Bad wrist pin/bushing, maybe?

#16

#17

It's been driven a couple hundred miles since the injector went in. My impression is it's a problem in the rotating assembly, but we'll see what the oil analysis has to say about it. If it comes back clean, a regulated return might be one of my next moves, too. Just kind of playing it by ear at the moment . . .

#18

A while ago i had a similar issue. I can't play the video for some reason because internet is acting flaky tonight.

My break out box showed me that #8 was indeed causing a strong knock. I fought with it for sometime trying to quiet it down.

Then the "lucky" swap,

https://www.ford-trucks.com/forums/9...oring-pic.html

Someone recently mentioned it could possibly be oil that was being pumped into the fuel rail and #8 hole was burning oil? Dunno, Either Way. I fixed the o rings and it has been years since.

My break out box showed me that #8 was indeed causing a strong knock. I fought with it for sometime trying to quiet it down.

Then the "lucky" swap,

https://www.ford-trucks.com/forums/9...oring-pic.html

Someone recently mentioned it could possibly be oil that was being pumped into the fuel rail and #8 hole was burning oil? Dunno, Either Way. I fixed the o rings and it has been years since.

#19

#20

#21

#22

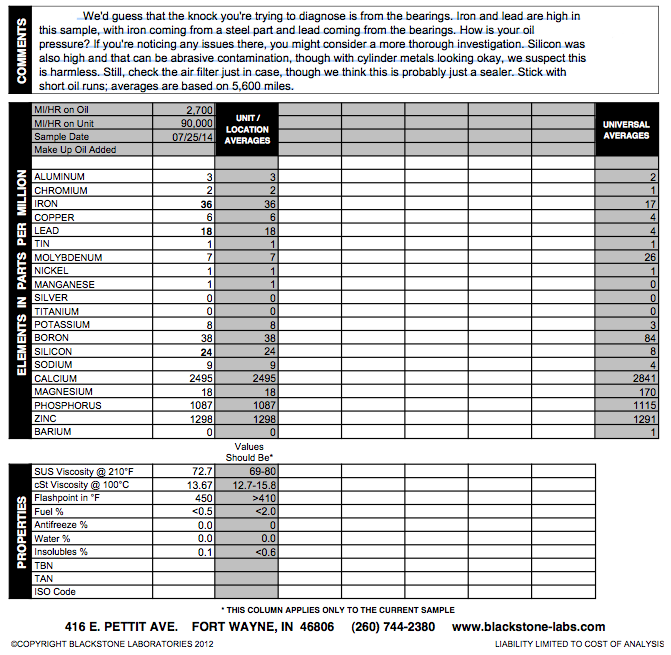

For the amount of miles on the oil, iron is about 4.4 times higher than average, and lead is roughly 9.33 times higher than average. I've known the owner of the salvage yard for a long time, and I did tell him about the knock before the 90 days on the warranty was up. I'm pretty sure he'll work with me on it, but I'll know for sure when I see him in the next couple days.

#23

Here's the analysis report. The averages are based on 5,600 miles on the oil while the sample I sent in had only 2,700 miles on it. They hit the nail on the head with the silicon level being due to sealant; it was the first oil change after the pan went on and the engine went in. The part about, "stick with short oil runs" is somewhat of an understatement . . .

#24

Damn!  Sorry to hear that man. Noob question here: if you were to continue to run with this motor what kind of long term damage are we talking? Are we talking windowing the block? I have a knock as well that seemed to just appear one day last year. It comes and goes and drives me nuts. I better send off another blackstone as it's been awhile.

Sorry to hear that man. Noob question here: if you were to continue to run with this motor what kind of long term damage are we talking? Are we talking windowing the block? I have a knock as well that seemed to just appear one day last year. It comes and goes and drives me nuts. I better send off another blackstone as it's been awhile.

Sorry to hear that man. Noob question here: if you were to continue to run with this motor what kind of long term damage are we talking? Are we talking windowing the block? I have a knock as well that seemed to just appear one day last year. It comes and goes and drives me nuts. I better send off another blackstone as it's been awhile.

Sorry to hear that man. Noob question here: if you were to continue to run with this motor what kind of long term damage are we talking? Are we talking windowing the block? I have a knock as well that seemed to just appear one day last year. It comes and goes and drives me nuts. I better send off another blackstone as it's been awhile.

#25

It could eventually cause a window, but I think I'd be too embarrassed to drive it before it got that loud. Pretty sure the most likely scenario is a wiped out, non-fixable crankshaft. Maybe I'll throw in a couple bottles of that Bars Leaks engine repair stuff. I mean they say it fixes knocks, so it must repair bad bearings, right?

#26

Chris, just a thought, but there's probably no accurate way to measure the stroke with the head on and the engine installed, is there? I'm just kind of wondering if I could get an idea of what's going on by seeing if the stroke is shortened at all due to slop in the bearing or pin.

but now that we know that little is left on the table but a bearing failure, maybe you would be willing to try an experiment?

i have been thinking about how to measure endplay with the heads on.

i think i have come up with something that could at the very least offer up a ballpark measurement of what kind of actual wear to expect...

i still need to come up with a way to securely extend an indicator stem (for the guy that wants to try this that does not have access to all the wonders of a machine shop inspection toolbox) to make this idea work, but here goes.

using a 1" travel .001" scale dial indicator, and magnetic base... orient base and indicator as to direct the indicating stem directly down the middle of an glow plug port. use of a stem extension will be required. extensions are commercially available, but for the purpose of this measurement i think something as simple as a cut off length of coat hanger would be sufficient.

in some fashion, attach the extension to the end of the indicator stem so that it is protruding through the glow plug hole at the bottom of the head.

preamble for this procedure is to have a wooden, or stiff plastic dowel that fits into the injector nozzle hole at the bottom of the injector cup. it will be needed to apply pressure to the piston.

the dowel could potentially be used to indicate TDC but with an indicator already set up to measure deep... i would just use the indicator for that....

for each cylinder you want to test....

1.place the indicator.

2.locate TDC.

3.follow through the stroke enough to drop the piston .5" on the indicator.

4.set the indicator to zero.

5.using hand pressure only, press the travel out of the piston with the dowel.

6.record any measurement.

7.split the measurement in half for a rough estimate of actual material wear.

unfortunately there is no way to determine for certain just how much of the crank has worn, but at the very least it could render a rough estimate.

1" dial indicators are available on the cheap a harbor freight.

#27

I may try that, but at this point I'm a little irked by this whole situation. If I hadn't gotten the analysis results back so quickly, I'd likely be off buying a dial indicator right now. On the other hand, it would be nice to know if your theory is viable. I'll let you know if I do end up doing it, and what the results are.

I keep trying to have a positive outlook by telling myself things like, "well at least it isn't 20 below zero this time", "I can paint the block and heads", "I can clean the engine compartment without it turning into a giant block of ice", and so on, and so on

I keep trying to have a positive outlook by telling myself things like, "well at least it isn't 20 below zero this time", "I can paint the block and heads", "I can clean the engine compartment without it turning into a giant block of ice", and so on, and so on

#28

I may try that, but at this point I'm a little irked by this whole situation. If I hadn't gotten the analysis results back so quickly, I'd likely be off buying a dial indicator right now. On the other hand, it would be nice to know if your theory is viable. I'll let you know if I do end up doing it, and what the results are.

I keep trying to have a positive outlook by telling myself things like, "well at least it isn't 20 below zero this time", "I can paint the block and heads", "I can clean the engine compartment without it turning into a giant block of ice", and so on, and so on

I keep trying to have a positive outlook by telling myself things like, "well at least it isn't 20 below zero this time", "I can paint the block and heads", "I can clean the engine compartment without it turning into a giant block of ice", and so on, and so on

I hear ya Brother.

Whatever happens... hold on to that motor!

If the block is ok, rebuild that sucker as a spare, or sell as remanufactured.

Heck I might be interested in it after I get Zombieheart finished up.

(Just got the call yesterday from engine shop letting me know its going on the boring machine, and they were REAL nervous about only opening it up .020". Seems they could only source kits for +.010, .030, and .060. Im gonna haveta introduce them to Brother Clay lol)

My thrown together method should work as long as the dowel will be enough ooomph to drive the piston down. Thinking about it a bit more after waking up way to early this morning... i think using a light rapping action on the end of the dowel with a small rubber mallet or something might convince a piston to move if hand pressure is inadequate. Under no circumstances would I consider using a metallic rod to drive the pistons.

If i have some time after this last part in the machine, and before the next bach of nightmare comes across my bench... i will put one of Zombieheart's heads on the bench and see what the measuring contraption looks like in place. I will take pictures to clarify for those who may not picture what im trying to convey.

#29

About the only metal I'd even consider using would be a soft aluminum alloy, but that would probably be too flexible for the long length and small diameter it would take to get it down in there. Or more likely with the way my luck has been running lately, it would mushroom and I'd destroy the injector cup on the way out