Rebuilding 351w heads

#1

Rebuilding 351w heads

Hey guys,

So I bought some D0OE heads off a '69 Mach 1. I'm building these for my trail truck. So far I have got the heads hot tanked, manga fluxed and decked(0.015".) I ordered some valves for them yesterday, intake only because someone did a valve job at point and replaced the exhaust valves, and planning on having the seats ground to match. This is where my knowledge ends. I have a few questions.

Will I be able to run 1.6 ratio rocker arms? Machinist said something about the push rods not clearing due to the extra throw. I thought stock ratio was 1.6?

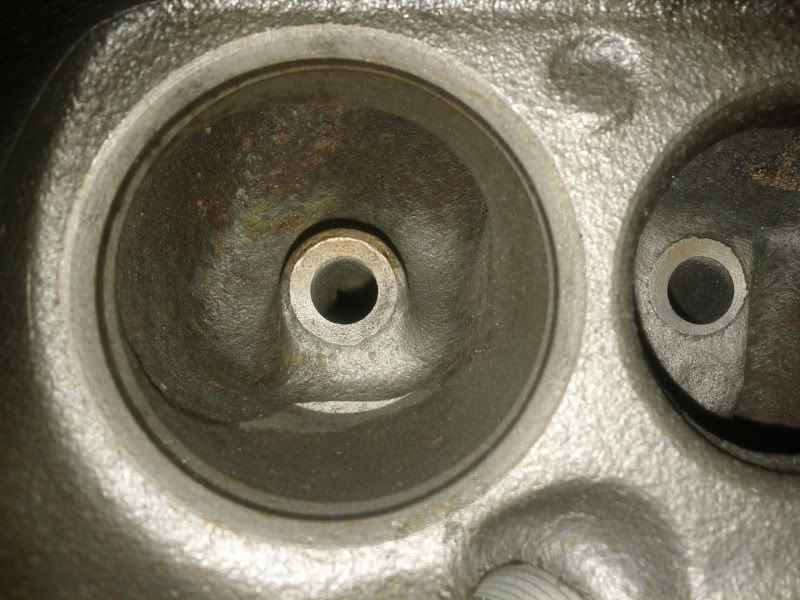

I'm planning on doing my own mild porting. On the exhaust ports, there is a hump in the middle of the port. Can I remove this hump without having to worry? I've read mixed opinions on port matching, can someone shine some light on this please.

The engine is in my '78 f150 trail truck. The lower end is out of a interceptor(E9AE.) Plans are these heads, comp 1.6 roller tip rockers, comp 4x4 cam for mid-range power, eddy performer intake and holley 500cfm 2 barrel. Thanks for the help in advance!

So I bought some D0OE heads off a '69 Mach 1. I'm building these for my trail truck. So far I have got the heads hot tanked, manga fluxed and decked(0.015".) I ordered some valves for them yesterday, intake only because someone did a valve job at point and replaced the exhaust valves, and planning on having the seats ground to match. This is where my knowledge ends. I have a few questions.

Will I be able to run 1.6 ratio rocker arms? Machinist said something about the push rods not clearing due to the extra throw. I thought stock ratio was 1.6?

I'm planning on doing my own mild porting. On the exhaust ports, there is a hump in the middle of the port. Can I remove this hump without having to worry? I've read mixed opinions on port matching, can someone shine some light on this please.

The engine is in my '78 f150 trail truck. The lower end is out of a interceptor(E9AE.) Plans are these heads, comp 1.6 roller tip rockers, comp 4x4 cam for mid-range power, eddy performer intake and holley 500cfm 2 barrel. Thanks for the help in advance!

#2

Join Date: Jun 2006

Location: Ottawa, Ontario

Posts: 30,966

Likes: 0

Received 984 Likes

on

776 Posts

Ok.. maybe not.. you do want to get your parts back.. so you'll have to find some non insulting way of telling him that a 1.6 ratio rocker is STOCK on a Ford.

Ok.. maybe not.. you do want to get your parts back.. so you'll have to find some non insulting way of telling him that a 1.6 ratio rocker is STOCK on a Ford.

Oh yeah.. port matching. Generally it's a good idea on paper as it will maximize airflow but engines don't produce a continuous flow of gasses and a small step in a port can have a benificial side effect of blocking reversion in the port which is good at lower rpms on the exhaust side and also good on the intake side of a carbed motor as it helps keep some air/fuel mix closer to the valves. So it's a nice to have thing if you already got sufficient port size to supply your motor, but since that's not the case with these Fords you're better off port matching everyhting if you can.

#3

Friggen Chevy guys... smack him up side of the head and tell him the distributor goes in the Front!! Ok.. maybe not.. you do want to get your parts back.. so you'll have to find some non insulting way of telling him that a 1.6 ratio rocker is STOCK on a Ford.

Ok.. maybe not.. you do want to get your parts back.. so you'll have to find some non insulting way of telling him that a 1.6 ratio rocker is STOCK on a Ford.

Ford small block cylinder heads are notoriously small with badly restrictive ports and there's almost no way you could make them worse so the general concensus is to hog them out as much as you dare. You still want to make them smooth and have a gradual increase in size from the valve seat out so you have to pay attention to get consistent results on all ports so see here for additional info. Porting Ford E7TE part 1

Oh yeah.. port matching. Generally it's a good idea on paper as it will maximize airflow but engines don't produce a continuous flow of gasses and a small step in a port can have a benificial side effect of blocking reversion in the port which is good at lower rpms on the exhaust side and also good on the intake side of a carbed motor as it helps keep some air/fuel mix closer to the valves. So it's a nice to have thing if you already got sufficient port size to supply your motor, but since that's not the case with these Fords you're better off port matching everyhting if you can.

Ok.. maybe not.. you do want to get your parts back.. so you'll have to find some non insulting way of telling him that a 1.6 ratio rocker is STOCK on a Ford.

Ok.. maybe not.. you do want to get your parts back.. so you'll have to find some non insulting way of telling him that a 1.6 ratio rocker is STOCK on a Ford.

Ford small block cylinder heads are notoriously small with badly restrictive ports and there's almost no way you could make them worse so the general concensus is to hog them out as much as you dare. You still want to make them smooth and have a gradual increase in size from the valve seat out so you have to pay attention to get consistent results on all ports so see here for additional info. Porting Ford E7TE part 1

Oh yeah.. port matching. Generally it's a good idea on paper as it will maximize airflow but engines don't produce a continuous flow of gasses and a small step in a port can have a benificial side effect of blocking reversion in the port which is good at lower rpms on the exhaust side and also good on the intake side of a carbed motor as it helps keep some air/fuel mix closer to the valves. So it's a nice to have thing if you already got sufficient port size to supply your motor, but since that's not the case with these Fords you're better off port matching everyhting if you can.

I read through that link about the E7's you posted. Some pretty good info there. I'm still curious if I can remove this huge chunk of casting in the exhaust port? How much material do I need to keep for the guide to remain structurally sound?

Here is a link I found with some more good info but died off...

porting a d00e head - Ford Muscle Forums : Ford Muscle Cars Tech Forum

#6

#7

If you're going to open up the exhaust's, I only remove metal from the port roof and walls, pretty much leave the bottom and short side radius alone. I don't have a flow bench to measure results, and I've heard that you can do more harm than good by changing the short sides, so I leave em alone.

Trending Topics

#8

If you're going to open up the exhaust's, I only remove metal from the port roof and walls, pretty much leave the bottom and short side radius alone. I don't have a flow bench to measure results, and I've heard that you can do more harm than good by changing the short sides, so I leave em alone.

#10

#11

Typically, the margins on intake valves are thicker than those on exhausts. Typically about twice as thick. This is due to the tremendous heat that the exhausts have to endure as the burning hot exhaust gases rush by them.

Both intake and exhaust valve faces see the high combustion temperatures, but only the exhausts get that burning gas going past when they are open.

Both intake and exhaust valve faces see the high combustion temperatures, but only the exhausts get that burning gas going past when they are open.

#12

Those roller tipped rockers, did they come off the engine? If not - and assuming the the heads haven't been machined for screw-in studs and guide plates - make sure they're self-aligning (rail rockers). They should have little ears below the roller edge on either side to keep them from sliding off the side of the valve stem.

#13

Those roller tipped rockers, did they come off the engine? If not - and assuming the the heads haven't been machined for screw-in studs and guide plates - make sure they're self-aligning (rail rockers). They should have little ears below the roller edge on either side to keep them from sliding off the side of the valve stem.

COMP Cams 1431-16 - COMP Cams Magnum Steel Roller Tip Rocker Arms - Overview - SummitRacing.com

#14

They did not come off the engine. I still have the pressed in studs but after looking at them closer, I have one that seems to be pulling out. I'm going to have my machinist look at it. These are the rockers I was looking at. They claim to be self-aligning.

COMP Cams 1431-16 - COMP Cams Magnum Steel Roller Tip Rocker Arms - Overview - SummitRacing.com

COMP Cams 1431-16 - COMP Cams Magnum Steel Roller Tip Rocker Arms - Overview - SummitRacing.com

#15

Those should be the right ones, but it shows both styles in the pics and the application says 69-89, which is wrong. Rail rockers started in mid 66 and were used until the D8OE 302/351 heads came out with pedestal rockers in late 77. Just me, but for what you're spending on those (new) you could have full roller rockers for the same or not much more money. The roller tips really do nothing to eliminate friction. Full rollers do with the roller trunions replacing the ball fulcrums. And as long as you're doing this rebuild, you'd also be well advised to install screw in studs and guide plates too.

I was trying to keep this build a little on the cheaper side. These heads are going in my trial truck. I'm not running anything radical, just upgrading to get a little more HP.