the way have been the way you suggested in this post for a couple of weeks now. But when it comes to timing and adjusting mixture/

You said your vacuum delay valves (the white & yellow things) are working? Yet your EGR valve isn't being actuated?

The smog guy told me this at the time of smog check. This was with the OLD set up of the vac lines. I have not checked for EGR movement since changing them.

This tells me that problem could very well be because of incorrect vacuum hose installation.

Yes Yes Yes...Which is where my questioning the hoses on the diagram comes into play. I really think that my problem lies with in those darn hoses and possibly related to the fact that my harmonic balancer has moved.

The red will be connected to the red (in the yellow circle on your sticker).

That is actually a length of hose that will reach all the way not 2 but Im with you I think although it doesnt really LOOK that way on the diagram (because of printing methods) it makes much more sense with that line going straight to the other.

That sticker bothers me... from the 3-port valve, the top red line connects to a restrictor device (V REST) which then connects to NOTHING! Orange arrow

I totally agree I mean it just STOPS and there is clearly no T just a connector between the 2 other lines. All of the other connections that show a T ...show a T and there is NOTHING that I can see that just shows a splice..It has got to be a printing error cause the one on the valve cover is the same thing.

It evaporates into the ether, I don't think that's right, but....

The EGR is only supposed to operate at cruising speeds (2,000 or so RPM and above) and only when the engine is warmed up.

Get your engine warmed up, start it up, look at the EGR valve as you raise the engine speed with your hand, you should be able to see the diaphragm moving as it opens & closes.

Yes this is an excellent suggestion. I mean we know for SURE that the EGR is operational well thats what the smog guy said. The real question here is is it operating.

If it doesn't, what you could do is first mark where everything is at right now so it can be put back to how it was if you need to.

I did this prior to changing it to the configuration we seem to be agreeing on here. I even took a photo.

If you are confident that 2-port white vacuum switch is working correctly, connect one nipple to the carb, the other nipple to a VDV, then from there to the EGR.

Thats EXACTLY how I have had it for a couple of weeks now.

It looks like that's how the factory had it set up to begin with (according to that diagram, with the one hose disappearing into the ether).

I read through your thread in the Carb forum, you haven't mentioned a VERY important point here (at least not that I remember) so I'm gonn ask you to go to User CP and finish filling out your profile so we can all see that you're in California.

Done

It sounds like you handled your starter solenoid problems?

Well it seems that way we shall see.

This can mean too little air in the fuel/air mixture, and/or too much gas, and/or incorrectly-set ignition timing.

I have yet to replace the Harmonic Balancer and there fore cannot time it with light I was going to try the vacuum gauge method but have not done so yet.

I cant seem to remember which I should tackle first. I think that is the real problem here SEQUENCE. I mean I know I have to address the vacuum lines which by the way have been the way you suggested in this post for a couple of weeks now. But when it comes to timing and adjusting mixture/

You said your vacuum delay valves (the white & yellow things) are working? Yet your EGR valve isn't being actuated?

The smog guy told me this at the time of smog check. This was with the OLD set up of the vac lines. I have not checked for EGR movement since changing them.

This tells me that problem could very well be because of incorrect vacuum hose installation.

Yes Yes Yes...Which is where my questioning the hoses on the diagram comes into play. I really think that my problem lies with in those darn hoses and possibly related to the fact that my harmonic balancer has moved.

The red will be connected to the red (in the yellow circle on your sticker).

That is actually a length of hose that will reach all the way not 2 but Im with you I think although it doesnt really LOOK that way on the diagram (because of printing methods) it makes much more sense with that line going straight to the other.

That sticker bothers me... from the 3-port valve, the top red line connects to a restrictor device (V REST) which then connects to NOTHING! Orange arrow

I totally agree I mean it just STOPS and there is clearly no T just a connector between the 2 other lines. All of the other connections that show a T ...show a T and there is NOTHING that I can see that just shows a splice..It has got to be a printing error cause the one on the valve cover is the same thing.

It evaporates into the ether, I don't think that's right, but....

The EGR is only supposed to operate at cruising speeds (2,000 or so RPM and above) and only when the engine is warmed up.

Get your engine warmed up, start it up, look at the EGR valve as you raise the engine speed with your hand, you should be able to see the diaphragm moving as it opens & closes.

Yes this is an excellent suggestion. I mean we know for SURE that the EGR is operational well thats what the smog guy said. The real question here is is it operating.

If it doesn't, what you could do is first mark where everything is at right now so it can be put back to how it was if you need to.

I did this prior to changing it to the configuration we seem to be agreeing on here. I even took a photo.

If you are confident that 2-port white vacuum switch is working correctly, connect one nipple to the carb, the other nipple to a VDV, then from there to the EGR.

Thats EXACTLY how I have had it for a couple of weeks now.

It looks like that's how the factory had it set up to begin with (according to that diagram, with the one hose disappearing into the ether).

Ok now here is the twist. As I was doing the second one (Back) the idle speed increased slightly.

I have not driven the truck since adjusting the second float level so I dont know if that got rid of the hesitating/back firing?

I have not driven the truck since adjusting the second float level so I dont know if that got rid of the hesitating/back firing?Im going to warm it up chech the EGR operation then dirve it around the block this moring to see if anything new has changed.

Thanks again and any and all continued help is greatly appreciated.

#12

With the engine off, remove the air cleaner and look down the throat of the carb as you fully open the throttle with your hand.

You should see two strong streams of fuel being injected into the engine.

If you see non, or only a dribble, your Accelerator Pump is shot (in which case I'd just rebuild the entire carb).

I would verify (and fix if needed) that, then do the harmonic balancer so you can get the timing correct.

#14

High CO levels can come from a number of things (glad I don't have to deal with smog checks). First item, when setting float levels on a Holley carb, if you are raising them because they are low, not a real problem. When you go to lower them, as you turn the adjustment down the float will push fuel out the sight plug. After an adjustment on the primary (front) bowl, you need to raise the rpm to about 2000 for a min or so, then idle and recheck. On the secondary, it's harder as the rear barrels don't come in until you get quite a bit of rpm. I used to take a rag and loosen one of the bottom bowl screws until gas ran out to "cheat" the level down.

What effect do your idle mixture screws have? if turning them all the way in just makes it run better, than you may have what I call "unmetered fuel" due to a number of things, leaking power valve, leaking O-rings on the accelerator pump transfer tube, warped secondary metering body. Make sure all of your air pump stuff is working correctly too.

What effect do your idle mixture screws have? if turning them all the way in just makes it run better, than you may have what I call "unmetered fuel" due to a number of things, leaking power valve, leaking O-rings on the accelerator pump transfer tube, warped secondary metering body. Make sure all of your air pump stuff is working correctly too.

#15

Join Date: Jul 2004

Location: Northern California

Posts: 8,786

Likes: 0

Received 18 Likes

on

17 Posts

As I remember it, vacuum to the distributor switches between ported (from the carb) & manifold (from the intake manifold) vacuum dependent on engine temperature... the dist would normally get its vacuum from the carb unless the engine is running "too warm" at which time it switches to manifold vacuum, this advances the ignition timing which raises the idle speed which draws more air through the fan and across the radiator.

Ported (carb-supplied) vacuum doesn't exist at idle, manifold vacuum always exists.

Ported (carb-supplied) vacuum doesn't exist at idle, manifold vacuum always exists.

There are variations even with manifold vacuum where it can increase and decrease depending on engine RPM and load. (Which is how this engine controls Distributor vacuum advance functions along with engine temperature)

The red will be connected to the red (in the yellow circle on your sticker).

That sticker bothers me... from the 3-port valve, the top red line connects to a restrictor device (V REST) which then connects to NOTHING! Orange arrow.

It evaporates into the ether, I don't think that's right, but....

What you are calling 9OL V is "SOL V" which is a computer-controlled solenoid valve, possibly related to the EVAP system (Evaporative Emissions, traps gasoline fumes in a charcoal canister (one per tank) and later injects them back into the engine for combustion).

TK is a Throttle Kicker, bumps up the idle speed in certain situations. (air conditioning turned on, for example).

VDV is Vacuum Delay Valve, slows down the initiation of vacuum to a device.

VDV is Vacuum Delay Valve, slows down the initiation of vacuum to a device.

The EGR is only supposed to operate at cruising speeds (2,000 or so RPM and above) and only when the engine is warmed up.

Get your engine warmed up, start it up, look at the EGR valve as you raise the engine speed with your hand, you should be able to see the diaphragm moving as it opens & closes.

If it doesn't, what you could do is first mark where everything is at right now so it can be put back to how it was if you need to.

If you are confident that 2-port white vacuum switch is working correctly, connect one nipple to the carb, the other nipple to a VDV, then from there to the EGR.

If you are confident that 2-port white vacuum switch is working correctly, connect one nipple to the carb, the other nipple to a VDV, then from there to the EGR.

It looks like that's how the factory had it set up to begin with (according to that diagram, with the one hose disappearing into the ether).