1985 F150 302 holley problems

#196

#197

I have never owned a vacuum gauge, never needed one. I turn the mixture screws in till the engine runs rough, then turn them out till it smooths out. Do it again, turn them in, then turn them out, and then give them about 1/2 turn more. Done. May not be perfect but works for me.

you need a vacuum gauge. this one is for 19 dollars + shipping and doubles as a fuel pressure tester (obviously i like a vacuum gauge with wider swing, but this is 1000 times better than no vacuum gauge)

i found this page useful when googling how to tune a carburator, I don't know if it will be any help. The article says point blank you need to tune with a vacuum gauge.

Setting Idle Mixture The Right Way

#198

Dave - That's exactly how Dad taught me to do it. But, I rebuilt my Eddy 1406 today and set the needles at 1 1/2 turns out. Started it up and it idled well, but I put the vacuum gauge on anyway. Went through the above process and that process put it at the highest vacuum. And, by the way, that was at 13.0:1 AFR.

#199

Exactly my point Dave^^^^

I have a vacuum gauge.

It's attached to my Mityvac.

Absolute measurements mean nothing when all you want to do is get it to run, and run well.

A VOM is very useful for troubleshooting,

A vacuum gauge... not so much.

99% of the time all you need is to know if vacuum is present.

I have a vacuum gauge.

It's attached to my Mityvac.

Absolute measurements mean nothing when all you want to do is get it to run, and run well.

A VOM is very useful for troubleshooting,

A vacuum gauge... not so much.

99% of the time all you need is to know if vacuum is present.

#202

Exactly my point Dave^^^^

I have a vacuum gauge.

It's attached to my Mityvac.

Absolute measurements mean nothing when all you want to do is get it to run, and run well.

A VOM is very useful for troubleshooting,

A vacuum gauge... not so much.

99% of the time all you need is to know if vacuum is present.

I have a vacuum gauge.

It's attached to my Mityvac.

Absolute measurements mean nothing when all you want to do is get it to run, and run well.

A VOM is very useful for troubleshooting,

A vacuum gauge... not so much.

99% of the time all you need is to know if vacuum is present.

what is the VOM? I googled it and am coming up with wounded solders page lol

#203

#205

Dave - That's exactly how Dad taught me to do it. But, I rebuilt my Eddy 1406 today and set the needles at 1 1/2 turns out. Started it up and it idled well, but I put the vacuum gauge on anyway. Went through the above process and that process put it at the highest vacuum. And, by the way, that was at 13.0:1 AFR.

so technically max vacuum is technically slightly slightly rich ( not even sure how this happens)

ideal air fuel ratio is 14.7:1 so 13.0:1 is technically richer than it should be.. i am happy you have air fuel ratio gauge, more people need them for so many reasons. (like it is very hard to stop on the freeway and pull plugs to check how /leanrich the higher rpms are under load conditions)

#206

I have question!!!!!!!!!

have you ever seen anything above 1 3/4 turns on the mixture screw. I read somewhere that between 1 1/4 mixture screw and 1 3/4 mixture screw is good 99% of the time?

#207

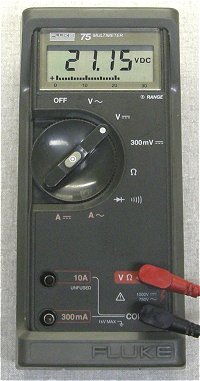

It is an old term for a Volt Ohm Meter.

Most would call them a DMM (digital MultiMeter) now.

Amps, Ohms, AC & DC Voltage, Capacitance, Continuity, diode check, etc.

My newer one even has a thermocouple.

My basic Fluke 75 has been serving well since the early '80's

I actually like my analog Simpson 260-6M best for hunting short or open wires.

It reacts much faster than the newer MeterMan 33XR

#208

But I have half again as much displacement and 20"Hg. with my "RV" cam.

#209

ideal air fuel ratio is 14.7:1 so 13.0:1 is technically richer than it should be.. i am happy you have air fuel ratio gauge, more people need them for so many reasons. (like it is very hard to stop on the freeway and pull plugs to check how /leanrich the higher rpms are under load conditions)

Stoichiometric ratio is 14.7:1 -by weight-at STP-using normal octane=.

This is NOT optimal for mileage or power, it just means optimal burn with the least waste products.

Every blend of gas at the pump varies by market price of the hydrocarbons used as constituents and the federal mandate for renewables.

This is why real racers use race fuel that is a consistent formula or (in top fuel) blend their own to conditions.

With most unadulterated gasoline, under MOST conditions, max power will be found at 13:1 or a little lower.

#210

Man, put your book away and go tune a car.

Stoichiometric ratio is 14.7:1 -by weight-at STP-using normal octane=.

This is NOT optimal for mileage or power, it just means optimal burn with the least waste products.

Every blend of gas at the pump varies by market price of the hydrocarbons used as constituents and the federal mandate for renewables.

This is why real racers use race fuel that is a consistent formula or (in top fuel) blend their own to conditions.

With most unadulterated gasoline, under MOST conditions, max power will be found at 13:1 or a little lower.

Stoichiometric ratio is 14.7:1 -by weight-at STP-using normal octane=.

This is NOT optimal for mileage or power, it just means optimal burn with the least waste products.

Every blend of gas at the pump varies by market price of the hydrocarbons used as constituents and the federal mandate for renewables.

This is why real racers use race fuel that is a consistent formula or (in top fuel) blend their own to conditions.

With most unadulterated gasoline, under MOST conditions, max power will be found at 13:1 or a little lower.