Anybody ever rebuild the ZF 5 speed? (s5-42)

#31

I got it all figured out over the weekend.

Turns out I was doing 2 things wrong.

1- I didn't realize that the collar has very tiny reliefs in the gear teeth for the plates to slide into.

2- I was trying to install the collar after the springs, plates and *****.

Turned out that the best way to do it is to install the collar first (aligning the reliefs properly, then stuffing each spring/plate/ball combo in all at once.

Thanks again for the help!

Turns out I was doing 2 things wrong.

1- I didn't realize that the collar has very tiny reliefs in the gear teeth for the plates to slide into.

2- I was trying to install the collar after the springs, plates and *****.

Turned out that the best way to do it is to install the collar first (aligning the reliefs properly, then stuffing each spring/plate/ball combo in all at once.

Thanks again for the help!

#32

#33

I used a puller like this to get the front bearing off the main shaft.

Automotive Pulley Puller

One like this to get the rear bearing off the main shaft.

Bearing Separator and Puller Set

or

Bearing Separator

I didn't actually disassemble the input shaft or counter shaft so I can't help you there.

Also, I found that the only way to get the pressed on inner race off of the main shaft was to stick the whole thing in the freezer, then take it out and heat the race and pound the whole shaft on a piece of wood on the concrete. The weight of the gears pushed it a little each time it hit the floor.

#34

I was looking at using a bearing splitter, but I don't think it will fit in the counter bore of the end gears on the counter-shaft. I'm wanting to put all new bearings throughout instead of just reassembling with the old ones. Thanks for the links and the freezer suggestion - I'll give that a go if I can't find a puller that will work.

#35

I was looking at using a bearing splitter, but I don't think it will fit in the counter bore of the end gears on the counter-shaft. I'm wanting to put all new bearings throughout instead of just reassembling with the old ones. Thanks for the links and the freezer suggestion - I'll give that a go if I can't find a puller that will work.

#36

#37

#40

Did you get the bearing off, Eppie? :)

The inner pinion bearing's race on my Ford9inch was the same way,

I had to cut the race with a Dremel and cut-off disc. Just take your

time and be careful not to get carried away, ...worked for me. ;)

It might break while Dremeling;) BTDT ...but stop and try driving a

screwdriver or cold chisel into the cut/groove ever' once in a while.

-------------------------

I have a stack of the larger 1+1/4"(?) fiber re-enforced discs from

somewhere like Brownell's but I also make even larger diameter

ones from used/broken .030" to .040" Norton hand-grinder discs. :)

IME and so IMO Norton stuff is the only stuff worth buying, YMMV.

I use a wornout TiN coated 1/16" drill bit and drill a hole where I

want it, then using dikes just cut/nibble-at-it and make it kinda

round using the hole as a guide. :)

--------------------------

They say to drill a hole into the axle retainers then use a cold chisel

but I drilled two and it snapped open while drilling the second. :)

Here they are being used as a spacer...

http://www.panix.com/~alvinj/file12/zf4.jpg

The Dremeled;) pinion race might be laying there on that hunk of

wood. :)

The hole in the hunk of wood was drilled with a 15/16" wood-spade

type bit and held the main shaft real nice but later needed a washer

under it to give the main shaft a larger surface to keep from mashing

the wood so much.

Alvin in AZ

ps- Doggonit, I was told, but I up-and-forgot how to make the

pictures pop up. :/

The inner pinion bearing's race on my Ford9inch was the same way,

I had to cut the race with a Dremel and cut-off disc. Just take your

time and be careful not to get carried away, ...worked for me. ;)

It might break while Dremeling;) BTDT ...but stop and try driving a

screwdriver or cold chisel into the cut/groove ever' once in a while.

-------------------------

I have a stack of the larger 1+1/4"(?) fiber re-enforced discs from

somewhere like Brownell's but I also make even larger diameter

ones from used/broken .030" to .040" Norton hand-grinder discs. :)

IME and so IMO Norton stuff is the only stuff worth buying, YMMV.

I use a wornout TiN coated 1/16" drill bit and drill a hole where I

want it, then using dikes just cut/nibble-at-it and make it kinda

round using the hole as a guide. :)

--------------------------

They say to drill a hole into the axle retainers then use a cold chisel

but I drilled two and it snapped open while drilling the second. :)

Here they are being used as a spacer...

http://www.panix.com/~alvinj/file12/zf4.jpg

The Dremeled;) pinion race might be laying there on that hunk of

wood. :)

The hole in the hunk of wood was drilled with a 15/16" wood-spade

type bit and held the main shaft real nice but later needed a washer

under it to give the main shaft a larger surface to keep from mashing

the wood so much.

Alvin in AZ

ps- Doggonit, I was told, but I up-and-forgot how to make the

pictures pop up. :/

#41

A friend at work suggested the machine the inner race method too. I'm thinking of stopping by the local dealer and see if they can pull the five bearings right quick for $cheap and if not I'll take them to a friend's axle and transmission shop in Durham where he can pull the bearings hopefully for free. If neither of those work out, I'm headed for the bridgeport to machine the inner races enough to pop them off.

Thanks for the suggestions!!

Thanks for the suggestions!!

#42

#43

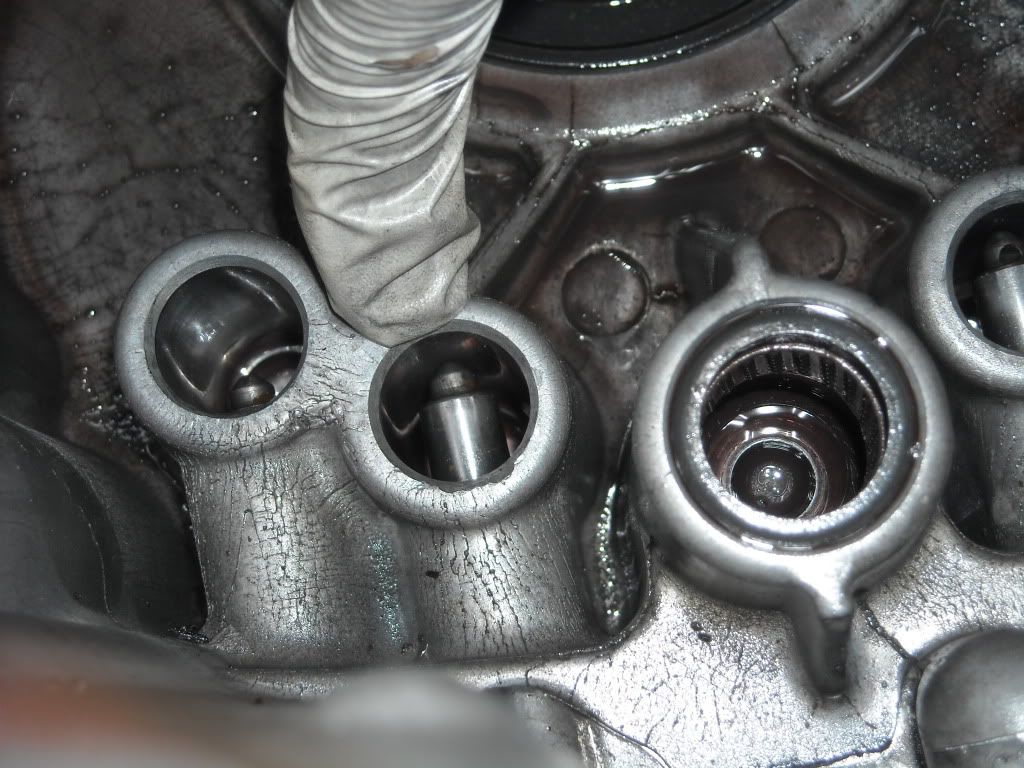

Someone dented the case to hold the "freeze plugs" in place. :/

You can't hold the detent plungers back, they gotta be pulled.

The trick that worked good for me was to hammer in one side using a

punch (or screw driver) then the spring popped the plug out. :) Got

real lucky with the first one, it didn't fly off into the weeds, the others

I was more careful. ;)

They made a big deal in the instructions not to dent the case like that.

They swore that they'd hold. :)

I double up on those springs and... so far so good. LOL :)

Alvin in AZ

#44

Oh crap. :/

Someone dented the case to hold the "freeze plugs" in place. :/

You can't hold the detent plungers back, they gotta be pulled.

The trick that worked good for me was to hammer in one side using a

punch (or screw driver) then the spring popped the plug out. Got

Got

real lucky with the first one, it didn't fly off into the weeds, the others

I was more careful.

They made a big deal in the instructions not to dent the case like that.

They swore that they'd hold.

I double up on those springs and... so far so good. LOL

Alvin in AZ

Someone dented the case to hold the "freeze plugs" in place. :/

You can't hold the detent plungers back, they gotta be pulled.

The trick that worked good for me was to hammer in one side using a

punch (or screw driver) then the spring popped the plug out.

Got

Gotreal lucky with the first one, it didn't fly off into the weeds, the others

I was more careful.

They made a big deal in the instructions not to dent the case like that.

They swore that they'd hold.

I double up on those springs and... so far so good. LOL

Alvin in AZ

Looks like I may have to clearance drill the back side a bit???

#45

Looks like I may have to clearance drill the back side a bit???

http://i133.photobucket.com/albums/q...Picture128.jpg

http://i133.photobucket.com/albums/q...Picture128.jpg

Tapered reamer maybe?

Just remove the bumps so the cup will slide in. :)

Alvin in AZ