Rocker Shaft Assembly Recomendations

#1

Rocker Shaft Assembly Recomendations

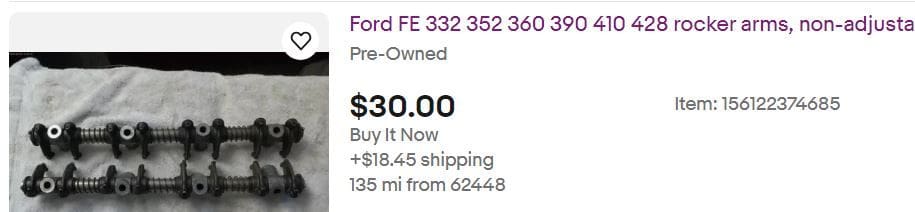

Looking to replace rocker shaft assembly including rockers and push rods if needed. Looking for recommendations. Currently running non-adjustable rocker assembly. Shaft is galled and rockers are ticking. Going to try to adjust in the mean time. I did a little cleaning up of the shaft and rockers to get me by.

Rebuilt 352 fe with mild/RV cam, headers, four barrel. Flat tappet lifters. Upgraded rear end. C6AE-R heads.

Looking to squeeze every ounce of torque out of this thing.

I'm not sure of all the options. I heard adjustable tend to back out and are made cheaply. I'm in San Diego north county. If anyone can recommend a good FE guru that would be great,

Rebuilt 352 fe with mild/RV cam, headers, four barrel. Flat tappet lifters. Upgraded rear end. C6AE-R heads.

Looking to squeeze every ounce of torque out of this thing.

I'm not sure of all the options. I heard adjustable tend to back out and are made cheaply. I'm in San Diego north county. If anyone can recommend a good FE guru that would be great,

#2

While it is possible to gain some very slight power with an aftermarket setup, such as Harland Sharp roller rockers for example, these are primarily needed for aggressive camshafts and spring loads a high performance engine would need. These type systems are also expensive if they are good, not cheap knock-offs. A factory non-adjustable replacement for your application is all you need. Where you get said factory setup that is not Chinese junk, dunno.

#4

Alright, maybe Iíll just replace the existing with another stock non-adjustable. I need to adjust my lash? though to make sure I have correct length push rods and hopefully address ticking. As I understand the process, I get a valve closed, fulcrum the rocker back to compress lifter, then measure gap between rocker and top of valve stem? Anybody know what that gap should be and how to measure it? Thanks for all the recommendations!

#5

Unless your heads, or block has been significantly machined, stock length pushrods and that set of non-adjustable rockers will do the trick. There's no lash to adjust. Your comments are conflicting.

The following users liked this post:

#6

The following users liked this post:

#7

For a stock rebuild or mild performance build, new stock style rockers & shafts like the ones shown earlier from Jegs are perfectly fine, and don't require custom pushrods. The time to consider switching to an aftermarket rocker arm setup is when you are running valve springs with spring rates that are much higher than stock, this is due to the outer rockers not being supported by the rocker stands (design issue with the FE). B/RB Mopar big blocks also have shaft mounted rockers, but have bolts through the shaft at the ends giving more support. Jegs also has an adjustable stainless roller rocker setup for around $350, but I believe these require switching to the ball/cup style pushrod instead of the original ball/ball style. I've never tried these rockers so I can't give any info regarding their quality.

Trending Topics

#8

I'm not surprised as I'm still learning, but I guess "adjust" was the wrong term. Maybe you can help with the process but I think I need to rule out improper push rod length as being a cause for my ticking. I had them out once and they are different sizes. Just want to confirm they are correct. Is the process I described the correct way to go about measuring the gap? I don't know what the gap should be or the best tool to measure it with.

#9

#10

Unless the heads have been milled quite a bit along with decking the block, stock length pushrods should be fine, For most hydraulic flat tappet cams the various manufacturers make them around 9.55-9.62 inches long with solid ball tips. Important thing to remember is to torque the rocker stand bolts in stages/steps in a consecutive pattern up to the recommended 40-45 ft/lb to prevent things getting bent out of shape or damaged.. A pushrod length checking tool isn't very expensive, they're basically an adjustable length pushrod with a locking nut on the threads. Personally I like using a lightweight spring (less tension than the plunger spring inside the lifter) to hold the valve shut when checking the required length. Cam lobe on the base circle (no lift applied) and unthread the adjustable pushrod until you feel resistance spinning it in your fingers. Then just add the suggested preload amount inside the lifter to your overall length needed.

The following users liked this post:

#11

Hopefully, you kept track of the pushrod locations. Roll them on a flat surface to check for a bent one. One of the rocker stand bolts is tapered to allow for oil to the stands. Look for the oiling hole next to the bolt. I have been able to compress the valve spring with channel locks, which is a lot easier with new lifters that aren’t filled with oil. Follow OC’s advice on installing the valve train - this also applies for removal.

#12

I got my new rocker shaft assembly from jegs and installed it. Still might add end stands and shims even though I'm not really hitting over 4500 rpms. Anyways, measured valve stem to rocker clearances and got the following numbers. I confirmed factory is between 0.050 and 0.150 for the 66' 352.

Going to change push rods for the two that are out of specs but do the rest look ok?

0.0780

0.1350

0.1

0.1430

0.1295

0.0875

0.1175

0.0685

0.0480

0.1320

0.1135

0.0985

0.1695

0.0500

0.0850

0.0600

Going to change push rods for the two that are out of specs but do the rest look ok?

0.0780

0.1350

0.1

0.1430

0.1295

0.0875

0.1175

0.0685

0.0480

0.1320

0.1135

0.0985

0.1695

0.0500

0.0850

0.0600

#13

Mismatched pushrod lengths indicate something a little ***** somewhere.

Without questioning the accuracy of your measurement method, those numbers are all over the map and shouldn't be. There are a few reasons for this but I would look to see how even the valve tip heights are. You'd have to disassemble the rocker assy. to get a good look. Lay a straight edge down on the valve tips and see how close they are to each other. Mainly looking for some that are obviously higher, or lower than the majority. Do you know if the heads have been rebuilt, and if so, what that entailed? I.E. Valve guides, hardened seats, new valves/springs, etc. What was done?

You should be able to install a stock set of pushrods(all same length), as suggested above, bolt down the rocker assy and it all work. No jacking around.

Fear not! It may come with pain, but this can be resolved so everything is correct.

Sorry, I will question one thing. Those numbers were obtained with each measured location where the valve is completely closed? Such as just after TDC on power stroke.

Without questioning the accuracy of your measurement method, those numbers are all over the map and shouldn't be. There are a few reasons for this but I would look to see how even the valve tip heights are. You'd have to disassemble the rocker assy. to get a good look. Lay a straight edge down on the valve tips and see how close they are to each other. Mainly looking for some that are obviously higher, or lower than the majority. Do you know if the heads have been rebuilt, and if so, what that entailed? I.E. Valve guides, hardened seats, new valves/springs, etc. What was done?

You should be able to install a stock set of pushrods(all same length), as suggested above, bolt down the rocker assy and it all work. No jacking around.

Fear not! It may come with pain, but this can be resolved so everything is correct.

Sorry, I will question one thing. Those numbers were obtained with each measured location where the valve is completely closed? Such as just after TDC on power stroke.

#14

Looking to replace rocker shaft assembly including rockers and push rods if needed. Looking for recommendations. Currently running non-adjustable rocker assembly. Shaft is galled and rockers are ticking. Going to try to adjust in the mean time. I did a little cleaning up of the shaft and rockers to get me by.

Rebuilt 352 fe with mild/RV cam, headers, four barrel. Flat tappet lifters. Upgraded rear end. C6AE-R heads.

Looking to squeeze every ounce of torque out of this thing.

I'm not sure of all the options. I heard adjustable tend to back out and are made cheaply. I'm in San Diego north county. If anyone can recommend a good FE guru that would be great,

Rebuilt 352 fe with mild/RV cam, headers, four barrel. Flat tappet lifters. Upgraded rear end. C6AE-R heads.

Looking to squeeze every ounce of torque out of this thing.

I'm not sure of all the options. I heard adjustable tend to back out and are made cheaply. I'm in San Diego north county. If anyone can recommend a good FE guru that would be great,

#15

I used exhaust opening intake closing and a pair of channel locks to compress the lifters. That was not easy as quite a bit of pressure had to be held for a while to compress the lifters. I also used TDC on number one cylinder then TDC on number six and checked each intake and exhaust that was indicated in the manual (can't remember which ones it indicated for each at the moment. I slid as many feeler gauges into each gap then measured the feeler gauges with digital calipers. Honestly there had to be some errors as it all seemed a little inexact. When I had the shaft off I did put a straight edge to the stems and they were all over the map, height wise, but none appeared to be off by a huge margin. I was told it had a long block rebuild not too long ago but I don't know what work was done to the heads. I do know it hauls ***! Anyways, got my clearances within specs and fired it up last night. Lots of sketchy sounding clacking at first but eventually smoothed out and runs great so far. Much less ticking so I guess I did something right. I'm going to put end stands and spacers from precision oil pumps in next and maybe rollers at some point. I've attached a couple photos. One valve stem looked really sketchy with a ground edge on top but it doesn't look like the rocker pad was causing it as I saw evidence of a more central wear on the top. Maybe the builder accidentally ground it on the side? See photo. Great learning experience. Thanks for all the help and please keep the advice coming. Oh, one more thing. I've been running VR1 10-30 non-synthetic with good pressure but I accidentally bought the VR1 10-30 synthetic. It's got a blue color. Am I ok running synthetic in my engine? Thanks again.