How to replace your Super Duty Ball Joints

#631

Do the new ball joints get PRESSED in or do they just snug up as you torque them in ?

Funny, I must have been really tired when I wrote that last post as I kept typing 'torch' not 'torque' LOL.... I know better... I have re-editted it.

I guess I am just going to have to take the front end apart and do this myself. Otherwise, I never seem to know exactly what they have done and what they have not done.

Can I hammer out these ball joints ? Or do they need to be pressed out ?

If I hammer them out, as long as I do not mess up the threads, do you think I could re-use them, or I guess at that point I should just replace them If I am taking them out.

First things first. I need to take the tie rods off and check the swing of the knuckle. If that is tight I know my issue. If it is not then what ?

Steering Box ?

I am going to have to find some time this weekend to do this, I will post back what I find.

Thanks.

Funny, I must have been really tired when I wrote that last post as I kept typing 'torch' not 'torque' LOL.... I know better... I have re-editted it.

I guess I am just going to have to take the front end apart and do this myself. Otherwise, I never seem to know exactly what they have done and what they have not done.

Can I hammer out these ball joints ? Or do they need to be pressed out ?

If I hammer them out, as long as I do not mess up the threads, do you think I could re-use them, or I guess at that point I should just replace them If I am taking them out.

First things first. I need to take the tie rods off and check the swing of the knuckle. If that is tight I know my issue. If it is not then what ?

Steering Box ?

I am going to have to find some time this weekend to do this, I will post back what I find.

Thanks.

#632

Also check your axle ujoints. If they are bad the steering can bind...I wouldn't mess with removing the ball joints unless you have all the tools and knowledge to do the job properly.

The joints get pressed into the knuckle then tightened onto the axle via 2 nuts. No hammering on anything.

The joints get pressed into the knuckle then tightened onto the axle via 2 nuts. No hammering on anything.

#633

#635

#636

#637

2005 and newer

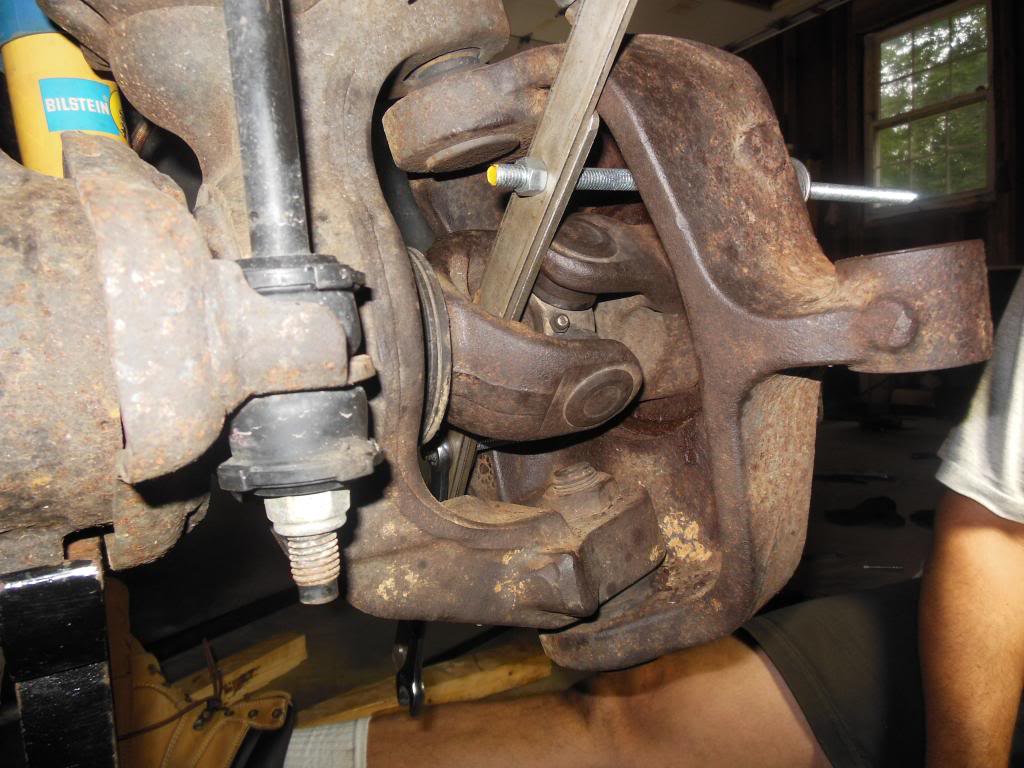

This a 2005, should be the same for 2005 and newer.

We fought with this for a while before figuring this out. This pulls the axle through with the knuckle seal. Use the holes in the knuckle and some all thread, and some flat stock.

.

.

I reused the knuckle seal, it did not look damaged. I never removed it from the axle. Please note, I do not have the vacuum operated hubs.

Also, new updated dust seal is BRS-170. It mounts in the axle housing tube in about a 1/8 flange. It does not look like it will hold but so far, so good.

We fought with this for a while before figuring this out. This pulls the axle through with the knuckle seal. Use the holes in the knuckle and some all thread, and some flat stock.

.

.

I reused the knuckle seal, it did not look damaged. I never removed it from the axle. Please note, I do not have the vacuum operated hubs.

Also, new updated dust seal is BRS-170. It mounts in the axle housing tube in about a 1/8 flange. It does not look like it will hold but so far, so good.

#638

Nice pull rig!

Well as for my issue with my sticking ball joints, I never did take them out and replace them. I tried loosening and re-torquing them. That did not work. I took it to the shop and paid them $240 to completely looses and readjust. It was better but still seemed to wander. Worse with the fifth wheel on the back.

Was going to replace the ball joints myself as I had noted here in a while back.

I loosened the nut on the steer box that I had tightened earlier. That helped.

Then I when on holidays with a big load in the truck, just about max load and drove a couple thousand kms with the fifth wheel on the back, and by the time I got home the steering seemed way better.

It does not appear to stick anymore and wander. My guess is that the extra weight helped to break in or wear in the ball joints to the point that they do not stick. Only took 5 months to break in, LOL. If they are not torqued correctly, I am assuming they might wear quicker, but don't care now, at least I do not have to replace them at this time.

So as far as I am concerned now, the steering is OK and will not be replacing the ball joints for hopefully another 100,000 mms.

Thanks for all your help and comments.

Well as for my issue with my sticking ball joints, I never did take them out and replace them. I tried loosening and re-torquing them. That did not work. I took it to the shop and paid them $240 to completely looses and readjust. It was better but still seemed to wander. Worse with the fifth wheel on the back.

Was going to replace the ball joints myself as I had noted here in a while back.

I loosened the nut on the steer box that I had tightened earlier. That helped.

Then I when on holidays with a big load in the truck, just about max load and drove a couple thousand kms with the fifth wheel on the back, and by the time I got home the steering seemed way better.

It does not appear to stick anymore and wander. My guess is that the extra weight helped to break in or wear in the ball joints to the point that they do not stick. Only took 5 months to break in, LOL. If they are not torqued correctly, I am assuming they might wear quicker, but don't care now, at least I do not have to replace them at this time.

So as far as I am concerned now, the steering is OK and will not be replacing the ball joints for hopefully another 100,000 mms.

Thanks for all your help and comments.

#639

Wheel bearing hub wont budge

Replacing my driver side ball joints. I have tried every trick listed in this thread. The four nuts retaining the hub came off relatively easily, then I came to a screeching halt. I have spent a can of PB blaster on it. Used a 3 arm puller.. broke it. Have a new beefier puller, putting enormous stress on it and hitting the seam with a chisel. Nothing. Went at the studs from the back while the puller is still on and very tight, now they are destroyed. nothing. Sacrificed the rotor to use as a pry / pounding base. beat the ever loving sh*#t out of it. Nothing. Put my 2 ton floor jack between the rotor and caliper mounting point. Nothing. This thing acts like it is welded on! I have run out of tricks. Any ideas? I do have air tools available but not sure what to use next. Air chisel? Dynamite?

This is a great site I look forward to any suggestions.

This is a great site I look forward to any suggestions.

#640

I feel for you. Stuck parts can be a real

What were you attaching the puller to?

Now for the smart @$$ idea. Use C4 universal disassembler.

But really what I would do is get a slide hammer for pulling the

real axels and try to do it that way. You know the type that has the

multiple slots so you are pulling from the center line of the axel.

WESTWARD Rear Axle Puller, Slide Hammer - Brake Tools - 2HLA3|2HLA3 - Grainger Industrial Supply

Put it on using the lugs and nuts to keep it in place. Also double check

to make sure that something did not get missed that could be holding it

on the knuckle. Don't want you to end up like the guy that missed a row

of bolts holding the head on his Chev 350 engine head. He used a pry bar

and left part of the head still bolted down.

Sean

What were you attaching the puller to?

Now for the smart @$$ idea. Use C4 universal disassembler.

But really what I would do is get a slide hammer for pulling the

real axels and try to do it that way. You know the type that has the

multiple slots so you are pulling from the center line of the axel.

WESTWARD Rear Axle Puller, Slide Hammer - Brake Tools - 2HLA3|2HLA3 - Grainger Industrial Supply

Put it on using the lugs and nuts to keep it in place. Also double check

to make sure that something did not get missed that could be holding it

on the knuckle. Don't want you to end up like the guy that missed a row

of bolts holding the head on his Chev 350 engine head. He used a pry bar

and left part of the head still bolted down.

Sean

#641

Thanks for the suggestion. I had not thought of that. Could be the thing that makes the difference.

I Used a three arm puller with hooks that I put on the hub base. One of the arms broke at the hook (or notch) that goes behind the wheel hub. I was thinking about getting a puller I can attach to the lugs much like the base of the tool you suggested.

Other than the 4 nuts behind the knuckle and the retaining clip on the axle, I don't see anything that can hold it on.

Maybe the PB blaster will work some magic overnight.

I Used a three arm puller with hooks that I put on the hub base. One of the arms broke at the hook (or notch) that goes behind the wheel hub. I was thinking about getting a puller I can attach to the lugs much like the base of the tool you suggested.

Other than the 4 nuts behind the knuckle and the retaining clip on the axle, I don't see anything that can hold it on.

Maybe the PB blaster will work some magic overnight.

#642

#643

The reason I asked about where you attached the puller

is I don't see any good place to use as a push point other

than the axel shaft and that really does not give you a

good advantage for pushing on with the center screw of the

puller.

Here is a Youtube I don't like this that much but this is a good look

at what is going on

Here is a look at one of the others I found. I think this might be the better of the two.

It is a lot more time to watch

Post back if you have more questions and Please let us know

when you get this done and how it's working

Sean

is I don't see any good place to use as a push point other

than the axel shaft and that really does not give you a

good advantage for pushing on with the center screw of the

puller.

Here is a Youtube I don't like this that much but this is a good look

at what is going on

It is a lot more time to watch

Post back if you have more questions and Please let us know

when you get this done and how it's working

Sean

#644

One thing I am getting tired of is THIS

Database error

Database error

The Ford Truck Enthusiasts Forums database has encountered a problem.

Please try the following:

Load the page again by clicking the Refresh button in your web browser.

Open the Ford Truck Enthusiasts, 1948-2011 Ford F150, Super Duty & SUV owners community and information source. Covers F100, F-150, F250, Bronco, Ranger, Explorer, Expedition, Lighting, Escape and More home page, then try to open another page.

Click the Back button to try another link.

The Ford Truck Enthusiasts, 1948-2011 Ford F150, Super Duty & SUV owners community and information source. Covers F100, F-150, F250, Bronco, Ranger, Explorer, Expedition, Lighting, Escape and More forum technical staff have been notified of the error, though you may contact them if the problem persists.

We apologise for any inconvenience.

Someone PLEASE find an fix this problem.

You loose the post or you end up with a double post.

Sean

The Ford Truck Enthusiasts Forums database has encountered a problem.

Please try the following:

Load the page again by clicking the Refresh button in your web browser.

Open the Ford Truck Enthusiasts, 1948-2011 Ford F150, Super Duty & SUV owners community and information source. Covers F100, F-150, F250, Bronco, Ranger, Explorer, Expedition, Lighting, Escape and More home page, then try to open another page.

Click the Back button to try another link.

The Ford Truck Enthusiasts, 1948-2011 Ford F150, Super Duty & SUV owners community and information source. Covers F100, F-150, F250, Bronco, Ranger, Explorer, Expedition, Lighting, Escape and More forum technical staff have been notified of the error, though you may contact them if the problem persists.

We apologise for any inconvenience.

Someone PLEASE find an fix this problem.

You loose the post or you end up with a double post.

Sean

#645