2004 Ford F150 Driving Dynamics

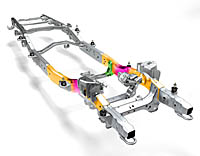

- Strength – All-new chassis brings improved dynamics and refinement to the pickup segment.

- Strong backbone – The industry’s stiffest, fully boxed frame with hydroformed front rails is approximately nine times stiffer in torsion for handling precision and ride isolation.

- Silence – Cab stiffness is improved by more than 75 percent, for a quieter, more composed ride.

- Stability – For additional stability and stance, the new F-150 has a wider track.

- Control – All-new coil-over-shock front suspension features aluminum lower control arms and rate-plate bushings.

- Suspension – Outboard rear shock absorbers and 20-percent wider rear springs provide greater roll damping and lateral stiffness for handling precision and a better ride.

- Response – New rack-and-pinion steering system has minimal friction and lash for steering control and feedback; “gripping” front stabilizer bushings help improve steering response.

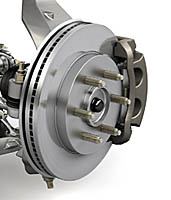

- Braking – All-new high-performance four-wheel disc brakes with standard four-wheel anti-lock control and electronic brake force distribution provide enhanced brake feel and confident stopping power.

- Torque – More torque, a laterally stiff rear suspension, precise steering and powerful brakes help make towing a trailer stress-free.

- Off-road – Unique 4-Low throttle calibration, stout structure and anti-lock brakes tuned for loose surfaces enhance off-road capabilities.

2004 FORD F-150 Driving Dynamics “To drive a tough pickup with this level of dynamics and ride comfort is most surprising and welcome. The new F-150 clearly provides a superior driving experience.” WHAT’S NEW FOR 2004

SUPERIOR DRIVING EXPERIENCE The all-new Ford F-150 delivers crisp and direct steering, the ride is plush yet controlled, the braking is assured and the cabin is quiet. Ford has brought its expertise in driving dynamics to F-Series, the best-selling vehicle in the world, and the result is a pickup truck that is an unqualified pleasure to drive. A SOLID FRAME, HYDROFORMED AND FULLY BOXED Essential to meeting the driving dynamics targets for the new F-150 is a solid and stable fully boxed frame with hydroformed front rails. It is approximately nine times stiffer in torsion and approximately 50-percent stiffer in bending than the current truck’s already robust backbone. A stiff frame is the enabler for the new F-150’s handling, ride and quietness. A frame that twists, bends or shakes excessively over bumps or while cornering would limit the ability of the suspension system to damp the input and therefore transmits vibration to the passenger compartment.

While hydroforming is used for the sections of the frame rails that bear the loads of the front suspension, the entire frame also is fully boxed to form a closed “box” section as opposed to the traditional “C” rail design. The result is increased stiffness and stronger attachment points for the brackets that attach the body and suspension to the frame – and minimal shake and shudder on rough roads. Advanced computer tools played a pivotal role in the design of F-150’s backbone, according to Anthony Selley, F-150 chassis supervisor. Digital three-dimensional representations of the frame, powertrain, suspension and body were run through deflection simulations that exaggerate actual movements by a factor of 50, to reveal areas that may need attention. “We were exploring thousands of design options at once,” said Selley. “The only way to do this is with computer-aided engineering. CAE allowed us to weigh all the options before we actually built the designs and subjected them to instrumented testing.” NEW SUSPENSION OFFERS IMPROVED RIDE A substantial contributor to the new F-150’s driving feel – plush, yet connected to road – is a front suspension system that reacts and absorbs bumps but stands strong against steering forces. Both 4×2 and 4×4 models use a new coil-over-shock, long-spindle double wishbone front suspension with a cast aluminum lower control arm. The use of cast aluminum is a first in the pickup truck segment, and by reducing “unsprung weight” (the parts of the suspension system that must move up and down with road irregularities) the aluminum lower control arm provides better ride and stability on choppy, broken surfaces. The front bushings are soft in response to road impacts but stiff for cornering capability, with ride tuning and handling tuning optimized independently. The ratio of lateral to longitudinal response of the aft lower control arm bushings is 29 to 1, which betters many performance sedans. Much of the all-new F-150’s previously unattainable combination of ride and handling comes from these subtle details.

F-150 engineers selected new “gripping” bushings to mount the front stabilizer bar. This novel design keeps the bushing compressed against the stabilizer bar, allowing the bushings to twist with it. The special design gives more linear loading for “crisper” steering response, yet maintains relatively low bushing rates for a smooth ride. The stabilizer bar ends use ball joints at both ends instead of rubber bushings, which further reduces compliance in the stabilizer bar system, providing for improved response. Mounting the shock absorber inside the coil spring is a packaging solution that allows four-wheel-drive models to use coil springs, permitting more precise suspension tuning and commonality across the lineup. In addition, the shock absorber has been moved closer to the wheel, providing increased mechanical advantage of approximately 25 percent. For increased stability and a more aggressive stance, the front track is 67.0 inches wide – an increase of 1.6 inches over the current F-150. In addition, the scrub radius of the front suspension has been reduced, which helps increase stability while braking, reduces tire wear and enhances handling and steering precision. OPTIMIZED REAR SUSPENSION F-150’s Hotchkiss-design rear suspension has been optimized with rear shock absorbers placed outboard of the frame rails – a segment exclusive. The shocks are positioned to maximize their effect at reducing the amount the truck leans, particularly during transitions like lane changes. They also provide better control of the axle “skipping” and “skating” that can happen on washboard-type surfaces. In any live-axle rear suspension, the two shock absorbers work in tandem to damp the vertical motion of the wheels when the truck traverses irregularities such as speed bumps. When the axle rolls in relation to the truck – when cornering or hitting a pothole, for example – the shocks also damp the axle’s movement, but are typically compromised by being located near the centerline of the vehicle, where the shocks have little “leverage” against the axle. This results in impact harshness, because the shocks need to be stiffened to compensate. The new F-150’s outboard rear shocks maximize the amount of leverage against lean – and because of this massive leverage advantage, the shocks can be tuned for a smoother ride. The rear leaf springs, which in addition to supporting the vehicle and its cargo also serve to locate the axle side-to-side and front-to-rear, are now 3 inches wide (20 percent wider than the current F-150 and the same width as on the Super Duty lineup) for less lateral motion during cornering and considerably better towing stability and controllability. Also contributing to the performance of the rear suspension is a track that is more than 1.5 inches wider than on the current model. PRECISE NEW RACK-AND-PINION POWER STEERING Improved steering response was a critical element in the engineering team’s goal of providing the new F-150 with good dynamics. To achieve the targets for on-center feel, steering response and precision, the team chose a rack-and-pinion steering system that is the largest, strongest and most rugged ever used by Ford. It is considerably stiffer than the recirculating-ball system used on the current F-150, and it has less operating friction. Both measures contribute to the accurate steering response and better driver feedback that makes the new F-150’s drive experience spirited and confidence-inspiring. The predictable, linear response of the steering comes from careful tuning by experienced engineers to help ensure that steering effort builds naturally with steering angle, and that response matches angle and effort. “You interact with the steering wheel for the entire time you are driving, and that interaction reveals more about the vehicle than anything else. As with the Ford Focus, the Escape, the Explorer and the Expedition, the steering wheel of the F-150 immediately communicates the performance potential of the vehicle,” said Dan Gompper, F-150 vehicle dynamics supervisor. In addition to its dynamic performance, the new F-150’s steering system also makes for a relatively tight 46-foot turning circle on SuperCab models with the 61/2-foot cargo box, which beats comparably equipped competitors. The F-150 SuperCrew has a smaller turning circle than the Dodge Ram Quad Cab. For the first time, F-150 has two steering rack ratios matched to the available wheelbases, which helps to provide a common steering feel across the model range. MORE POWERFUL BRAKES

New standard four-wheel disc brakes are larger and more powerful while providing better feel. The rotors are larger and thicker and the calipers are larger and even more robust – 60 percent stiffer – for enhanced stopping power and better brake pedal “feel.” Four-wheel anti-lock control (ABS) and electronic brake force distribution (EBD) are standard. As with the communicative steering, experienced engineers tuned the brake system for a natural, confidence-inspiring feel. Short pedal travel, reduced efforts and lack of any “dead zone” as the brakes are applied are prerequisites to good brake feel. Linear response of the pedal – in which force felt by the driver increases in direct proportion to the pedal travel – and linear vehicle deceleration are additional benefits the new F-150 brakes provide. The brake pads are made of high-friction semi-metallic lining material that helps provide increased stopping power. By going to a higher friction pad, engineers were able to fine-tune pedal feel by tailoring boost from the power brakes. This provides a linear stopping rate that is proportional to the amount of pedal force being applied.

The vented front discs have twin-piston calipers and are 330 millimeters (13 inches) in diameter, an increase of 22 millimeters (0.87 inches), or approximately 7 percent. The vented rear discs, with single-piston calipers, have a diameter of 348 millimeters (13.7 inches), an increase of 14 millimeters (0.55 inches). Increasing rotor size provides more surface area for brake pad contact, more powerful braking and better heat dissipation for more consistent braking performance in stop-and-go driving or while towing. Electronic brake force distribution (EBD) actively manages the brake force between the front and rear wheels, helping reduce braking distances and maximizing rear-wheel braking while towing. EBD uses data measured by sensors to compare wheel speed more than 100 times during each rotation. If wheel lockup is imminent, the EBD controller is able to redirect brake force within milliseconds to optimize available traction. The front suspension is designed to counteract any tendency for the front wheels to toe-out during any brake-induced body dive – the tendency for the nose of the vehicle to be forced downward during hard braking. Ford engineers have designed in a small amount of toe-in under braking to counteract most of the natural toe-out motion, resulting in minimal geometry change during braking and thus help achieve very predictable stops.

F-150’s new front suspension design places the brake deeper inside the wheel, which reduces scrub radius – the distance between the tire patch center and the steering pivot. Reducing the scrub radius reduces leverage on the steering pivot applied by road forces, further increasing stability and steering control while braking. The new F-150 has a dramatically decreased scrub radius – 15 millimeters vs. 50 millimeters in the 2002 F-150. TOWING PERFORMANCE The new F-150’s chassis and powertrain make pulling a trailer easier than ever. Its laterally stiff new rear suspension helps to resist side loads. The outboard rear shocks help reduce overall axle motion, while the 20-percent wider leaf springs limit side-to-side motion. Precise steering and a stiff frame and body contribute to confident, stress-free trailering, while powerful brakes, beefed up for greater resistance to fade and enhanced by standard anti-lock control and electronic brake force distribution, maximize stopping power. The 5.4-liter, 3-valve Triton V-8 is expected to have competitive low-end torque, and the sophisticated electronic throttle control is designed to provide seamless, instant response and consistent transmission shift quality at various altitudes and vehicle loading. Four axle ratios – from 3.31:1 to 4.10:1 – are available, and all but the 3:31:1 can have optional limited-slip capability for enhanced traction. HIGH-TECH ELECTRONICS IMPROVE OFF-ROAD DRIVING

While the most dramatic improvement in the F-150’s drive experience comes on-road, Ford has steadily improved off-pavement performance with key upgrades. Four-wheel-drive models use the proven manual- or electronic shift-on-the-fly transfer case of the current F-150, and a selection of limited-slip rear axles is optional. The standard electronic throttle control allowed engineers to incorporate a dedicated low-range accelerator response strategy for better control of torque in the most slippery conditions and reduced bucking while crossing rough terrain. Aside from the new F-150, this type of system is available only on the new Range Rover and a $50,000 dedicated off-roader. Braking performance off-road was the subject of careful tuning. On loose surfaces like gravel, anti-lock brakes can sometimes result in less swift stops than with conventional brakes, although the ability to steer while braking with ABS is thought to outweigh the sometimes longer stopping distances. F-150 braking engineers were able to improve off-road stopping distances by approximately 13 percent on the new pickup. On rough roads, the stiff frame, compliant suspension and outboard rear shocks give excellent control, helping to reduce or eliminate the shaking, skating and axle hop certain surfaces can induce.

For the most serious off-road enthusiasts, the F-150 FX4 provides skid plates, heavy-duty shock absorbers, optional LT tires and a standard limited-slip 3.73:1 rear axle. LARGER WHEELS AND TIRES Even base series versions of the new F-150 are equipped with large 17-inch wheels, while Lariat versions have 18-inch wheels as standard equipment. Available tires range in size from P235/70R17 to LT275/65R18. COMFORTABLE, CONTROLLED RIDE The new F-150 combines a comfortable, isolated and well-supported ride with balanced communication between the vehicle and the driver. The new F-150’s superior frame stiffness, advanced body mounts and carefully tuned suspension work together to deliver a quieter, more comfortable ride.

From an engineering perspective, any piece of structural metal acts as a spring. The only variable is its stiffness – how far it will deflect for a given load. By designing stiffness into the F-150’s frame, engineers are able to use other, purpose-built springs to handle specific tasks, such as smoothing out the effects of road surface irregularities and isolating the passenger compartment from noise and vibration. For example, all of the suspension mounting points on the frame are robust and rigid “large-footprint” designs to provide a strong base for the suspension system. Likewise, the engine mounting location is reinforced so that the hydraulic engine mounts can do their job of absorbing powertrain vibrations before they can get to the passenger compartment. The bushings that attach the front suspension are soft in response to road impacts but stiff in response to cornering loads. Voids in key areas of the bushings let the rubber “give” under pressure and allow the front wheels to momentarily move rearward in response to a sharp jolt, resulting in a plusher ride. Their direction-specific response gives them considerable stiffness against cornering loads, however, so the ride comfort they provide does not compromise steering response.

The front suspension’s lower control arms are made of cast aluminum – a pickup truck first – to reduce “unsprung mass,” the parts of the vehicle that move up and down as the suspension compresses and extends. The heavier a suspension component, the more likely it is to resist motion initially in response to a change in the road surface – and the longer it tends to remain in motion after the irregularity has passed. SHEAR-STYLE BODY MOUNTS Body mounts were also the subject of careful engineering innovation. These mounts serve to isolate the passenger compartment from vibrations that reach the frame. The mounts on both sides of the passenger cabin are built with a “shear” design. The basic concept is that of two concentric tubes, one bolted to the frame, the other bolted to the body structure. Rubber is bonded between the two tubes. As with the front suspension’s control arm bushings, this design gives direction-specific response and protects the bushing material from the elements.

The metal tubes in the shear-style mounts also serve a crucial function in improving crash performance by limiting fore and aft movement of the passenger compartment. Body and engine mounts were computer designed, but then subjected to repeated evaluation to make sure they achieved the team’s goal: a quieter cabin and a more comfortable ride. Computer tools include three-dimensional representations of the frame, powertrain, suspension and body, which can be run through deflection simulations that exaggerate actual movements by a factor of 50, to reveal areas that may need attention. STIFF BODY STRUCTURE The new F-150’s body structure is approximately 75 percent stiffer than that of the current truck, which means that vibrations that are transmitted to the cab are less likely to induce after-shake, squeaks or rattles. Particularly impressive is that the gains in cab stiffness were made in conjunction with lengthening both Regular Cab and SuperCab models by 6 inches, and adding standard dual rear access panels on Regular Cabs.

A key contributor to the new F-150’s stiff body structure is a special structural adhesive used to join the stampings that comprise the body’s floor. Applied by robots for consistency and speed, the adhesive bonds the metal in the spaces between spot welds, forming a continuous seam. This provides increased stiffness, and reduces the localized stresses at the spot welds, for durability. Many of the body stiffness improvements that promote a quiet cabin came from the aggressive efforts to provide integrity of the body shell during crashes. High-strength-steel reinforcements – particularly at the rocker panels – and stiff door openings are chief among these improvements. |