Removing PS Pump Bolts & Fluid Lines From PS Gearbox

#1

Removing PS Pump Bolts & Fluid Lines From PS Gearbox

This ol' 94 F-250 been sittin' around long time, but before I bought it for a song (sat in an auction yard and got rusty), from the guy who just bought it from the auction yard, took it for a ride with a vacuum guage sittin' with me in the cab watchin' it as I drove it around for half a day. Tight engine & lots of power (351w). Not sure what the exact benefit of "Windsor" means, but grateful to know if you do. Something to do with a Canadian plant and the quality of the block I believe. Been driving it occasionally for maybe five years now & no engine problems. Other normal stuff.

Among other things, just installed the new columnsgalore.com rebuilt column, and preparing now for a new PS Pump and installation of the Redhead Gearbox I bought a while back (longer than I realize probably - obviously didn't send the gearbox core back WA for my refund).

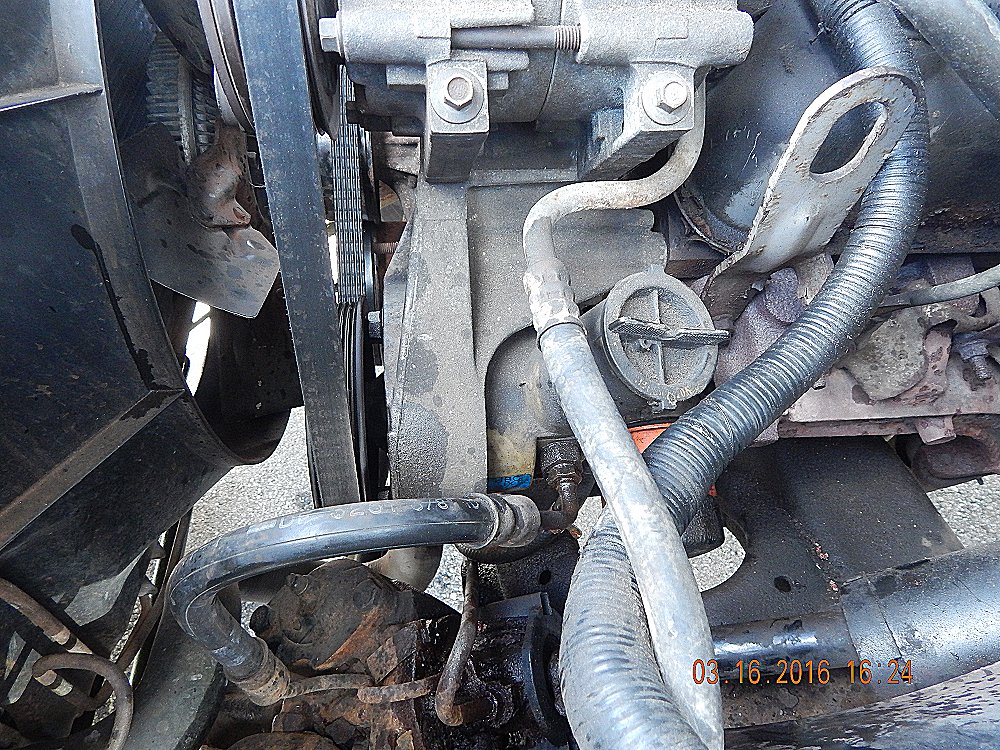

Bolts are wet in the pics cause I put PB Blaster on em. Don't have the new PS Pump yet, but gonna remove the old one, remove & check out the fluid lines, get ready. Also see if the gearbox bolts are gonna be a problem. Don't have a Pitman Arm Puller just yet either. I put a new gas tank on it a while back, and couldn't get the tank strap bolts off until I PB Blasted it at intervals and the let it sit overnight. Easy as pie the next day. So I guess I'll try the same with the PSP bolts and G-box bolts. No air tools yet.

If those fluid lines nuts on top of the gearbox are tough to get out, is a little heat appropriate? No problem for the PSP and Gearbox of course, but wondering about those threaded nuts (forget what you call 'em) on the lines if I wanted to reuse them..... which may not be a good idea of course.

In the pic below, are two bolts immediately behind the PSP pulley might be the ones for removal of the pump. If that's correct, is there then enough room to get the pump out without remove the AC and that huge mounting bracket?

Grateful for any tips on R&R of the PSP and/or the Gearbox, if ya got 'em.

Among other things, just installed the new columnsgalore.com rebuilt column, and preparing now for a new PS Pump and installation of the Redhead Gearbox I bought a while back (longer than I realize probably - obviously didn't send the gearbox core back WA for my refund).

Bolts are wet in the pics cause I put PB Blaster on em. Don't have the new PS Pump yet, but gonna remove the old one, remove & check out the fluid lines, get ready. Also see if the gearbox bolts are gonna be a problem. Don't have a Pitman Arm Puller just yet either. I put a new gas tank on it a while back, and couldn't get the tank strap bolts off until I PB Blasted it at intervals and the let it sit overnight. Easy as pie the next day. So I guess I'll try the same with the PSP bolts and G-box bolts. No air tools yet.

If those fluid lines nuts on top of the gearbox are tough to get out, is a little heat appropriate? No problem for the PSP and Gearbox of course, but wondering about those threaded nuts (forget what you call 'em) on the lines if I wanted to reuse them..... which may not be a good idea of course.

In the pic below, are two bolts immediately behind the PSP pulley might be the ones for removal of the pump. If that's correct, is there then enough room to get the pump out without remove the AC and that huge mounting bracket?

Grateful for any tips on R&R of the PSP and/or the Gearbox, if ya got 'em.

#2

Yes you need to remove the 3 bolts directly behind the pulley.

Too get the pulley off you can either buy a specialized tool or cut the pulley off using a small saw that can cut threw thick plastic.

You will have to buy a new pulley of course if you do that.

But YOU WILL have to have a tool the press pulley back onto the new pump.

Also to make this much easier I recommend removing the fan clutch and the fan shroud.You do not have to remove ac or the bracket.

Too get the pulley off you can either buy a specialized tool or cut the pulley off using a small saw that can cut threw thick plastic.

You will have to buy a new pulley of course if you do that.

But YOU WILL have to have a tool the press pulley back onto the new pump.

Also to make this much easier I recommend removing the fan clutch and the fan shroud.You do not have to remove ac or the bracket.

#3

Your first priority should be getting that FRAM oil filter off of your engine. Unscrew it and put it where it belongs... in the trash! Replace with a Motorcraft or Wix filter and relax knowing your engine is no longer in danger.

The Ford 351 Windsor (351W) engine is part of the Windsor series of Ford engines. There's also 351 Cleveland (351C) and 351 Modified (351M) which are part of a different series of engines, the 335 series.

You can heat the lines on the gearbox if you need to, they are standard hydraulic lines with flare fittings. Do NOT heat the line at the pump, because it's some sort of goofy design with an o-ring inside and a teflon seal on the outside.

Note that every time you disconnect the output line from the pump, you need to replace the teflon seal. Warm it up with a hair dryer and it will stretch into place over the fitting. Teflon seals are available at any auto parts store.

You do not have to completely remove the a/c compressor. Just unplug the clutch and remove the compressor mounting bolts, then set it off to the side. After that the huge mounting bracket actually comes out real easy, it's just a few (3?) bolts that hold it onto the engine.

You need this tool to properly remove/install the pump pulley: Pulley Remover and Installer Set

I have that same tool and it works just fine. If you don't want to buy it then AutoZone and probably other parts stores will rent you one for a fully-refundable deposit.

The Ford 351 Windsor (351W) engine is part of the Windsor series of Ford engines. There's also 351 Cleveland (351C) and 351 Modified (351M) which are part of a different series of engines, the 335 series.

You can heat the lines on the gearbox if you need to, they are standard hydraulic lines with flare fittings. Do NOT heat the line at the pump, because it's some sort of goofy design with an o-ring inside and a teflon seal on the outside.

Note that every time you disconnect the output line from the pump, you need to replace the teflon seal. Warm it up with a hair dryer and it will stretch into place over the fitting. Teflon seals are available at any auto parts store.

You do not have to completely remove the a/c compressor. Just unplug the clutch and remove the compressor mounting bolts, then set it off to the side. After that the huge mounting bracket actually comes out real easy, it's just a few (3?) bolts that hold it onto the engine.

You need this tool to properly remove/install the pump pulley: Pulley Remover and Installer Set

I have that same tool and it works just fine. If you don't want to buy it then AutoZone and probably other parts stores will rent you one for a fully-refundable deposit.

#4

It is easier with the fan shroud out of the way. You could try removing the two bolts for the shroud so it will move out if the way enough to not need to remove the fan. At least on mine the end of the pulley removal tool was up against the shroud. There is no need to touch the AC compressor and the mounting bracket. Be sure to use the proper line wrench to remove the lines for the gear box. I believe it is an 18mm

#5

Since the Puller/Installer tool dixie460 used is on sale for $18.00, and the guy in this video used a puller on his after moving the fan shroud out of the way as much as possible, gonna give that a shot first.

I'll change the Fram filter after I get it running again. Gonna be goin' kinda slow. Thx for the Windsor info, and I see that Teflon seal. After penetrating oil on the gearbox bolts and fluid line nuts, none were a problem. G-box bolts were especially easily (well, I was using a breaker bar cause I expected it to be tough, but didn't have to pull hard at all - was surprised how easy... dunno, maybe they're usually not a problem?). I don't know if it helps, but I put a little oil on all the nuts/bolts soon after the penetrating oil, and let it sit overnight. I'll be sure to clean up the bolt holes for the g-box bolt so there's no oil in them, if it does get into 'em. We'll see.

However, the PS fluid lines themselves are apparently stuck to the nuts (gearbox fittings only). Maybe a little heat on the lines or nuts?

Is it best to use a Pitman Arm Puller, then pull the g-box out, or can it be left on while using the tool (forget its name) to separate the arm from the tie rod, then remove the g-box, leaving the arm on the g-box till after I get it out? Would appreciate knowing the size of the large nut on the Pitman Arm connection to the g-box.

Thx so much for all the replies.

#6

I don't have a vise so keeping the gear box on the truck is better for me you don't need to disconnect the pitman arm from the linkage.

Will the nut not turn at all or is the line also turning with the nut? I would be apprehensive about using a torch on it still in the truck. Have you tried tightening the lines? Sometimes that helps break them loose

Will the nut not turn at all or is the line also turning with the nut? I would be apprehensive about using a torch on it still in the truck. Have you tried tightening the lines? Sometimes that helps break them loose

#7

I don't have a vise so keeping the gear box on the truck is better for me you don't need to disconnect the pitman arm from the linkage.

Will the nut not turn at all or is the line also turning with the nut? I would be apprehensive about using a torch on it still in the truck. Have you tried tightening the lines? Sometimes that helps break them loose

Will the nut not turn at all or is the line also turning with the nut? I would be apprehensive about using a torch on it still in the truck. Have you tried tightening the lines? Sometimes that helps break them loose

If I end up trying a little heat on 'em as a last resort, I could clean the area up real good, de-grease everything, wash away all the penetrating oil, etc.), then set up my 24" dia. circulator fan just in case (edit: 24"?... Overkill!.. have a smaller one), to keep any dangerous vapor from accumulating in the engine compartment while putting a little heat to it. Hopefully if I keep at it (tightening/loosening it), more penetrating oil, keep shocking the nuts a little, I won't have to use heat. Of course, I guess I could always get new lines. Do they come pre-formed?

Trending Topics

#8

Ah, the nut is seized to the line. You could try to bend the pressure line enough to unscrew it from the box. Or if that doesn't work there are only a couple of bolts that hold the return to the crossmember. Once out of the truck, a MAPP torch on the line at the nut has worked for me to free them up: alternating between heat, PB Blaster & turning the nut

Yes the lines have the correct ends to "bolt" right on.

Yes the lines have the correct ends to "bolt" right on.

#9

Ah, the nut is seized to the line. You could try to bend the pressure line enough to unscrew it from the box. Or if that doesn't work there are only a couple of bolts that hold the return to the crossmember. Once out of the truck, a MAPP torch on the line at the nut has worked for me to free them up: alternating between heat, PB Blaster & turning the nut

Yes the lines have the correct ends to "bolt" right on.

Yes the lines have the correct ends to "bolt" right on.

#10

Ah, the nut is seized to the line. You could try to bend the pressure line enough to unscrew it from the box. Or if that doesn't work there are only a couple of bolts that hold the return to the crossmember. Once out of the truck, a MAPP torch on the line at the nut has worked for me to free them up: alternating between heat, PB Blaster & turning the nut

Yes the lines have the correct ends to "bolt" right on.

Yes the lines have the correct ends to "bolt" right on.

Does the gearbox remove upward thru the engine compartment with both the high press and low press lines still attached (only one bolt below holding the low pressure line to the cross-member), or thru the bottom once you get the Pitman Arm off the g-box spline?

Does this low pressure line typically develop a leak in the metal part eventually?

#12

Just got off the phone ordering the low press line locally, be in tomorrow, and discovered Advanceautoparts, also local, has the high press line if I need it. Just went to their site (rockauto.com), will keep them in mind, thx much... actually, maybe I should check them out for a Saginaw Power Steering Pump I've been reading about on here?

Can I get a Saginaw pump that will bolt on? Just scanned a post about the Saginaw having a remote tank. If I have to do anything like that, I'd just get the standard replacement unit for now. Just don't want to bother with having to mount a remote tank, right now anyway, if that's the case.... Cardone Reman/$67.00 I guess, unless anyone has a better suggestion.

Can I get a Saginaw pump that will bolt on? Just scanned a post about the Saginaw having a remote tank. If I have to do anything like that, I'd just get the standard replacement unit for now. Just don't want to bother with having to mount a remote tank, right now anyway, if that's the case.... Cardone Reman/$67.00 I guess, unless anyone has a better suggestion.

#13

Just got off the phone ordering the low press line locally, be in tomorrow, and discovered Advanceautoparts, also local, has the high press line if I need it. Just went to their site (rockauto.com), will keep them in mind, thx much... actually, maybe I should check them out for a Saginaw Power Steering Pump I've been reading about on here?

Can I get a Saginaw pump that will bolt on? Just scanned a post about the Saginaw having a remote tank. If I have to do anything like that, I'd just get the standard replacement unit for now. Just don't want to bother with having to mount a remote tank, right now anyway, if that's the case.... Cardone Reman/$67.00 I guess, unless anyone has a better suggestion.

Can I get a Saginaw pump that will bolt on? Just scanned a post about the Saginaw having a remote tank. If I have to do anything like that, I'd just get the standard replacement unit for now. Just don't want to bother with having to mount a remote tank, right now anyway, if that's the case.... Cardone Reman/$67.00 I guess, unless anyone has a better suggestion.

Once you get the wheels centered look at the end of your pitman arm find a place for reference. Mark your reference. Now you can disconnect the pitman arm from the gearbox. When you get ready to put the new gearbox in, take a small pair of vise grips and turn the shafts end of the gear left to right back to center. At this point do not turn anything. When you put the gear back in. Line up your marks on the pitman arm. After you are all done take and have the alignment checked.

#14

I am in the middle of a hydroboost brake conversion. I am going to order pump from Rock. I can get the pump and resivior cheaper than just the resivior and reseal kit. 52.99 including core. I have some play in the gear box so changing it out since the system will be open anyway. Found one on ebay 159 no core. If the gas mount is the same as mine, there just two bolts that hold the pump on. I was able to get mine off without moving anything The three bolts that hold the pump to the mount will not come out with the pulley on. You can do the loan a tool from a parts store. On the gear box make sure you wheels are dead on center. What I did is jack the front up to get tires off ground. Turned the steering wheel all the way left. Used a piece of tape and a sharpie made a mark on column and wheel then turned the wheel all the way right counting each time my marks were inline. After that turned the wheel 1/2 the number of turns then made a new center mark.

Once you get the wheels centered look at the end of your pitman arm find a place for reference. Mark your reference. Now you can disconnect the pitman arm from the gearbox. When you get ready to put the new gearbox in, take a small pair of vise grips and turn the shafts end of the gear left to right back to center. At this point do not turn anything. When you put the gear back in. Line up your marks on the pitman arm. After you are all done take and have the alignment checked.

Once you get the wheels centered look at the end of your pitman arm find a place for reference. Mark your reference. Now you can disconnect the pitman arm from the gearbox. When you get ready to put the new gearbox in, take a small pair of vise grips and turn the shafts end of the gear left to right back to center. At this point do not turn anything. When you put the gear back in. Line up your marks on the pitman arm. After you are all done take and have the alignment checked.

Love that rear view camera!

#15

Thank you on the camera

I getting the Lares

Lares Corporation

Here the part number for you engine

LARES 2375

Same price as mine.

As far as the pitman arm. Since you are changing the box you could just buy a new pitman arm about 20 bucks

I getting the Lares

Lares Corporation

Here the part number for you engine

LARES 2375

Same price as mine.

As far as the pitman arm. Since you are changing the box you could just buy a new pitman arm about 20 bucks