351W build

#1

351W build

Building a 351W to put in my 93 4x4. Was wondering what you guys think. Stock stroke .030 over bore flattop pistons balanced roating assembly zero decked RHS Alum. heads with 200cc intake runners airgap dual plane intake reto fit hyd roller cam .541 lift at 230 duration. how much HP do you think this combination will make? Also what does or does not look good about my parts list. Thanks

#7

Join Date: Jun 2006

Location: Ottawa, Ontario

Posts: 30,883

Likes: 0

Received 946 Likes

on

751 Posts

Trending Topics

#9

Was the RHS recommendation before or after you indicated what cam you intended to run?

heads for the Windsor (even a 408-inch Windsor) that have 200cc intake ports belong only on the dragstrip.

Even with 408 inches, you'd have to be funneling Oxycontin like Rush Limbaugh to deal with something that hairy on a daily basis or at low-to-moderate speeds. Out-of-the-box, a set of AFR aluminum, 165-cc intake runner heads will provide enough flow to support more than 450 horsepower (perhaps more than 500 horsepower with a radical cam). Even a set of unmodified 185-cc AFR heads would be way too much for your application.

200cc heads might be fine for a 427-inch, short-rod weekend/bracket racer that might see 10 miles per week on the street, but most of its time either parked, on a trailer or on the track. The same applies to a 230-degree cam (@ .050) in a 351 (357.156 CID with the bore you indicated): while it can technically be installed in a vehicle that can then be driven on the street, it would be a nightmare to operate at partial throttle settings and a disaster in terms of idle quality.

To give you an idea of how ridiculous the 200cc heads are for your application: if the ports are any good at all, a 200cc head would be what you'd put on an engine designed to make at least 600 peak horsepower (and, more likely, at least 750). If they're not flowing that well, then they're horribly inefficient -- meaning greatly increased engine wear from fuel falling out of suspension at practical engine speeds, because mixture velocity stalls in the giant ports, and liquid gasoline enters the cylinders and washes the oily film from your cylinders and contaminates your oil. Additionally, tuning is going to be a PITA (assuming it is even possible), plus you'll have problems with plug fouling and cold-weather performance.

For most applications, the stock head is more than adequate -- but for the price of upgrading to the E7TE (assuming you don't have those heads already), you could probably get a set of the M-6049-X306 (likely less than $1100 per pair, delivered) that perform about as well as a prepped E7TE head. According to FRPP, the X306 has extra-tall intake ports that don't work with all intakes; from test results, we observe that the (out-of-the-box) FRPP -X306 doesn't perform as well as the AFR 165.

For heads, there are 2 ways to go: cast iron and aluminum. For an unmodified engine, it is less expensive to go with cast iron, since that's what came on the your engine when it was originally manufactured; however, as you seek to improve power, you're going to discover that factory heads can run out of breath fairly quickly -- especially on a cost-vs-benefit basis. You could put a set of ported-and-polished E7TE heads on your 351 and they would perform well -- but there are serious risks to that strategy: competent head work costs serious change, and price doesn't guarantee quality -- meaning you could easily drop a couple of grand into improving a set of iron heads and end up with junk. That, of course, isn't what usually happens, but it certainly can (and sometimes does) happen.

The low-risk alternative is the aluminum head, most of which in "out-of-the-box" condition outperform even the "fully prepped" E7TE head. Especially if you go into boggy areas (sand, mud, swamps, etc.), the lighter your vehicle is, the better. The weight savings from the heads alone probably won't be enough to noticeably improve your fuel economy (but it won't hurt it, either).

Even out-of-the-box (unmodified), AFR-165s would make a pretty huge boost in power with the stock cam (and with no other changes, the AFR heads will also slightly raise the rpm at which torque and horsepower peak). This is normal for all improved-flow heads. With the stock cam, you're probably looking at only a 200-300 rpm upward shift in your 357-inch 351. Together with the weight savings (small, but not entirely insignificant), the aluminum AFR heads will transform your ride.

However, if you're replacing the stock cam anyway, a shorter-duration stick with the right lift & lobe separation will get you where you want to go: it'll pack power into the lower rpm range where you want most of your power anyway. Ultradyne/Bullet camshafts can custom-tailor a camshaft for your application; if you give them good info up front, their results are hard to beat. Other cam grinders also offer this service, most commonly based on adjusting the relative position of the intake & exhaust lobes, and how advanced or retarded that is relative to the crankshaft. I know, that probably sounds like gobbledygook, but it isn't anything for you to worry about: just give your camshaft supplier the truth (even if you think it isn't sexy) and you'll probably be amazed at what they can do for you.

If I truly expected to go to the 408-inch engine and if I didn't want to re-cam for the 408 (which begs the question, "Why not?"), I'd keep the stock cam: even though it will be a little racy with the 357 and the AFR 165 heads, it will be pretty close to ideal in terms of duration for the 408. Add a set of 1.7 rockers to the AFR heads on the stock-cam 408, check your piston-to-valve clearances, and you're good to go!

For the 351W in a 4x4, the smallest hydraulic Lunati "Voodoo" camshaft part number 61000 or the Comp Cams "Xtreme 4x4" camshaft part number 35-231-3 is probably about right with the AFR 165 heads. Of these camshafts, if my choices were limited to an off-the-shelf hydraulic flat-tappet cam for the engine you're starting with, I'd probably choose the Lunati: it has more intake lift and only a degree more duration, and the exhaust specs, LSA, etc. are generally comparable. If it was my ride, I'd start with the AFR heads (don't bother getting the 185s: they're way overkill for your application) and I'd get the Lunati stick. If I went to a 408 (or some other stroker in the 393-413 CID range) in the future, I'd re-cam with something like the 256-degree Lunati Voodoo camshaft part number 61001.

Since you mentioned your block is a pre-roller, I didn't bother looking for retrofit hydraulic rollers; these companies can generally fix you up if that's what you're hoping to do, but don't let anyone sell you on the idea that you need a roller-tappet camshaft for your application. The hydraulic flat tappet is technology that has a rich and storied history of proven reliability and durability, and advances in materials and shaping technology have led to the modern generation of truly excellent hydraulic "flat-tappet" cams.

Just in case someone has sold you on the idea of retrofitting a hydraulic roller into your block, I did take a look at the Comp Cams Extreme Energy hydraulic rollers; their off-the-shelf Extreme Energy cams in that range [for a 351-366 CID engine in a 4x4, the 35-413-8]; [for a 393-413 CID stroker in a 4x4, the 35-421-8] are probably going to have a powerband more narrow than you'd like in a 4x4. I don't think Lunati makes a "retrofit hydraulic roller" for the 351Ws that didn't have factory hydraulic rollers.

If I could find a set that would fit, I would go with a set of either 14-gauge or 16-gauge (but no thinner than 16-gauge) "shorty" headers having either 1.5-inch or 1.625-inch primary tube diameter and 2.5-inch collectors. I'd get stainless tubing headers if they were available (ceramic coated is a plus), and I'd use a thermal wrap on them. Here is some information about thermal wraps. I'd use 2.5-inch down-tubes to a (crossover tube, "X-pipe" or similar), if I was running true dual exhaust; if not, I'd run those tubes to my collector.

If you're running a single exhaust, a single 3.5-inch tube with a 0.095-inch wall thickness will generally support 450 horsepower; dual 2.5-inch tubes (each having a wall thickness of 0.118 inch) will generally support 375 horsepower. Keep in mind, though, that such ratings are generally for sustained power levels, as in an industrial or marine setting: for occasional short bursts of peak power, you can use significantly smaller tubing diameters, which means your exhaust system can be less heavy.

If you're building a professional race truck, then the specific details contained in the above recommendations don't apply; however, your posts thus far indicate you're looking to maximize performance from a vehicle that you operate on public roads and perhaps in fields and forests -- in which case, the following recommendations are in my personal opinion spot-on; your opinion may differ. I am not an employee, representative or agent for any of the companies mentioned herein; I receive no compensation based on whether you choose or don't choose any of the parts or technologies mentioned herein. I do not own stock or other interest in any of the companies, products or services mentioned herein. No warranty expressed or implied is by me made regarding the availability, fitness for use, performance, reliability or any other aspect or combination of aspects of any entity, product or service herein mentioned, whether individually or in any combination.

Last edited by wireflight; 07-02-2011 at 07:44 PM. Reason: p/n correction

#10

Join Date: Jun 2006

Location: Ottawa, Ontario

Posts: 30,883

Likes: 0

Received 946 Likes

on

751 Posts

Howards Cams 91168 - Howards Cams Street Series Retrofit Hydraulic Roller Lifters - Overview - SummitRacing.com

#11

Ok well what size runner would you go with? I was told that a 200cc would be fine but I am learning as I go with this small block build. I have had all BBF builds so far this 351w is a first for me. RHS offers 160 and a 180cc intake runner. I got on this forum to get good information so far it has been all good.

#12

Join Date: Jun 2006

Location: Ottawa, Ontario

Posts: 30,883

Likes: 0

Received 946 Likes

on

751 Posts

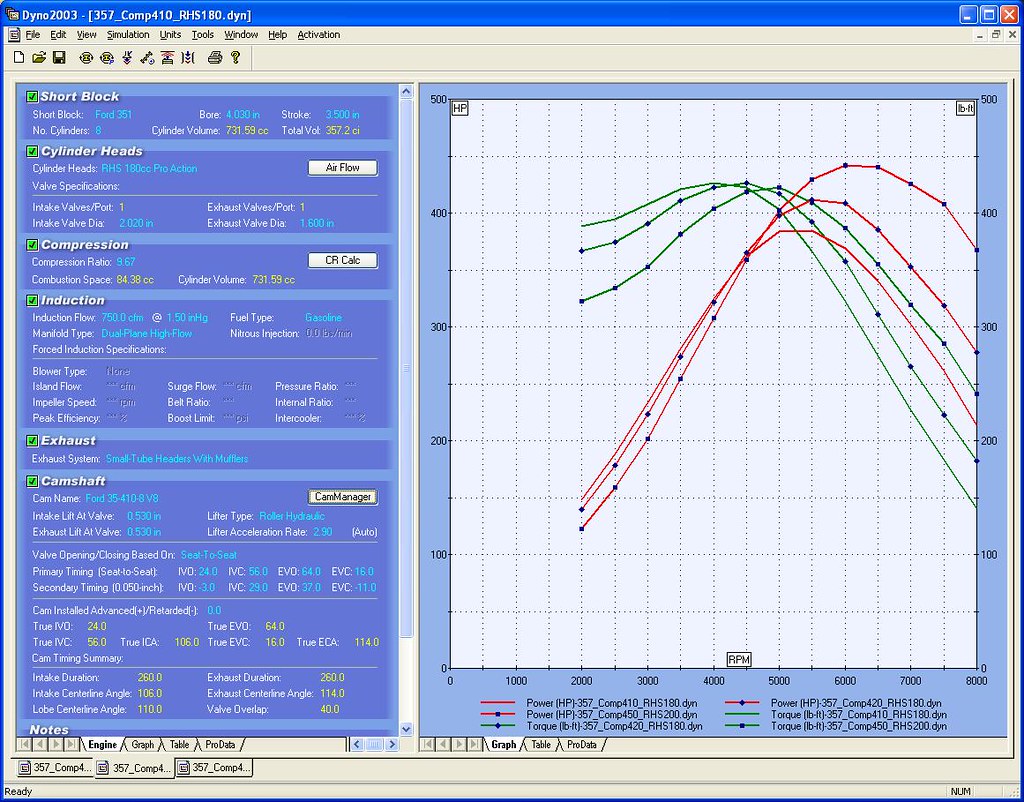

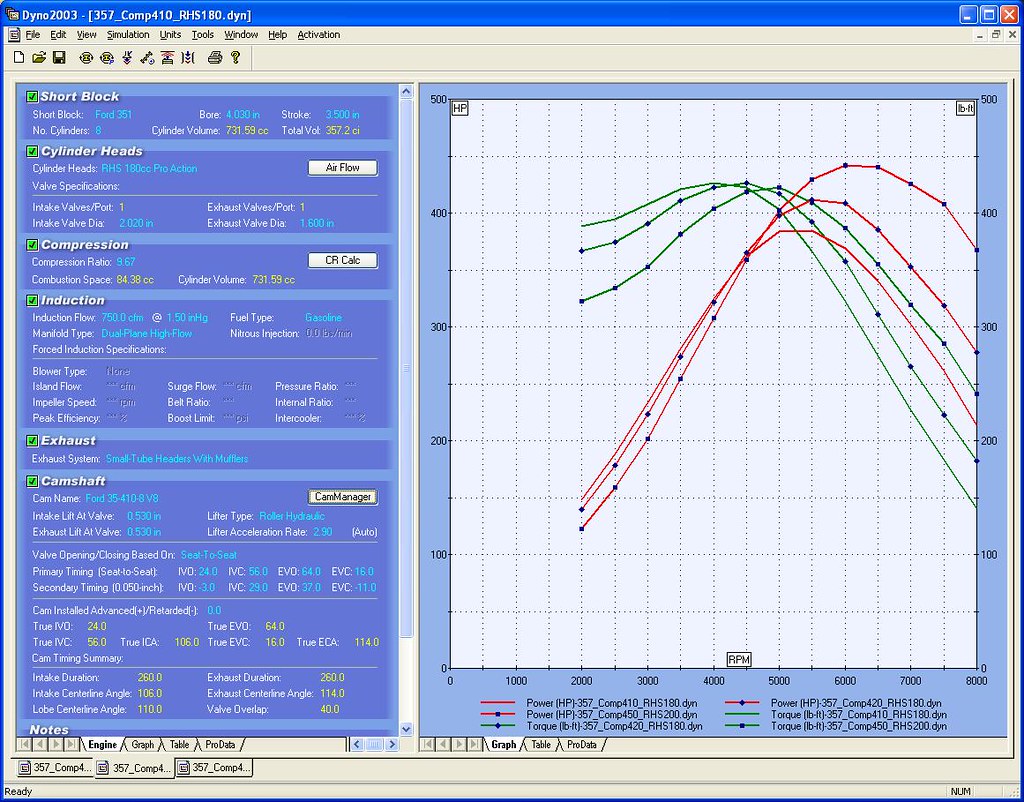

The problem with getting advice from the parts vendors and manufacturers is that they mostly deal with guys building drag race motors and all they care about is peak HP. Building a truely streetable truck motor is a lot different and will require different choices, and yes it will sacrifice some peak HP but it will provide a more balanced powerband that will be able to use more conservative gearing and as a result produce somewhat decent fuel milage. A picture says a thousand words so I'm going to start with that and comment on what you see. The graphs below represent a motor using the components we're discussing here, the legend at the bottom shows you what traces go with what combo, but in short the combo you originally spec'd with 200cc heads and a 230 deg cam produces the highst HP numbers but it's really soft in the TQ department below 3000rpm( top red and bottom green traces). With a heavy truck you need about 350 ft/lbs of TQ from the motor to move it around with what I call authority, yes it'll move just fine with less TQ but it won't have that light on it's feet feeling, so ideally you want as much TQ as possible at as low an rpm as possible. The other two sets of traces are with 180cc RHS heads and cams that produce 206 and 215 deg intake duration(at 0.50" lift) respectively. The cam whose specs are shown only produces about 385hp(bottom red trace) but with nearly 400 TQ available(top green trace) from 2000rpm you'll have tire spinning grunt a mere tap of the throttle away all the time, which will make the truck an absolute hoot to drive. This type power is what I suggest you aim for.. but it depends if you want street and trail friendly power or if you just want to play in the mud pits.. which like drag racing is all about horsepower.

#13

#15

Truckin' Heads

I realize you're not looking at anything that radical, now, but I just wanted to show you what sort of power and rpm a set of AFR 185 heads would unleash with the sort of combination you were considering. Hopefully, you will see that even a 185-cc AFR port is overkill for what you're trying to do. Especially now that your cam choice has become reasonably streetable, I still think the 165-cc AFR heads will outperform your engine (meaning, "that combination won't demand more than they can supply"). The 165-cc intake port sounds small, but the AFR ports are remarkably efficient for out-of-the-box Windsor castings, and if you want to build a race motor or simply add a supercharger later-on, they're good for well over 400 horsepower.

Unless I personally had it in for AFR, I'd go with their 165-cc (intake port) heads. Check out this article where the AFR 165 beats the 185 up to 4400 rpm. Yeah, it's on a 302 -- but it's a Cobra 302 (not a bread-and-butter truck mill). Not close enough to the same combo as yours? Try this link. It's another 302, but it uses the Comp Cams XE264HR grind (212/218 @ 0.050, 0.512 lift), which should be slightly milder than the cam you indicated, which sounds to me like the Comp Cams 35-238-3.

Here is a set of out-of-the-box AFR 165 heads making 396 hp @ 5800, 378 lbs-ft @ 4700 -- all on a 302 using the XE264HR cam ground on a 114-degree LSA (raises rpm for peak torque). Average horsepower during the test was 288.89; average torque was 353.86. Compare those numbers with the baseline E7TE heads (306 hp @ 5300, 342 lbs-ft @ 4000 with the same cam; 253.08 average horsepower, 316.00 average torque) and you'll see the "tiny" 165-cc AFR heads are no slouch in the performance department.

Holley now has the Systemax II heads available; I haven't seen them tested. The original Systemax design apparently had problems that, presumably, the Systemax II has solved; if I was dead-set against AFR (which I'm not), I might consider either the Holley Systemax II or the Edelbrock Performer (not the Performer RPM) heads. Based on their performance record, though, I'd probably just suck it up and get a set of AFR 165s and be done with it. The AFR heads hold their value; the other heads may work reasonably well, but they don't keep their value like AFRs.

The rod:stroke ratio of the 302 is roughly 1.6967; the rod:stroke ratio of the 351W is roughly 1.7017. Therefore, the 351W should use slightly less air on a horsepower-per-horsepower (or torque-per-torque) basis -- but the difference will be very sight. Since the 351W has more than 14 percent more stroke than the 302, it will be remarkably better at drawing air through the ports than the 302 (assuming the same piston and combustion chamber designs, same compression ratio, etc.); the questions then are (a) do you have the cam to feed the additional stroke, and (b) do you have heads that won't choke the engine?

In the case of the Comp Cams 35-238-3 (which comes ground on a 106-degree LSA), I think you've got plenty of cam for a 351, and if it was my engine, I'd insist on the AFR 165 heads, even if it meant using a different builder or doing it myself.

Here is an article that illustrates why I think the AFR 165s are so good for your application: Article, Part 1; Article, Part 2. With your 357-cube engine and (XE262H) cam, with 165 cc AFR heads, I'd expect more than 400 horsepower (averaging perhaps as high as 340) and at least 400 lbs-ft of torque (with a good intake manifold, over 430 lbs-ft) for my peaks, and an average torque around 370-400 lbs-ft (depending on intake & exhaust). That is very seriously healthy!

If we assume that (at operating temperature) your cylinders have a bore of exactly 4.0300 inches, that your engine's deck height is 9.5000 inches, that and that your connecting rods have a center-to-center length of 5.9560 inches, and that your head gaskets are 0.0320 inches thick and that the published compression height of the listed pistons is accurate, and that the volume of your compressed head gasket is exactly 4 cc, and that the spark plug provides no net change in the combustion chamber volume listed for the cylinder head, and that the volume of the piston dish is accurate -- then, and only then, are the following dimensions reasonably accurate:

Assuming 58-cc AFR 165 heads.

There are several piston dishes available; a few at random are the:

22.0 cc Keith Black 181, which yields a 9.7094:1 static compression ratio and a piston-crown-to head clearance (quench zone thickness) of 0.052 inches;

19.5 cc Keith Black 303, which yields a 9.9766:1 static compression ratio and a piston-crown-to head clearance (quench zone thickness) of 0.052 inches;

15.9 cc Probe P2446F, which yields a 10.3914:1 static compression ratio and a piston-crown-to head clearance (quench zone thickness) of 0.054 inches; and the

15.0 cc Keith Black 379, which yields a 10.5012:1 static compression ratio and a piston-crown-to head clearance (quench zone thickness) of 0.052 inches.

Those quench-zone thicknesses seem a little large to me -- and they'd be even larger if your compressed gasket is thicker or your deck height is taller or your con-rods are shorter or if your stroke is less than 3.5 inches -- blah blah blah (in other words, these "reference" numbers could very easily be different in your specific, unique engine) -- but my guess is that it works well enough for 99.999 percent of the real-world applications, and it allows a little extra room for decking the block, if necessary (to equalize the deck heights and "square" the engine).

All of these compression ratios seem workable with your cam; without a test of a nearly-identical build, I'd be hesitant about using more than a 10.3:1 ratio (with a 106 LSA) in a street vehicle without computerized ignition and a knock sensor -- but that's just me. There are people who are willing to risk more, and they get bigger rewards when all goes well; frankly, even with a 9.71 compression ratio, you ought to be able to get 400 horsepower pretty easily (and with a really good tune, maybe 50 more) without revving to 6000.

I think the AFR 165 heads are available in both a 58-cc and a 60-cc chamber size. If I was shooting for 500+ horsepower, I'd get the AFR 185 heads, but even with the small-port heads, you should be between 400 & 450 peak horsepower -- and that's enough to be scary fast in a truck that isn't purpose-built for racing. I might would consider the AFR 185 if I was absolutely certain that I was going to build a 400+ cube stroker, but as long as it was "iffy," I'd stick with AFR 165s.

One more thing about your cam choice: if you use a 106 LSA, forget ever using nitrous and pretty much forget about using forced induction -- not that you'll need any of that with the AFR 165s, if that's the way you decide to go: they make much power on their own. If you want to run nitrous or forced induction, you'll generally need a significantly larger LSA and/or a longer-duration cam (all of which shifts your powerband upward).