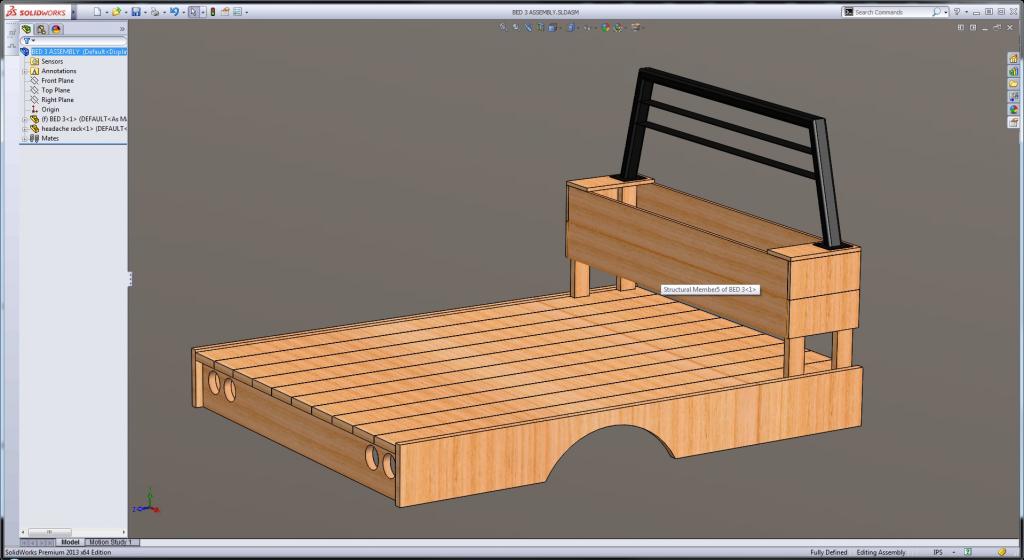

WOOD FLATBED BUILD - 3D MODEL AND CONSTRUCTION PLANS

#46

This is exactly why I started this thread, for everyone's ideas! You guys have given me some good ones. Wade, I really like how the side rails on yours come up above the deck. I imagine that would be good for helping loads stay put from side to side. Have you had any problems with it sticking up like that? Only positive remarks? I may try working that concept into my design if you think its a good thing to have.

The hardest part of this project, IMO, is the filler location. My original idea was to incorporate it into the box. I scrapped that idea so I can remove the box with ease. I'll be interested to see how you guys address this issue. I'll try and snap a pic tonight of the set up I have been running. Its not the greatest, and is the weak link of my build for sure.

#47

#48

I think you should also consider the rear of the truck and the trailer hitch. The side boards you are using covers up some of the "business" part of the side frame area, though when I looked at buying a aftermarket flatbed for my old truck, they had dress up plates that went on the sides to cover the gaps on top of the frame to the bed.

But you still might have open gaps in the rear. I especially like that polished aluminum diamond plate you can get, though it would not be cheap. But it would look nice with the red lights in the rear, and give it a finished look in the rear, and hide the frame in the back. Something like this;

But you still might have open gaps in the rear. I especially like that polished aluminum diamond plate you can get, though it would not be cheap. But it would look nice with the red lights in the rear, and give it a finished look in the rear, and hide the frame in the back. Something like this;

#49

Dave, I planned on keeping the stock bumper in place, and building the bed up to it. That way I have a step on the back for getting up on the bed. Look at Wades photo of his Dodge, sort of like that.

You see, the trailer hitch I got from Gary mounts to my frame rails, however it is also supported by the bumper. If I remove the bumper I would have to rethink how the hitch is installed. My truck really needs a hitch, the ball on the bumper is way too high for most trailers. When I brake while towing something on the bumper the trailer load pushes up on the back of the truck and is very dangerous. The hitch lowers the tongue height to an acceptable angle and the truck brakes with the load shifting through the frame into the front brakes.

I guess I could redrill the holes in the frame and move the hitch forward, thus allowing me to attach an angle iron cross brace of some sort to support the tongue.

You see, the trailer hitch I got from Gary mounts to my frame rails, however it is also supported by the bumper. If I remove the bumper I would have to rethink how the hitch is installed. My truck really needs a hitch, the ball on the bumper is way too high for most trailers. When I brake while towing something on the bumper the trailer load pushes up on the back of the truck and is very dangerous. The hitch lowers the tongue height to an acceptable angle and the truck brakes with the load shifting through the frame into the front brakes.

I guess I could redrill the holes in the frame and move the hitch forward, thus allowing me to attach an angle iron cross brace of some sort to support the tongue.

#50

Dave, I planned on keeping the stock bumper in place, and building the bed up to it. That way I have a step on the back for getting up on the bed. Look at Wades photo of his Dodge, sort of like that.

You see, the trailer hitch I got from Gary mounts to my frame rails, however it is also supported by the bumper. If I remove the bumper I would have to rethink how the hitch is installed. My truck really needs a hitch, the ball on the bumper is way too high for most trailers. When I brake while towing something on the bumper the trailer load pushes up on the back of the truck and is very dangerous. The hitch lowers the tongue height to an acceptable angle and the truck brakes with the load shifting through the frame into the front brakes.

I guess I could redrill the holes in the frame and move the hitch forward, thus allowing me to attach an angle iron cross brace of some sort to support the tongue.

You see, the trailer hitch I got from Gary mounts to my frame rails, however it is also supported by the bumper. If I remove the bumper I would have to rethink how the hitch is installed. My truck really needs a hitch, the ball on the bumper is way too high for most trailers. When I brake while towing something on the bumper the trailer load pushes up on the back of the truck and is very dangerous. The hitch lowers the tongue height to an acceptable angle and the truck brakes with the load shifting through the frame into the front brakes.

I guess I could redrill the holes in the frame and move the hitch forward, thus allowing me to attach an angle iron cross brace of some sort to support the tongue.

I do like Franklins suggestion about the rear bumper. My bed ends where the factory bumper begins. Yes, it makes for easy step up, but I do wish I had another 6-12" of bed at times. Those solid bumpers would allow for it. I dont have the welding skills or the $$$ for one myself, but it would be nicer than the OEM bumper as far as looks go.

I think I'm up to around 50cents worth of 2 cent ideas now.

#51

#52

#53

I think you should also consider the rear of the truck and the trailer hitch. The side boards you are using covers up some of the "business" part of the side frame area, though when I looked at buying a aftermarket flatbed for my old truck, they had dress up plates that went on the sides to cover the gaps on top of the frame to the bed.

But you still might have open gaps in the rear. I especially like that polished aluminum diamond plate you can get, though it would not be cheap. But it would look nice with the red lights in the rear, and give it a finished look in the rear, and hide the frame in the back. Something like this;

But you still might have open gaps in the rear. I especially like that polished aluminum diamond plate you can get, though it would not be cheap. But it would look nice with the red lights in the rear, and give it a finished look in the rear, and hide the frame in the back. Something like this;

Pardon the old picture.

#54

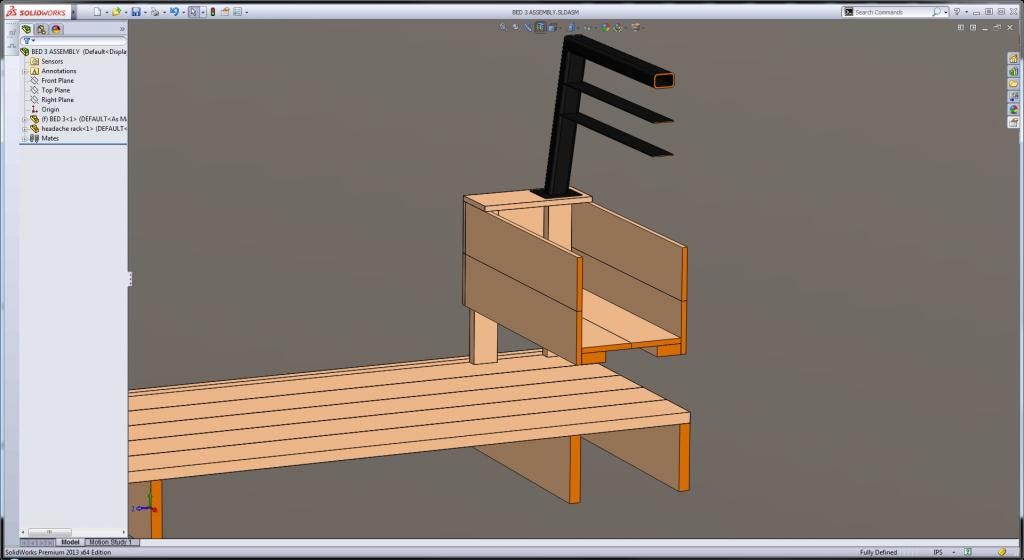

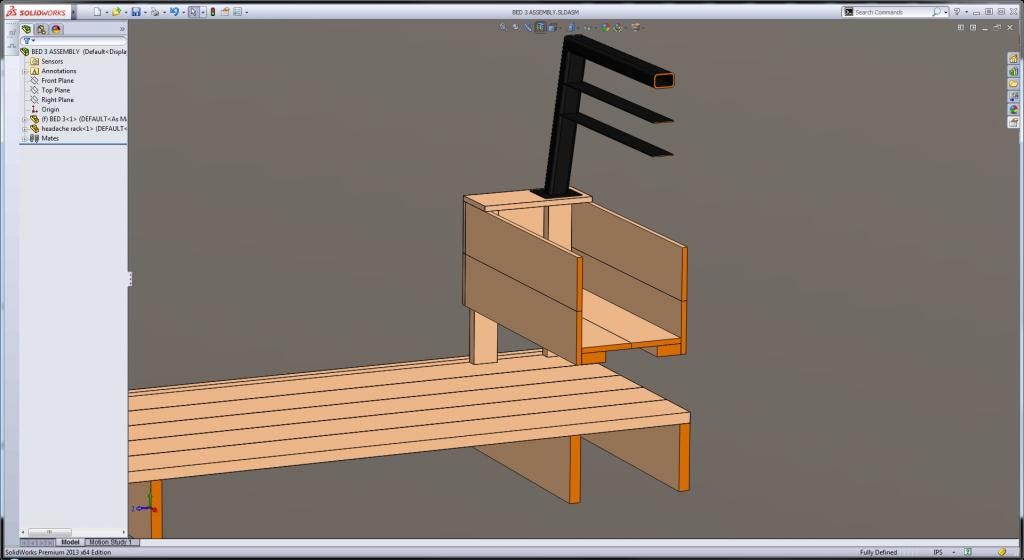

What do you guys think about elevating the toolbox? I might loose some storage room in the box, but I gain valuable bed length. I can slide boards and sheets and things under the toolbox. The effective length of the bed would be 100". That about 8'4" long and bring the end of the bed up to the bumper.

I don't think this looks as cool as the toolbox that goes all the way to the deck though. I need to add a board to the back side of the toolbox that prevents stuff from hitting the back of the cab when sliding.

Thoughts guys?

I don't think this looks as cool as the toolbox that goes all the way to the deck though. I need to add a board to the back side of the toolbox that prevents stuff from hitting the back of the cab when sliding.

Thoughts guys?

#55

Really diggin the 3D plans

IMHO the raised box makes a LOT of sense. I think it will also give you a better or easier way of mounting your fuel filler. Mine has a 4" rise to it, and havent done anything that I've needed more. 2x4's slide right under on the side or stack two.

I like where this is going

IMHO the raised box makes a LOT of sense. I think it will also give you a better or easier way of mounting your fuel filler. Mine has a 4" rise to it, and havent done anything that I've needed more. 2x4's slide right under on the side or stack two.

I like where this is going

#56

Really diggin the 3D plans

IMHO the raised box makes a LOT of sense. I think it will also give you a better or easier way of mounting your fuel filler. Mine has a 4" rise to it, and havent done anything that I've needed more. 2x4's slide right under on the side or stack two.

I like where this is going

IMHO the raised box makes a LOT of sense. I think it will also give you a better or easier way of mounting your fuel filler. Mine has a 4" rise to it, and havent done anything that I've needed more. 2x4's slide right under on the side or stack two.

I like where this is going

#58

The box section steel frame could be extended on down full depth of the deck, & bolted to reduce the flex caused by the space under the toolbox.

I intend making up a flatdeck for my own truck (in steel though - just because I'm an engineer by trade)............I know how the ideas start to flow & these projects take on a life of their own

.

.I've found that keeping weight down can start to become an issue as you plan in features, extra strength etc.

#59

If you expect to be carting 8' loads much in the future, that would be the way to go.

The box section steel frame could be extended on down full depth of the deck, & bolted to reduce the flex caused by the space under the toolbox.

I intend making up a flatdeck for my own truck (in steel though - just because I'm an engineer by trade)............I know how the ideas start to flow & these projects take on a life of their own .

.

I've found that keeping weight down can start to become an issue as you plan in features, extra strength etc.

The box section steel frame could be extended on down full depth of the deck, & bolted to reduce the flex caused by the space under the toolbox.

I intend making up a flatdeck for my own truck (in steel though - just because I'm an engineer by trade)............I know how the ideas start to flow & these projects take on a life of their own

.

.I've found that keeping weight down can start to become an issue as you plan in features, extra strength etc.

I am a draftsman/designer that engineers. I am not a degree'd engineer. I'm not sure why you feel the need to use steel just because you are an engineer.

I always come at projects from a practical standpoint. What are my needs? What will it carry? How much will it cost? How much can I do myself? A wood deck properly supported will carry anything the suspension on this truck is designed to carry, so there is no need for a steel deck. If you think steel looks better and want to spend all that money then I'd say go for it.

This truck is going to be retired in a couple years to do duty on my farm, and be used to haul building materials to build my log cabin. We are moving to Kentucky this year to do all this. So getting this truck ready for all that is a part of the plan.