Fiveology MAF ground wire

#1

Fiveology MAF ground wire

Hey fellas,

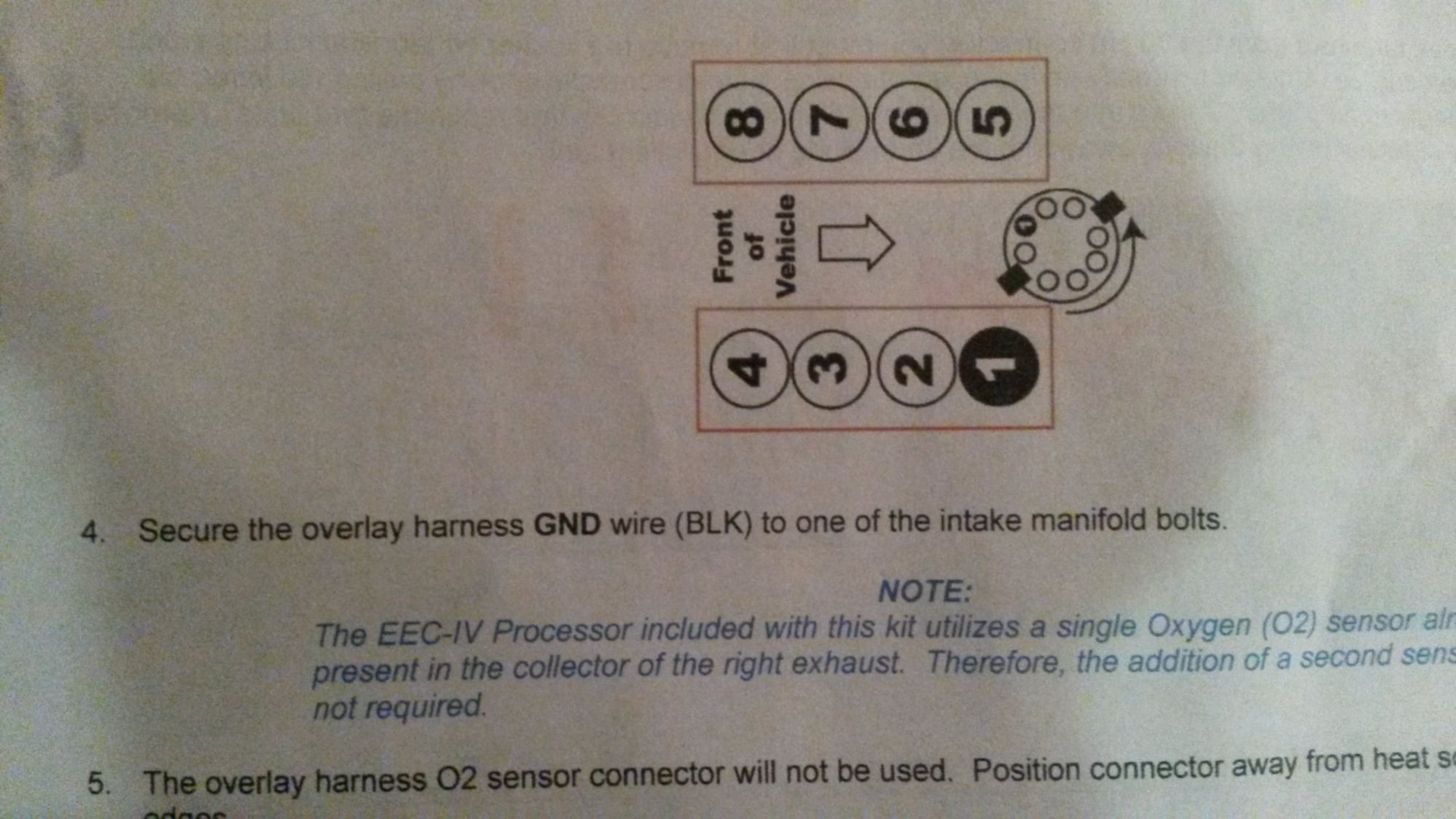

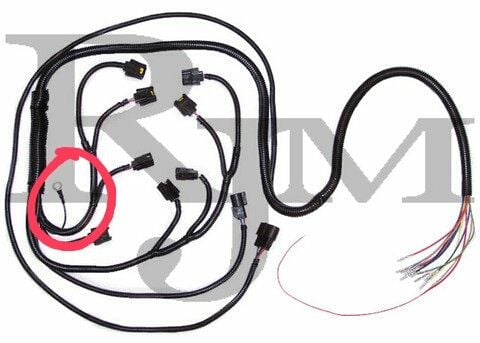

Pulled the trigger on a MAF conversion kit from fiveology( '93 7.5L F250). Tore into it today, and the kit is pretty plug and play. Minus the re-pinning.

Had a question about the ground wire that's in the same loom as the injector harnesses. The instructions say to ground it to "one of the manifold bolts". Well, with all the new injector wires, old injector wires, and vacuum lines, it's near impossible to get to any of the intake manifold to head/block bolts.

I was thinking of attaching it to one of the throttle body bolts. You guys think that's a sufficient ground point? Could it cause any interference with the TPS?

What you guys think?

Pulled the trigger on a MAF conversion kit from fiveology( '93 7.5L F250). Tore into it today, and the kit is pretty plug and play. Minus the re-pinning.

Had a question about the ground wire that's in the same loom as the injector harnesses. The instructions say to ground it to "one of the manifold bolts". Well, with all the new injector wires, old injector wires, and vacuum lines, it's near impossible to get to any of the intake manifold to head/block bolts.

I was thinking of attaching it to one of the throttle body bolts. You guys think that's a sufficient ground point? Could it cause any interference with the TPS?

What you guys think?

#2

A ground is a ground is a ground is a ground.

From my research though, it was said that you should tie the ground into an ECU ground.

Also, https://www.ford-trucks.com/forums/1...-question.html

From my research though, it was said that you should tie the ground into an ECU ground.

Also, https://www.ford-trucks.com/forums/1...-question.html

#3

A ground is a ground is a ground is a ground.

From my research though, it was said that you should tie the ground into an ECU ground.

Also, https://www.ford-trucks.com/forums/1...-question.html

From my research though, it was said that you should tie the ground into an ECU ground.

Also, https://www.ford-trucks.com/forums/1...-question.html

There are two grounds, one off the PCM to chasis, and one in the same wire loom as the drivers' side injector connectors.

...iI'll find a pic

#5

#6

#7

Trending Topics

#8

#9

It was a PITA to get to, but I got it done.

#10

The truck isn't running though. It fires right up with just a tap of the ignition, revs to 1200-1500, plumets, then dies. If I hold throttle to about 1500 it stays running but misses in a fairly consistent rythm. I'm working with Bryan from Fiveology on diagnosing the issue. He's been extremely helpful and has offered to send out a new PCM or MAF if it comes to that.

Now, my connector. On the back of the connector is a plastic piece (usually blue) that covers the unused terminal ports for your PCM. some of the covered ports are required to be used with the swap. The instructions say to carefully drill a hole in the back of the cover to expose the opening on the other side. Well, what it doesn't mention is; it's not just a flat plastic cover. In the "blanks" there are plastic "bullets" inserted into the empty port. Drilling the back of the cover can force the bullets into the connector breaking the tiny little retainer tabs, making the connector useless. That's what happened to me.

I know guys have drilled the back of the cover, but I don't know how they got the bullets out without damaging anything.

I was able to find a spare 60 pin and had to transfer everything over. I did it wire by wire so I was unable to carry over a rubber piece from the old connector that helps hold the terminals in place. That's one of the things I'm inspecting for a possible error. I'm wondering if without that rubber piece, the pins on the PCM might be pushing a terminal or two backwards, rather than creating the connection.

#11

Finished the install. Took a few days from start to finish (including the optional K&N intake) because I ruined my original 60 pin connector. I'll caution you about what I did to mangle it in a sec.

The truck isn't running though. It fires right up with just a tap of the ignition, revs to 1200-1500, plumets, then dies. If I hold throttle to about 1500 it stays running but misses in a fairly consistent rythm. I'm working with Bryan from Fiveology on diagnosing the issue. He's been extremely helpful and has offered to send out a new PCM or MAF if it comes to that.

Now, my connector. On the back of the connector is a plastic piece (usually blue) that covers the unused terminal ports for your PCM. some of the covered ports are required to be used with the swap. The instructions say to carefully drill a hole in the back of the cover to expose the opening on the other side. Well, what it doesn't mention is; it's not just a flat plastic cover. In the "blanks" there are plastic "bullets" inserted into the empty port. Drilling the back of the cover can force the bullets into the connector breaking the tiny little retainer tabs, making the connector useless. That's what happened to me.

I know guys have drilled the back of the cover, but I don't know how they got the bullets out without damaging anything.

I was able to find a spare 60 pin and had to transfer everything over. I did it wire by wire so I was unable to carry over a rubber piece from the old connector that helps hold the terminals in place. That's one of the things I'm inspecting for a possible error. I'm wondering if without that rubber piece, the pins on the PCM might be pushing a terminal or two backwards, rather than creating the connection.

The truck isn't running though. It fires right up with just a tap of the ignition, revs to 1200-1500, plumets, then dies. If I hold throttle to about 1500 it stays running but misses in a fairly consistent rythm. I'm working with Bryan from Fiveology on diagnosing the issue. He's been extremely helpful and has offered to send out a new PCM or MAF if it comes to that.

Now, my connector. On the back of the connector is a plastic piece (usually blue) that covers the unused terminal ports for your PCM. some of the covered ports are required to be used with the swap. The instructions say to carefully drill a hole in the back of the cover to expose the opening on the other side. Well, what it doesn't mention is; it's not just a flat plastic cover. In the "blanks" there are plastic "bullets" inserted into the empty port. Drilling the back of the cover can force the bullets into the connector breaking the tiny little retainer tabs, making the connector useless. That's what happened to me.

I know guys have drilled the back of the cover, but I don't know how they got the bullets out without damaging anything.

I was able to find a spare 60 pin and had to transfer everything over. I did it wire by wire so I was unable to carry over a rubber piece from the old connector that helps hold the terminals in place. That's one of the things I'm inspecting for a possible error. I'm wondering if without that rubber piece, the pins on the PCM might be pushing a terminal or two backwards, rather than creating the connection.

Be careful at this point, since things are not working right just stay close to the key so you can turn the motor off if it goes wild.

Now...from the looks of that kit, it doesn't look like you are able to pull a log from your PCM. Makes it a little more difficult.

Pull the codes, see if there are any. Pull out and inspect your ACT, make sure it looks clean. Also verify your idle air screw is set right (see "For those using non-decipha tunes or to perform a base idle reset on a stock tune" here Idle Air / EFIDynoTuning). The idle screw is not causing your problem but is good to set now.

Pull a plug or two and see if it has too much fuel after you try to start. Does exhaust smell rich at all?

See if your MASS AIr sensor is working by either back probing it while cranking or the motor is running...or you can take out the MASS Air sensor from the housing and blow on it while back probing it (key on). This will tell you if it is registering at all.

Those are a few things to look at.

#12

FYI - in a stock setup, this ground wire goes back to the PCM and is grounded in there.

#13

Try unplugging the MAF, and see how it runs (I suspect he uses a "calibrated" MAF for 24 lb-hr injectors, so it probably will not run great). If it still doesn't want to run, I'd start checking your injector wiring.

Also, that rubber piece in the EEC connector keeps water out of the pins. It's pretty important.

Also, that rubber piece in the EEC connector keeps water out of the pins. It's pretty important.

#14