Brake light on? Bottom left corner of dash 69 f250

#17

There is not supposed to be any brake fluid in the middle of the PV under the 2b264 light switch. The pintel that floats back and forth in the PV as per pressure in front and back systems has a seal on either end of it. If fluid leaks past those seals and then past or through the 2b264 switch that means the 2B257 PV is bad. I am assuming this is why Ford made it out of nylon. 2B264 switch does not have to hold any brake pressure.

#18

so, I have had my 72 for a couple years and never knew this light existed. I am having issues with my steering column/gear selector/neutral safety switch/IDK... truck decides to go into any gear it wants to when I want it in park. So after the truck fell into reverse one day and drove itself into my fence while I was warming it up, I decided I needed to tighten the E-brake cuz it obviously wasn't tight enough. Perhaps I tightened it too much? After tightening the cable, I pulled the release and the "clunk" sound was really loud and caused that light to come on and now remains on. I assumed it was a light indicating that the E-brake was on. Seems weird to me. DId I maybe manage to mess something up when I (over) tightened the e-brake?

#19

#20

The brake warning light in your truck isn't a warning of low brake fluid. It's a warning of an imbalance in brake pressure between the primary and secondary brake circuits. (It's a warning of a brake component/system failure).

The brake warning light is generally triggered by a blown wheel cylinder/caliper seal, ruptured flexible or hard line or, a leaking MC. --although, it's most often triggered by the imbalance of fluid pressure when you are bleeding the brakes out.

...in the case of a component or line rupture, you would lose brake fluid. This would make the fluid level low in one circuit and technically, you would have low brake fluid but again, the warning light isn't warning you of a low fluid level situation. It's warning you that the brake pressures are not equal between the primary and secondary brake circuits. It's an indication of a brake system or component failure.

The plastic warning switch screws into a 3/8"-24 threaded port on top of the brake valve, in between the primary (front) and secondary (rear) brake circuits. There should never be any fluid under this switch and it should never be under any pressure. It will also not let air into the brake system by unscrewing it from the valve body.

The warning switch is isolated on either side by the O-rings on the pressure differential valve spool. The only way brake fluid would get on the warning switch is if one or both differential valve spool seals are bad.

Force and PSI are two different things. Force acts in only one direction. A good example of force is when you press down on the brake pedal. You are moving the input rod of the MC in only one direction --forward. The resultant force applied begins to push fluid out of the MC and takes up the slack in the brake system.

The wheel cylinders fill and the drum brake shoes overcomes the tension of the retracting springs and pushes the brake shoes into the friction surfaces of the drums. The calipers (if you have discs) fill with fluid and pushes the pads into the friction surfaces of the rotors.

Once the shoes and pads bottom out against the friction surfaces (the slack is taken up), they can no longer move forward. At this point the force is transferred into pressure (PSI). Unlike force, PSI (Pounds per Square Inch) does not act in only one direction. In a closed hydraulic system, like a brake system, the pressure acts equally and in all directions within the internal hydraulic surfaces of the brake system and all of its components.

The pressure can be as little as a few hundred PSI or, in a panic stop, it can be well over 1500 PSI. Knowing this, it's easy to see that there's no way the plastic 3/8"-24 threads of the brake warning light switch would hold up to that kind of pressure, if it was in direct contact with the brake fluid of the brake valve. The first time you stepped on the brakes, the hydraulic pressure would blow the plastic brake warning switch right out of the valve body and you would have a geyser of brake fluid shoot out of the valve body, if the switch was not isolated from the pressure and fluid of the brake system.

All brake valves do not contain a proportioning valve. The only place you'll find a proportioning valve is in a factory Ford brake system with discs front/drums rear.

An all-wheel drum brake system only has a pressure differential valve --no proportioning valve inside it.

The pressure differential valve has an hour glass design in the middle of the valve spool. The brake warning switch has a metal plunger that sits in the middle of the spool (the narrow portion of the hour glass). In this location, the contacts of the warning switch are open and the brake warning light will remain off.

The pressure of the primary and secondary sides of the brake system apply equal pressure across both ends of the pressure differential valve spool --so long as there's not a problem in the brake system to make one side lower in pressure than the other.

If there is an imbalance in brake pressure, the higher pressure of the good circuit will push harder on the end of the valve spool and shove the spool over to the lower pressure (failed) side.

This causes the plunger of the warning switch to ride up the ramp of the hour glass and closes the contacts of the switch. The closing of the switch contacts completes a path to ground, through the valve body, and illuminates the brake warning light on the dash.

Sometimes restoring equal pressure in the brake system between the primary and secondary brake circuits will re-center the differential valve spool and the warning light will go out. Most of the time though, if the light comes on and then the problem is corrected, the light stays on any way. If this happens, you'll have to determine what the failed side was and open a bleeder of the opposite side, slowly press down on the brake pedal to build pressure to get the valve spool to re-center and turn the warning light off.

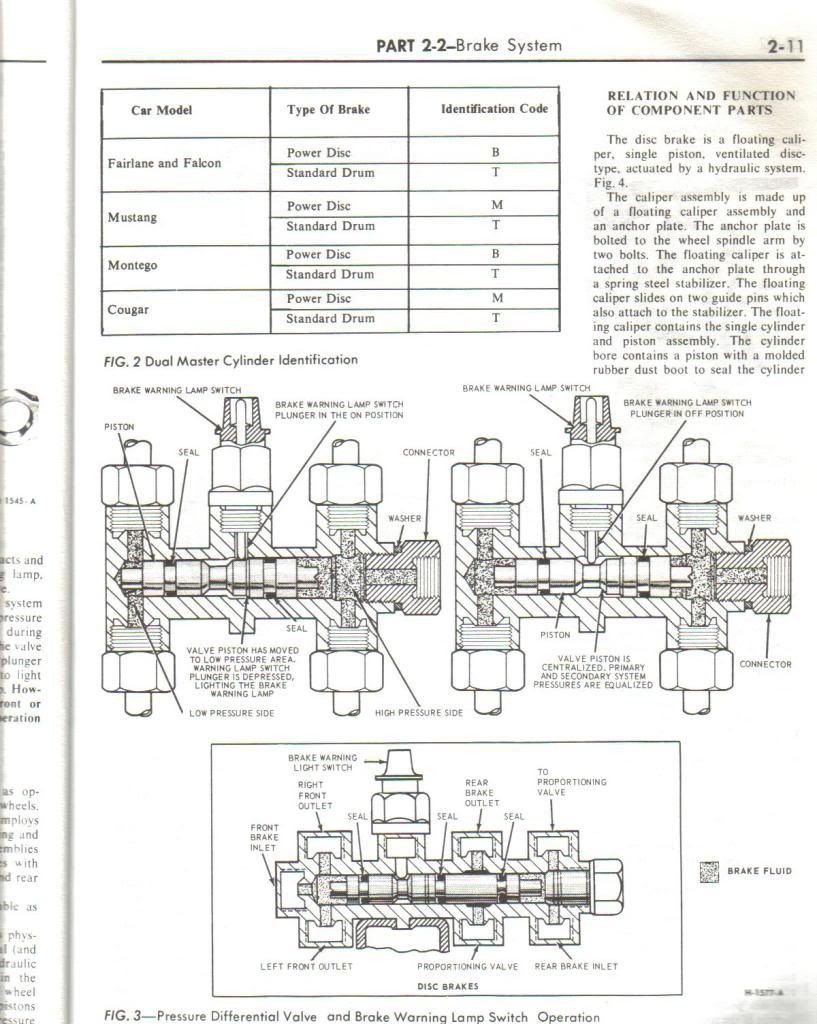

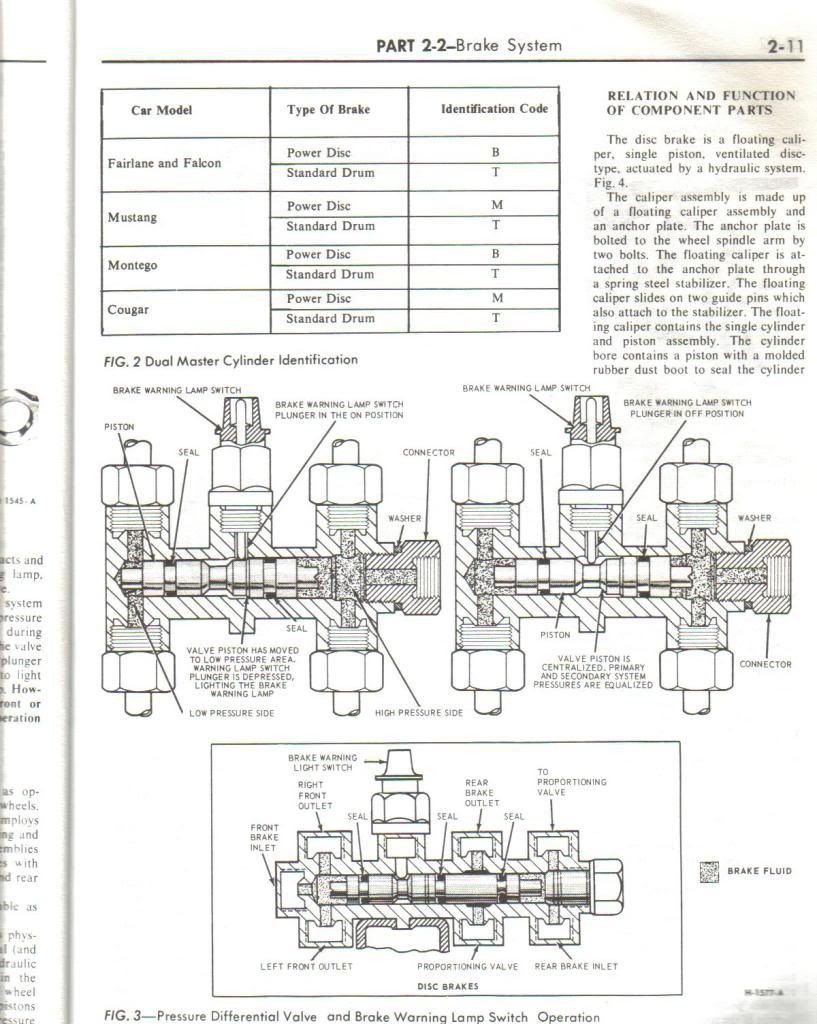

This is the internal workings (in diagram below) of a drum/drum brake pressure differential valve and how it works (as I described above).

The drum/drum pressure differential valve from my '69 F-100. (It was located inside the left frame rail, right behind the steering gear box).

Internal view of the drum/drum pressure differential valve. (notice the location of the O-rings on either side of the pressure differential valve spool, that isolates the plastic warning switch from the brake fluid/pressure of the system. If the switch is wet, it's because this seal(s) are bad. Under normal circumstances, no fluid will be present here).

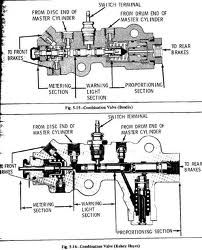

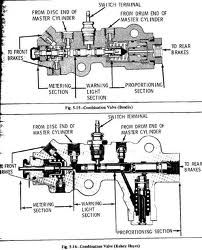

If you installed front disc brakes from a Dentside truck onto your Bumpside, there would have been a valve on the donor truck designed for discs front/drums rear. This valve is commonly referenced as a 'combination' valve because it has three functions within the same valve body assembly:

1. Metering (or, 'hold-off') to the front discs.

2. Pressure differential sensing (same exact component/function as the drum/drum pressure differential valve has).

3. And, proportioning to the rear brakes.

Two common styles of combination brake valves you'll find on a Dentside truck:

Kelsey-Hayes cast iron disc/drum combination valve.

Cutaway of the K-H valve assembly.

Weatherhead brass disc/drum combination valve.

As I mentioned above, bleeding the brakes out can often trip the warning light. There's a very simple valve lock tool available that can stop the pressure differential valve spool from shifting, when bleeding the brakes out. --it WON'T re-center a spool that has already shifted. --You have to install the lock tool BEFORE you begin bleeding the brakes.

This is the valve lock tool I have.

Shown here installed in place of the plastic brake warning switch to keep the pressure differential valve spool centered, while I was (very recently) bleeding the brakes out on my '69 F-100. --I had just converted the front of my '69 F-100 to disc brakes from a '77 F-100.

This is where I got the valve lock tool.

https://www.musclecarresearch.com/brake-valve-tool

The brake warning light is generally triggered by a blown wheel cylinder/caliper seal, ruptured flexible or hard line or, a leaking MC. --although, it's most often triggered by the imbalance of fluid pressure when you are bleeding the brakes out.

...in the case of a component or line rupture, you would lose brake fluid. This would make the fluid level low in one circuit and technically, you would have low brake fluid but again, the warning light isn't warning you of a low fluid level situation. It's warning you that the brake pressures are not equal between the primary and secondary brake circuits. It's an indication of a brake system or component failure.

The plastic warning switch screws into a 3/8"-24 threaded port on top of the brake valve, in between the primary (front) and secondary (rear) brake circuits. There should never be any fluid under this switch and it should never be under any pressure. It will also not let air into the brake system by unscrewing it from the valve body.

The warning switch is isolated on either side by the O-rings on the pressure differential valve spool. The only way brake fluid would get on the warning switch is if one or both differential valve spool seals are bad.

Force and PSI are two different things. Force acts in only one direction. A good example of force is when you press down on the brake pedal. You are moving the input rod of the MC in only one direction --forward. The resultant force applied begins to push fluid out of the MC and takes up the slack in the brake system.

The wheel cylinders fill and the drum brake shoes overcomes the tension of the retracting springs and pushes the brake shoes into the friction surfaces of the drums. The calipers (if you have discs) fill with fluid and pushes the pads into the friction surfaces of the rotors.

Once the shoes and pads bottom out against the friction surfaces (the slack is taken up), they can no longer move forward. At this point the force is transferred into pressure (PSI). Unlike force, PSI (Pounds per Square Inch) does not act in only one direction. In a closed hydraulic system, like a brake system, the pressure acts equally and in all directions within the internal hydraulic surfaces of the brake system and all of its components.

The pressure can be as little as a few hundred PSI or, in a panic stop, it can be well over 1500 PSI. Knowing this, it's easy to see that there's no way the plastic 3/8"-24 threads of the brake warning light switch would hold up to that kind of pressure, if it was in direct contact with the brake fluid of the brake valve. The first time you stepped on the brakes, the hydraulic pressure would blow the plastic brake warning switch right out of the valve body and you would have a geyser of brake fluid shoot out of the valve body, if the switch was not isolated from the pressure and fluid of the brake system.

All brake valves do not contain a proportioning valve. The only place you'll find a proportioning valve is in a factory Ford brake system with discs front/drums rear.

An all-wheel drum brake system only has a pressure differential valve --no proportioning valve inside it.

The pressure differential valve has an hour glass design in the middle of the valve spool. The brake warning switch has a metal plunger that sits in the middle of the spool (the narrow portion of the hour glass). In this location, the contacts of the warning switch are open and the brake warning light will remain off.

The pressure of the primary and secondary sides of the brake system apply equal pressure across both ends of the pressure differential valve spool --so long as there's not a problem in the brake system to make one side lower in pressure than the other.

If there is an imbalance in brake pressure, the higher pressure of the good circuit will push harder on the end of the valve spool and shove the spool over to the lower pressure (failed) side.

This causes the plunger of the warning switch to ride up the ramp of the hour glass and closes the contacts of the switch. The closing of the switch contacts completes a path to ground, through the valve body, and illuminates the brake warning light on the dash.

Sometimes restoring equal pressure in the brake system between the primary and secondary brake circuits will re-center the differential valve spool and the warning light will go out. Most of the time though, if the light comes on and then the problem is corrected, the light stays on any way. If this happens, you'll have to determine what the failed side was and open a bleeder of the opposite side, slowly press down on the brake pedal to build pressure to get the valve spool to re-center and turn the warning light off.

This is the internal workings (in diagram below) of a drum/drum brake pressure differential valve and how it works (as I described above).

The drum/drum pressure differential valve from my '69 F-100. (It was located inside the left frame rail, right behind the steering gear box).

Internal view of the drum/drum pressure differential valve. (notice the location of the O-rings on either side of the pressure differential valve spool, that isolates the plastic warning switch from the brake fluid/pressure of the system. If the switch is wet, it's because this seal(s) are bad. Under normal circumstances, no fluid will be present here).

If you installed front disc brakes from a Dentside truck onto your Bumpside, there would have been a valve on the donor truck designed for discs front/drums rear. This valve is commonly referenced as a 'combination' valve because it has three functions within the same valve body assembly:

1. Metering (or, 'hold-off') to the front discs.

2. Pressure differential sensing (same exact component/function as the drum/drum pressure differential valve has).

3. And, proportioning to the rear brakes.

Two common styles of combination brake valves you'll find on a Dentside truck:

Kelsey-Hayes cast iron disc/drum combination valve.

Cutaway of the K-H valve assembly.

Weatherhead brass disc/drum combination valve.

As I mentioned above, bleeding the brakes out can often trip the warning light. There's a very simple valve lock tool available that can stop the pressure differential valve spool from shifting, when bleeding the brakes out. --it WON'T re-center a spool that has already shifted. --You have to install the lock tool BEFORE you begin bleeding the brakes.

This is the valve lock tool I have.

Shown here installed in place of the plastic brake warning switch to keep the pressure differential valve spool centered, while I was (very recently) bleeding the brakes out on my '69 F-100. --I had just converted the front of my '69 F-100 to disc brakes from a '77 F-100.

This is where I got the valve lock tool.

https://www.musclecarresearch.com/brake-valve-tool

#22

Join Date: Aug 2003

Location: **** hole San Jose ca.

Posts: 7,592

Likes: 0

Received 9 Likes

on

9 Posts

Well a very good write up by ultraranger:

I hope this sets record straight finally putting an end to the notions of the Plastic/nylon warning light trip switch is some how having to hold any fluids under it.

I don't think the Hwy Safety Transportations would ever approve that plastic/nylon threaded switch could be safe under any normal driving conditions..

My 2 cents input!

Orich

I hope this sets record straight finally putting an end to the notions of the Plastic/nylon warning light trip switch is some how having to hold any fluids under it.

I don't think the Hwy Safety Transportations would ever approve that plastic/nylon threaded switch could be safe under any normal driving conditions..

My 2 cents input!

Orich

#23

The pressure differential switch on the '67 models had a single electrical prong in the top of the switch, where the wiring connector plugs into it.

The '68 and up switches are physically the same as the '67 switch --only physical difference being that there are TWO prongs in the '68-up switch, instead of just one.

However, the two prongs of the '68-up pressure differential switch are, electrically, at the same potential (common). If you look down into the switch (where the wiring connector plugs into it), you'll see that there's a small metal bar that links the two prongs together.

You can see the small bar that links the two prongs together in this photo.

If there's a pressure differential in the brake system, the pressure differential valve spool will shift to the side of least hydraulic pressure (the failed side). The thicker portion of the valve spool will close the switch contacts and the pressure warning light will come on.

The wiring harness connector does not have to be hooked up or powered up to determine if the pressure differential valve spool is shifted.

If the valve has shifted and closed the contacts of the switch, it will complete an electrical path to ground, through the valve body itself.

Shown here, a '69 F100 drum/drum pressure differential brake valve. I have one lead of the multimeter connected to one of the switch prongs (doesn't matter which one, they are common), and I have the other meter lead touching the valve body.

If the differential valve spool is centered (as it should be), there will be no electrical path to ground through the body of the valve and the meter will read Open Line (OL). This means the switch contacts are open and there's no continuity though the switch and that things are good.

If you read the switch out and there is continuity, you'll get a resistance value on the meter. This means the valve spool is shifted and that there's a pressure differential problem that has shifted the valve spool over.

If your meter has an audible continuity check feature, it's even easier to determine if the valve is shifted or not. If you touch the meter leads and there's no "beep," it means the differential valve is centered. If you touch the leads and there is a "beep," this is bad and means the spool is shifted.

If you're trying to source a valve from a wrecking yard donor, that can't be powered up to check for a brake warning light coming on, checking at the valve with a meter will tell you if it's centered or not, before you pull the valve from the donor vehicle.

Thread

Thread Starter

Forum

Replies

Last Post

billybob_81067

1967 - 1972 F-100 & Larger F-Series Trucks

6

08-26-2005 09:17 AM

CN313WC

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

3

10-23-2001 06:16 AM