Need upgrade advice - Specifically Injector and Turbo advice

#31

The tunes for e99 dpc402 are good these days, some tune writers prefer the later dpc422, but I do not feel it is really needed.

I would start with that (easy enough to switch should you desire). The Hydra comes with access to all sorts of pcm code tune files for stock injectors, and switching them is a breeze.

If you ever need a good remanned pcm, Diesel Tech Chatt si the place to go. Of course fb marketplace can be good too, just hit and miss. I just got a good dpc422 shipped to me for $60, which was a sweet deal.

This is a good site for installing the Hydra Flash software, and info on the Hydra chip

Hydra Help

Here is the place for pcm's

http://www.dieseltechchatt.com

I would start with that (easy enough to switch should you desire). The Hydra comes with access to all sorts of pcm code tune files for stock injectors, and switching them is a breeze.

If you ever need a good remanned pcm, Diesel Tech Chatt si the place to go. Of course fb marketplace can be good too, just hit and miss. I just got a good dpc422 shipped to me for $60, which was a sweet deal.

This is a good site for installing the Hydra Flash software, and info on the Hydra chip

Hydra Help

Here is the place for pcm's

http://www.dieseltechchatt.com

Maybe I can get my hands on a used hydra as well if possible for cheaper and then have the luxury of being able to switch and tinker around as I am expecting myself to get deeper into PMS (Powerstroke modification syndrome) as I get older.

#32

#33

Welcome to FTE!

My opinion of your condition is a little different than the others. I think you have exhaust drive pressure and/or boost leaks. Those need corrected first, or at the very least at the same time. Leaks will kill performance and cause excessive smoke. Just getting things sealed up may make a world of difference.

I disagree about smoke looking cool. All the smoke does is show poor tuning/setup and makes the already sensitive subject of diesels look bad to outsiders.

Here’s what I would do first.

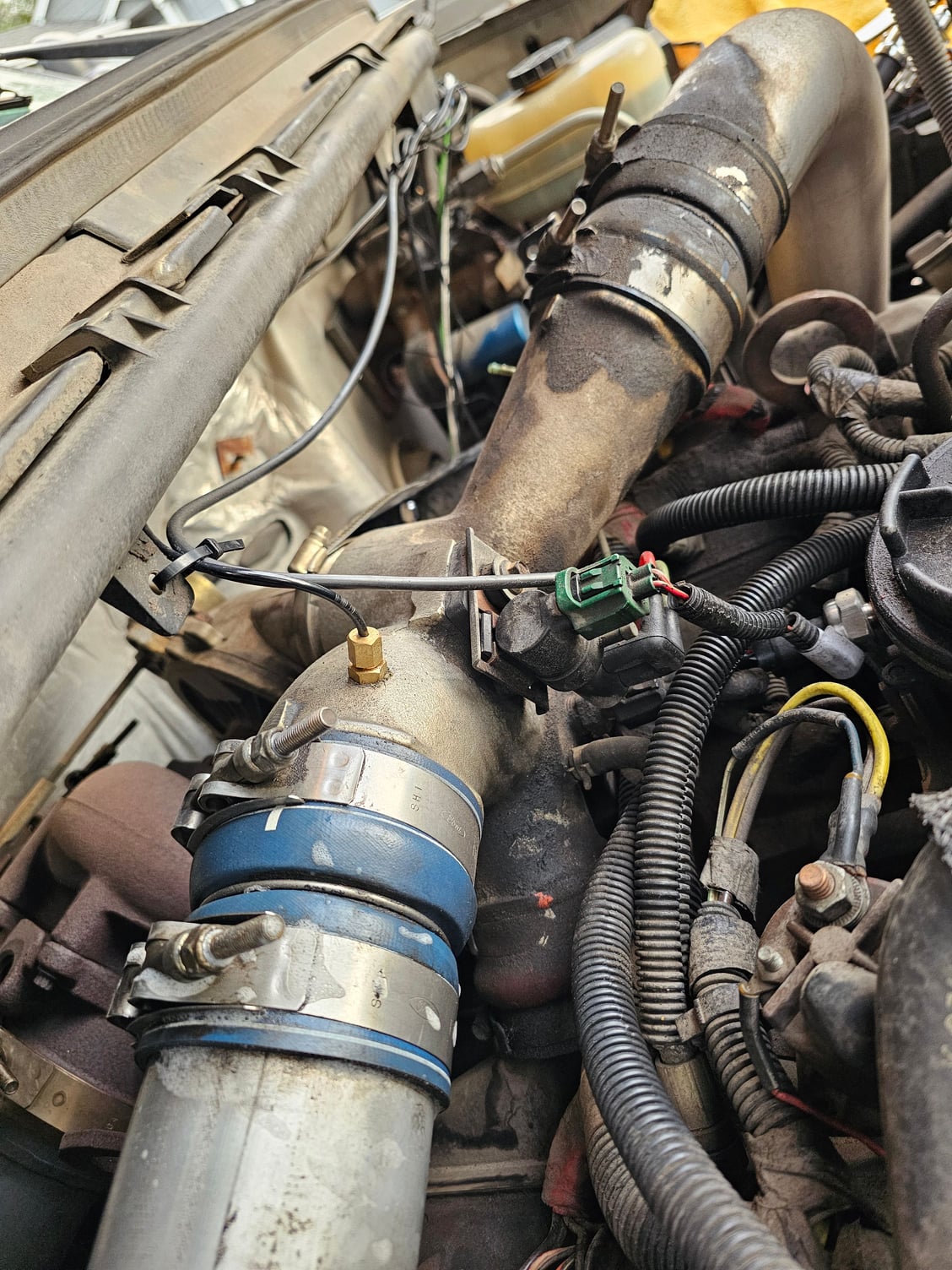

1- check for leaks on uppipes etc

2- do a boost leak pressure test (tester can be made for cheap)

3- check turbo for endplay wear (confirming rebuildable condition)

Next I feel your best turbo for application is likely the KC Balanced Assembly.

I would probably order the KC Balanced Assembly which comes with a rebuild kit.

Would definitely install some bellowed uppipes, cheap are fine, while doing the turbo work.

Possibly some plenum inserts, good boots & clamps.

Be aware of potential plenum leaks etc which should be corrected if needed as well.

The largest turbo I would consider is the KC stage 1 which will spool at higher rpm than the stock or balanced assembly as you stated.

Seems like you may have already read this thread but here’s a link just in case. https://www.ford-trucks.com/forums/1...e-reviews.html

I’m not too knowledgeable on injectors but bigger nozzles tend to work against you at elevation from what I’ve read. Maybe use 30% tops. But I doubt you’ll need them after getting everything else squared away.

I’d hold off on new tunes until everything is sealed up and done. You may find them to suit your needs.

Good luck with your updates!

My opinion of your condition is a little different than the others. I think you have exhaust drive pressure and/or boost leaks. Those need corrected first, or at the very least at the same time. Leaks will kill performance and cause excessive smoke. Just getting things sealed up may make a world of difference.

I disagree about smoke looking cool. All the smoke does is show poor tuning/setup and makes the already sensitive subject of diesels look bad to outsiders.

Here’s what I would do first.

1- check for leaks on uppipes etc

2- do a boost leak pressure test (tester can be made for cheap)

3- check turbo for endplay wear (confirming rebuildable condition)

Next I feel your best turbo for application is likely the KC Balanced Assembly.

I would probably order the KC Balanced Assembly which comes with a rebuild kit.

Would definitely install some bellowed uppipes, cheap are fine, while doing the turbo work.

Possibly some plenum inserts, good boots & clamps.

Be aware of potential plenum leaks etc which should be corrected if needed as well.

The largest turbo I would consider is the KC stage 1 which will spool at higher rpm than the stock or balanced assembly as you stated.

Seems like you may have already read this thread but here’s a link just in case. https://www.ford-trucks.com/forums/1...e-reviews.html

I’m not too knowledgeable on injectors but bigger nozzles tend to work against you at elevation from what I’ve read. Maybe use 30% tops. But I doubt you’ll need them after getting everything else squared away.

I’d hold off on new tunes until everything is sealed up and done. You may find them to suit your needs.

Good luck with your updates!

2. Havent checked with a boost leak pressure tester yet.

3. No signs of wear on the turbo. Turbine wheel spins, doesn't lock up and is not seized to any extent. Spins and stops after a little bit of manually twisting it. No cracked or notably damaged components that I can see

Should I still check with a boost leak pressure tester? I have my column gauges of which one shows the real time boost psi. I do not think I notice anything out of the norm when it comes to the boost when driving. I was able to get around 25-28 psi on the race tune (highest tune) with stock turbo and stock injectors.

#34

The following users liked this post:

#35

I would still do a pressure test to confirm. That way you know if there’s anything needing taken care of while doing the other mods. I could hit 34psi with stock injectors and still found a plenum leak so just having good peak numbers doesn’t rule out a leak.

You want the tester connected at the turbo. Do not include the CCV or it will pressurize your crankcase.

Here’s what a good result will look like. Wish I’d have recorded the leak version. 🤦♂️ The biggest difference is in how the good one goes down slowly and drops slower as the pressure gets lower. My bad one would bleed off all the way down to zero, not super fast but steady.

7.3 Powerstroke Good Boost Leak Test Reference

For the turbo check, so far it sounds good. Did you check for endplay? In/out movement is bad. It will go side to side a little and is ok as long as it doesn’t touch the housing.

You want the tester connected at the turbo. Do not include the CCV or it will pressurize your crankcase.

Here’s what a good result will look like. Wish I’d have recorded the leak version. 🤦♂️ The biggest difference is in how the good one goes down slowly and drops slower as the pressure gets lower. My bad one would bleed off all the way down to zero, not super fast but steady.

7.3 Powerstroke Good Boost Leak Test Reference

For the turbo check, so far it sounds good. Did you check for endplay? In/out movement is bad. It will go side to side a little and is ok as long as it doesn’t touch the housing.

The following users liked this post:

#36

You could pull what's needed off the top of the 00 over to you're e99...turbo, spider, injectors, possibly intake plenums, etc. In the interim drive your e99 while you clean up and rebuild the parts so you can install them over the weekend. Rebuild the turbo with a 360* kit and while you have it apart install the KC s300 turbine wheel, then finish it off with the compressor wheel of your choice. This is the same you will get with the balanced assembly, but with the choice of a compressor wheel...most, including myself chose the Riffraff 4+4 wheel for several reasons. You could go ahead and do the AIH delete in the spider and do the 7-turn mod on the waste gate actuator...I did 8 turns. Since you have the injectors out, I would check armature clearance and shim them if need be...they probably will given mileage. With the injector spacers between the solenoid and body being off, drill an extra hole on the bottom to get the oil out of there for easier/cleaner cold starts...especially up there in Colorado. With the valve covers off check glow plugs and UVCH (fifty cent mod). I say possibly intake plenum swap because the 00 are bigger, but you would also rule out boost leaks there given the reseal. Next is to get the Riffraff intake plenum inserts, new CAC boots with upgraded T-clamps, and stainless steel bellowed up pipes. I did this to my F350 and everything but the KC s300 turbine wheel and only 5 turns on the waste gate actuator to the wife's Excursion as you will see results in that Turbo Matrix thread RacinJasonWV linked above. I wanted to keep the stock injectors given better mpg and reliability, and the other things I did were a really good match. No smoke (other than just slightly at tip in), more power, a little more boost down low (maybe 200 rpms or so), and better mpg (maybe 2 or so hwy, but with going from 33" to 35" tires and my stock up-pipes were still tight and not leaking). Here is the thread I started during the process: https://www.ford-trucks.com/forums/1...-upgrades.html Here is the thread I started after I finished up and was able to put a few miles on them: https://www.ford-trucks.com/forums/1...-upgrades.html

The following users liked this post:

#37

I would still do a pressure test to confirm. That way you know if there’s anything needing taken care of while doing the other mods. I could hit 34psi with stock injectors and still found a plenum leak so just having good peak numbers doesn’t rule out a leak.

You want the tester connected at the turbo. Do not include the CCV or it will pressurize your crankcase.

Here’s what a good result will look like. Wish I’d have recorded the leak version. 🤦♂️ The biggest difference is in how the good one goes down slowly and drops slower as the pressure gets lower. My bad one would bleed off all the way down to zero, not super fast but steady.

7.3 Powerstroke Good Boost Leak Test Reference

https://youtu.be/y3186JM9F18

For the turbo check, so far it sounds good. Did you check for endplay? In/out movement is bad. It will go side to side a little and is ok as long as it doesn’t touch the housing.

You want the tester connected at the turbo. Do not include the CCV or it will pressurize your crankcase.

Here’s what a good result will look like. Wish I’d have recorded the leak version. 🤦♂️ The biggest difference is in how the good one goes down slowly and drops slower as the pressure gets lower. My bad one would bleed off all the way down to zero, not super fast but steady.

7.3 Powerstroke Good Boost Leak Test Reference

https://youtu.be/y3186JM9F18

For the turbo check, so far it sounds good. Did you check for endplay? In/out movement is bad. It will go side to side a little and is ok as long as it doesn’t touch the housing.

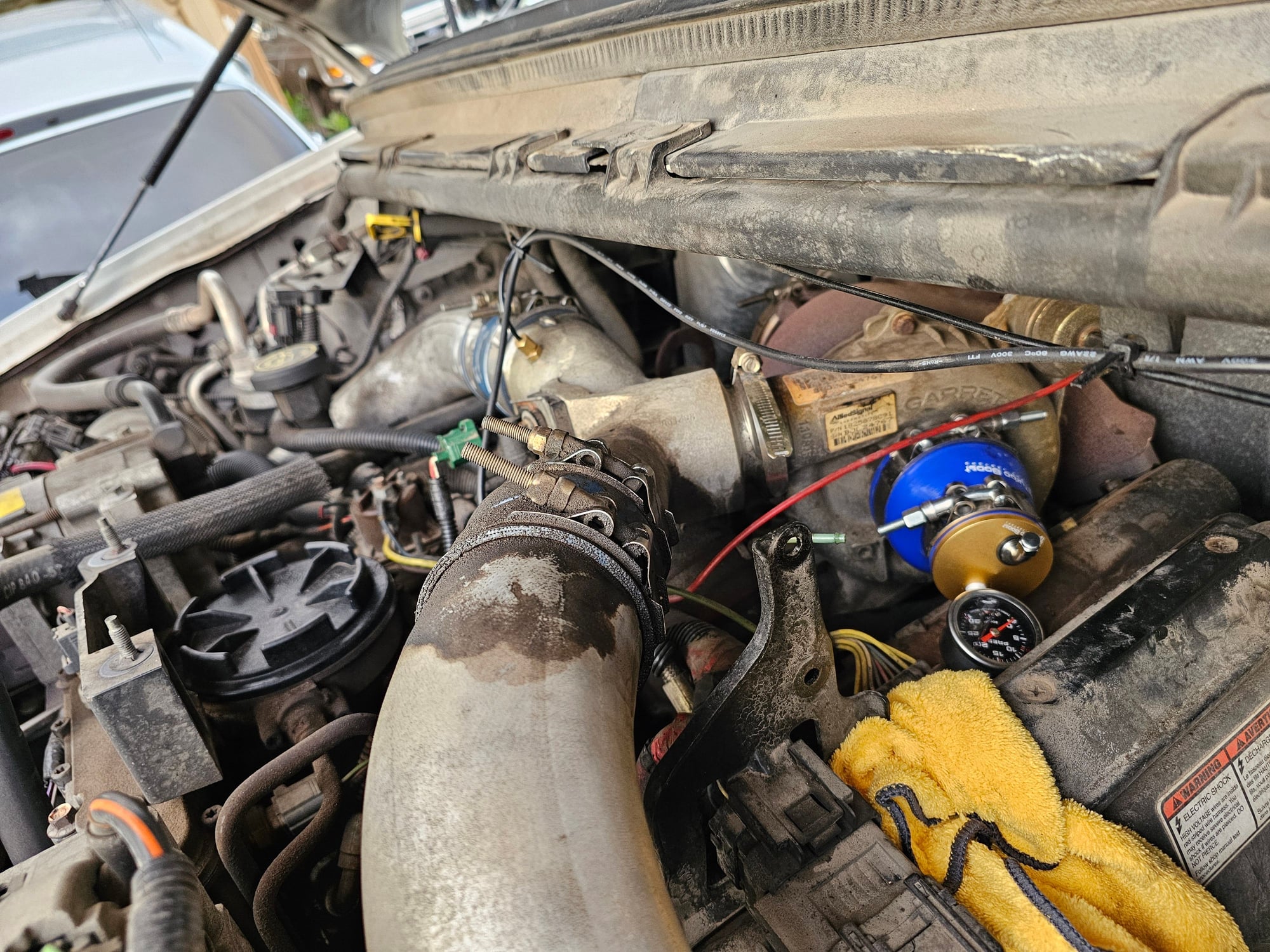

I got my pressure up on the boost tester to 20 psi. Will try for 30 psi tomorrow. So from 20 psi to 0 it took about 60 seconds. I did not hear or see any leaks with my soapy water. Again, I did not check the plenums! Still, I did not hear any leaks. I also noticed that my gauge fitting was leaky when I sprayed soapy water on it. Keep that in mind as well. I will adjust that tomorrow.

However, as I was inspecting the leak testing process I noticed a microfiber I lightly and barely stuffed into the crank case connection that connects to the intake blew the microfiber out when I reached 5-10psi. This was the only source of air coming out that I could find other than the previously mentioned gauge connection point on the boost leak tester.

With a little bit of research I saw that it could a compression issue and that the truck would usually have blowby if that were the case. I know the trick of taking off oil fill cap and flipping it upside down on the oil fill while the truck is running to see if the truck has blowby. My truck does not fail that blowby test and neither does it spew smoke when I have the oil cap off running. The family's 95 7.3l F350 has that issue so I do recognize the difference.

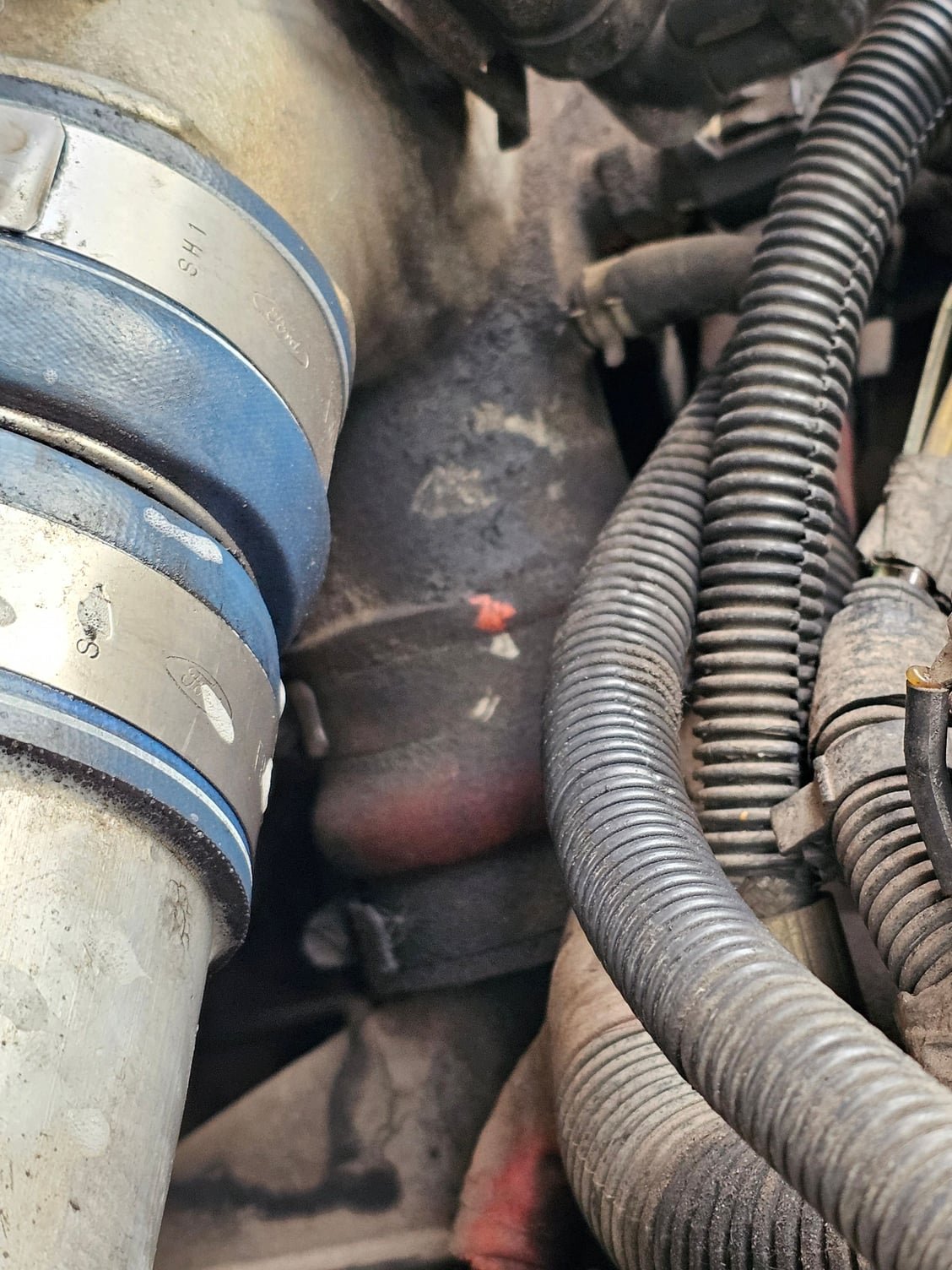

Since I took a better look this time around I did notice a lot of soot accumulation on many of the boots. I did say last time I did not see any soot accumulation but I had checked whatever I could quickly see in the dark. Sprayed all those boots down with soapy water along with the up pipes, turbo, wastegate actuator, and I believe everything else of importance EXCEPT for the plenums. Again, I did not hear any leaks whatsoever but neither did I hear the air coming out the crankcase or the somewhat loose gauge connection on the tester.

I see your video Jason and you seem to have a steady decrease on the psi and seems to be much slower of a "leak" compared to what I saw today on mine. Looks like yours could take 2 minutes or more to get to 0 psi from 30psi. Mine took only 1 minute from 20 psi. Also, I noticed the pressure would drop REALLY fast from 20ish psi to 10-15 psi then slow down SIGNIFICANTLY to 0. Yours seems pretty consistent for the time you took that video.

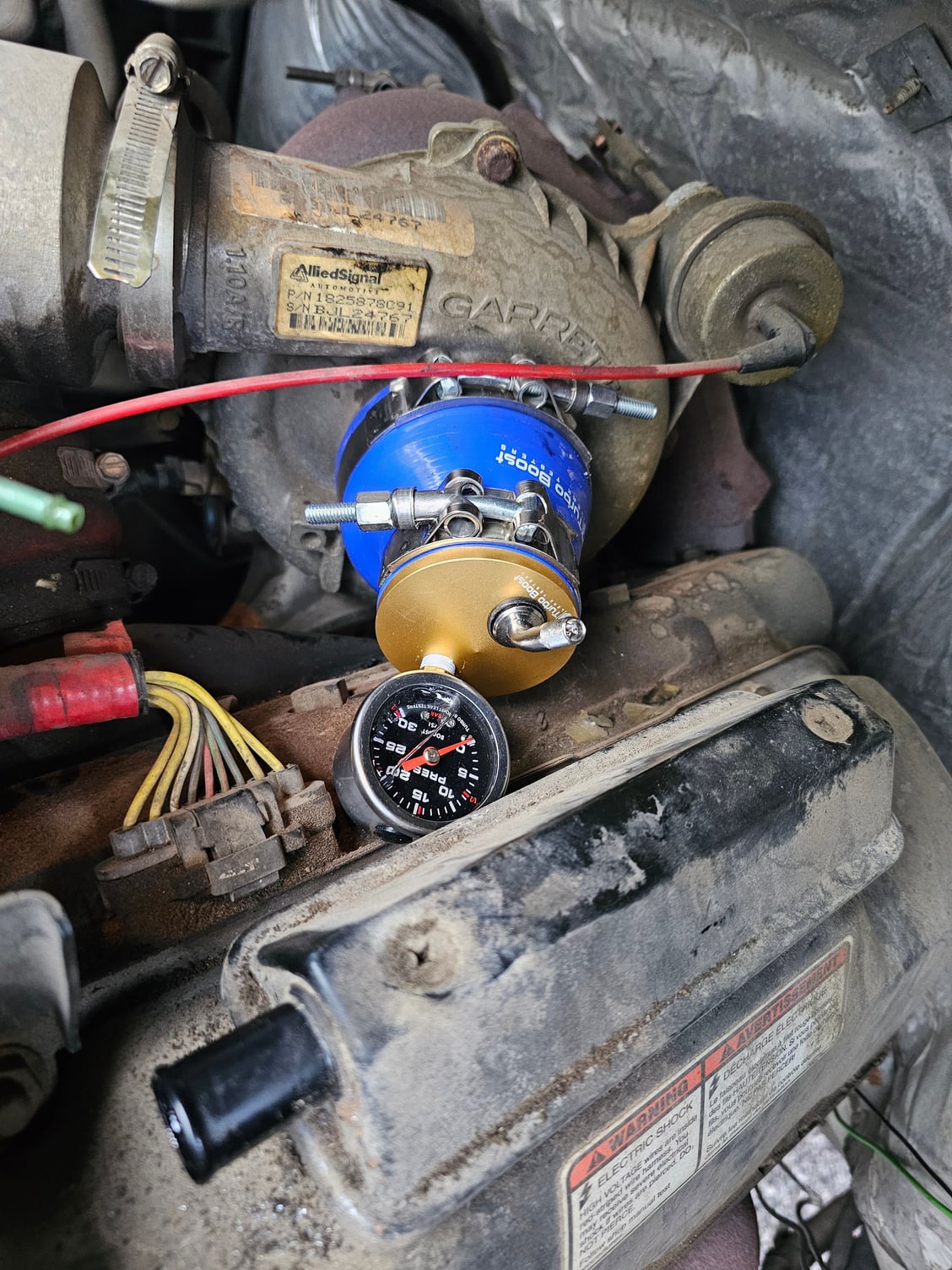

I have some pictures attached. Will attempt to post a video link from youtube where I was spinning the turbine wheel. Seems like part of the turbine blades are nicked slightly. Hard to make it out in the video. Seems to spin fairly well, doesn't seem like it is seizing much but my guess it maybe a little (170k miles on it). Don't have a reference point to a new one. I did not push it back and forth to see if there is play but will tomorrow.

#39

You could pull what's needed off the top of the 00 over to you're e99...turbo, spider, injectors, possibly intake plenums, etc. In the interim drive your e99 while you clean up and rebuild the parts so you can install them over the weekend. Rebuild the turbo with a 360* kit and while you have it apart install the KC s300 turbine wheel, then finish it off with the compressor wheel of your choice. This is the same you will get with the balanced assembly, but with the choice of a compressor wheel...most, including myself chose the Riffraff 4+4 wheel for several reasons. You could go ahead and do the AIH delete in the spider and do the 7-turn mod on the waste gate actuator...I did 8 turns. Since you have the injectors out, I would check armature clearance and shim them if need be...they probably will given mileage. With the injector spacers between the solenoid and body being off, drill an extra hole on the bottom to get the oil out of there for easier/cleaner cold starts...especially up there in Colorado. With the valve covers off check glow plugs and UVCH (fifty cent mod). I say possibly intake plenum swap because the 00 are bigger, but you would also rule out boost leaks there given the reseal. Next is to get the Riffraff intake plenum inserts, new CAC boots with upgraded T-clamps, and stainless steel bellowed up pipes. I did this to my F350 and everything but the KC s300 turbine wheel and only 5 turns on the waste gate actuator to the wife's Excursion as you will see results in that Turbo Matrix thread RacinJasonWV linked above. I wanted to keep the stock injectors given better mpg and reliability, and the other things I did were a really good match. No smoke (other than just slightly at tip in), more power, a little more boost down low (maybe 200 rpms or so), and better mpg (maybe 2 or so hwy, but with going from 33" to 35" tires and my stock up-pipes were still tight and not leaking). Here is the thread I started during the process: https://www.ford-trucks.com/forums/1...-upgrades.html Here is the thread I started after I finished up and was able to put a few miles on them: https://www.ford-trucks.com/forums/1...-upgrades.html

Some of this is French to me but I am still learning. It will be a while before I will get to some of what you mention. As for right now, I need to get to the bottom of where this leak or leaks are/is and nip it in the butt. Only thing of significance I did not check are the darn plenums which should have been one of the first. Takes me a while to figure stuff out but I take my time to make sure I understand.

#40

#41

Originally Posted by Hexus

So from 20 psi to 0 it took about 60 seconds. I did not hear or see any leaks with my soapy water. Again, I did not check the plenums!

——

I see your video Jason and you seem to have a steady decrease on the psi and seems to be much slower of a "leak" compared to what I saw today on mine. Looks like yours could take 2 minutes or more to get to 0 psi from 30psi. Mine took only 1 minute from 20 psi. Also, I noticed the pressure would drop REALLY fast from 20ish psi to 10-15 psi then slow down SIGNIFICANTLY to 0. Yours seems pretty consistent for the time you took that video.

——

I did not push it back and forth to see if there is play but will tomorrow.

——

I see your video Jason and you seem to have a steady decrease on the psi and seems to be much slower of a "leak" compared to what I saw today on mine. Looks like yours could take 2 minutes or more to get to 0 psi from 30psi. Mine took only 1 minute from 20 psi. Also, I noticed the pressure would drop REALLY fast from 20ish psi to 10-15 psi then slow down SIGNIFICANTLY to 0. Yours seems pretty consistent for the time you took that video.

——

I did not push it back and forth to see if there is play but will tomorrow.

The biggest difference I saw was in how the good test would slow its pace while approaching zero. The bad version would just keep dropping at a fairly steady pace. My theory on this is when sealed well the leaks past valves/rings and such become less impactful as pressure drops, but if there’s a true leak it will just keep blowing out all the way down to zero.

For the record, I missed the plenum leak at least 2 times before finding it. Finally got it with some soapy water. All these locations can be difficult to spray/check.

I don’t think the little air from CCV is bad. The crank case is where it would leak down naturally in my opinion.

For the turbo the major check point is in/out play. You should basically have none. It will move a little side/side but shouldn’t be contacting the housing. I tend to push too hard… Don’t be too forceful with the side to side check.

If I remember correctly we were discussing the turbo condition just to get a feeling if it’s best to rebuild or buy new, or at least understand how deep the rebuild might be in extra parts.

The following users liked this post:

#42

It sounds like your system is fairly well sealed up if it takes that long to drop. I so wish I’d have taken a “bad” video before fixing mine.

The biggest difference I saw was in how the good test would slow its pace while approaching zero. The bad version would just keep dropping at a fairly steady pace. My theory on this is when sealed well the leaks past valves/rings and such become less impactful as pressure drops, but if there’s a true leak it will just keep blowing out all the way down to zero.

For the record, I missed the plenum leak at least 2 times before finding it. Finally got it with some soapy water. All these locations can be difficult to spray/check.

I don’t think the little air from CCV is bad. The crank case is where it would leak down naturally in my opinion.

For the turbo the major check point is in/out play. You should basically have none. It will move a little side/side but shouldn’t be contacting the housing. I tend to push too hard… Don’t be too forceful with the side to side check.

If I remember correctly we were discussing the turbo condition just to get a feeling if it’s best to rebuild or buy new, or at least understand how deep the rebuild might be in extra parts.

The biggest difference I saw was in how the good test would slow its pace while approaching zero. The bad version would just keep dropping at a fairly steady pace. My theory on this is when sealed well the leaks past valves/rings and such become less impactful as pressure drops, but if there’s a true leak it will just keep blowing out all the way down to zero.

For the record, I missed the plenum leak at least 2 times before finding it. Finally got it with some soapy water. All these locations can be difficult to spray/check.

I don’t think the little air from CCV is bad. The crank case is where it would leak down naturally in my opinion.

For the turbo the major check point is in/out play. You should basically have none. It will move a little side/side but shouldn’t be contacting the housing. I tend to push too hard… Don’t be too forceful with the side to side check.

If I remember correctly we were discussing the turbo condition just to get a feeling if it’s best to rebuild or buy new, or at least understand how deep the rebuild might be in extra parts.

No play in the turbo whatsoever as well. All checks great.

Yes, I want to upgrade to the KC balanced assembly now and get my early 99 PCM tuned with the hydra chip now that I know I have no leaks and no play in turbo. Costs just under 1k with taxes and all. I may go a slightly different route and look into the Riffraff wheel or Wicked Wheel 2. Time to do some research and advice is much appreciated!

Here is a video of the boost leak test. Caught it from 24psi all the way down to 0 psi. Took 1 minute 21 seconds to go to just about 0 psi from 24psi and still had a little bit of pressure still left in the system. I fixed the connections on the boost leak tester so all good there.

Picture also attached of new hose clamps to replace those crappy clic hose clamps.

#43

The following users liked this post:

#44

I can tell you that with my stock '02 Excursion 7.3

there is a major difference noted between stock and the 65hp daily driver mode, which is what I have defaulted to because it treats the Transmission almost exactly like my '01 K1500 Suburban does, at the proper throttle/speed and no slipping.

for towing, I use the 25hp tow mode with Tow Haul engaged, let the engine rap up higher, the MPG is almost exactly the same, but the Shifting is way less.

there is a major difference noted between stock and the 65hp daily driver mode, which is what I have defaulted to because it treats the Transmission almost exactly like my '01 K1500 Suburban does, at the proper throttle/speed and no slipping.

for towing, I use the 25hp tow mode with Tow Haul engaged, let the engine rap up higher, the MPG is almost exactly the same, but the Shifting is way less.

The following users liked this post:

#45

I can tell you that with my stock '02 Excursion 7.3

there is a major difference noted between stock and the 65hp daily driver mode, which is what I have defaulted to because it treats the Transmission almost exactly like my '01 K1500 Suburban does, at the proper throttle/speed and no slipping.

for towing, I use the 25hp tow mode with Tow Haul engaged, let the engine rap up higher, the MPG is almost exactly the same, but the Shifting is way less.

there is a major difference noted between stock and the 65hp daily driver mode, which is what I have defaulted to because it treats the Transmission almost exactly like my '01 K1500 Suburban does, at the proper throttle/speed and no slipping.

for towing, I use the 25hp tow mode with Tow Haul engaged, let the engine rap up higher, the MPG is almost exactly the same, but the Shifting is way less.