Really FORD...Rotted Brake Plates...AGAIN

#31

Ah ok - I must have missed the part of the owners manual where it said my SD was not designed to be used where it rains or snows or they use salt on the roads. And the part where it says my warranty was voided the first time I put my snow plow on or a bale of hay in the bed. Damn fine print got me again, lol.

Salt on roads is a reality, a well known one. Design for it. Duh.

Salt on roads is a reality, a well known one. Design for it. Duh.

Now I could get on board with an optional "rust belt" protection package that would apply a coating to the not so easy to get to parts that are rusting out on your trucks. I don't see a reason to do it to all trucks (and share the expense across all buyers) since the reality is, we do not all need it. Just my 2 cents, opinions will vary. Here is a picture of the 99 I was talking about in a previous post. The dust shields/backings are in great shape for a truck that has never been in a garage and spent plenty of time in water and snow.

#32

OK, fair enough - maybe the "plow package" should include parts in the "line of fire" made from some decent material. Or they could just build a truck like a truck. As I said, even here in the NE rusting out backing plates was never an issue until they started what I consider the big race to the bottom, quality-wise.

#33

OK, fair enough - maybe the "plow package" should include parts in the "line of fire" made from some decent material. Or they could just build a truck like a truck. As I said, even here in the NE rusting out backing plates was never an issue until they started what I consider the big race to the bottom, quality-wise.

#34

My former career was in brakes, friction material part of it, and yeah I'm very familiar with SD brakes both personally and professionally.

Like the HFCM placement, I too have wanted to the have the design engineer who designed this work for me for a year or two. This could have been avoided, or altered to be avoided, and probably never became an engineering concern because it's problematic way past warranty.

It's a poor design in context to us in the Northeast. The deicer issue has been around for more then a decade, greatly an issue with commercial trucking, as as the referenced in the newspaper article, a great problem due to the hydroscopic nature of the mag chloride component. The great concern over road clearing liability has caused vehicle corrosion to take a back seat, and the other issue that politicians seem to not realize in the unintended consequences column is bridge corrosion. Ever wonder why we need so much money nowadays for bridge repair?

Deicer causes not only the backing plate rot, but as also mentioned rotor rot. I'm collected a lot of scary pictures. And I believe it's more of a mixture of different types of deicers as a person drives through state, county, town, and local commercial pavement treatments, creating a soup of everything that can go wrong.

The sandwich design is a disaster for this situation, and the wearing away of any paint under the retention pins is also an issue with this thin metal, and it's a race for which location will have the fastest rust through. In my environment six years is typically the lifespan for these parts, so a yearly inspection of these components after the five year install point is my way of attempting to prevent the more expensive situation of having pull through.

I've made it to eight years with this second set of plates on this truck doing some preventive measures at install. The first was to spray BelRay chain lube within the sandwiched area. This is a thickening compound so I hoped it would stay in place better then others and I gave it a few days to set. Yes, it in a oven bake area and could migrate under high temps, but I've taken that risk.

At the pin locations on the outside I coated the metal with a thick silicon moly grease used by the Asian brake manufacturers on the back of brake pads for noise abatement. If you've replaced Honda or Toyota pads you've probably come across it. It is sold in small packets in auto parts stores, but I have a tub of it, Dow MolyKote 77. Over the greased pin holes I installed stainless steel fender washers as to spread the pin load. You can buy the stainless versions from McMaster. After full install, I also covered these pins with the MolyKote again.

As I mentioned, so far after eight years no rust through. It's a sad state of affairs that those of us in the Northeast have to go proactive, but what we have been delt with this was my attempt to deal with it.

Like the HFCM placement, I too have wanted to the have the design engineer who designed this work for me for a year or two. This could have been avoided, or altered to be avoided, and probably never became an engineering concern because it's problematic way past warranty.

It's a poor design in context to us in the Northeast. The deicer issue has been around for more then a decade, greatly an issue with commercial trucking, as as the referenced in the newspaper article, a great problem due to the hydroscopic nature of the mag chloride component. The great concern over road clearing liability has caused vehicle corrosion to take a back seat, and the other issue that politicians seem to not realize in the unintended consequences column is bridge corrosion. Ever wonder why we need so much money nowadays for bridge repair?

Deicer causes not only the backing plate rot, but as also mentioned rotor rot. I'm collected a lot of scary pictures. And I believe it's more of a mixture of different types of deicers as a person drives through state, county, town, and local commercial pavement treatments, creating a soup of everything that can go wrong.

The sandwich design is a disaster for this situation, and the wearing away of any paint under the retention pins is also an issue with this thin metal, and it's a race for which location will have the fastest rust through. In my environment six years is typically the lifespan for these parts, so a yearly inspection of these components after the five year install point is my way of attempting to prevent the more expensive situation of having pull through.

I've made it to eight years with this second set of plates on this truck doing some preventive measures at install. The first was to spray BelRay chain lube within the sandwiched area. This is a thickening compound so I hoped it would stay in place better then others and I gave it a few days to set. Yes, it in a oven bake area and could migrate under high temps, but I've taken that risk.

At the pin locations on the outside I coated the metal with a thick silicon moly grease used by the Asian brake manufacturers on the back of brake pads for noise abatement. If you've replaced Honda or Toyota pads you've probably come across it. It is sold in small packets in auto parts stores, but I have a tub of it, Dow MolyKote 77. Over the greased pin holes I installed stainless steel fender washers as to spread the pin load. You can buy the stainless versions from McMaster. After full install, I also covered these pins with the MolyKote again.

As I mentioned, so far after eight years no rust through. It's a sad state of affairs that those of us in the Northeast have to go proactive, but what we have been delt with this was my attempt to deal with it.

#35

Trying to have an inventory of snow plow package axles and other components (I lobbied for stainless steel brake lines overall, but as snow plow items as a minimum for years) complicates the assembly line situation as I was told. Hard sell for me. My solution would be to segregate snow plow trucks to a specific time period, although the belief is that the customers would not take well to more of a production delay.

#36

I appreciate the good and hard work all of you in the friction business have accomplished to design and manufacture quality brakes which not only stop effectively but also wear well. Balance of rotor and pad materials should produce many miles of efficient service. Although the Northeast in particular (rust belt) account for many sales,to the automotive business we have always been an afterthought at the manufacturers board room as too difficult a problem to modify the whole industry. Small strides are taken but the profit margin is a difficult mountain, even double sided to scale. Rot more vehicles, sell more vehicles, regardless of the cost of failed brakes, suspension components and body panels and frames to the consumer. The squeaky wheel gets the grease....but even molybdenum is far from permanent.

#37

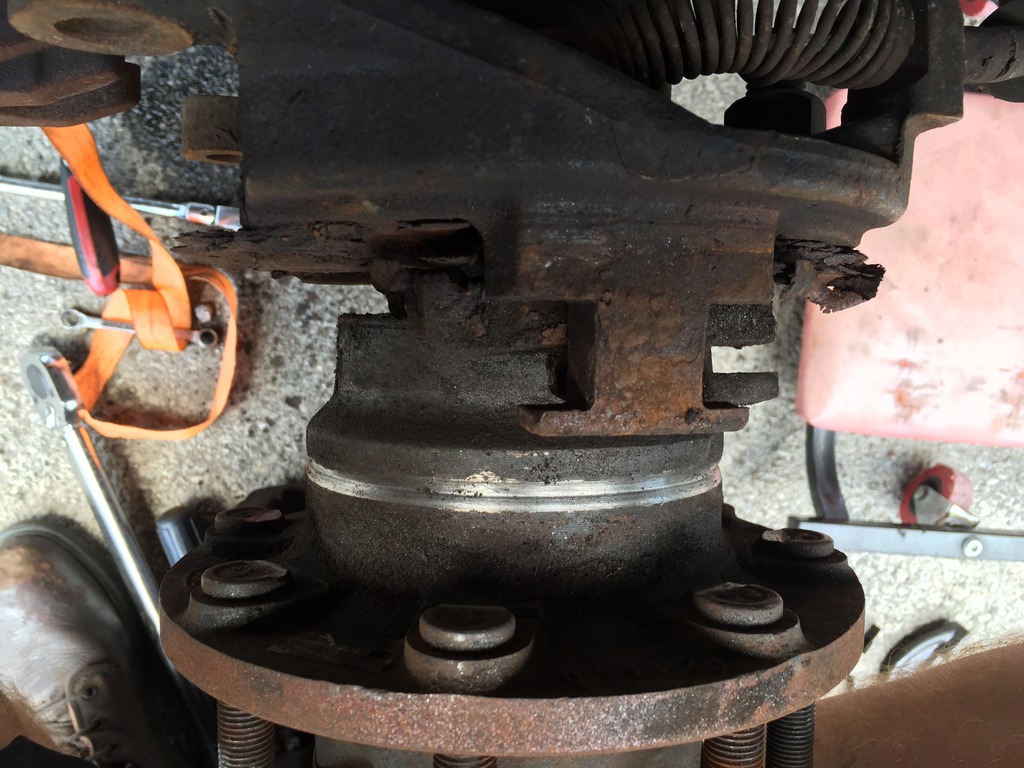

This is what's left of my passenger side parking brake as of yesterday

The backing rotted, lost all the pins and whatnot, and the shoes "bear trapped" onto the hub, wearing a nice curve into the pad. Also wearing a deep groove into the hub, which was probably the source of the noise I was hearing.

PO lived in PA, I bought the truck two years ago and it's lived in NW Ohio, all salty places. So now in addition to replacing the parking brakes, I'll replace at least that hub.

The backing rotted, lost all the pins and whatnot, and the shoes "bear trapped" onto the hub, wearing a nice curve into the pad. Also wearing a deep groove into the hub, which was probably the source of the noise I was hearing.

PO lived in PA, I bought the truck two years ago and it's lived in NW Ohio, all salty places. So now in addition to replacing the parking brakes, I'll replace at least that hub.

#38

This is what's left of my passenger side parking brake as of yesterday

The backing rotted, lost all the pins and whatnot, and the shoes "bear trapped" onto the hub, wearing a nice curve into the pad. Also wearing a deep groove into the hub, which was probably the source of the noise I was hearing.

PO lived in PA, I bought the truck two years ago and it's lived in NW Ohio, all salty places. So now in addition to replacing the parking brakes, I'll replace at least that hub.

The backing rotted, lost all the pins and whatnot, and the shoes "bear trapped" onto the hub, wearing a nice curve into the pad. Also wearing a deep groove into the hub, which was probably the source of the noise I was hearing.

PO lived in PA, I bought the truck two years ago and it's lived in NW Ohio, all salty places. So now in addition to replacing the parking brakes, I'll replace at least that hub.

#40

Well, there are only a couple of people on this earth I would wish bad luck upon. You were NOT one of them. However, It gives me some type of satisfaction when an engineer gets to experience another engineers idea of a good design that a 1st grader can see is fubar.

Sorry about your truck problem..

Sorry about your truck problem..

#41

Well, there are only a couple of people on this earth I would wish bad luck upon. You were NOT one of them. However, It gives me some type of satisfaction when an engineer gets to experience another engineers idea of a good design that a 1st grader can see is fubar.

Sorry about your truck problem..

Sorry about your truck problem..

Last edited by droldsmorland; 06-20-2016 at 06:31 PM. Reason: Stupid electronics...cant delete thie dup sorry???

#43

Most likely. There is also damage to the backs of the lugs that you can see. Probably nothing to worry about though

#45

The rot is not a new issue, i lived in Vermont in the 80s and 90s and had the same issues with my 1990 F150 4x4. purchased new and had it undercoated before it left the dealers. put 95000 miles and 5 years,

over the 5 years brakes were done, brake lines replaced, both gas tanks, oil pan, both fenders, hood, both doors, and bed were replaced.

and until we bought the motor home in 2014 I had not owned a ford since 95. because of the rust issue.

over the 5 years brakes were done, brake lines replaced, both gas tanks, oil pan, both fenders, hood, both doors, and bed were replaced.

and until we bought the motor home in 2014 I had not owned a ford since 95. because of the rust issue.