Exhaust manifold removal... DONE, back on truck (Pics!)

#61

#62

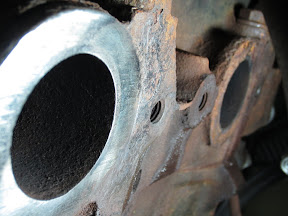

So I didn't get much done this weekend, kinda Mama focused  , but managed to clean up the mating surface on the heads, and found my manifolds were leaking pretty good. Also found a lot of cancer that would inhibit proper sealing of the manifolds.

, but managed to clean up the mating surface on the heads, and found my manifolds were leaking pretty good. Also found a lot of cancer that would inhibit proper sealing of the manifolds.

Clearly you can see there is relief here.

<table style="width: auto;"><tbody><tr><td> </td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

It was a job to remove all the rust.

<table style="width: auto;"><tbody><tr><td> </td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

And some useful shop items

<table style="width: auto;"><tbody><tr><td> </td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

Sure shot in action, love that thing.

<table style="width: auto;"><tbody><tr><td> </td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

All done cleaning...

<table style="width: auto;"><tbody><tr><td> </td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

<table style="width: auto;"><tbody><tr><td> </td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds</td></tr></tbody></table>

Applying the high temp ceramic lube to the bolt holes.

<table style="width: auto;"><tbody><tr><td>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds

https://picasaweb.google.com/CasperC...eat=directlink

</td></tr></tbody></table>

, but managed to clean up the mating surface on the heads, and found my manifolds were leaking pretty good. Also found a lot of cancer that would inhibit proper sealing of the manifolds.

, but managed to clean up the mating surface on the heads, and found my manifolds were leaking pretty good. Also found a lot of cancer that would inhibit proper sealing of the manifolds.Clearly you can see there is relief here.

<table style="width: auto;"><tbody><tr><td>

It was a job to remove all the rust.

<table style="width: auto;"><tbody><tr><td>

And some useful shop items

<table style="width: auto;"><tbody><tr><td>

Sure shot in action, love that thing.

<table style="width: auto;"><tbody><tr><td>

All done cleaning...

<table style="width: auto;"><tbody><tr><td>

<table style="width: auto;"><tbody><tr><td>

Applying the high temp ceramic lube to the bolt holes.

<table style="width: auto;"><tbody><tr><td>

</td></tr><tr><td style="font-family: arial,sans-serif; font-size: 11px; text-align: right;">From Exhaust Manifolds

https://picasaweb.google.com/CasperC...eat=directlink

</td></tr></tbody></table>

#63

Ok, so finally had warm enough weather to paint, so I did.

I've updated my album, https://picasaweb.google.com/CasperC...eat=directlink and here is a glimpse.

<embed type="application/x-shockwave-flash" src="https://picasaweb.google.com/s/c/bin/slideshow.swf" flashvars="host=picasaweb.google.com&captions=1&hl =en_US&feat=flashalbum&RGB=0x000000&feed=https%3A% 2F%2Fpicasaweb.google.com%2Fdata%2Ffeed%2Fapi%2Fus er%2FCasperCPU%2Falbumid%2F5597833463792590913%3Fa lt%3Drss%26kind%3Dphoto%26hl%3Den_US" pluginspage="http://www.macromedia.com/go/getflashplayer" width="400" height="267"><table style="width:auto;"><tbody><tr><td> </td></tr><tr><td style="font-family:arial,sans-serif; font-size:11px; text-align:right">From Exhaust Manifolds</td></tr></tbody></table>

</td></tr><tr><td style="font-family:arial,sans-serif; font-size:11px; text-align:right">From Exhaust Manifolds</td></tr></tbody></table>

Only question I have is (two really) Why are the torque specs for the exhaust manifold so blasted hard to find in the manual, AND different for each side! Helm manual states, in their specs section 21ft/lbs for driver side, 37ft/lbs for passenger side

I've updated my album, https://picasaweb.google.com/CasperC...eat=directlink and here is a glimpse.

<embed type="application/x-shockwave-flash" src="https://picasaweb.google.com/s/c/bin/slideshow.swf" flashvars="host=picasaweb.google.com&captions=1&hl =en_US&feat=flashalbum&RGB=0x000000&feed=https%3A% 2F%2Fpicasaweb.google.com%2Fdata%2Ffeed%2Fapi%2Fus er%2FCasperCPU%2Falbumid%2F5597833463792590913%3Fa lt%3Drss%26kind%3Dphoto%26hl%3Den_US" pluginspage="http://www.macromedia.com/go/getflashplayer" width="400" height="267"><table style="width:auto;"><tbody><tr><td>

Only question I have is (two really) Why are the torque specs for the exhaust manifold so blasted hard to find in the manual, AND different for each side! Helm manual states, in their specs section 21ft/lbs for driver side, 37ft/lbs for passenger side

#64

got a set of those bolt grips. they really work a treat. As for the manifold, patience. my came out but its a real battle in there. Access was the issue for me. I dont know how close your steering arm is to the manifold but on our RHD it runs right over one of the bolts so you cant get a wrench on it.

#66

. I'm very interested in how all the different stuff/ideas hold up, to do that right you need good documentation.

. I'm very interested in how all the different stuff/ideas hold up, to do that right you need good documentation.

#68

. After 20mins of searching, at the end of the 7.3l engine section there is a spec section, clearly delineates between the left and right banks. Last freakin error was 55ft/lbs for my 4 wheel bearing studs! It'll have to ride at 40ft/lbs, cause that was what seemed like a good compromise. Think I could get my $$$ back on the manuals, only bought them 11 years ago, direct from Helm.

. After 20mins of searching, at the end of the 7.3l engine section there is a spec section, clearly delineates between the left and right banks. Last freakin error was 55ft/lbs for my 4 wheel bearing studs! It'll have to ride at 40ft/lbs, cause that was what seemed like a good compromise. Think I could get my $$$ back on the manuals, only bought them 11 years ago, direct from Helm.

#70

Exhaust Coating, Black Satin Header Coating 4 oz - Exhaust Coatings by Tech Line Coatings, Inc.

This is the size I purchased to check it out, and to date have painted the manifold in my fast car (Accord

), both manifolds on the truck along with the turbine housing (both parts), and the collector... I still have 2 ounces left! Very thin application, and it seems to be holding up. I've had a couple good runs so far in the ~1200degree range.

), both manifolds on the truck along with the turbine housing (both parts), and the collector... I still have 2 ounces left! Very thin application, and it seems to be holding up. I've had a couple good runs so far in the ~1200degree range.

#71

#72

OUCH! How is that possible? Did the gasket hole at the end of the manifold tear? Your gasket looks "thinner" then the one I put on. Who was the manufacturer?

#73

Had me stumped as well. It was the last place I looked when chasing the leak. If you look close you can see that it was still around the first bolt all be it a little stretched. Have to ask Clay who the manufacturer was. It was a flat gasket with a raised ring around the outer edge of each port (like fire ring).

#74

Had me stumped as well. It was the last place I looked when chasing the leak. If you look close you can see that it was still around the first bolt all be it a little stretched. Have to ask Clay who the manufacturer was. It was a flat gasket with a raised ring around the outer edge of each port (like fire ring).

#75

Hammer, Heat, and drill bolts

Can you hit the head of the bolt with a hammer to shock the threads? It sometimes loosens them up without having to resort to heat. Worth a shot. I work on heavy equipment and trucks that are exposed to coal ash dust. The effects of it are caustic and dealing with stuck parts are an everday occurrence.

Heating the bolts is tricky. There are a few problems. If you just heat it once and get the head nice and red, you will most likely just twist the head off. You also lose any hardness or temper in the bolt. Repeated heatings and coolings to get the heat to the end of the bolt (not easy) might do the trick. Try not to get the head red and heat the surrounding head as much as possible is even better if you can get to it - usually not...

Nuts are a different story. Heat them red and zipp them off fast with an air gun.

I'm still reading from the top of the thread. Have no idea how to get my manifold off yet, or the best way. It seems there is no way without broken bolts. When the head is off one day you can drill them out and re-tap. For now it will probably still leak after all that work. Mine is burning a plug wire off. Real PITA.

Im a machinist. Have drilled out thousands of bolts. (I'm old) There is a process. 25 ways to get out a broke bolt. You have to start with the easiest and work your way to drilling it completely out then re-tapping which will ruin a head if the tap breaks - 30% of the time if you've had a lot of practice. Well not really. With persistence and a small punch you cant break the tap to bits and blow them out - then start again!

I hope this helped anyone. I'm going back to the top and see if anyone has an idea how to reach down in there and get a manifold off. Like I said, I'm old. Can't crawl around like a monkey anymore.

Danny