Ford F-150: How to Replace Front Struts and Shocks

If you notice the back of your car hitting the pavement, the shock fluid is visible, the front of your Ford F-150 pushes forward when you press the breaks, the car moves side to side when driving around corners or your car vibrates even when driving on smooth roads, it is time to replace your front struts and shocks.

Modern F-150s have a combination of shock absorber and coil spring called a "strut." The shocks on your Ford F-150 help maintain of your tires for a smooth drive while on the road. When you drive over pot holes and bumps, these parts create a comfortable drive for both the driver and passenger. If you notice the back of your car hitting the pavement, the shock fluid is visible, the front of your truck dips when you press the brakes, the car moves side to side when driving around corners or your car vibrates even when driving on smooth roads, it is time to replace your front struts.

Materials Needed

- Tire iron

- 15mm socket/wrench

- 17mm socket

- 18mm deep socket

- 21mm deep socket

- 30mm socket

- 1 1/16" wrench

- Floor jack

- Jack stands

- Pitman arm puller, pickle fork (not required)

- Spring compressor tool

Step 1 - Loosen wheel from suspension

Pry off the cap in the center of the rim with a flat head screw driver. There's a small notch in the wheel specifically for that. Use the tire iron to slightly unscrew the lug nuts without taking them off completely.

Step 2 - Lift truck and remove wheel

Use the floor jack to lift the truck by the front suspension crossmember. Put a jack stand under this area and lower it until weight is firmly distributed. To maintain safety, keep the jack in the same place. Finally, remove the lug nuts and wheels.

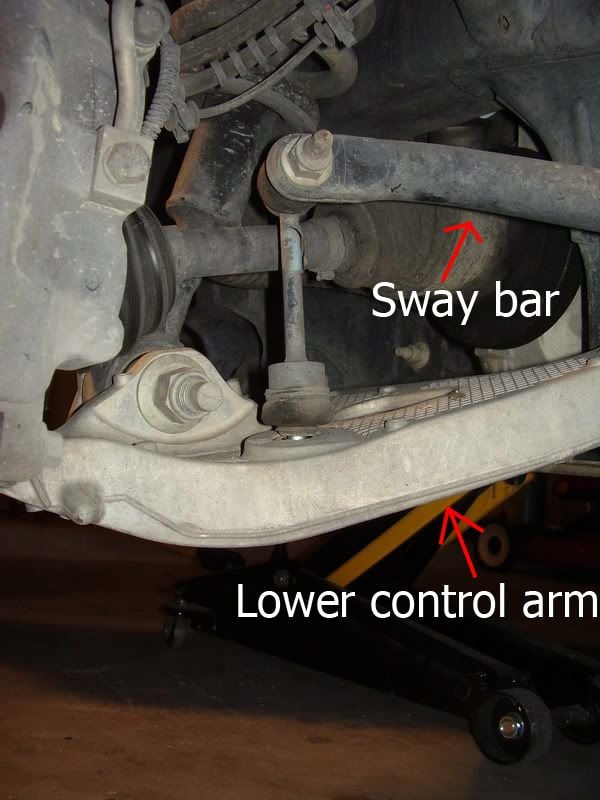

Step 3 - Unbolt bottom of sway bar end link

Use an 18mm socket to unbolt your sway bar endlink from the lower control arm. This will allow the control arm to move downward when you're removing the sway bar.

Step 4 - Unbolt strut

Have a second person help you with using a 30mm socket and 1-1/26 wrench to take off the bolt on the lower strut. Remove the three upper strut nuts using a 15mm socket.

-

Figure 4. Use another wrench to hold the nut on the opposite side steady while removing the bolt. -

Figure 5. There are three bolts on the top of the strut holding it in place. Two are highlighted in this picture and the third is not visible.

Step 5 - Disconnect wheel spindle from ball joint

Use a 21mm deep socket to loosen up the ball joint bolt nut. Take the ball joint off of the spindle with a pitman arm puller and take the floor jack from under the control arm. Without the the jack to support it, the control arm pull downward. This will allow you the flexibility and leverage to separate the wheel spindle from the upper ball joint. With the ball joint and all bolts free, remove the strut.

-

Figure 6. Remove the bolt connecting these the control arm (top) and the wheel hub. Spray with a penetrating lubricant (PB blaster, liquid wrench, et cetera) if the bolt is stuck. -

Figure 7. Ford recommends using a pitman arm puller to separate the two. If you don't want to buy one, you could also use a few taps with a hammer, or a pickle fork.

Step 6 - Replace old strut

Place the new strut where the old one went. Tighten the strut in its place with 17mm nuts. Fasten the lower strut bolt and nut.

-

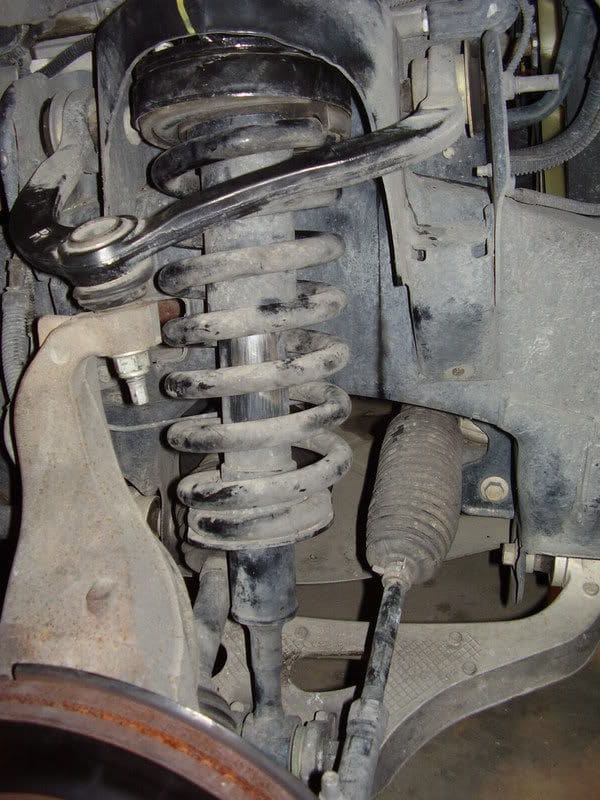

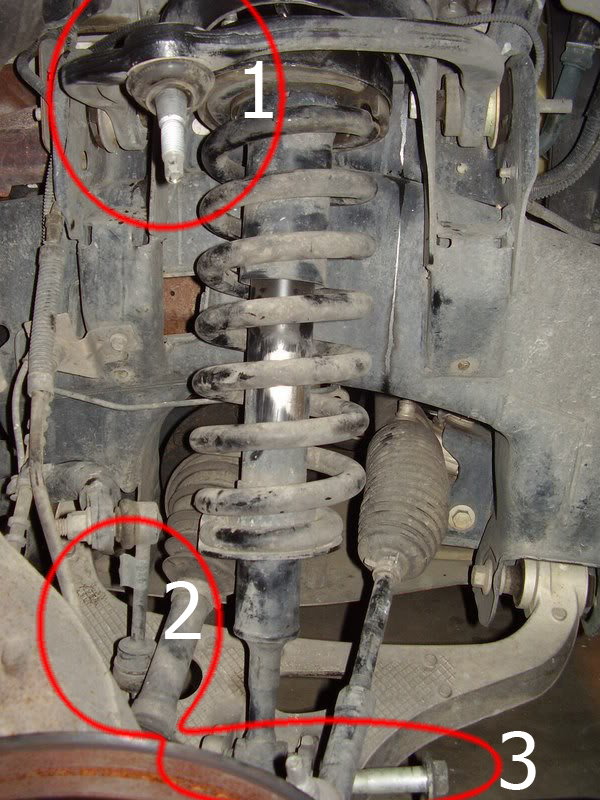

Figure 8. Strut with all other suspension components installed. -

Figure 9. Strut with other suspension components uninstalled.

1. Notice that the upper ball joint is free from the wheel spindle.

2. The tie-rod end link is separate from the control arm.

3. The lower shock bolt is also pulled out. -

Figure 10. Strut removed from truck.

Step 7 - Reattach suspension

Have a second person help you with bolting the ball joint and upper control arm on the spindle and make sure to have a 21mm nut available to put the ball joint bolt back on and tighten the 21mm ball joint nut. Remember to tighten and put on the 18mm sway bar nut.

Step 8 - Reattach wheel

Place the tire and lug nuts on. Tighten lug nuts

Pro Tip

For those who are interested in replacing the front struts and shocks by yourself, please keep in mind that using a spring compressor to do the job is highly recommended to ensure your safety. In some cases, certain cars can have these parts replaced with 2-4 personal compressors, but springs for trucks are heavy. After the work is done, get an alignment on your car.

Related Discussion

- How to Install a Levelling Kit- F150online.com

- Why Replacing Front Struts at Home Might be Dangerous - Ford-trucks.com