49 truck with 4.6 modular motor-IT'S ALIVE!!!

#241

#242

I've been back and forth on whether to use a tilt front-end or try and repair some pretty bad fenders and hood. I've finally decided on the tilt front-end.

It got pretty dirty sitting around all this time so I used a degreaser then dawn soap and some comet cleanser on the underside. I'm using some conduit and duraglas to strengthen it for use with a linear actuator.

Here's the first piece of reinforcement I made today. I filled the conduit with sand to keep it from collapsing then bent it with this bender I rigged up.

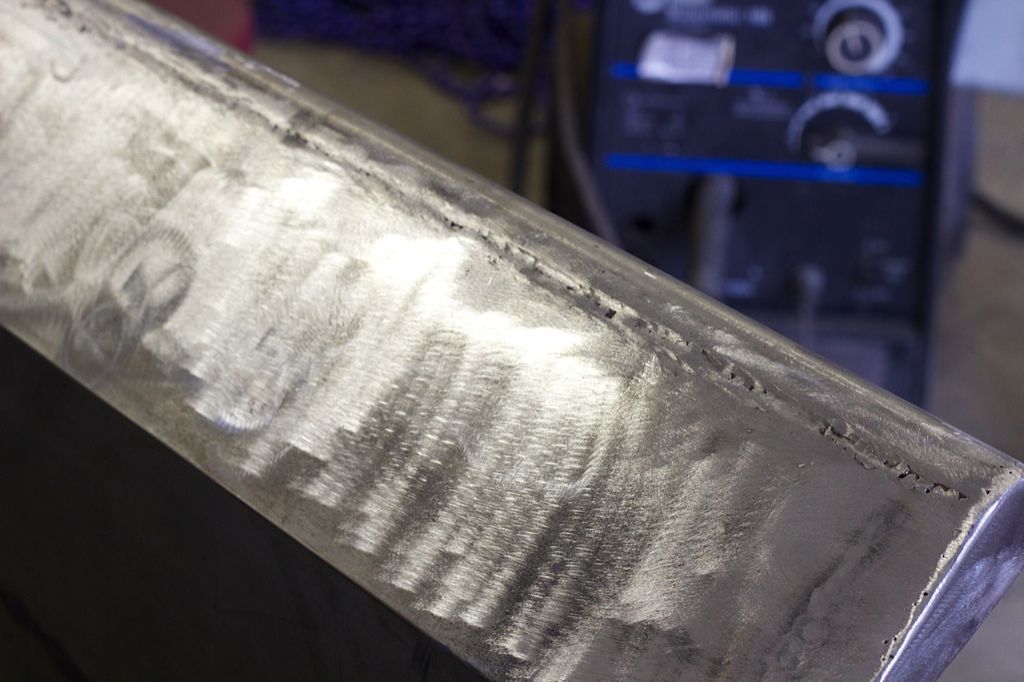

This is actually two pieces of 1/2" EMT conduit. I ground the coating off on the end and welded together. The coating is toxic when welding so care must be taken. I welded next to an open overhead door with a respirator on. I laid a few tacks and walked away for a few seconds then repeated.

I roughed up the conduit with 40 grit on a roloc then followed with some 36 grit by hand. I've also cut some grooves in it on top and bottom side to help the Duraglas bite some more. I sanded the fiberglass with 36 grit by hand and used a pick to scar up the surface as well.

I still have to weld the top piece(it's on the bottom here) of the mount on. I'm also going to add a couple of braces from the mount to the halo support I made.

The Duraglas should be here by this weekend.

It got pretty dirty sitting around all this time so I used a degreaser then dawn soap and some comet cleanser on the underside. I'm using some conduit and duraglas to strengthen it for use with a linear actuator.

Here's the first piece of reinforcement I made today. I filled the conduit with sand to keep it from collapsing then bent it with this bender I rigged up.

This is actually two pieces of 1/2" EMT conduit. I ground the coating off on the end and welded together. The coating is toxic when welding so care must be taken. I welded next to an open overhead door with a respirator on. I laid a few tacks and walked away for a few seconds then repeated.

I roughed up the conduit with 40 grit on a roloc then followed with some 36 grit by hand. I've also cut some grooves in it on top and bottom side to help the Duraglas bite some more. I sanded the fiberglass with 36 grit by hand and used a pick to scar up the surface as well.

I still have to weld the top piece(it's on the bottom here) of the mount on. I'm also going to add a couple of braces from the mount to the halo support I made.

The Duraglas should be here by this weekend.

#243

#244

Well, another change of plans. I tried to get on board with making this a tilt front end but it just wasn't meant to be. I think it would be kinda cool but it just didn't excite me enough to put in the work involved to make it happen. I always wanted stationery fenders, grill, etc. with a tilt hood. So I'm trying to make it happen with fiberglass unit. I took the sawzall to it yesterday so no turning back.

I will extend the fenders inward with some fiberglass, the hood needs some work as well, the fenders where they meet the cab also.

I will extend the fenders inward with some fiberglass, the hood needs some work as well, the fenders where they meet the cab also.

#245

#246

#248

Thanks Jeff and Nicolle.

Getting around to some detail work. It's tedious but needs to be finished.

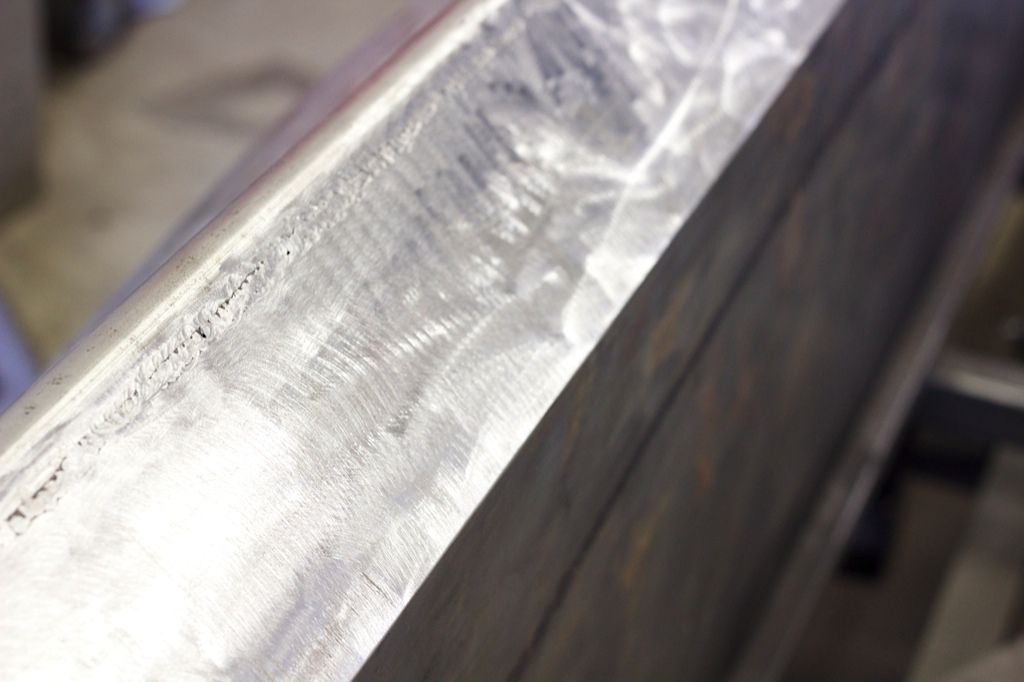

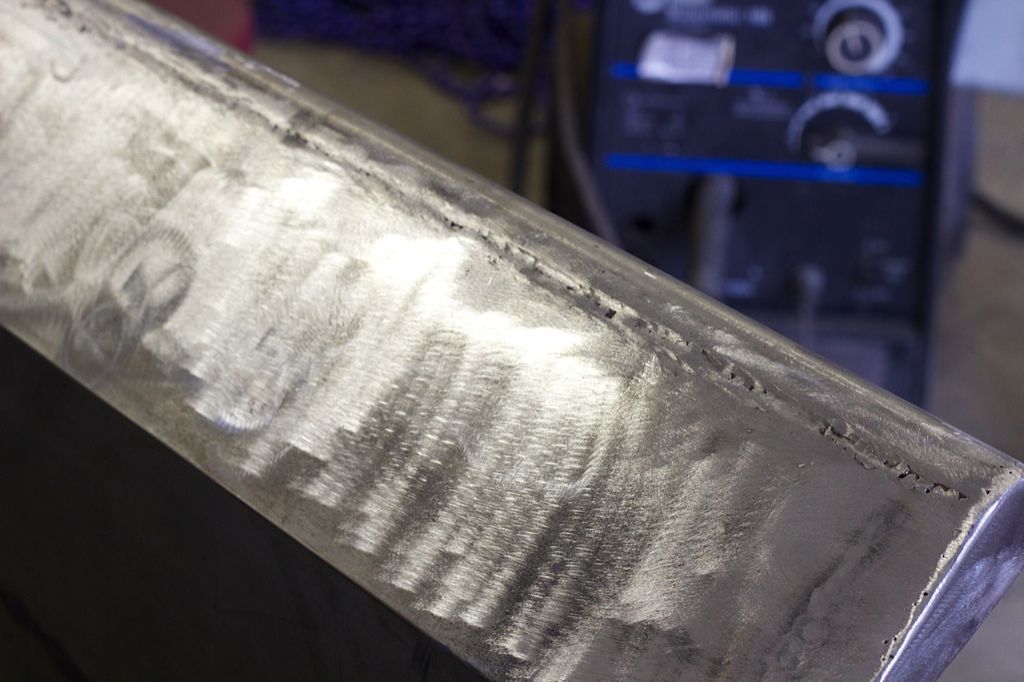

I ground down the welds on the bed rails and inside of tailgate top rail.

BEFORE

AFTER

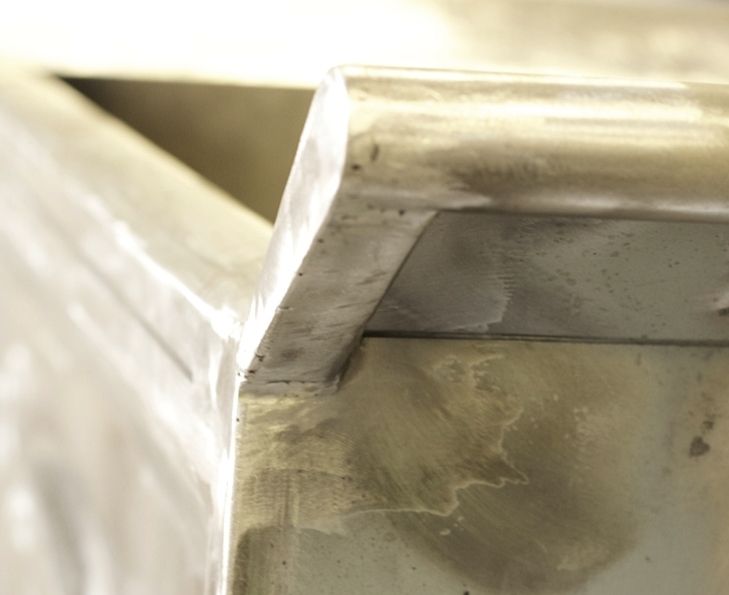

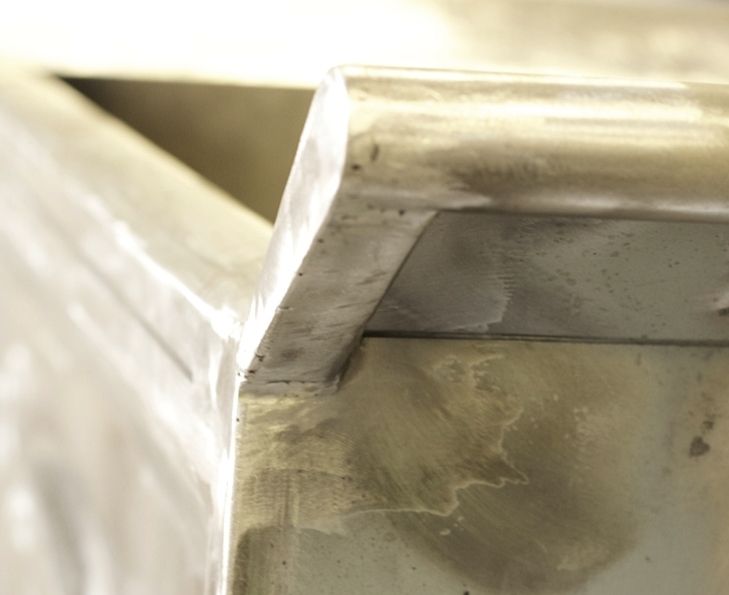

The teardrop on the corners of the bed was to flimsy so I boxed it in.

BEFORE

Four pieces shaped to box it in.

AFTER

Getting around to some detail work. It's tedious but needs to be finished.

I ground down the welds on the bed rails and inside of tailgate top rail.

BEFORE

AFTER

The teardrop on the corners of the bed was to flimsy so I boxed it in.

BEFORE

Four pieces shaped to box it in.

AFTER

#250

Thank you. Small, tedious work that has to get done but can sometimes cause burnout when you don't see "big" stuff getting finished.

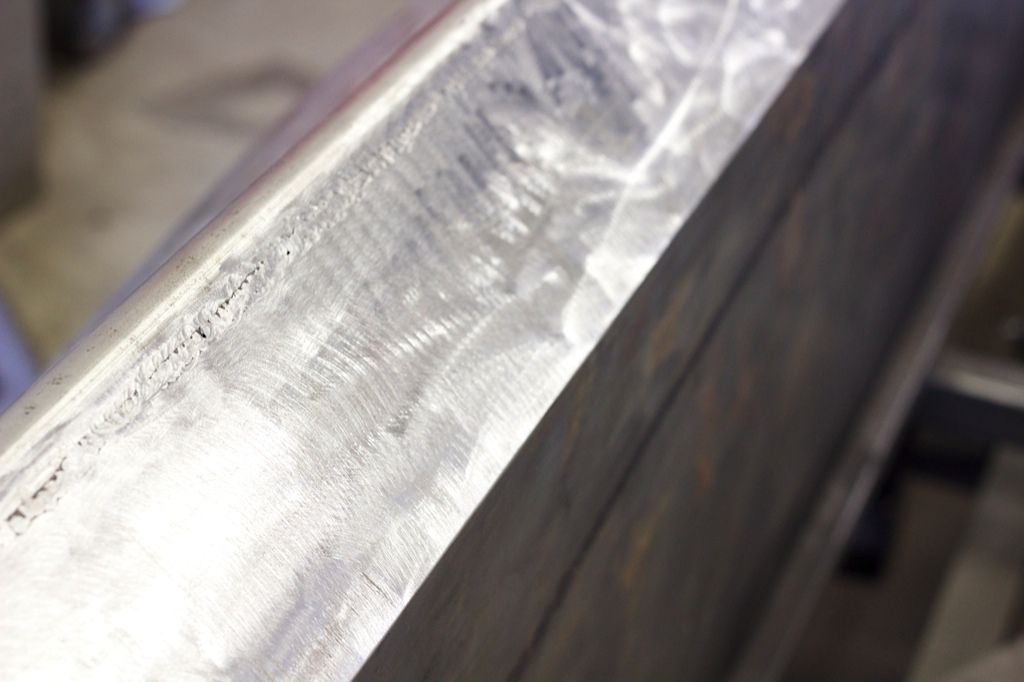

I didn't have a wide enough piece of metal when I made the bedsides to go all the way down to the running board and I didn't want a bolt on filler piece so I'm welding in a piece. Got the passenger side finished tonight. I plan on making the running boards on down the road.

I didn't have a wide enough piece of metal when I made the bedsides to go all the way down to the running board and I didn't want a bolt on filler piece so I'm welding in a piece. Got the passenger side finished tonight. I plan on making the running boards on down the road.

#251

Finished extending the bedside on the drivers side. I had an issue with the bedside previously when I was welding the fender on. I had some extreme oil canning. I used a stud gun then and eliminated the oil canning but there was still a really high spot that I never addressed.

Instead of trying to keep shrinking areas I just cut some slits in the trouble spot, straightened the metal and welded back. Probably took an hour or more to weld back. I laid a few tacks, ground down with cutoff wheel then smoothed with roloc then repeat. It turned out great. The metal is straight and no oil canning.

Instead of trying to keep shrinking areas I just cut some slits in the trouble spot, straightened the metal and welded back. Probably took an hour or more to weld back. I laid a few tacks, ground down with cutoff wheel then smoothed with roloc then repeat. It turned out great. The metal is straight and no oil canning.

#253

Well church got cancelled tonight because of snow and I got a little stir crazy sitting around so I at least put in an hour of tinkering. P/O butchered the dash filled with resin and mat.

I cut the hole a little more square. Tried to hammer the edges a little flatter and made a brace out of 1/8" steel to weld back in the middle. I put it in the vice and bent the edges for support to match the original brace.

Hopefully try to patch the sheetmetal this week.

I cut the hole a little more square. Tried to hammer the edges a little flatter and made a brace out of 1/8" steel to weld back in the middle. I put it in the vice and bent the edges for support to match the original brace.

Hopefully try to patch the sheetmetal this week.