4R100 mechanical diode fun

#31

One school of thought stated increasing line pressure was the best way to firm up the shift points. The argument against that method was the possible long-term affect it would have on the trans pump, so those people argued for using a modified valve body to firm up the shift instead, thereby keeping the line pressure at the stock setting.

Stewart

#32

I took some pics of stuff.

I took the case in to be cleaned and was very adamant about not scratching the valve body surface. In hind sight I should have probably bolted the pan on for the cleaning but I wanted the journals all cleaned too. I know pretty much everyone at the shop I took it too so I trust they will take care of me/it. Said I could pick it up tomorrow.

Anyhow pics.

These are the only discs that show heat. These are from the direct drum. Note the writing still on them.

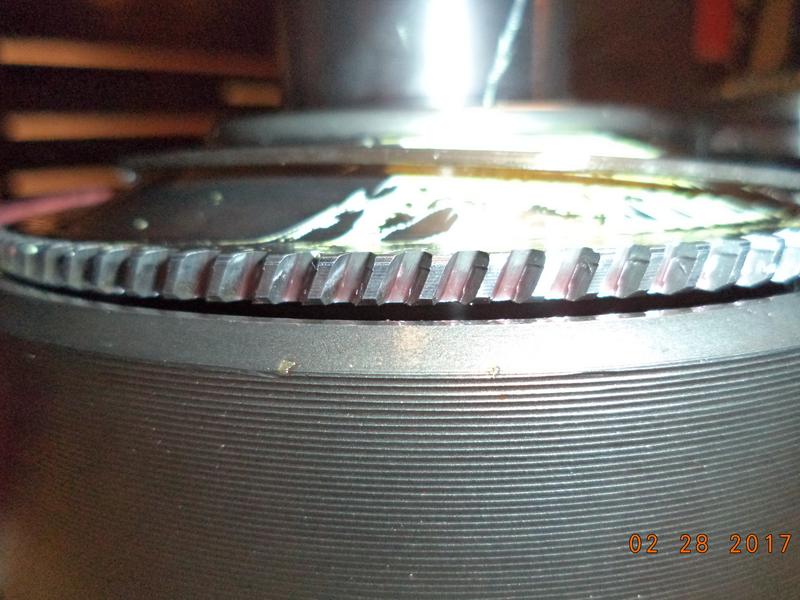

Forward drum splines I mentioned earlier that got hammered by the clutches.

To much wear? A little more than the .003 I said earlier. Maybe pushing .010 I should have checked.

I took the case in to be cleaned and was very adamant about not scratching the valve body surface. In hind sight I should have probably bolted the pan on for the cleaning but I wanted the journals all cleaned too. I know pretty much everyone at the shop I took it too so I trust they will take care of me/it. Said I could pick it up tomorrow.

Anyhow pics.

These are the only discs that show heat. These are from the direct drum. Note the writing still on them.

Forward drum splines I mentioned earlier that got hammered by the clutches.

To much wear? A little more than the .003 I said earlier. Maybe pushing .010 I should have checked.

#34

Is any wear on it bad? How much is to much? I have seen some pics of some that have hardly anything left to them.

Is it because the shaft wobbles around in the drum that causes the wear? Also why so little engagement? Who designs this stuff? lol

A thought that crossed my mind: Why can't the center shaft be welded to the drum?

#37

Guy says I can send the whole kit back no problem. I feel going that route will put the truck out of commission for too long.

So I went searching and found just the direct borg-warner frictions for $15 shipped for all 5.

Today I cleaned the parts washing tank. That is a gross job. Filled with new solvent and ready to clean up some internals tomorrow. I may be able to stick a few parts in the trans tomorrow even!

I kinda don't want to use my parts washer now. It looks like a clean fish tank inside now.

Ah yes, I got the case back today from being washed. No scratches in the valve body surface! However the solvent they use left the aluminum looking "tarnished".

So I went searching and found just the direct borg-warner frictions for $15 shipped for all 5.

Today I cleaned the parts washing tank. That is a gross job. Filled with new solvent and ready to clean up some internals tomorrow. I may be able to stick a few parts in the trans tomorrow even!

I kinda don't want to use my parts washer now. It looks like a clean fish tank inside now.

Ah yes, I got the case back today from being washed. No scratches in the valve body surface! However the solvent they use left the aluminum looking "tarnished".

#38

Join Date: Jun 2003

Location: Damon (South East Texas)

Posts: 8,298

Likes: 0

Received 14 Likes

on

13 Posts

Exedy is well known in the late model Mustang community for their friction and steel sets for the 6R80. I am heavily considering their Stage 1 kit for my '13 F150, if there comes a time to rebuild my 6R80. I don't know much about their line of parts for the 4R100, but I would consider them to provide premium quality products. I can understand you apprehension when receiving a kit with mixed friction sets. I would prefer to have a kit with matching sets, and friction coefficients, that are balanced for their particular application.

#39

The exedy frictions seem to be a harder more abrasive material. I would have entertained the idea of running them but I couldn't find a single thing about them in the 4r100 on the net. Not one person mentions using them. I have ran exedy clutches in cars and don't remember ever having a bad time with one. But being just randomly in the kit I don't know anything about the ones I got. If they are stock replacements, more aggressive, super aggressive, anything, just there they are. lol

I will probably offer them up in the free section if someone else can use them.

I finally got around to reading the atsg book last night. I must say it is one of the best written manuals I have read in a long time! Mine has "updates something or other" on the cover and it does cover a couple of the updates used but like someone mentioned earlier they don't talk about even close to half the mods/updates known today.

I will probably offer them up in the free section if someone else can use them.

I finally got around to reading the atsg book last night. I must say it is one of the best written manuals I have read in a long time! Mine has "updates something or other" on the cover and it does cover a couple of the updates used but like someone mentioned earlier they don't talk about even close to half the mods/updates known today.

#40

Join Date: Jun 2003

Location: Damon (South East Texas)

Posts: 8,298

Likes: 0

Received 14 Likes

on

13 Posts

I finally got around to reading the atsg book last night. I must say it is one of the best written manuals I have read in a long time! Mine has "updates something or other" on the cover and it does cover a couple of the updates used but like someone mentioned earlier they don't talk about even close to half the mods/updates known today.

It was probably me. I use the ATSG manual for a quick reference sometimes, but it could be more detailed in the inspection of parts and what to look for. This is where it is lacking for the first time builder. To me, it's not really a training manual.

#41

I agree it doesn't cover much inspection or even many clearances and whatnot. But it does cover what I was hoping, the assembly. The rest I can find on the internet as far as inspecting, what parts should be replaced, and what stuff to look for. At least mostly.

You have been a great help so far for me Roland, I thank you!

You have been a great help so far for me Roland, I thank you!

#42

Join Date: Jun 2003

Location: Damon (South East Texas)

Posts: 8,298

Likes: 0

Received 14 Likes

on

13 Posts

I just don't want people to get the wrong impression. Buying an ATSG manual and a rebuild kit is not a guarantee for a successful rebuild. It is an attention to detail that will. Overlooking problem areas can spell heartbreak in the future. It took ~40k miles for a problem to "rear its ugly head" because I didn't replace a few worn parts that I should have on my very first rebuild. Lesson learned.

#43

Even doing everything by the book, all the tricks, everything to a tee, sometimes they still just fail.

I've learned this with building motors, everything can be spot on and still sometimes they just blow up. A flawed/weak part, something odd with the fluid, a dry spot, the weather that day, never know.

I built a motor one time, everything was perfect, fired right up and sounded absolutely amazing! In short time it bogged, then died and wouldn't restart. Low compression. Found out the blast media collected in a crevice in the intake manifold, when the motor was started it sucked the media into the motor and stuck the rings in the pistons.

The intake was blasted, then washed with solvent, blown out, washed again, blown out again and scrubbed with a brush to remove all the media. Still some stuck.

The motor was tore down and every single little part was torn apart, cleaned, and all reassembled. Assembled and went to the track the next day.

That'll learn you not to use blast media on parts you can't clean out 100% afterwards. It sticks and has to be physically wiped off.

I've learned this with building motors, everything can be spot on and still sometimes they just blow up. A flawed/weak part, something odd with the fluid, a dry spot, the weather that day, never know.

I built a motor one time, everything was perfect, fired right up and sounded absolutely amazing! In short time it bogged, then died and wouldn't restart. Low compression. Found out the blast media collected in a crevice in the intake manifold, when the motor was started it sucked the media into the motor and stuck the rings in the pistons.

The intake was blasted, then washed with solvent, blown out, washed again, blown out again and scrubbed with a brush to remove all the media. Still some stuck.

The motor was tore down and every single little part was torn apart, cleaned, and all reassembled. Assembled and went to the track the next day.

That'll learn you not to use blast media on parts you can't clean out 100% afterwards. It sticks and has to be physically wiped off.

#44

Direct drum came in today and a few snap rings.

The clutches in the direct drum I received are in great condition. The unit smells like burnt electronics oddly. The roller clutch is smooth and the whole assembly is clean. The snap ring for the 'spring assembly' was popped off. Not sure if the PO did it or if that is how it was found in the trans.

After a month of my kids and wife passing around the flu and I was able to avoid it. Today I was aching all over and weak so I wasn't able to do anything in the shop. Hopefully tomorrow.

Roland talked me into a $40 Transgo kit that has the snap rings I need like the one for the coast clutch and some springs and replacement valves for the VB. The valves replace some anodized (I assume aluminum) valves in the trans stock that start to stick when the coating starts coming off.

The clutches in the direct drum I received are in great condition. The unit smells like burnt electronics oddly. The roller clutch is smooth and the whole assembly is clean. The snap ring for the 'spring assembly' was popped off. Not sure if the PO did it or if that is how it was found in the trans.

After a month of my kids and wife passing around the flu and I was able to avoid it. Today I was aching all over and weak so I wasn't able to do anything in the shop. Hopefully tomorrow.

Roland talked me into a $40 Transgo kit that has the snap rings I need like the one for the coast clutch and some springs and replacement valves for the VB. The valves replace some anodized (I assume aluminum) valves in the trans stock that start to stick when the coating starts coming off.