TUX: FE Finally Gets A Makeover

#17

Freshly machined metal like a cylinder wall or crank journal can show rust spots within hours of coming into contact with moisture. for example a fresh machine block and 460 crank sitting in a van closed doors out of the weather for 2 weeks we had intense rain for a couple days and just the humity over the one night caused rust spots on things that cylinder does look like bad oil control and possibly head gasket leak but that rust does not look too intense for a quick hone to take out. I have reworked alot worse looking.

#18

Join Date: May 2007

Location: Victoria (North Saanich)

Posts: 960

Likes: 0

Received 9 Likes

on

7 Posts

Ceetwarrior,

Hope it is not a crack, even with Sleepy's arrows I can't say I see it, but with your eyes on the block you would.

Either way it is pretty certain that you had a coolant leak into that cylinder, and for your own sake you need to try and figure it out. I would be interested so please post what you figure out.

By the way, very nice truck.

Hope it is not a crack, even with Sleepy's arrows I can't say I see it, but with your eyes on the block you would.

Either way it is pretty certain that you had a coolant leak into that cylinder, and for your own sake you need to try and figure it out. I would be interested so please post what you figure out.

By the way, very nice truck.

#19

NO crack, confirmed. You guys always expect the worst in these old engines. But you gotta remember, there was over $1600 of machine work to this engine just 20,000 miles ago.

#20

Join Date: May 2007

Location: Victoria (North Saanich)

Posts: 960

Likes: 0

Received 9 Likes

on

7 Posts

Ceetwarrior,

I don't think it is because we assume the worst with these old engines. On the contrary, it is our admiration of them that keeps us interested in them.

You need to understand that first you posted an image of an engine that is in all likelihood leaking coolant into a cylinder, second, we are just looking at pictures and can't touch the block. There are only a few possible causes of coolant in a cylinder: one is a crack (in the block or head), next is a failed gasket, third is a part is not tight (not likely in an engine with 20K on it), forth is a broken head bolt (I've had that one).

We assume you would have mentioned a few of them such as a broken head bold, so a crack is not an unreasonable suggestion. I just can't really see what Hypoid and Sleepy were looking at.

Really happy for you that it is not a cracked block, thanks for posting the new picture. Have you examined the gasket (or what remains of it) to see if you had a leak?

I don't think it is because we assume the worst with these old engines. On the contrary, it is our admiration of them that keeps us interested in them.

You need to understand that first you posted an image of an engine that is in all likelihood leaking coolant into a cylinder, second, we are just looking at pictures and can't touch the block. There are only a few possible causes of coolant in a cylinder: one is a crack (in the block or head), next is a failed gasket, third is a part is not tight (not likely in an engine with 20K on it), forth is a broken head bolt (I've had that one).

We assume you would have mentioned a few of them such as a broken head bold, so a crack is not an unreasonable suggestion. I just can't really see what Hypoid and Sleepy were looking at.

Really happy for you that it is not a cracked block, thanks for posting the new picture. Have you examined the gasket (or what remains of it) to see if you had a leak?

#21

More importanly I need to get some parts on order ASAP. I need someone (with more knowledge) than me about the subject to tell me what compression ratio I currently have with the setup, and (if) and what I need to increase it to for more power and to compliment the possible cam choice in post #1.

Also, I'm really concerned that I have 352 rods with a 390 crank according to the part #'s on the rod's...

Thanks!

#22

Join Date: May 2007

Location: Victoria (North Saanich)

Posts: 960

Likes: 0

Received 9 Likes

on

7 Posts

65f100Cory certainly knows that stuff (he is a friend of mine), but I can't help without the books out.

I can't see how condensation would leave that much liquid in one cylinder if you had fired it for more than a few seconds. The heat from running the engine would have evaporated any water, unless you had a dead miss on the cylinder. You may have poured coolant in when you took the heads off, but it looked like it was pretty completely splashed around.

Good luck with it.

I can't see how condensation would leave that much liquid in one cylinder if you had fired it for more than a few seconds. The heat from running the engine would have evaporated any water, unless you had a dead miss on the cylinder. You may have poured coolant in when you took the heads off, but it looked like it was pretty completely splashed around.

Good luck with it.

#23

Glad it's not the block. Like yellowtruck said, not assuming the worst, just an observation of the pic given and problem stated.

According to my book that is a 352/360 rod.

You are correct that the 2U crank is a 390.

I dont have much experience with drag application cam selection so I'm gonna leave that to the older fellas.

As for static CR, you'll need a few measurement to figure that, head chamber cc, deck height, compressed head gasket thickness, piston top volume (see the manufacturers specs), bore, stroke.

With that rod and crank combo, it means that you have the 390 truck(low compression) pistons or at least they have the same wrist pin height and they sit .058 in the hole. If you had the earlier 390 pistons with the higher wrist pin height you would get .038 ABOVE the deck....CLANK.

Get some of the shorter rods 6.488" instead of the 6.540" you have. The long rods are known to fail at high rpm.

This will allow you a larger piston selection with the normal rod/crank setup.

According to my book that is a 352/360 rod.

You are correct that the 2U crank is a 390.

I dont have much experience with drag application cam selection so I'm gonna leave that to the older fellas.

As for static CR, you'll need a few measurement to figure that, head chamber cc, deck height, compressed head gasket thickness, piston top volume (see the manufacturers specs), bore, stroke.

With that rod and crank combo, it means that you have the 390 truck(low compression) pistons or at least they have the same wrist pin height and they sit .058 in the hole. If you had the earlier 390 pistons with the higher wrist pin height you would get .038 ABOVE the deck....CLANK.

Get some of the shorter rods 6.488" instead of the 6.540" you have. The long rods are known to fail at high rpm.

This will allow you a larger piston selection with the normal rod/crank setup.

#24

#25

#26

[quote=Sleepy445FE;10022684]

With that rod and crank combo, it means that you have the 390 truck(low compression) pistons or at least they have the same wrist pin height and they sit .058 in the hole. If you had the earlier 390 pistons with the higher wrist pin height you would get .038 ABOVE the deck....CLANK.

quote]

There are different compression heights between the 390 truck pistons (aka 410) and the 360/390 4v high comp. pistons. The earlier car 390 4v pistons and the 360 pistons are 1.776 or so and the 410 later recast as the low compression truck 390 pistons are 1.68.

The 390crank 360rod combo is only possible with the lower height. It's possible, but I've never seen it done until now. Usually people will put the 360/390 4v piston on the 390 crank and rods to give somewhere around 9.5:1.

With that rod and crank combo, it means that you have the 390 truck(low compression) pistons or at least they have the same wrist pin height and they sit .058 in the hole. If you had the earlier 390 pistons with the higher wrist pin height you would get .038 ABOVE the deck....CLANK.

quote]

The 390crank 360rod combo is only possible with the lower height. It's possible, but I've never seen it done until now. Usually people will put the 360/390 4v piston on the 390 crank and rods to give somewhere around 9.5:1.

#27

The new cam choice needs minium 9.5 comp. If I already have that then I'll keep what I got. I know it's not right, but compression is compression. He says if there is clearance issues with new cam we can clay, and fly cut them.

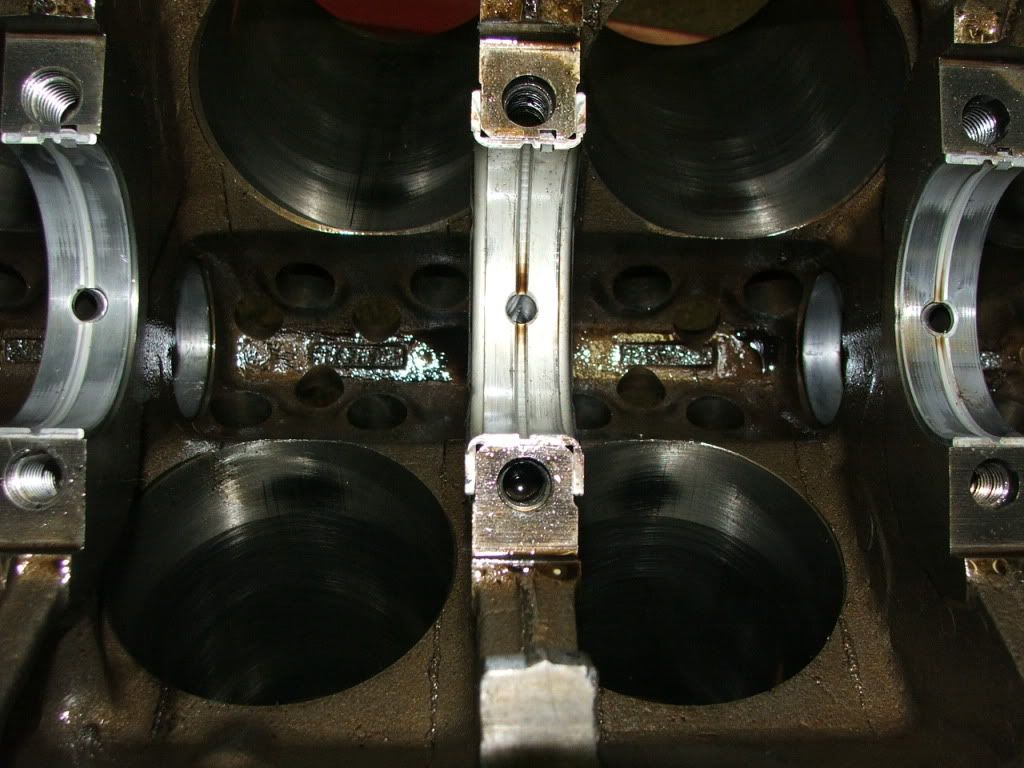

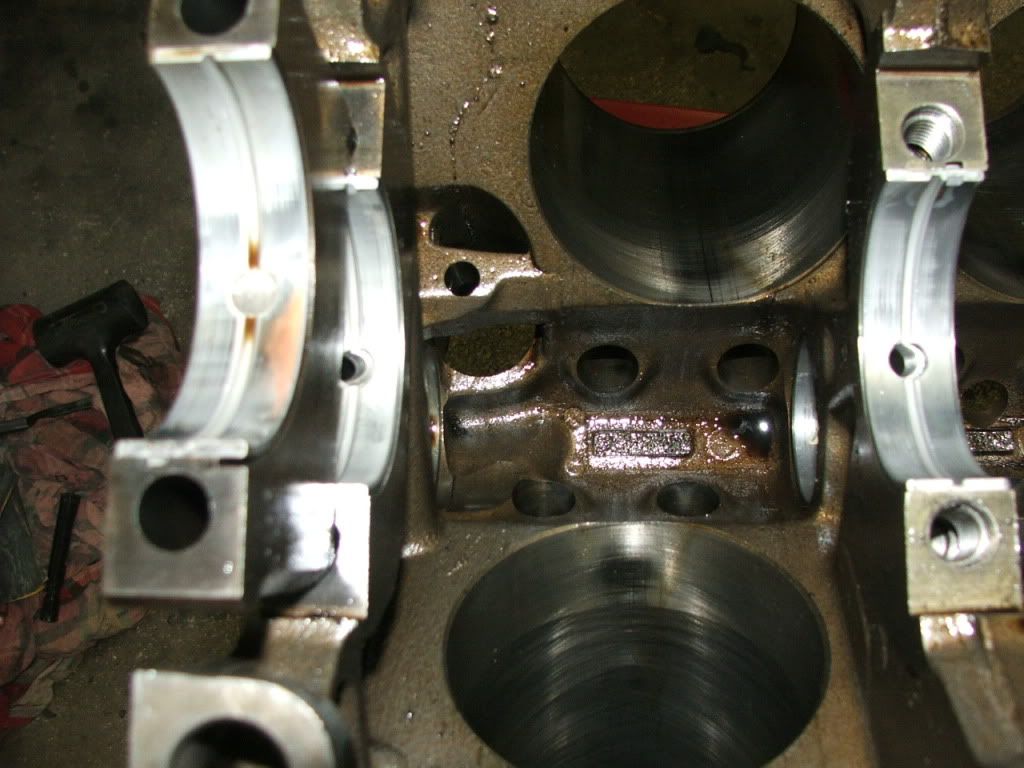

Here's the latest and greatest news: I brought in my expert engine builder friend to check out the build. He shed lots of light as to what's been going on. I don't even know where to start. He took one look at the main bearings and said, "did this engine make a slow tapping noise?" I said, "yes, I was never able to fix it as I thought it was valvetrain." Check out these main bearings in the pic below.

Now at his strong suggestion I gotta take engine block to another local machine shop (who I've dealt with on other FE builds) and knows a lot about FE's) and get a line bore done.

Other news. My $700 heads have now turned out to be a joke. When I was buffing them... I noticed the intake valves weren't sealing! I could blow air right through them into the runner. On almost all of them. Today he wants try to lap the worst ones in and see if they aren't worn crooked. If they are, I don't want to put any extra money into them and I'll probably bite the bullet and buy Edelbrock aluminum heads.

The center bearing isn't even touching on block side, then wore down bad on cap. Then bearings on either side are exact opposite.

Then I finally decided to pull off the baffle on the intake and found what's been circirulating through my engine for 20,000 miles. Great.

#28

#29

You're probably right. He did install hardend seats and bronze guides but probably f'd them up. Or never lapped 'em in after final? Yeah, this whole thing is a nightmare. It's amazing how strong the engine was in this condition. Still strong enough to run mid 15's at 5800ft elevation.