fordman75

December 1, 2010

5-03-09: I took the grinder to the bird poo welds and cleaned it up pretty good.

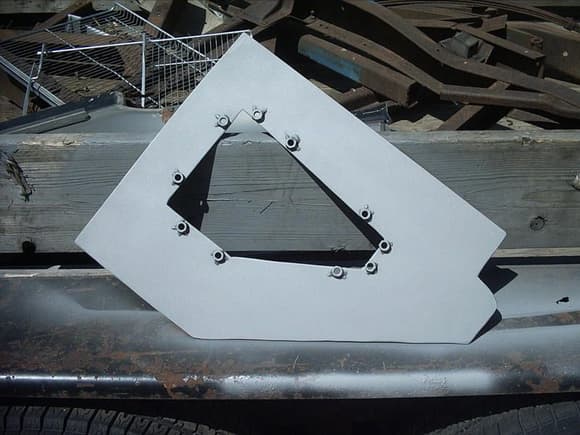

Next I needed to weld the nuts on the back side of the kick panel plate. I had to figure out a way to weld the nuts to the plate without messing up the threads. In the past I was told to use some grease but I remembered I had some tip gel for my welder. It's suppose to keep slag/ splatter from sticking to the tips. So I put some of the tip gel on the threads of each bolt. I then put 6 washers on each bolt. Doing this kept the end of the bolts flush with the nuts so there were no exposed threads. After I had all the bolts on the panel and had them all tight I put a little more tip gel on top of each nut. After that I clamped the panel down onto a couple jack stands and welded each nut to the panel. The tip gel worked great all the bolts came right out. Grease would have probably worked just as well since the tip gel just seemed to be thick grease. After the panel cooled down I cleaned it up then sprayed it with a coat of weld-thru primer.

More About This Picture

Vehicle

N/A

Location

N/A

Keywords

N/A

Discover More Pictures

See MoreAdvertisement

Be the first to comment on this picture!