How to replace your Super Duty Ball Joints

#91

OK, I've just read right through. Big thanks to Racerguy, good guide.

I've got an '06 4WD Superduty front axle that's only done 10k miles but I'm gutting it to do some welding work on the housing. Still it's all the same procedure. Being the later model, it has that mongrel cir-clip deep in the hub. What a bitch that is! I must recommend getting a good pair of big cir-clip pliers for this sucker.

I'm up to removing the axle shaft and knuckle seal. From reading this I take it I'm going to have to destroy it to get it out. The seal can't be reused no matter what.

Does the replacement seal come with the metal flanges?

Or do I have to preserve these?

And while I'm ordering parts. What other parts am I going to need when re-installing the diff centres (I'm installing ARB air-lockers), and hubs front and rear. As I said, it's only done 10k miles so nothing "needs" replacing, just what has to be replaced as part of stripping down and re-assembling.

(Suggest you read my project thread in signature below)

Any advice and tips gladly appreciated.

I've got an '06 4WD Superduty front axle that's only done 10k miles but I'm gutting it to do some welding work on the housing. Still it's all the same procedure. Being the later model, it has that mongrel cir-clip deep in the hub. What a bitch that is! I must recommend getting a good pair of big cir-clip pliers for this sucker.

I'm up to removing the axle shaft and knuckle seal. From reading this I take it I'm going to have to destroy it to get it out. The seal can't be reused no matter what.

Does the replacement seal come with the metal flanges?

Or do I have to preserve these?

And while I'm ordering parts. What other parts am I going to need when re-installing the diff centres (I'm installing ARB air-lockers), and hubs front and rear. As I said, it's only done 10k miles so nothing "needs" replacing, just what has to be replaced as part of stripping down and re-assembling.

(Suggest you read my project thread in signature below)

Any advice and tips gladly appreciated.

#92

Wait a minute. I just re-read your original post. You said your truck only has 10,000 miles on it? I'm not sure if you can reuse the seal or not. Most of us have 30k or more on our trucks when we replaced the ball joints. I would assume that while you have everything apart it is probably best to change the seals.

If you are talking about the the small axle dust seal, yes you will probably need to replace it if you pry against it to get the axle shaft out. But I'm not sure about the large knuckle/oil seal. It wouldn't really get damaged just by removing the axle shaft. Maybe you can reuse it, but you might want to wait for someone else who has more experience to chime in.Sorry for the confusion.

If you are talking about the the small axle dust seal, yes you will probably need to replace it if you pry against it to get the axle shaft out. But I'm not sure about the large knuckle/oil seal. It wouldn't really get damaged just by removing the axle shaft. Maybe you can reuse it, but you might want to wait for someone else who has more experience to chime in.Sorry for the confusion.

#93

OK. Seen as no one has posted any pictures of the '06 Superduty hubs yet, I've taken some to share here.

Here's the hub with the brake caliper, bracket and rotor already removed.

This is the auto hub. Just remove the three torx head screws with a T27 size tool, crack the seal with either a tap with a chisel or lever against a wheel stud with a pry bar. Then gently wiggle it out, don't force it.

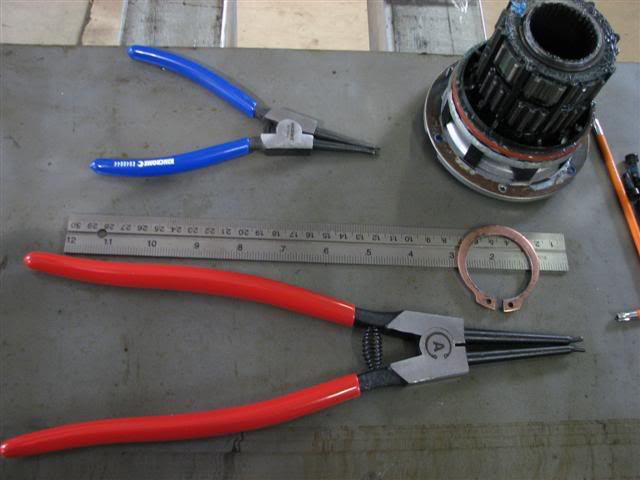

This is the circlip that has to be removed......

Normal sized pliers won't do at all! You'll need the bigger ones, they're 320mm long and have 3mm tips. When you get them, grind the ends of the tips so that they are flat when they are about 25mm apart. This helps to get a better grip. I'd also suggest countersinking the backside of the circlip holes so the pliers grip even easier next time you have to remove them.

Even then, they'll open the circlip fine but it's still virtually impossible to pull the circlip out. So I loosened the four nuts on the hub studs. They are flanged so you can then hit it with an impact socket and crack the hub out a little. No need to damage any studs. I then knocked some wood behind the uni-joint and pushed the hub out of the knuckle a few mm and held it there with the chisels and then removed the wood. Also be careful not to damage the heat shield, it's sandwiched between the hub and knuckle.This gets the axle trying to pull out of the hub so when you open the circlip, it should help getting it out of it's groove. Much easier!

They hub should come out easy enough now.

There's a normal sealed ball bearing instead of a needle bearing. Should be much more reliable, and easy enough to replace by removing the other circlip.

With the hub out, the massive knuckle seal is revealed.

The inner side of it is completely protected by this metal shield. The workshop manual says to just pound it out with a drift....... But this would destroy it well and truly. And with all the rubber in the seal, it just seemed to bounce right back at you, doing nothing but denting the metal shield.

This is the pathetic axle tube seal. No protection whatsoever. I doubt it would keep water out at all.

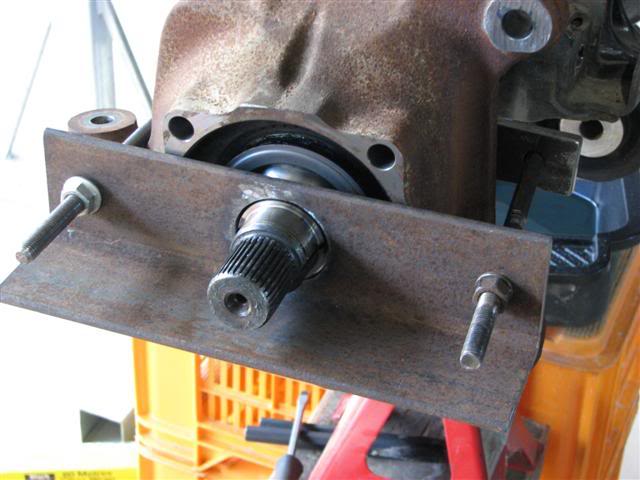

So I made my own knuckle seal puller. Consists of a peice of 3" angle, 12" long, with a 2.5" hole in the centre, 0.5" holes an inch from the ends. And a flat bar 1.5" wide by 3/8" thick, 12" long, same holes at the ends. And two bits of threaded rod to pull them together. Set one rod under the steering arm, not over as in the photo.

This put some real force on it and pulled it out a treat.

I'm yet to get the seal off the axle shaft, but it looks like I'll need to pull it using a bearing separator under the metal flange. I'll update this when I get to it.

Turns out the metal shield was two pieces, and the inner part has dished from pushing the knuckle seal out. I don't think it will affect the function of the seal, but it won't protect as well and I'll try to flatten it out again before re-installing. I think the seal itself is ok and could be reused, but I'll still replace it. [I'll try to pull the other side out without punching on it first and hopefully it won't dish so much. Let you know tomorrow....]

I should add, I won't be re-assembling this for quite some time, but I will update this when I can.

Here's the hub with the brake caliper, bracket and rotor already removed.

This is the auto hub. Just remove the three torx head screws with a T27 size tool, crack the seal with either a tap with a chisel or lever against a wheel stud with a pry bar. Then gently wiggle it out, don't force it.

This is the circlip that has to be removed......

Normal sized pliers won't do at all! You'll need the bigger ones, they're 320mm long and have 3mm tips. When you get them, grind the ends of the tips so that they are flat when they are about 25mm apart. This helps to get a better grip. I'd also suggest countersinking the backside of the circlip holes so the pliers grip even easier next time you have to remove them.

Even then, they'll open the circlip fine but it's still virtually impossible to pull the circlip out. So I loosened the four nuts on the hub studs. They are flanged so you can then hit it with an impact socket and crack the hub out a little. No need to damage any studs. I then knocked some wood behind the uni-joint and pushed the hub out of the knuckle a few mm and held it there with the chisels and then removed the wood. Also be careful not to damage the heat shield, it's sandwiched between the hub and knuckle.This gets the axle trying to pull out of the hub so when you open the circlip, it should help getting it out of it's groove. Much easier!

They hub should come out easy enough now.

There's a normal sealed ball bearing instead of a needle bearing. Should be much more reliable, and easy enough to replace by removing the other circlip.

With the hub out, the massive knuckle seal is revealed.

The inner side of it is completely protected by this metal shield. The workshop manual says to just pound it out with a drift....... But this would destroy it well and truly. And with all the rubber in the seal, it just seemed to bounce right back at you, doing nothing but denting the metal shield.

This is the pathetic axle tube seal. No protection whatsoever. I doubt it would keep water out at all.

So I made my own knuckle seal puller. Consists of a peice of 3" angle, 12" long, with a 2.5" hole in the centre, 0.5" holes an inch from the ends. And a flat bar 1.5" wide by 3/8" thick, 12" long, same holes at the ends. And two bits of threaded rod to pull them together. Set one rod under the steering arm, not over as in the photo.

This put some real force on it and pulled it out a treat.

I'm yet to get the seal off the axle shaft, but it looks like I'll need to pull it using a bearing separator under the metal flange. I'll update this when I get to it.

Turns out the metal shield was two pieces, and the inner part has dished from pushing the knuckle seal out. I don't think it will affect the function of the seal, but it won't protect as well and I'll try to flatten it out again before re-installing. I think the seal itself is ok and could be reused, but I'll still replace it. [I'll try to pull the other side out without punching on it first and hopefully it won't dish so much. Let you know tomorrow....]

I should add, I won't be re-assembling this for quite some time, but I will update this when I can.

#94

Got the other side out fine just by using the puller I made. It's got to be easier than pounding it out. The metal flanged dished a little on this one too, but I think it could still be reused if necessary.

My knuckles came off easy enough. In fact I don't think the nuts were tightened to spec at all. The stud of one of the bottom one's started turning on me with the nut half unscrewed. Had to use my bearing puller to press it back tight enough to get the nut off.

Some stout parts here. And heavy!

Curiously, the axle and spider gears are not machined? Die cast and probably forged too.

My knuckles came off easy enough. In fact I don't think the nuts were tightened to spec at all. The stud of one of the bottom one's started turning on me with the nut half unscrewed. Had to use my bearing puller to press it back tight enough to get the nut off.

Some stout parts here. And heavy!

Curiously, the axle and spider gears are not machined? Die cast and probably forged too.

#95

#96

Powerstrokeshop.com

I may also do the brakes and swap the front rotors since I've been getting front end vibration when applying brakes.

Bob

#97

Question- has anyone replaced the U-joint in the axle shaft while doing this? I bought a new U-joint from Napa, but the one in there seems to be fine (it also looks like a PITA to remove since you can't drive the caps straight through). I do NOT want to have to pull it apart again to change the U-joint later though. Right now I'm stuck at getting the knuckle off- 166K on the original ball joints equals a stubborn to remove lower ball joint.

#98

Question- has anyone replaced the U-joint in the axle shaft while doing this? I bought a new U-joint from Napa, but the one in there seems to be fine (it also looks like a PITA to remove since you can't drive the caps straight through). I do NOT want to have to pull it apart again to change the U-joint later though. Right now I'm stuck at getting the knuckle off- 166K on the original ball joints equals a stubborn to remove lower ball joint.

Since I knew I was not going to use the old ball joints I just used a big hammer on them alternating the blows between the top and lower ball joints. The just popped right out.

#99

#100

#101

Here's a trick-drive your pickle fork (I assume you have one, right?) as far as you can into the upper ball joint. Now take your hammer and tap on the part of the axle that the lower ball joint comes through- it will pop out, I just did ball joints on mine and tried this trick and it worked flawlessly.

#102

I just did this job today (finished it anyway) and referred to mostly this thread and guzzle's page, as well as this link at The Diesel Stop which is very helpful. HOWEVER, beware on the part numbers listed on that page- that was apparently written for an 05+ truck and the part number for the yellow O-ring on the hub is different. That site lists the part number as 5C3Z-4A322-AA , the part for a 99-04 truck is F81Z-4A322-AA. This oversight cost me an extra trip to my dealer today to get the correct part.

Also a little trick I came up with for getting the 4x4 hub out- mine was being stubborn and I couldn't get it to come out simply by pulling on it. I simply placed 2 large screw drivers opposite eachother and gently pried against the hub assembly to pop the 4x4 hub right out.

Also a little trick I came up with for getting the 4x4 hub out- mine was being stubborn and I couldn't get it to come out simply by pulling on it. I simply placed 2 large screw drivers opposite eachother and gently pried against the hub assembly to pop the 4x4 hub right out.

#103

I just hammered it on the part of the ball joint where the nut threads on to.

I used a pretty big hammer and alternated between the lower and upper ball joint. Another methode is if you force a ball joint fork into the lower ball joint and then hit the end of the knuckle with a hammer it will distort the metal just enouph that it will cause the ball joint to come loose.

#104

#105

I had my ball joints replaced at a local shop(Moog). My left hub was pretty rusty and was replaced along with the u joint on that side. I had swaybar bushings done front and rear, new shocks(Monroe reflex), new tires, and an alignment. The right hub had been done on warranty just near the end of the extended warranty program (160000 kms). The truck now has 190000 kms. All other front end parts checked out okay.

Since the work was done it feels funny. The truck goes very nice and straight down the road and the combination of new shocks, tires, and swaybar bushings got rid of any clunking that was starting to show up. However, when a steering correction is required, it feels like I must push the wheel a bit then when it corrects it darts off and requires similar input again to counter the over correction. Its actually very unpredictable now. The shop said to bring it back but have not had time yet. I have made about 3000 kms since the work was done.

Any suggestions??

Since the work was done it feels funny. The truck goes very nice and straight down the road and the combination of new shocks, tires, and swaybar bushings got rid of any clunking that was starting to show up. However, when a steering correction is required, it feels like I must push the wheel a bit then when it corrects it darts off and requires similar input again to counter the over correction. Its actually very unpredictable now. The shop said to bring it back but have not had time yet. I have made about 3000 kms since the work was done.

Any suggestions??