1968 Ford F250 Loose fan pulley

#32

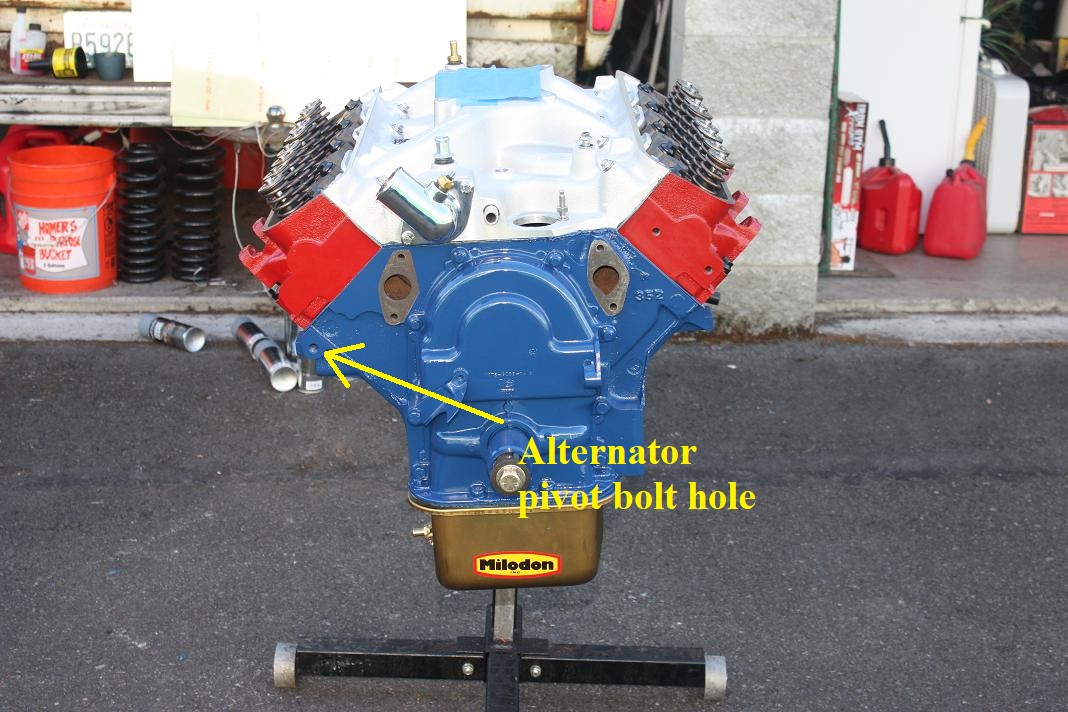

picture of bolt

Here's the bolt. I tried again this morning with the blowtorch and vice grips. The head of the bolt is definitely rounding out; even vice grips seem to slide on the head of the bolt. I'm going to try the acetone/tranny fluid mixture next. The problem is compounded by limited space access from above and below.

#33

Do you own a welder? If you do just grind the head off the bolt, then weld a nut with the same inside diameter as the shaft. Remove the alternator, and spacer. Weld the nut near the block face. The heat from welding, and the larger nut size should give you enough leverage to remove the bolt.

Is that PB blaster on the bolt head? It would do a lot more good if you sprayed it where the bolt goes into the block.

Is that PB blaster on the bolt head? It would do a lot more good if you sprayed it where the bolt goes into the block.

#34

This going to sound really weird. Soak the bolt where it bolts in to the head. Use your 1/2” break over bar and try to tighten the bolt just a pinch. When/if it moves, loosen it.

Maybe heat the head up with your torch and then try to tighten it.

I use this trick with brake bleeders and on my manifold bolts.

Maybe heat the head up with your torch and then try to tighten it.

I use this trick with brake bleeders and on my manifold bolts.

#35

#36

#37

Answering some of the questions: no welder, that is PB Blaster on the head, but I sprayed it also where the bolt goes into the block; I've torched both the bolt and where it enters the block.

I just liberally squirted the 50/50 acetone/trannyfluid mixture into the area where the bolt enters the block. According to various online sources, you should wait an hour, or longer, before trying to loosen the bolt.

I just liberally squirted the 50/50 acetone/trannyfluid mixture into the area where the bolt enters the block. According to various online sources, you should wait an hour, or longer, before trying to loosen the bolt.

#38

Amen to that. When I replaced all my hoses and belts (on a 360) everything was lovely until I took off the bypass hose at the water pump. I had to split it with a box cutter to get it off and then.... Holy moly, the ends of the two necks were 1/4 apart. I hacksawed 1/2" or so off of the one on the pump in order to get a new piece of hose on there.

I think that the bypass hose went on with the water pump.

I think that the bypass hose went on with the water pump.

#39

The bolt will not budge. In addition to methods I've already described, I used a 10" locking plier to grab the bolt head--this time, no sliding on the head. But the bolt held fast after many attempts to loosen it. Immediately prior to trying the locking pliers, I torched the area. Per another poster to this thread, I purchased a set of 6-point sockets, but the head of the bolt is now so rounded that the socket slipped immediately.

Compounding everything, I think, is the weather. Unavoidably, the truck is outside. Recently, the weather has been in the 30-40 degree range. Perhaps even the heat from the torching cannot transfer heat to the lower threads of the bolt, if that's the point of seizure.

Given how tight the bolt is, the problem is one of access and clearance. Access is best from beneath the truck. I need something, however, with the bite of the locking pliers that can be extended 6"-12" for more leverage--and I'm only wishing and hoping that might work. I thought about putting a pipe on the handle of the locking plier, but am concerned that the pipe might break the thinner, more fragile, tightening adjustment mechanism at the end of the plier handle, and render the pliers useless.

I'm still at it, but not sure how to proceed. As always, comments are welcome.

Compounding everything, I think, is the weather. Unavoidably, the truck is outside. Recently, the weather has been in the 30-40 degree range. Perhaps even the heat from the torching cannot transfer heat to the lower threads of the bolt, if that's the point of seizure.

Given how tight the bolt is, the problem is one of access and clearance. Access is best from beneath the truck. I need something, however, with the bite of the locking pliers that can be extended 6"-12" for more leverage--and I'm only wishing and hoping that might work. I thought about putting a pipe on the handle of the locking plier, but am concerned that the pipe might break the thinner, more fragile, tightening adjustment mechanism at the end of the plier handle, and render the pliers useless.

I'm still at it, but not sure how to proceed. As always, comments are welcome.

#40

Cut the head of the bolt off. There is five inches of bolt sticking out of the block to play with. Once the alternator and spacer are out of the way torch the **** out of the bolt. Clamp a pair of vice grips on it, and work it back and forth until it breaks loose.

Remove the belts to drive the truck. You'll get a couple miles before it overheats, and the battery dies.

Congratulations on having so many paper weights laying around. You may want to go and double check your statement. Not all FE cylinder heads were drilled on both ends. So, it seems rather implausible that Ford would mount the alternator to it.

Remove the belts to drive the truck. You'll get a couple miles before it overheats, and the battery dies.

#41

mrollings53, thanks for the advice.

I want to spend a little more time trying to get the bolt out before having to cut off the head as you suggested.

Is there a way to grind off some of the rounded bolt head and then try to loosen the bolt with a smaller 6-point socket?

I'm also going to try to extend the locking pliers with a pipe for more leverage. These Milwaukee locking pliers can be locked on so as not to slip on the head, so it's probably worth taking a chance on the pipe not breaking off the protruding adjustment mechanism at the end of the pliers handle.

I want to spend a little more time trying to get the bolt out before having to cut off the head as you suggested.

Is there a way to grind off some of the rounded bolt head and then try to loosen the bolt with a smaller 6-point socket?

I'm also going to try to extend the locking pliers with a pipe for more leverage. These Milwaukee locking pliers can be locked on so as not to slip on the head, so it's probably worth taking a chance on the pipe not breaking off the protruding adjustment mechanism at the end of the pliers handle.

#42

#44

Steve 340, thank you. I may try what you suggest. I'll have to think about it, as the presence of the belt is not keeping me from accessing the bolt; the bolt simply does not budge. I realize, however this works out, that I may have to cut the belt if I cannot get the bolt to turn.

We've had days of constant 30 degree temperature and 6 inches of snow, so I'm waiting for nature to cooperate before I can do anything more on the truck--hopefully in 2 or 3 days.

I appreciate all the comments, and will update the thread as I progress (or regress?).

We've had days of constant 30 degree temperature and 6 inches of snow, so I'm waiting for nature to cooperate before I can do anything more on the truck--hopefully in 2 or 3 days.

I appreciate all the comments, and will update the thread as I progress (or regress?).