Air at schrader valve problem

#16

If air is allowed to enter the return system, it will drain the fuel filter head and the inlet to the injection pump. The fuel input to the injection pump is tied together with the return lines around the injectors. So while the engine would run with the injector return lines not connected, there is no way to keep the input to the injection pump primed and full of fuel ready for the next start.

#17

If air is allowed to enter the return system, it will drain the fuel filter head and the inlet to the injection pump. The fuel input to the injection pump is tied together with the return lines around the injectors. So while the engine would run with the injector return lines not connected, there is no way to keep the input to the injection pump primed and full of fuel ready for the next start.

The Fuel filter will not drain as the return on the filter is an orifice with check valve it will only allow fuel/air to flow in to the return if there is pressure behind it. Now a failed filter head fuel return check valve can cause issues is with higher mileage fuel pumps where the internal check valves are not sealing properly as is common on higher mileage fuel pumps. That will cause the filter head to drain a significant amount of fuel out of the filter in the same manner as a failed fuel heater O-ring.

I over looked the fuel return check valve and it;s failure in the previous post so thanks for bringing this up......

But regardless leaking injector return lines will have NO affect on starting. A leaking fuel return check valve on the filter head on the other hand.......

#18

The Fuel filter will not drain as the return on the filter is an orifice with check valve it will only allow fuel/air to flow in to the return if there is pressure behind it. Now a failed filter head fuel return check valve can cause issues is with higher mileage fuel pumps where the internal check valves are not sealing properly as is common on higher mileage fuel pumps. That will cause the filter head to drain a significant amount of fuel out of the filter in the same manner as a failed fuel heater O-ring.

I over looked the fuel return check valve and it;s failure in the previous post so thanks for bringing this up......

But regardless leaking injector return lines will have NO affect on starting. A leaking fuel return check valve on the filter head on the other hand.......

I over looked the fuel return check valve and it;s failure in the previous post so thanks for bringing this up......

But regardless leaking injector return lines will have NO affect on starting. A leaking fuel return check valve on the filter head on the other hand.......

I can't explain the exact scenario of how it does it, but air coming in around the o-rings will let the fuel drain back. Just the other day I had the same thing start to happen to my truck again. It turned out this time it was the o-ring around the fuel heater on top of the filter head was leaking. It did the same thing as always. It was a very small leak, so I could let it sit overnight and in the morning it would start right up, stumble a little bit and then run fine. If I let it sit 2 or 3 nights and then start it, it would start right up and then stall. Then crank crank crank till it would finally fire off and run fine again.

#19

You are overlooking something, I just can't put my finger on it. I am going by actual experience with my truck, and many other people's trucks. It's very common knowledge that leaking o-rings around the injectors causes the fuel system on the top of the engine to drain, causing hard starting. We fight these o-rings all the time to seal, it's also common when someone has this problem to ask if their little rubber lines between the injectors are grey. If they are, that means the lines are original, international painted the engine with the lines in place. Grey lines are a sure sign that the o-rings are old and leaking air. I can't imagine any engine by now having original o-rings and lines, they have all gotten hard and caused problems.

I can't explain the exact scenario of how it does it, but air coming in around the o-rings will let the fuel drain back. Just the other day I had the same thing start to happen to my truck again. It turned out this time it was the o-ring around the fuel heater on top of the filter head was leaking. It did the same thing as always. It was a very small leak, so I could let it sit overnight and in the morning it would start right up, stumble a little bit and then run fine. If I let it sit 2 or 3 nights and then start it, it would start right up and then stall. Then crank crank crank till it would finally fire off and run fine again.

I can't explain the exact scenario of how it does it, but air coming in around the o-rings will let the fuel drain back. Just the other day I had the same thing start to happen to my truck again. It turned out this time it was the o-ring around the fuel heater on top of the filter head was leaking. It did the same thing as always. It was a very small leak, so I could let it sit overnight and in the morning it would start right up, stumble a little bit and then run fine. If I let it sit 2 or 3 nights and then start it, it would start right up and then stall. Then crank crank crank till it would finally fire off and run fine again.

We need to separate the 2 sides of the fuel system here. lets call it low pressure high pressure and return fuel. Every thing between the IP and the and the lift pump we will consider the low pressure side. Between the injectors and IP feed the high side. There is also the return system but well cover that as we go along.

There are 3 typical hard start scenarios A start run then quit. A hard start all the time And hard start with a low fuel level in the tank and normal start with high fuel level in the tank.

Now exactly as you described if you get a leak in the low pressure side such as a bad fuel heater o-ring failed or potentially a filter head check valve you will get you a start, run and then a stall. That is the symptom of a low pressure side leak. It immediately tells you to suspect the the filter head. Now is the return fuel system lines always full of fuel, no, not by a long shot.

The return line terminates in the fuel tank well above the the suction line. this will allow the return line to drain of fuel if the fuel level in the tank is below the termination point of the return line this is even more likely if you have leaking fuel return lines at the injectors. basically the whole return fuel system can evacuate. But this should not be an issue. As the return side of the fuel system only handles the leak off from the injectors (not pressurized) the by pass on the IP pumps fuel regulator/ check valve and the check valve flow on the filter head. The return side of the fuel system is isolated from the HP side. Except at the injectors.....

The Injectors work like a trap as it is lowest point on the high pressure side of the fuel system and will prevent the high pressure fuel lines from draining also the IP should be air tight so there is no way for the lines to drain. Like the finger over the straw trick. Now if the fuel pressure regulator/ check valve on the IP pump has failed this may allow the IP pump to drain down through the leak down on the injectors this is even more likely if the injectors are worn and the return lines are leaking at the injectors.

If the injectors are not sealing properly at their seat (generally only an issue on high mileage injectors that will have high leak down) it will allow the injector lines to evacuate through the leak down as air is allowed in to the injector line at the seat. Throw in a worn injection pump and this will allow ALL the injector lines to drain down and potentially the whole injection pump given enough time, and this will happen even faster with a failed pressure regulator check valve.

Diagnosing hard start should first include checking the filter head fuel heater O ring the filter head check valve and the IP pump fuel pressure regulator check valve.

Next should include an injector pop test to check for excessive leak down and leaking seats. Ideally there should be little to no leak down on the injectors. Excessive leak down will delay injector firing thus hurting fuel economy and power. There is also a worn IP Pump but that the last thing that should be checked and can not practically be done in vehicle. One of these 5 things will be the root cause of the hard start.

Bad injector return lines only highlight the real issue and are not the cause of it.....

#21

I did something stupid on my truck one time, and it came back to bite me. I was messing with the injection lines for some reason, I forget why, and I needed to take one of those clamp things off from around the lines. I thought they were just there as over kill like the factory seems to do sometimes, I mean really where is a hard metal line going to go on top of the engine? Well on a trip a few months later I found out those clamps are very important. They keep the metal lines from vibrating when the injection pump is injecting. That line cracked right at the injection pump and the engine started missing.

On the road I pulled it off and found out what was going on. Those things have a special flare to them, I tried a regular brass ferrule to get me through but it would not work. I ended up taking the line off the injector, reversing it and putting it on the injection pump, and then running a hose from the free end down into the return system. No more leaking fuel but I was running on only 7 cylinders. I ran from Tenn all the way to Pensacola Fl on 7 cylinders, and then I spent a whole day going to every junkyard in Pensacola trying to find a hard line for it. That was right when they had cash for clunkers and the old diesel trucks got hit hard by that. I finally found one the guy would sell me off a 6.9. Put it on in the campground and was good to go. I rigged some wire ties and rubber hose to hold the line tight till I got back home. There was the clamp I needed, sitting on my workbench still.

#22

We need to separate the 2 sides of the fuel system here. lets call it low pressure high pressure and return fuel. Every thing between the IP and the and the lift pump we will consider the low pressure side. Between the injectors and IP feed the high side. There is also the return system but well cover that as we go along.

There are 3 typical hard start scenarios A start run then quit. A hard start all the time And hard start with a low fuel level in the tank and normal start with high fuel level in the tank.

Now exactly as you described if you get a leak in the low pressure side such as a bad fuel heater o-ring failed or potentially a filter head check valve you will get you a start, run and then a stall. That is the symptom of a low pressure side leak. It immediately tells you to suspect the the filter head. Now is the return fuel system lines always full of fuel, no, not by a long shot.

The return line terminates in the fuel tank well above the the suction line. this will allow the return line to drain of fuel if the fuel level in the tank is below the termination point of the return line this is even more likely if you have leaking fuel return lines at the injectors. basically the whole return fuel system can evacuate. But this should not be an issue. As the return side of the fuel system only handles the leak off from the injectors (not pressurized) the by pass on the IP pumps fuel regulator/ check valve and the check valve flow on the filter head. The return side of the fuel system is isolated from the HP side. Except at the injectors.....

The Injectors work like a trap as it is lowest point on the high pressure side of the fuel system and will prevent the high pressure fuel lines from draining also the IP should be air tight so there is no way for the lines to drain. Like the finger over the straw trick. Now if the fuel pressure regulator/ check valve on the IP pump has failed this may allow the IP pump to drain down through the leak down on the injectors this is even more likely if the injectors are worn and the return lines are leaking at the injectors.

If the injectors are not sealing properly at their seat (generally only an issue on high mileage injectors that will have high leak down) it will allow the injector lines to evacuate through the leak down as air is allowed in to the injector line at the seat. Throw in a worn injection pump and this will allow ALL the injector lines to drain down and potentially the whole injection pump given enough time, and this will happen even faster with a failed pressure regulator check valve.

Diagnosing hard start should first include checking the filter head fuel heater O ring the filter head check valve and the IP pump fuel pressure regulator check valve.

Next should include an injector pop test to check for excessive leak down and leaking seats. Ideally there should be little to no leak down on the injectors. Excessive leak down will delay injector firing thus hurting fuel economy and power. There is also a worn IP Pump but that the last thing that should be checked and can not practically be done in vehicle. One of these 5 things will be the root cause of the hard start.

Bad injector return lines only highlight the real issue and are not the cause of it.....

There are 3 typical hard start scenarios A start run then quit. A hard start all the time And hard start with a low fuel level in the tank and normal start with high fuel level in the tank.

Now exactly as you described if you get a leak in the low pressure side such as a bad fuel heater o-ring failed or potentially a filter head check valve you will get you a start, run and then a stall. That is the symptom of a low pressure side leak. It immediately tells you to suspect the the filter head. Now is the return fuel system lines always full of fuel, no, not by a long shot.

The return line terminates in the fuel tank well above the the suction line. this will allow the return line to drain of fuel if the fuel level in the tank is below the termination point of the return line this is even more likely if you have leaking fuel return lines at the injectors. basically the whole return fuel system can evacuate. But this should not be an issue. As the return side of the fuel system only handles the leak off from the injectors (not pressurized) the by pass on the IP pumps fuel regulator/ check valve and the check valve flow on the filter head. The return side of the fuel system is isolated from the HP side. Except at the injectors.....

The Injectors work like a trap as it is lowest point on the high pressure side of the fuel system and will prevent the high pressure fuel lines from draining also the IP should be air tight so there is no way for the lines to drain. Like the finger over the straw trick. Now if the fuel pressure regulator/ check valve on the IP pump has failed this may allow the IP pump to drain down through the leak down on the injectors this is even more likely if the injectors are worn and the return lines are leaking at the injectors.

If the injectors are not sealing properly at their seat (generally only an issue on high mileage injectors that will have high leak down) it will allow the injector lines to evacuate through the leak down as air is allowed in to the injector line at the seat. Throw in a worn injection pump and this will allow ALL the injector lines to drain down and potentially the whole injection pump given enough time, and this will happen even faster with a failed pressure regulator check valve.

Diagnosing hard start should first include checking the filter head fuel heater O ring the filter head check valve and the IP pump fuel pressure regulator check valve.

Next should include an injector pop test to check for excessive leak down and leaking seats. Ideally there should be little to no leak down on the injectors. Excessive leak down will delay injector firing thus hurting fuel economy and power. There is also a worn IP Pump but that the last thing that should be checked and can not practically be done in vehicle. One of these 5 things will be the root cause of the hard start.

Bad injector return lines only highlight the real issue and are not the cause of it.....

I know it does it, but I am trying to find out why since you questioned it and I am trying to find a answer.

http://www.conestogadiesel.com/suppo...diengines.html

#23

This one seems to run fine once i get it started, it chugs a little at first because of the air in the system. The lines are really wet up there around the fittings on the injection pump. It looks like that the fuel line that comes over from the filter to the injection pump might be the problem. I just got to find more time to start tearing it all apart. That little pool of diesel at the front of my engine looks like it ran down from the injection pump. I had parked it one a hill like one of you had told me, just noticed that now that i got a better look at things.

#24

Here is a link I found that explains the problem from a 3rd party. What you said about the return line system being separate from the fuel input and filter makes sense, but I am thinking that those two systems may be bridged by something inside the injection pump. You can see the injection pump has a line going to the return system. If that line is somehow connected internally to the fuel input,and air got in around one of the injector return o-rings, that would let the fuel start gurgling down the return line to the tank, and empty out the whole return system,, and the fuel input system to the IP including the fuel filter.

I know it does it, but I am trying to find out why since you questioned it and I am trying to find a answer.

fuel injection injection pump injection pump rebuilding injection pump repair, Conestoga Diesel Injection Fuel Injection and Turbocharger Rebuilding. The Moose Pump people! Willow Street, PA Fuel line routing options for Ford IDI engines

I know it does it, but I am trying to find out why since you questioned it and I am trying to find a answer.

fuel injection injection pump injection pump rebuilding injection pump repair, Conestoga Diesel Injection Fuel Injection and Turbocharger Rebuilding. The Moose Pump people! Willow Street, PA Fuel line routing options for Ford IDI engines

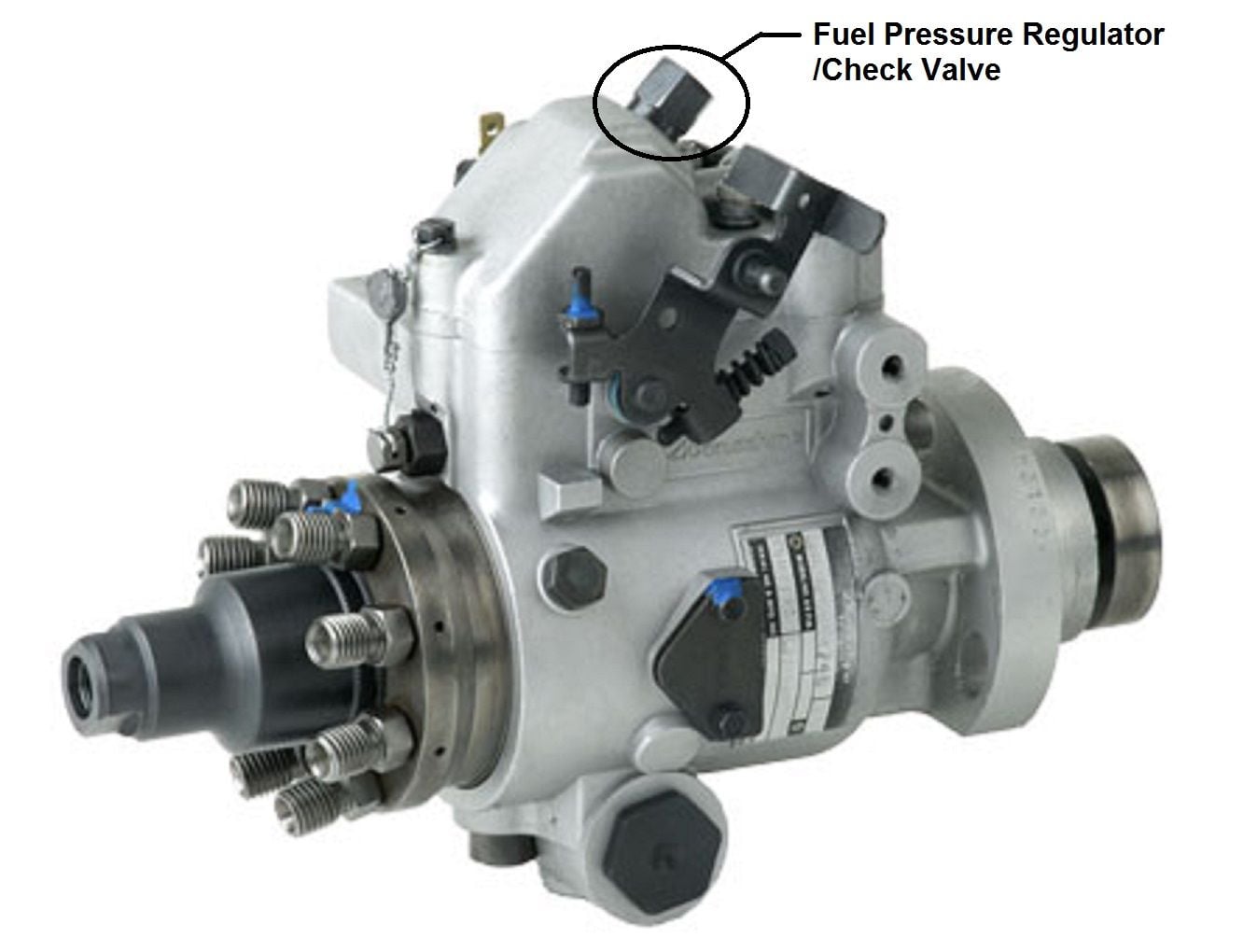

That line you are referring to on the IP pump is the fuel pressure regulator bleed and is at the highest point in the IP pump just like the filter head check valve.

The fuel pressure regulator bleeds off fuel in to the return system to regulate the fuel pressure on the feed side of the IP Pump. The pressure regulator is closed and sealed tight (no flow in to or from the return system) until the pressure in the IP pump feed side exceeds 3 PSI.. If there were no check valves in the fuel filter head and and the IP pump then what they are saying would be true. But the IP pressure regulator and the filter head return both are sealed closed at rest.. Also the return line is not always under the fuel level in the tank so there is no vacuum to retain the fuel in the return system.

The Low and high side of the IP pump are sealed from each other, in a properly functioning IP pump. When the pump wears they can be leakage between the two. Unlike in the Bosch P pumps and the VE pumps used on the Cummins there is no way for fuel to transfer between the high and low side of the IP pump. In rotary pumps such as the DB2 (as used on the idi's) and the CAV rotary pumps this happens once these pumps wear. This then it becomes an issue if you have a leaking injectors or injectors with high leak down and a failed pressure regulator as it can allow the whole of the IP to evacuate of fuel. Additional another bit that gets over looked is the IP pump shaft seal if this starts to fail it can allow the whole of the IP pump to evacuate through injectors with high leak down just like a failed pressure regulator.

You can keep searching but on a properly function fuel system leaking return line o rings on the injectors will have no impact on starting. In fact you could pull the whole return system all the hoses off everything and it would have no impact on starting provided that the rest of the system was sealing properly.

#25

#26

Whenever I have glowplug problems, it will start with the same routine, maybe a little more cranking is needed, and when it does start it starts a little rough with one or two cylinders miss-firing and after running a couple of seconds they clear up and it runs smooth.

#27

Ya that write up is incorrect.

That line you are referring to on the IP pump is the fuel pressure regulator bleed and is at the highest point in the IP pump just like the filter head check valve.

The fuel pressure regulator bleeds off fuel in to the return system to regulate the fuel pressure on the feed side of the IP Pump. The pressure regulator is closed and sealed tight (no flow in to or from the return system) until the pressure in the IP pump feed side exceeds 3 PSI.. If there were no check valves in the fuel filter head and and the IP pump then what they are saying would be true. But the IP pressure regulator and the filter head return both are sealed closed at rest.. Also the return line is not always under the fuel level in the tank so there is no vacuum to retain the fuel in the return system.

The Low and high side of the IP pump are sealed from each other, in a properly functioning IP pump. When the pump wears they can be leakage between the two. Unlike in the Bosch P pumps and the VE pumps used on the Cummins there is no way for fuel to transfer between the high and low side of the IP pump. In rotary pumps such as the DB2 (as used on the idi's) and the CAV rotary pumps this happens once these pumps wear. This then it becomes an issue if you have a leaking injectors or injectors with high leak down and a failed pressure regulator as it can allow the whole of the IP to evacuate of fuel. Additional another bit that gets over looked is the IP pump shaft seal if this starts to fail it can allow the whole of the IP pump to evacuate through injectors with high leak down just like a failed pressure regulator.

You can keep searching but on a properly function fuel system leaking return line o rings on the injectors will have no impact on starting. In fact you could pull the whole return system all the hoses off everything and it would have no impact on starting provided that the rest of the system was sealing properly.

That line you are referring to on the IP pump is the fuel pressure regulator bleed and is at the highest point in the IP pump just like the filter head check valve.

The fuel pressure regulator bleeds off fuel in to the return system to regulate the fuel pressure on the feed side of the IP Pump. The pressure regulator is closed and sealed tight (no flow in to or from the return system) until the pressure in the IP pump feed side exceeds 3 PSI.. If there were no check valves in the fuel filter head and and the IP pump then what they are saying would be true. But the IP pressure regulator and the filter head return both are sealed closed at rest.. Also the return line is not always under the fuel level in the tank so there is no vacuum to retain the fuel in the return system.

The Low and high side of the IP pump are sealed from each other, in a properly functioning IP pump. When the pump wears they can be leakage between the two. Unlike in the Bosch P pumps and the VE pumps used on the Cummins there is no way for fuel to transfer between the high and low side of the IP pump. In rotary pumps such as the DB2 (as used on the idi's) and the CAV rotary pumps this happens once these pumps wear. This then it becomes an issue if you have a leaking injectors or injectors with high leak down and a failed pressure regulator as it can allow the whole of the IP to evacuate of fuel. Additional another bit that gets over looked is the IP pump shaft seal if this starts to fail it can allow the whole of the IP pump to evacuate through injectors with high leak down just like a failed pressure regulator.

You can keep searching but on a properly function fuel system leaking return line o rings on the injectors will have no impact on starting. In fact you could pull the whole return system all the hoses off everything and it would have no impact on starting provided that the rest of the system was sealing properly.

Hows that?

#28

#29

All of those places are dry. However where the fuel goes into the injector is wet, and the bottom steel lines that come off the injector are wet with diesel. Looks like it is leaking, and has leaked to the back of the engine and created a little pool of diesel fuel. (Its the black thing in the picture). The truck also does not like to shut off when I turn the key off, it just stays running. That is why I am starting to think its Injector pump problem. This trucks pump has most likely never been replaced. I do not know how many times the odometer has rolled over, but the pump that is in there looks pretty dirty.

I have fuel right away at the schrader valve as soon as start cranking on the engine, which leads me to believe I have good pressure from the pump the way it comes shooting out of there. But the truck just will not start. It is getting fuel obviously, but it will not fire with out that ether.

When the engine is all warmed up and I shut the truck off, I can start it again with ease, but when I start it, it will blow white smoke out of the exhaust.

I have fuel right away at the schrader valve as soon as start cranking on the engine, which leads me to believe I have good pressure from the pump the way it comes shooting out of there. But the truck just will not start. It is getting fuel obviously, but it will not fire with out that ether.

When the engine is all warmed up and I shut the truck off, I can start it again with ease, but when I start it, it will blow white smoke out of the exhaust.

#30

I did some more research, the explanation I am getting now is the high pressure side of the injection system stays charged, the return system is filled with air from a leaking o-ring. When the engine is first started and it pushes fuel out and opens the injector, the injector sprays the fuel in the cylinder, but as the injector goes to close air from the return system will invade the injection line. Since air is in there now, it compresses and won't open the injector and the engine quickly dies. It will not start again till the fuel from the ip pushes all the air out of the injection lines and it can open the injector.

Hows that?

Hows that?

Nope not gonna work. The Injector is a pressure release device. the injector will open at X pressure and close at X pressure both of which are above the return line pressure so even at rest it is wanting bleed down through the leak off.

There is no practical way for air to get in to the injector from the return line short of worn injectors whose valve seat is not sealing when the engine is off.. Remember with new injectors there could be piles of air in the return lines as new injectors have little to no leak off.

Also the clearance between the needle valve and injector body is so close just the presence of diesel fuel between the two is enough to seal it air tight in a good injector.. Plus you would have to evacuate all the fuel out of the injector body that houses the valve spring to get air in to annular fuel gallery. The only way for this happen is to have a leaking injector (leaking at the pintle seat as stated above) or have a failed pressure regulator on the IP pump allowing a worn IP to drain down through worn injectors up the needle valve in the nozzle and out the return line..

See below pic of a bosch style injector that is used used on the IDI's.

This is a big myth that bad return lines or injector cap O-rings cause hard starting. What they do is uncover that failed component/s are present. But they are not the root cause of the issue.