Offy C PITA!!!! Quick Question? may have found my problem!

#1

Offy C PITA!!!! Quick Question? may have found my problem!

ok I finally got my truck back in the garage and found that the stupid Offy C intake has another cracked mounting tab! whats gives why did this crack? I think that the runners are to long causing the thing to be to heavy with the 2100 mounted on it and nothing under the EFI manifolds to keep it braced. Would it help if I went back to a stock exhaust maniflold under the Offy C had it fixed and kept the thing.

Could I mount the offy c to a stock exhaust manifold and have heat to it?

How do I go about making the washers grab more of the mounting tabs? I guess I could have some steel ones made just a little larger in Diamiter or oval shapped?

Could I mount the offy c to a stock exhaust manifold and have heat to it?

How do I go about making the washers grab more of the mounting tabs? I guess I could have some steel ones made just a little larger in Diamiter or oval shapped?

#2

Sounds like a pain. However, the only reason I've ever had one break is from the gasket underneath it splitting, causing the tab to fold in.

If I were you, I'd have the tab welded back on (find a shop that specializes in aluminum welding), and then have it planed flat. I'm thinking it could be warped, so when you torque it, it bends and breaks.

Also, be sure there's NO residual pieces of previous gaskets on any mounting surface on the block or intake, that'll cause breakage right away.

Even though it didn't cause any breaking, I have had problems with washers not being large enough to spread over the distance of some of the tabs. Find a local fastener place and get some hardened grade-8 washers that are larger in diameter than the ones you're using now. On mine, I have a stack of two washers, and then a split washer to give a little extra press onto the manifold for a better seal. It works really well.

Other than that, I've taken mine on some pretty serious hard off-roading and banging around with the weight of a Holley 4bbl on top of it and it doesn't have any problems. I don't think they're heavy enough to break themselves.

If I were you, I'd have the tab welded back on (find a shop that specializes in aluminum welding), and then have it planed flat. I'm thinking it could be warped, so when you torque it, it bends and breaks.

Also, be sure there's NO residual pieces of previous gaskets on any mounting surface on the block or intake, that'll cause breakage right away.

Even though it didn't cause any breaking, I have had problems with washers not being large enough to spread over the distance of some of the tabs. Find a local fastener place and get some hardened grade-8 washers that are larger in diameter than the ones you're using now. On mine, I have a stack of two washers, and then a split washer to give a little extra press onto the manifold for a better seal. It works really well.

Other than that, I've taken mine on some pretty serious hard off-roading and banging around with the weight of a Holley 4bbl on top of it and it doesn't have any problems. I don't think they're heavy enough to break themselves.

#3

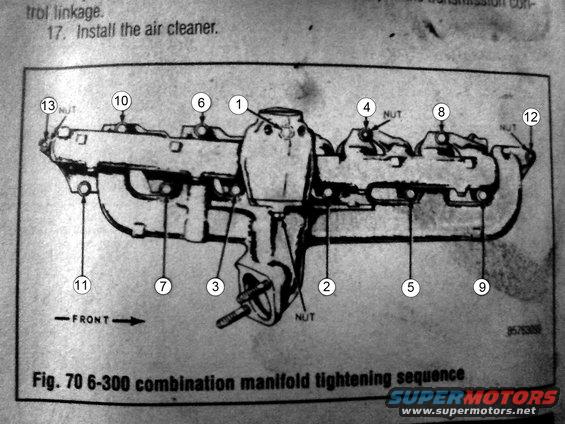

Use only Mr. Gasket #260 for the int/exh. Torque in two stages, starting at half what the book says, when the engine is stone cold. Torque by the book sequence, or from center in clockwise spiral. On second pass, use what book calls for. Run, cool, retorque twice.

I use studs and swear by them.

I use studs and swear by them.

#4

#6

#7

Trending Topics

#8

How did you torque the studs? Locktite 'em and the old two nut trick? What torque specs on the studs? And how long are they? I've got an exhaust leak that needs fixing...

I like a four hole spacer on the C. Seems like the carb get better vacuum signal, or maybe just getting it higher above the manifold bottom helps. The 4100 is cool, better yet if it's the 1.08".

I like a four hole spacer on the C. Seems like the carb get better vacuum signal, or maybe just getting it higher above the manifold bottom helps. The 4100 is cool, better yet if it's the 1.08".

#9

#10

Hopefully you still have the piece that broke off (looks like it's missing). If you do, it's fixable. Kind of expensive for shop time, but less than a new intake.

Baron,

Nothing special on the studs. I think they were about 2.5". I tried loctite when I originally installed them, but after some uninstalls and reinstalls during the last few years (and taking the studs in and out), I haven't worried about it since and it's never been an issue.

Put the studs in, put the manifolds on, appropriate thick washer (or stacked washers), and a single nut. Torque in order to around 25 ft/lbs like normal.

Baron,

Nothing special on the studs. I think they were about 2.5". I tried loctite when I originally installed them, but after some uninstalls and reinstalls during the last few years (and taking the studs in and out), I haven't worried about it since and it's never been an issue.

Put the studs in, put the manifolds on, appropriate thick washer (or stacked washers), and a single nut. Torque in order to around 25 ft/lbs like normal.

#12

If you can find a good core, try it out. I would get the 1/8" plate thru Pony. It seals the base and prevents v.leaks. The 1.08" venturi size, made for the 289 mustang (480 cfm) works nicely, but is difficult to find, due to mustang restoration enthusiats, and the propaganda put out by Pony. You might want to try the 1.12" model, which is a 600 cfm, and much easier to find. On the float bowl, just in front of the throttle linkage, you'll see a clock face. Inside the clock it is stamped either 1.08, or 1.12. Pony also makes sleeves for the 1.12 primaries, converting them to 1.00", and thereby making you carb a spread bore in theory ... small primaries for putting around town, and the big secondaries to snap you neck back, almost.

The Holley jets work in the 4100. Like any rebuild, make sure the throttle shaft bore is not leaking/sucking air. I'd also replace the 40+ year old copper floats with the neoprene ones from Pony or ebay.

On the front of the carb is the accellerator p. housing. You want the 'short snout' one, about 3/4" long, no more.

Good luck.

<a href="http://s659.photobucket.com/albums/uu316/bobbyrogue/?action=view&current=P1010123.jpg" target="_blank"><img src="http://i659.photobucket.com/albums/uu316/bobbyrogue/P1010123.jpg" border="0" alt="Photobucket"></a>

Since you're using the C intake, you won't have the fitment probs I did. With the dp manny, the mix screws were impossible to get to.

#15

why? how can it be backwards when the offy keeps breaking and the truck dont run anyways

. I can always have the stock manifold milled for a 2bbl if I want one which mayeb the plan. this truck for now is only for driving to an from work and around town at about 35-40 mph untill I can find afford and find a nicer 80's era 250/350 4rd 4x4 to put the 300 in. All im after is TORQUE 100% above hp I love Toruqe hense why Diesels are my normal thing.

. I can always have the stock manifold milled for a 2bbl if I want one which mayeb the plan. this truck for now is only for driving to an from work and around town at about 35-40 mph untill I can find afford and find a nicer 80's era 250/350 4rd 4x4 to put the 300 in. All im after is TORQUE 100% above hp I love Toruqe hense why Diesels are my normal thing.ps. I m taking the manifold to a machinest/welding friend to have fixed and milled flat again but I need ti runnign rihgt now for CHEAP and stock for now is reliable and cheap