96 5.8 compression ratio

#1

96 5.8 compression ratio

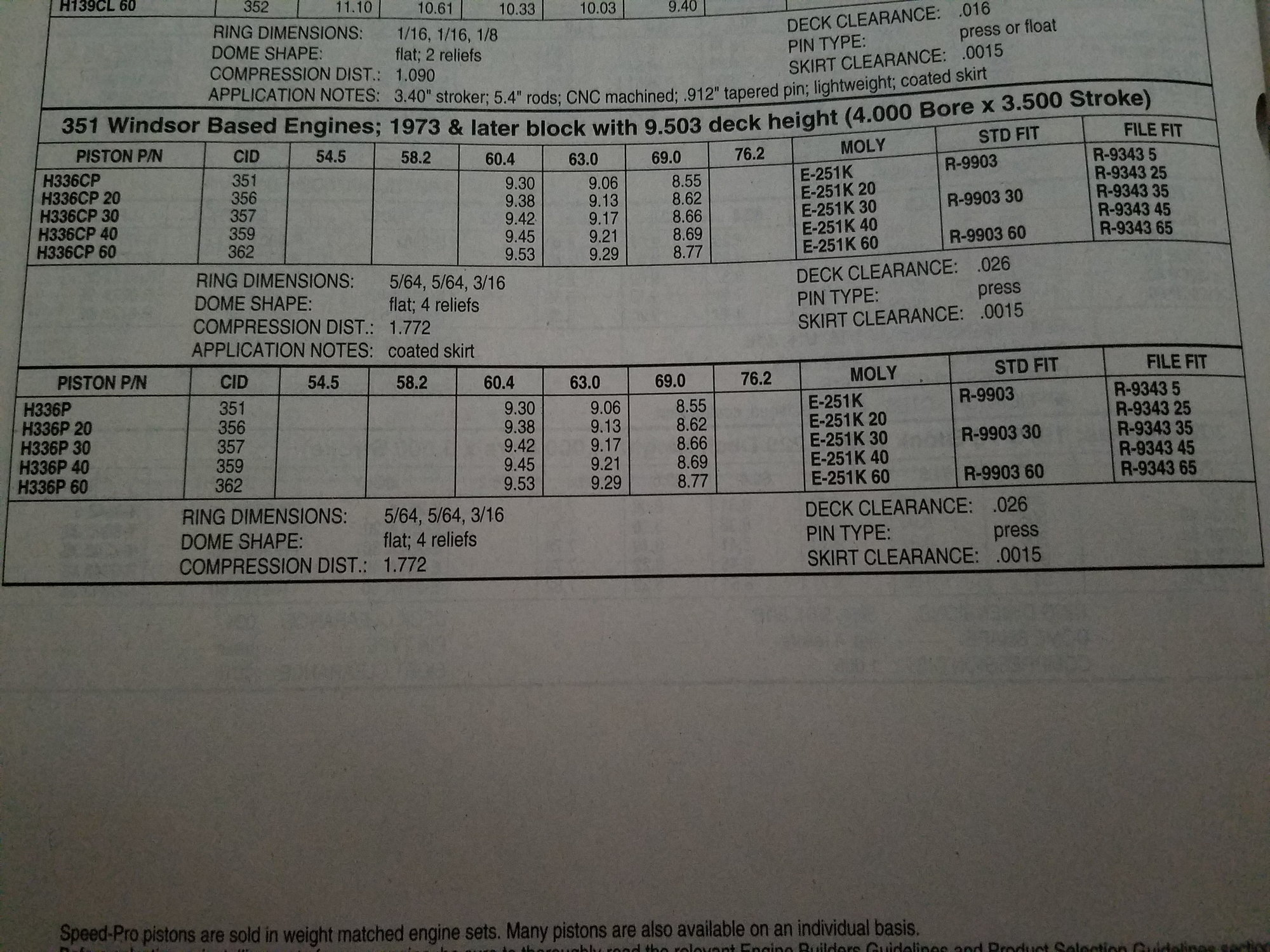

Hi guys, I need a little help figuring my compression ratio. GT40 heads (F3ZE casting), stock thickness head gasket, piston is a .020 over, compression height 1.772, flattop with 12cc valve reliefs. Deck and heads have not been shaved. I was figuring around 9.0:1 to 9.5:1 ratio. Am I in the ballpark?? Thanks a lot!

#3

#6

#7

Trending Topics

#8

I used this to compute my compression ratio: Engine Compression Ratio (CR) Calculator SBFTECH.com

Bore: 4.020"

Stroke: 3.5"

Head Gasket Bore: 4.100"

0.039" head gasket

Combustion Chamber volume: 64

Piston dome volume: -12cc (valve reliefs)

Piston deck height: 0

Calculated C/R: 9.62:1

Some things should be measured, like CC volume, and piston deck height, so that you know what they are and are not left guessing.

We know stock, these were 8.8:1. Testing the calculator, 4" bore, 3.5" stroke, gasket 0.039", 64cc CC, -20cc dish pistons, zero decked. 8.8:1, just like Ford lists. I measured stock pistons at -20cc last fall, along with the piston deck height on an unmolested 96' 351W being 0.

Bore: 4.020"

Stroke: 3.5"

Head Gasket Bore: 4.100"

0.039" head gasket

Combustion Chamber volume: 64

Piston dome volume: -12cc (valve reliefs)

Piston deck height: 0

Calculated C/R: 9.62:1

Some things should be measured, like CC volume, and piston deck height, so that you know what they are and are not left guessing.

We know stock, these were 8.8:1. Testing the calculator, 4" bore, 3.5" stroke, gasket 0.039", 64cc CC, -20cc dish pistons, zero decked. 8.8:1, just like Ford lists. I measured stock pistons at -20cc last fall, along with the piston deck height on an unmolested 96' 351W being 0.

#9

I used this to compute my compression ratio: Engine Compression Ratio (CR) Calculator SBFTECH.com

Bore: 4.020"

Stroke: 3.5"

Head Gasket Bore: 4.100"

0.039" head gasket

Combustion Chamber volume: 64

Piston dome volume: -12cc (valve reliefs)

Piston deck height: 0

Calculated C/R: 9.62:1

Some things should be measured, like CC volume, and piston deck height, so that you know what they are and are not left guessing.

We know stock, these were 8.8:1. Testing the calculator, 4" bore, 3.5" stroke, gasket 0.039", 64cc CC, -20cc dish pistons, zero decked. 8.8:1, just like Ford lists. I measured stock pistons at -20cc last fall, along with the piston deck height on an unmolested 96' 351W being 0.

Bore: 4.020"

Stroke: 3.5"

Head Gasket Bore: 4.100"

0.039" head gasket

Combustion Chamber volume: 64

Piston dome volume: -12cc (valve reliefs)

Piston deck height: 0

Calculated C/R: 9.62:1

Some things should be measured, like CC volume, and piston deck height, so that you know what they are and are not left guessing.

We know stock, these were 8.8:1. Testing the calculator, 4" bore, 3.5" stroke, gasket 0.039", 64cc CC, -20cc dish pistons, zero decked. 8.8:1, just like Ford lists. I measured stock pistons at -20cc last fall, along with the piston deck height on an unmolested 96' 351W being 0.

#10

DO NOT use a thicker than stock gasket. You'll be going the wrong direction in regard to quench.

The way 'boarding showed his calculations is the correct way to go about it, also the way he emphasized the defining of *all* variables is the only way to move forward in your calculations.

if you're willing to run 93 octane (or 91 for you unlucky parts of the country) fuel, you might as well get as much compression out of it as you can within reason....I build these to 10.5:1, but anything around 10+ will be nice and snappy. I use cometic .030 thick MLS gaskets for both compression increase and optimizing quench. The MLS gaskets also endure the higher compression vs steel core. Milling the heads is the next easiest way to fine tune your compression ratio. You have little to worry about in terms of piston to valve clearance, as the cams on these close early and open late compared to a race oriented cam selection, so have at it. If you go with the added compression, you will not be disappointed.

The way 'boarding showed his calculations is the correct way to go about it, also the way he emphasized the defining of *all* variables is the only way to move forward in your calculations.

if you're willing to run 93 octane (or 91 for you unlucky parts of the country) fuel, you might as well get as much compression out of it as you can within reason....I build these to 10.5:1, but anything around 10+ will be nice and snappy. I use cometic .030 thick MLS gaskets for both compression increase and optimizing quench. The MLS gaskets also endure the higher compression vs steel core. Milling the heads is the next easiest way to fine tune your compression ratio. You have little to worry about in terms of piston to valve clearance, as the cams on these close early and open late compared to a race oriented cam selection, so have at it. If you go with the added compression, you will not be disappointed.

#11

DO NOT use a thicker than stock gasket. You'll be going the wrong direction in regard to quench.

The way 'boarding showed his calculations is the correct way to go about it, also the way he emphasized the defining of *all* variables is the only way to move forward in your calculations.

if you're willing to run 93 octane (or 91 for you unlucky parts of the country) fuel, you might as well get as much compression out of it as you can within reason....I build these to 10.5:1, but anything around 10+ will be nice and snappy. I use cometic .030 thick MLS gaskets for both compression increase and optimizing quench. The MLS gaskets also endure the higher compression vs steel core. Milling the heads is the next easiest way to fine tune your compression ratio. You have little to worry about in terms of piston to valve clearance, as the cams on these close early and open late compared to a race oriented cam selection, so have at it. If you go with the added compression, you will not be disappointed.

The way 'boarding showed his calculations is the correct way to go about it, also the way he emphasized the defining of *all* variables is the only way to move forward in your calculations.

if you're willing to run 93 octane (or 91 for you unlucky parts of the country) fuel, you might as well get as much compression out of it as you can within reason....I build these to 10.5:1, but anything around 10+ will be nice and snappy. I use cometic .030 thick MLS gaskets for both compression increase and optimizing quench. The MLS gaskets also endure the higher compression vs steel core. Milling the heads is the next easiest way to fine tune your compression ratio. You have little to worry about in terms of piston to valve clearance, as the cams on these close early and open late compared to a race oriented cam selection, so have at it. If you go with the added compression, you will not be disappointed.

#14

#15

I wouldn't buy gaskets until I had the pistons in the block. My machine shop advised decking the block & heads for a long lasting head gasket seal. Don't have to take much off just want the surfaces clean & true. This is why I wouldn't bother making the final call on head gasket until the pistons are in the block, and heads are ready to bolt on. Measure CC volume, dial indicator on the piston to check deck clearance. No guessing. I trust my machine shop, but everyone can make mistakes, so I measure their work to be sure. Then make a decision from there to hit your target.

EDIT: But, keep in mind what was said about squish! You want to prevent deto by ensuring squish is tight enough to have good quench. So, some planning of which pistons & heads to use is required. Can't run 53cc heads with flat tops and expect 8.5 CR via thick gasket; it'll ping worse than a properly built 9.7:1 version of the same thing.

EDIT: But, keep in mind what was said about squish! You want to prevent deto by ensuring squish is tight enough to have good quench. So, some planning of which pistons & heads to use is required. Can't run 53cc heads with flat tops and expect 8.5 CR via thick gasket; it'll ping worse than a properly built 9.7:1 version of the same thing.