|

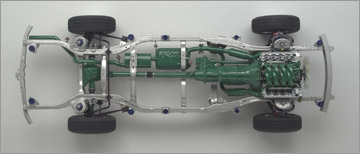

2006 Ford Explorer Powertrain

MOST POWERFUL AND REFINED EXPLORER

EVER

The 2006 Ford Explorer’s advanced engine

technologies improve both the drive experience and the environment.

The 2006 Explorer with the standard V-6 engine produces 74

percent less smog-forming emissions than the previous model. In

fact, V-6-powered Explorers are expected to be certified to the same

federal tailpipe emissions standards as the Ford Escape Hybrid, the

world’s cleanest SUV.

Additionally, fuel economy for the

all-new 4.6-liter three-valve V-8 engine paired with the new

six-speed transmission is expected to increase by up to 10 percent,

while delivering 53 more horsepower.

“Performance and fuel

economy can go hand-in-hand if you invest in the right

technologies,” says Dave Szczupak, vice president, Powertrain

Operations. “That’s why Ford is investing in six-speed automatic

transmissions, electronic throttles, variable cam timing and other

advanced powertrain technologies.”

Ford has a leadership

position in powertrain technologies such as six-speed automatic

transmissions to simultaneously boost performance — without

necessarily going to larger engines — and fuel economy with

the wider ratio spreads allowed by the extra gear. This investment

in technology is particularly appropriate in the SUV market, where

Ford is increasing capability without resorting to

larger-displacement engines that consume more fuel.

“The

new V-8 and six-speed automatic drivetrain is a tremendous advantage

for the 2006 Explorer,” says Raj Nair, SUV and Body-on-Frame

Vehicles executive director. “Not only does it offer more power,

more refinement and better fuel economy, but it also offers

increased utility. The additional power output helps Explorer

deliver improved payload — up to 1,520 pounds — and a

7,300-pound maximum towing capacity when properly equipped.”

Explorer’s standard powertrain is a refined version of the

SOHC 4.0-liter V-6, paired with a five-speed automatic. Both

powertrains boast modifications to improve noise, vibration, and

harshness.

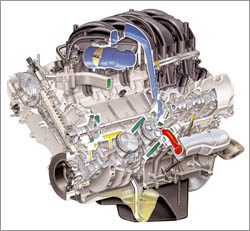

Three-valve heads,

variable cam timing, muscle car power

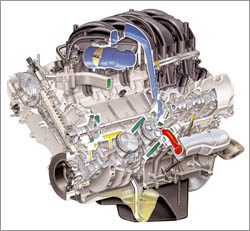

The 2006 Ford Explorer features a new,

4.6-liter, 3-valve V-8 with variable cam timing, delivering 292 hp

and 300 ft.-lbs. of torque.

|

The most

significant powertrain improvement, from the driver’s perspective,

is the new 4.6-liter V-8, with three-valves per cylinder, and single

overhead cams with variable cam timing. These features are common

with the highly lauded 2005 Ford Mustang GT, as well as the

5.4-liter V-8 in the F-Series pickups and Expedition. With the

introduction of the Explorer, Ford Motor Company is approaching one

million three-valve V-8s produced. This multi-application approach

to Ford’s “modular” V-8s delivers benefits in manufacturing

efficiencies, proven customer reliability, and performance.

In the Explorer, the 4.6-liter V-8 delivers 292

horsepower. The slight decrease in output from Mustang’s 300

horsepower can be attributed to a more restrictive exhaust necessary

to accommodate Explorer’s available four-wheel-drive system.

The new head enables a higher compression ratio on regular grade 87

Octane gasoline. Two of the three valves assigned to each cylinder

are intake valves because more airflow into the engine means more

power output. A new, tuned-length exhaust manifold offers optimized

exhaust flow to help scavenge burned gases from the cylinders.

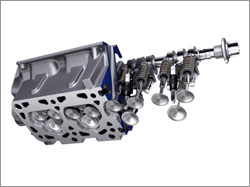

The three-valve heads feature center-mounted sparkplugs

that offer three benefits:

- Placing the sparkplug in the

center of the cylinder provides symmetrical flame for more complete

fuel combustion. This extracts more power from the engine while

decreasing the amount of unconsumed fuel in the exhaust system,

resulting in low emissions

- A longer and narrower spark

plug design enabled powertrain engineers to use larger-diameter

valves, for increased economy and performance

- The compact

coil-on-plug ignition system enables the powertrain control module

(PCM) more precise spark control, again for improved efficiency

The three-valve heads are smaller and lighter than

equivalent four-valve heads. Their large dual intake ports provide

a direct path to the twin intake valves for better airflow at peak

engine speeds. At lower speeds and loads, a charge motion control

valve (CMCV) closes, increasing air velocity and in-cylinder motion

for optimum fuel economy. Likewise, lightweight intake and exhaust

valves reduce inertia for high-speed performance capability, while

enabling lower friction for fuel economy. The cylinder heads are

capped with lightweight magnesium cam covers that help suppress

valvetrain noise.

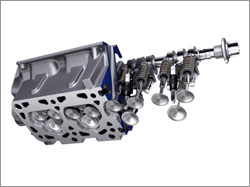

The ABCs of

VCT

Variable camshaft timing (VCT) plays an

important part in generating more power as well as improving

efficiency and reducing emissions.

The VCT system allows

up to 50 degrees of cam variation in relation to the crankshaft

angle. Ford’s “dual-equal” variable cam timing design shifts the

timing of both the intake and exhaust valves together, with a single

camshaft per cylinder head. This provides all the benefits of

variable valve timing — but creates far less complexity and

adds less weight than VCT systems that actuate the intake valves

separately.

The single-overhead-cam heads feature “dual

equal” variable cam timing that rotates the camshafts up to 50

degrees in relation to the crankshaft.

|

The cam in each cylinder head operates both sets

of valves using low-profile roller-finger followers, helping reduce

friction. The powertrain control module (PCM) directs solenoids to

alter the oil flow in the hydraulic cam timing mechanism, which

rotates the camshafts in relation to their drive sprockets. The

unit can shift between fully advanced and fully retarded in

milliseconds.

The result is enhanced efficiency under

low-load conditions, such as at idle or highway cruising, and

increased power for brisk acceleration for times of high

demand.

Paired with the six-speed automatic, 4×4 V-8 models

are expected to deliver up to a 10 percent increase in fuel economy,

or two miles per gallon. Just as significant, it is anticipated to

qualify for Tier II Bin 5 emissions certification, which is

compliant with California’s Low Emissions Vehicle II (LEV II)

standards.

Class-leading

six-speed automatic transmission

The 4.6-liter V-8

comes standard with a new six-speed 6R automatic transmission,

introducing transmission technology normally found only in luxury

vehicles to the mid-price mid-size SUV segment.

For the

best possible shift quality, each 6R transmission is bench tested at

Ford’s Livonia (Mich.) Transmission Plant. There, the transmission

build quality is verified, detecting even minute variabilities in

the manufacturing process. These variances would normally lead to

changes in shift feel. However, the 6R’s electronic controller is

programmed with its own unique software to account for these

variances, producing smooth, precisely controlled shifts that

improve durability and customer satisfaction.

The class-leading, six-speed 6R electronically

controlled transmission features the first console-mounted shifter

in an Explorer.

|

The electronically controlled

transmission offers the smooth shift quality of a luxury car, but is

fully tested for heavy-duty use. In fact, it contributes to the

7,300-pound maximum towing capacity of the V-8 drivetrain. For

example, the torque converter assembly features three friction

plates with improved durability, and increased cooling flow for

heavy-duty, high-load use.

New for 2006, the transmission

selector is mounted on the center console (rather than the steering

column.) As a result, the transmission can be shifted manually with

crisp response, thanks to full electronic solenoid control of the

clutch elements. Lastly, focalized transmission mounts mean an even

greater reduction in NVH levels.

The 6R has a 6.04:1 gear-ratio span. The company’s 5R55W5 automatic

has a span in the range of 4.5:1. The wide ratio span of the 6R

enables the engine to spend more time in the optimum powerband

— either at peak power for acceleration, or at peak efficiency

for more fuel economy.

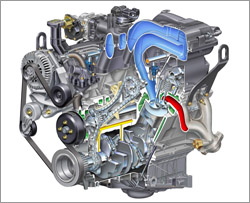

Cleaner

emissions on standard V-6 engine

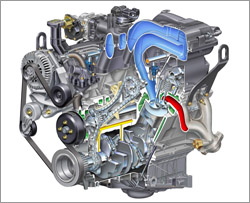

Explorer’s standard

4.0-liter SOHC V-6 engine received significant improvements for the

2006 model year as well. New engine calibrations and an improved

emission controls cut smog-forming emissions by 74 percent. Idle

quality was improved by 50 percent, thanks to a new camshaft and

spark plugs.

The 4.0-liter SOHC V-6 produces the same 210 hp

of its predecessor, but now produces 74 percent less smog-forming

emissions.

|

Additionally, the 2006 Explorer V-6 is expected to be certified to

the same federal tailpipe emissions standards as Ford’s Escape

Hybrid, the world’s cleanest SUV.

The 4.0-liter V-6 is

rated at 210 horsepower at 5,100 revolutions per minute and 254

foot-pounds at 3,700 revolutions per minute.

The torque

curve is designed to be relatively flat across the entire engine

range and to provide strong performance at nearly any engine speed.

An equal-length composite plastic intake system improves sound

quality.

The V-6 engine comes with a five-speed automatic

transmission. The wide-ratio five-speed 5R55W provides good

acceleration and fuel economy. In addition, the 5R55W has a single

aluminum transmission casting that greatly reduces NVH and

powertrain bending at higher speeds. To reduce noise, it utilizes a

quieter oil pump and planetary gear designs.

Cooling system designed to pass rigors of Ford

truck towing tests

The 2006 Explorer also features

an improved cooling system, delivering increased capability,

decreased NVH, and improved fuel economy.

The clutch that

operates the cooling system fan is now under the command of the

powertrain control module. This electronic control allows the fan

to be operated at just the right time to keep the engine within the

proper range of operating temperature yet not run so long as to draw

off engine power and draw down fuel economy. Controlling when the

fan operates, how long it operates and how fast it operates also

makes it less intrusive in terms of NVH.

The cooling system

is a key component in the Explorer’s impressive payload and towing

capability. One of the most tortuous tests Explorer is subject to

is the Davis Dam towing test in Arizona. The truck is loaded down

to its maximum gross vehicle weight, and then climbs up the Davis

Dam grade as the ambient temperature peaks over 100 degrees. This

is just one of the battery of towing tests Explorer must pass to

certify that its engine and transmission cooling systems are up to

the task, not to mention its engine calibration and system hardware.

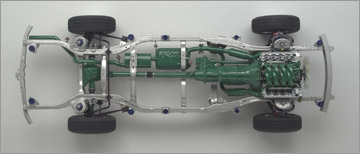

New driveshafts improve

NVH

As part of its campaign to elevate refinement of

the 2006 Explorer, Explorer also features new driveshafts.

On V-6 models, the traditional aluminum-tube driveshaft is

engineered for improved balance and decreased run-out.

To

accommodate the longer 6R transmission, V-8 Explorers have new,

improved “slip-in-tube” driveshafts. These feature a pair of

splined tubes that plunge into one another, eliminating the need for

the steel slip and forged stud yokes used in conventional

slip-between-center driveshafts.

2006 Explorer 4×4 models feature improved

slip-in-tube driveshafts, differential mounts and transfer-case

mounts for improved NVH isolation.

|

The slip-in-tube

driveshaft is more resistant to bending than conventional

driveshafts and thus is inherently less prone to NVH. In addition,

the increased overlap between the tubes enables increased driveshaft

extension, as well as increased durability.

A computer

numerically controlled (CNC) cold rolling spline process is used to

make the slip-in-tube driveshaft. That means that no material

— inside or outside — is machined away. The primary

benefit of this process is that it allows the tubes to slide in and

out of each other easily, even under heavy torque, which eliminates

unpredictable NVH behavior and provides a smooth, quiet ride.

Finally, the rear differential mounts of all 2006

Explorers have been reconfigured for improved isolation, greater

durability and reduced NVH. The differential is suspended by four

mounts: Two, close-set, vertical mounts are connected to the front

of the differential casing, while two vertical mounts have a wider

stance at the rear of the casing. Like the legs of a table, these

wide set mounts better stabilize the differential, for improved

isolation and durability.

Control Trac® delivers automatic torque

split, low-range

Explorer continues to offer the

advanced Control Trac® four-wheel-drive system. It includes

electronic logic and a two-speed transfer case with a locking center

differential.

Control Trac® is an advanced

four-wheel-drive system that allows a driver to select between three

driving modes:

- The 4×4 AUTO (or A4WD) mode provides full

power to the rear axle until the rear wheels begin to slip. Then

power is automatically proportioned to the front axle as required

for increased traction. This mode is appropriate for any driving

condition.

- The 4×4 HIGH (4H) mode effectively locks the

center differential, providing a constant 50/50 torque split between

the front and rear axles. It only is intended for severe winter or

off-road conditions, such as deep snow and ice and shallow sand.

- The 4×4 LOW (4L) mode locks the transfer case and engages

a torque-multiplying gear set in the transfer case. It only is

intended for off-road applications that require extra power

including deep sand, steep grades and towing a boat trailer out of

water.

These powertrain changes help Explorer retain its

leadership, offering genuine SUV capability to tow or go off-road,

without compromising the fuel-economy, refinement, or performance

that have made the Explorer the benchmark of its class.

.

|