Metal Bumping help needed

#1

Metal Bumping help needed

I have been trying to gently hammer out half a century of little bumps and dents on my '53 F-100. For the most part I have been successful, although I'm slow. I don't have any training with hammer and dolly technique, so I'm learning as I go. I have made a few mistakes. The one I am concerned with here is that I think I may have over-hammered part of the cab roof, causing the metal to expand and form an outward bulge. I need some advice. Is there a way to hammer this bulge down, or will any more hammering just increase the size of the bulge as I hammer on it? Would shrinking lower the bulge? If so, heat or shrinking hammer? I just got "Key To Metal Bumping" book which describes lowering bulges using heat and a pick hammer. Is this the best technique? Note that the roof section that I have messed up curves in both directions, but the curving is very gradual. Do shrinking hammers work on concave/convex surfaces, or just flat surfaces? Eventually, I will move onto repairing the back panel of the metal bed, where a considerable belly in that panel will have to be starightened out. So, I'm probably going to have to buying a shrinking hammer at some point. Thanks for any advice.

#3

Yes, I have been using a dolly, but I think I may be using it incorrectly. For most of the small dents that I have been hammering out, I have used the dolly as if it was a little anvil. For what it;s worth, I spent some time today working on the spot, and I was able to "reduce the swelling" of the bulge that I created. What I have now is a spot about two or three inches in diameter that has a high point about 1/16" higher than it should be.

#4

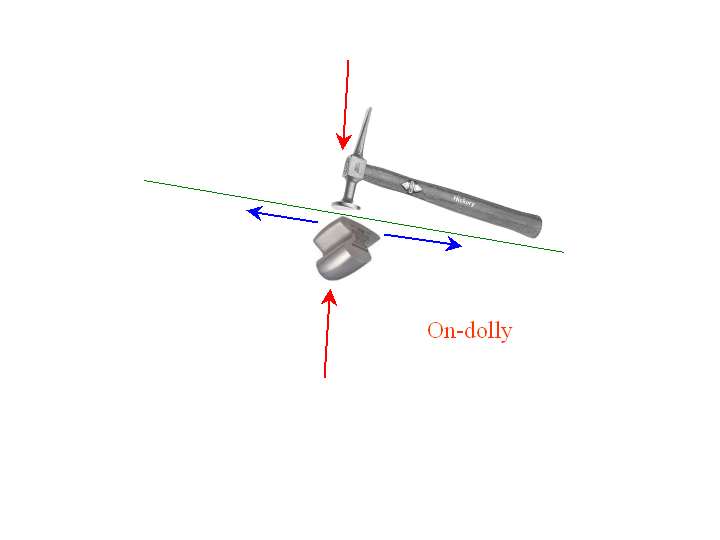

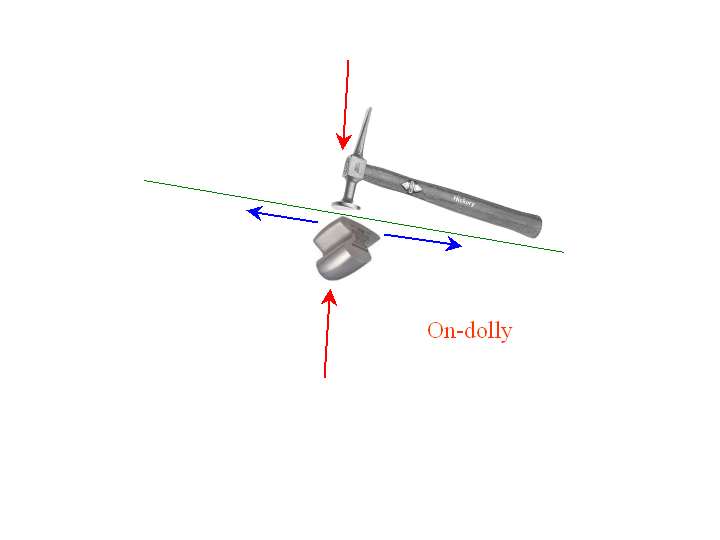

Two basic methods of using the hammer and dolly....on-dolly and off-dolly. To further explain what is occurring when using On-dolly, hammer and dolly are directly lined up with each other on opposite sides of the metal, and when you strike the hammer you will hear a ping as the force travels through to the dolly. (see red arrows in sketch below) The secondary action is that this forces the metal outward (blue arrows), in essence stretching the metal.

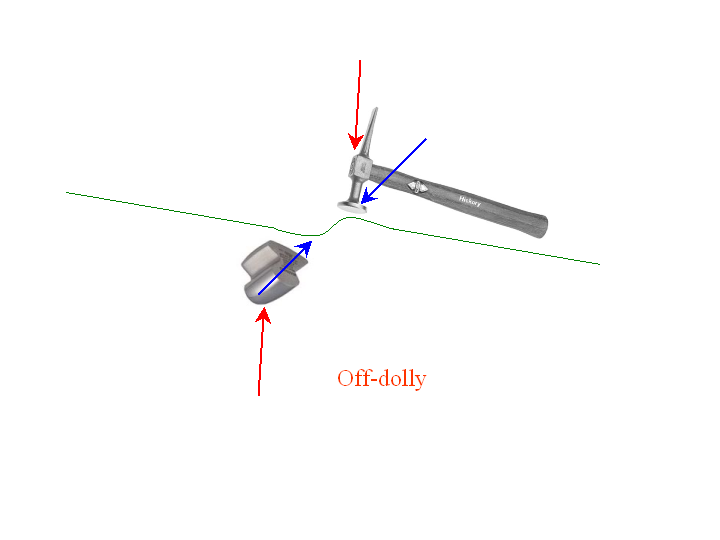

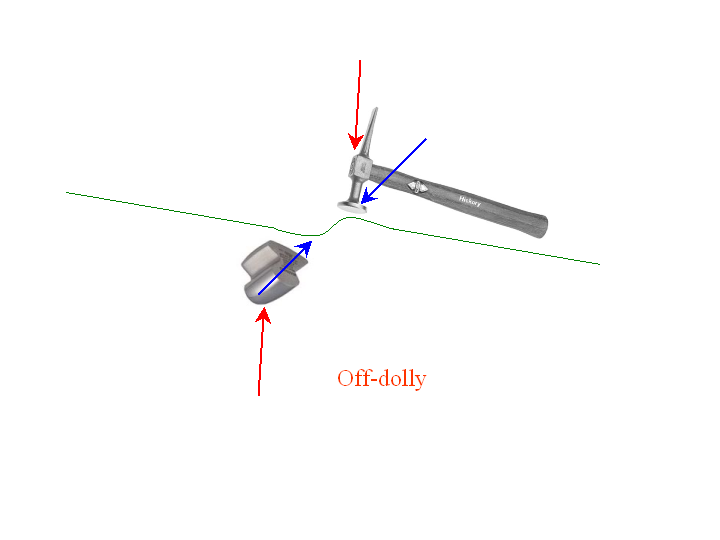

Using the off dolly technique, each tool on the high part of their side of a dent in the panel, striking the panel with the hammer will force the metal bulge of that side downward (see red arrow in sketch below) as does the dolly on its side of the panel. The secondary action in this case is to force the metal back into itself (blue arrows), as well as raising/lowering the metal more toward being level. By no means will you see the amount of shrinking that takes place when you introduce heat, such as with the torch or shrinking disc. But it shrinks, just the same. For a small, localized dent, a body spoon may work better than the hammer as it has a larger face to spread the force across, less chance of hammer marks.

Also try doing a search on YouTube for videos on the subject, there are some good ones out there that will surely be a better study than my text reply..

.

Using the off dolly technique, each tool on the high part of their side of a dent in the panel, striking the panel with the hammer will force the metal bulge of that side downward (see red arrow in sketch below) as does the dolly on its side of the panel. The secondary action in this case is to force the metal back into itself (blue arrows), as well as raising/lowering the metal more toward being level. By no means will you see the amount of shrinking that takes place when you introduce heat, such as with the torch or shrinking disc. But it shrinks, just the same. For a small, localized dent, a body spoon may work better than the hammer as it has a larger face to spread the force across, less chance of hammer marks.

Also try doing a search on YouTube for videos on the subject, there are some good ones out there that will surely be a better study than my text reply..

.

#5

So, it looks like I have created the new swollen spot on my cab roof by hammering on dolly and stretching the metal. I spent some time gently tapping around the affected area off-dolly, and I did reduce it somewhat. Now, it looks like I have to try and shrink the spot that I stretched. I have access to a torch, and I'm up for trying to shrink the spot using the shrinking method described in "The Key to Metal Bumping". Or, as I have seen online, I could just heat and quickly cool the spot and try to shrink it that way. I am interested in trying out a shrinking hammer, too. I currently do not own one. And, if a shrinking hammer is not a recommended way to shrink this spot (and a few others), then I would just as soon put off spending the money. If a shrinking hammer is the way to go, then which kind is best. I am aware of the traditional waffle pattern as well as a spiral pattern on the face that twists a bit when it strikes the metal.

#6

The spiral pattern ones are junk IMHO, to hit the panel with enough force for the spiral effect to work, you are risking more stretching. The waffle pattern ones will gather the metal fairly well, but don't leave the metal flat as you now have a waffled panel. I personally don't find this a metal bumping tool, but more of a body work tool. I'd rather not use a tool that dictates I use body filler to fix the flaws that it leaves. You can do plenty of shrinking with heat, with a shrinking disc, off-dolly with a low crown hammer, etc without making your roof look like a meat tenderizer has been there.

I'd also suggest looking on you tube for videos on shrinking metal with the shrinking disc, and also with a torch. View quite a few different ones by different users and then decide which method would work best for you (before running out and buying any shrinking gadgets)

I'd also suggest looking on you tube for videos on shrinking metal with the shrinking disc, and also with a torch. View quite a few different ones by different users and then decide which method would work best for you (before running out and buying any shrinking gadgets)

#7

I appreciate the advice. I think the best thing for me to do now is recreate the bulge that I made on my cab roof on a piece of scrap sheet steel. Then I'll practice using a torch shrinking this new bulge till it's flat. I will follow up on this post by describing the success or failure of my attempts. That may not be for a few weeks. Thanks again for your input.

Trending Topics

#8

The one thing you need to remember before any dent repair...the metal is already stretched. Depending on how big the dent(s) are and how many there are in one panel will greatly affect how you remove those dents. The hammers, dollies and slapping spoons with the waffle pattern is used for shrinking the metal. I am not really sure how they work since I learned a different technique (heating, hammering and then quenching) We always heated the panel, then using a dollie and hammer, hammer around the heated area, striking towards the center of the heated area. Then once you are satisfied, take a wet rag and put the rag on the heated spot. This is an old school way of hammering out major dents that have stretched the metal.

#10

Shrinking hammers are worthless. They do more damage then good. Look into a smooth shrinking disc. That's what I'm going to use on my dented up roof.

Check out this site if you want to learn about metal shaping/repair. All MetalShaping - Powered by vBulletin

Thread

Thread Starter

Forum

Replies

Last Post

AXracer

1948 - 1956 F1, F100 & Larger F-Series Trucks

109

08-21-2020 02:41 PM

underthebridgejim

1948 - 1956 F1, F100 & Larger F-Series Trucks

12

05-10-2017 08:34 PM

James Hogan

1968-Present E-Series Van/Cutaway/Chassis

6

01-23-2016 12:38 AM

AXracer

1948 - 1956 F1, F100 & Larger F-Series Trucks

11

05-08-2015 03:42 PM