Last edit by: IB Advertising

See related guides and technical advice from our community experts:

Browse all: Coolant System Guides

- How to Flush Radiator

Step by step instructions for do-it-yourself repairs

Browse all: Coolant System Guides

Gooch's Radiator/Engine Backflush Procedure and Coolant Information

#1

Gooch's Radiator/Engine Backflush Procedure and Coolant Information

6/24/15 Edit: If you're using a thermostat with a built-in gasket, disregard whenever a thermostat gasket is referenced. Back when these instructions were written, thermo's and gaskets were two separate pieces.

-----------------------------------------------------------------------------------------------------------------------

As most of you know, Gooch is the guru when it comes to coolants and ELC's. In his own words: "Coolants and cooling systems are my field of expertise...trained, educated, and experienced."

I've been meaning to post Gooch's procedure for quite some time now, but I keep putting it off. Well, my water pump is giving up the ghost and since I'm gonna switch over to Chevron Delo Extended Life Coolant when I change out the pump, I figure I'd better stop procrastinating.

I used this procedure a few years ago when I changed the water pump on my Ex and switched over to an ELC and it works great. I also contacted Gooch last year and asked him if all the info was still current. Gooch said it was and thought it was a great idea to post his info here in a thread strictly dedicated to the procedure, as well as listing all the info I've garnered from his posts, threads, and my own Internet research over the years. I just wish I hadn't procrastinated so badly!

--------------------------------------------------------------------------------------------------------------------------

Gooch's Radiator Flush Procedure

Here's the latest and most thorough instructions:

You'll need the following:

4 gallons of anti-freeze concentrate.

*Tip* Do not use 50/50 pre-mixed coolant. After flushing, residual water will remain in your engine and cooling system that you can't get out. Therefore, adding pre-mixed 50/50 will further dilute the solution and yield a weak freeze point, along with a low level of corrosion and cavitation inhibitors. Your cooling system holds approximately 8 gallons. Adding 4 gallons of concentrate after flushing, and then topping off with distilled water, will ensure optimal protection.

*Tip* International who made your engine, and who's engine your Ford cooling system was designed around, recommended a Heavy Duty Extended Life Coolant (HD ELC) for all 2/2/99-up built engines (SN 940614-up). These are generally red coolants with operation lives of 300K-750K miles/6-8 years, depending on brand. They are very robust and require no maintenance or additives. Popular brands include International's Fleetrite ELC, Shell Rotella ELC, CAT ELC, Chevron Delo ELC, Peak Final Charge, Prestone Heavy Duty ELC, Zerex Extreme Heavy Duty, etc.

*Tip* Due to International's compatibility tests, all pre-2/2/99 build engines (pre-SN 940614) should use a conventional coolant with the addition of SCA (or a pre-charged conventional coolant already charged with SCA). Most conventional coolants will be green, "low-silicate" and meet ASTM D4985. There are too many brands to list. They will require the addition of a supplemental coolant additive (SCA) at initial fill and maintenance of that SCA thereafter. Most pre-charged conventional coolants will be pink, purple, or blue and meet ASTM D6210. These coolants do not require an initial dose of SCA, but will require SCA maintenance thereafter. These are coolants like Peak Fleet Charge, Prestone Heavy Duty, Zerex Precharge, Shell Diesel Ready, Fleetguard Fleetcool, Fleetrite Fully Formulated, and so on.

*Tip* Do not use "All Makes - All Models" coolants, or "Universal" coolants. They will not meet the needs of your diesel engine.

SCA (if using conventional non-charged coolant). Amount depends on the SCA maker (usually 3-4 pints).

*Tip* Either a Nitrite only DCA-2 SCA or a Molybdate/Nitrite DCA-4 SCA will work. (Not applicable for those replacing coolant with an OAT Heavy Duty ELC)

Up to 20 gallons of distilled water

*Tip* Tap water contains undesirable minerals, chemicals, and pH. If your tap water is good quality, you can do fewer distilled water flushes.

A Prestone flush kit with 5/8" "T". HERE is a photo of a NAPA #720-1286 5/8" flush kit with "T".

*Tip* The "T" regulates and restricts faucet flow. Directly connecting to your faucet without one of these "T's" could damage your cooling system.

1-1/2 foot of 5/8" hose (to go on flush "T").

A new thermostat gasket. OEM Part# F4TZ-8255-A

*Tip* Now might be a good time to consider replacing:

Tools needed:

*Tip* A children's small plastic wading pool works good for a catch container. Some fit between the front wheels perfectly.

Flushing procedure:

Park truck on level surface. Allow to cool.

Remove degas bottle cap slowly (be careful if hot).

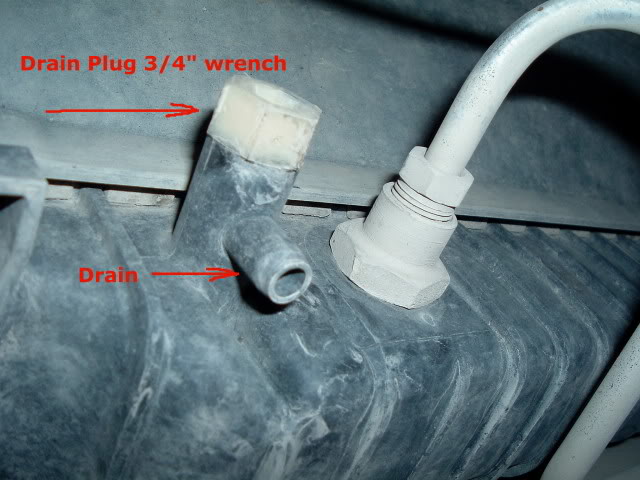

Use 3/4" wrench to losen radiator drain valve (bottom left-hand driver's side). Drain into suitable container. Expect at least a 5-gallon bucket-full.

Remove lower radiator hose (at radiator) and drain any sediment and/or coolant from radiator and hose into container.

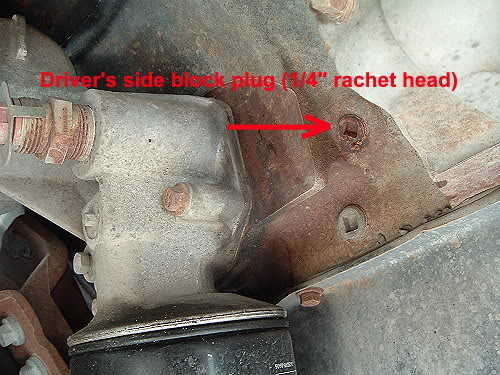

Remove driver's side block plug with 1/4" socket wrench driver, and drain coolant into suitable container.

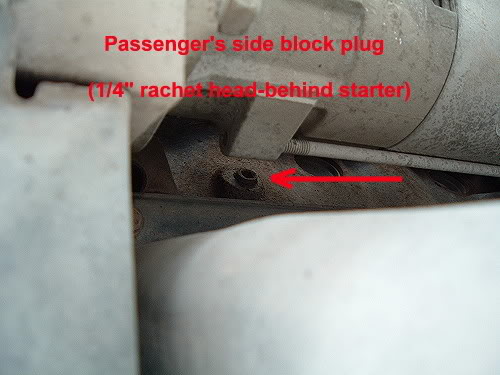

Remove passenger's side block plug with 1/4" socket wrench driver, and drain coolant into suitable container.

*Tip* This is best done without an extension on the wrench, working under the truck from the top rear side of starter - no need to remove starter.

Re-install both block plugs finger-tight.

Re-install lower radiator hose temporarily.

Close radiator drain valve.

Remove thermostat housing and thermostat.

Re-install thermostat housing without thermostat, using old gasket (it's ok if it leaks a little while flushing and running engine).

Remove heater hose at passenger's side coming off the engine (just below intercooler tube).

Install that heater hose to one end of the 5/8" flush "T".

Install 1 1/2 foot of 5/8" hose to other end of flush "T", Like this.

Install the remaining end of the 5/8" hose to fitting where the original hose was removed from the engine.

*Tip* You could permanently install the flushing "T" in the heater hose if desired. The heater hose removed in this procedure is the one consistent with what you'll find on the flush "T" directions. However, you could install the "T" on either heater hose.

Install garden hose onto flush "T", noting the direction of flow stamped on the "T".

Turn garden hose on until clear water (no green tint) runs (backflushes) out of top of degas bottle. This will take several minutes.

With hose still on, start and run engine for a couple of minutes, again until water coming out of degas bottle is clear (no green tint). Minor water leaks and spray from fan are normal.

Turn engine off. Turn garden hose off.

Drain radiator at drain valve, remove both block plugs, remove lower radiator hose.

Remove flushing "T", the extra 5/8" hose, and reinstall the original heater hose back onto engine.

Close radiator drain valve, reinstall and finger-tighten both block plugs, reinstall lower radiator hose (permanently).

Fill system with distilled water until the degas bottle is full.

Run engine a couple of minutes.

Drain radiator at drain valve, remove both block plugs.

Close radiator drain, reinstall and finger-tighten both block plugs.

Again, fill degas bottle with distilled water.

Run engine a couple of minutes.

Drain radiator at drain valve, remove both block plugs.

*Tip* You may decide to flush with distilled water one more time if your tap water is extremely bad.

Close radiator drain valve permanently. Do not over-tighten.

Install both block plugs and tighten permanently and firmly. Sealant can be used on the plugs sparingly, but it is not necessary.

Install thermostat and new thermostat gasket. If reusing the thermostat housing, use emery cloth to clean any rust/corrosion before installing.

Carefully torque the thermostat housing bolts to a maximum 15 ft-lbs. Do not over-tighten.

Add 4 gallons of anti-freeze concentrate to the degas bottle.

If using SCA, add it to cooling system per SCA manufacturer's instructions (usually 3-4 pints). Do not use SCA's if you're using an Organic Acid Technology Extended Life Coolant meeting CAT EC-1 specifications.

Add distilled water to finish filling the system until the degas bottle indicates between min/max.

Replace degas bottle cap.

Rinse off any coolant from engine and underbody of vehicle.

Turn in-cab heater valve all the way to "hot". This will help you determine if the thermostat is operating or if there is air left in the system.

Run engine (or drive truck for faster heating), until thermostat opens and hot air is felt through heater in cab. Periodically check coolant level adding distilled water as necessary. If heater does not get hot (or stay hot), it may be necessary to rev engine or purge air from the cooling system.

Add distilled water until level equalizes (min/max mark) in degas bottle (this may take several days).

Use test strip to test and add SCA if applicable. Again, not applicable if using an OAT ELC.

This method will yield approximately a 50/50 mixture of coolant/distilled water. It is always best to have the freeze/boil protection tested with a quality refractometer. Most shops will do this free.

Write down date and mileage of coolant maintenance for future use.

--------------------------------------------------------------------------------------------------------------------------

Additional coolant info to follow.

Stewart

EDIT: For clarity sake, obviously if you're gonna replace the coolant with an OAT ELC meeting CAT EC-1 specs, ignore the parts referring to SCA's

-----------------------------------------------------------------------------------------------------------------------

As most of you know, Gooch is the guru when it comes to coolants and ELC's. In his own words: "Coolants and cooling systems are my field of expertise...trained, educated, and experienced."

I've been meaning to post Gooch's procedure for quite some time now, but I keep putting it off. Well, my water pump is giving up the ghost and since I'm gonna switch over to Chevron Delo Extended Life Coolant when I change out the pump, I figure I'd better stop procrastinating.

I used this procedure a few years ago when I changed the water pump on my Ex and switched over to an ELC and it works great. I also contacted Gooch last year and asked him if all the info was still current. Gooch said it was and thought it was a great idea to post his info here in a thread strictly dedicated to the procedure, as well as listing all the info I've garnered from his posts, threads, and my own Internet research over the years. I just wish I hadn't procrastinated so badly!

--------------------------------------------------------------------------------------------------------------------------

Here's the latest and most thorough instructions:

You'll need the following:

4 gallons of anti-freeze concentrate.

*Tip* Do not use 50/50 pre-mixed coolant. After flushing, residual water will remain in your engine and cooling system that you can't get out. Therefore, adding pre-mixed 50/50 will further dilute the solution and yield a weak freeze point, along with a low level of corrosion and cavitation inhibitors. Your cooling system holds approximately 8 gallons. Adding 4 gallons of concentrate after flushing, and then topping off with distilled water, will ensure optimal protection.

*Tip* International who made your engine, and who's engine your Ford cooling system was designed around, recommended a Heavy Duty Extended Life Coolant (HD ELC) for all 2/2/99-up built engines (SN 940614-up). These are generally red coolants with operation lives of 300K-750K miles/6-8 years, depending on brand. They are very robust and require no maintenance or additives. Popular brands include International's Fleetrite ELC, Shell Rotella ELC, CAT ELC, Chevron Delo ELC, Peak Final Charge, Prestone Heavy Duty ELC, Zerex Extreme Heavy Duty, etc.

*Tip* Due to International's compatibility tests, all pre-2/2/99 build engines (pre-SN 940614) should use a conventional coolant with the addition of SCA (or a pre-charged conventional coolant already charged with SCA). Most conventional coolants will be green, "low-silicate" and meet ASTM D4985. There are too many brands to list. They will require the addition of a supplemental coolant additive (SCA) at initial fill and maintenance of that SCA thereafter. Most pre-charged conventional coolants will be pink, purple, or blue and meet ASTM D6210. These coolants do not require an initial dose of SCA, but will require SCA maintenance thereafter. These are coolants like Peak Fleet Charge, Prestone Heavy Duty, Zerex Precharge, Shell Diesel Ready, Fleetguard Fleetcool, Fleetrite Fully Formulated, and so on.

*Tip* Do not use "All Makes - All Models" coolants, or "Universal" coolants. They will not meet the needs of your diesel engine.

SCA (if using conventional non-charged coolant). Amount depends on the SCA maker (usually 3-4 pints).

*Tip* Either a Nitrite only DCA-2 SCA or a Molybdate/Nitrite DCA-4 SCA will work. (Not applicable for those replacing coolant with an OAT Heavy Duty ELC)

Up to 20 gallons of distilled water

*Tip* Tap water contains undesirable minerals, chemicals, and pH. If your tap water is good quality, you can do fewer distilled water flushes.

A Prestone flush kit with 5/8" "T". HERE is a photo of a NAPA #720-1286 5/8" flush kit with "T".

*Tip* The "T" regulates and restricts faucet flow. Directly connecting to your faucet without one of these "T's" could damage your cooling system.

1-1/2 foot of 5/8" hose (to go on flush "T").

A new thermostat gasket. OEM Part# F4TZ-8255-A

*Tip* Now might be a good time to consider replacing:

- Thermostat (OEM Part #F6TZ-8575-EA)

- Thermostat housing (OEM Part# F81Z-8592-AA)

- Upper radiator hose that goes around serpentine belt (OEM Part# F81Z-8260-CA)

- Lower Radiator hose (OEM Part# YC32-8286-CE)

- Degas bottle cap (OEM Part# F6DZ-8100-A)

- New coolant filter (if you've added one)

- Any hose clamps that you feel should be replaced.

Tools needed:

- 3/4" wrench for drain plug

- 8mm socket with ratchet and extension for thermostat housing bolts

- 1/4" socket driver for block plugs

- Pliers for hose clamps

- Torque wrench to re-torque thermostat housing bolts

- Emery cloth to clean thermostat housing and hose connections

- Bucket and suitable catch containers.

- Funnel

*Tip* A children's small plastic wading pool works good for a catch container. Some fit between the front wheels perfectly.

Flushing procedure:

Park truck on level surface. Allow to cool.

Remove degas bottle cap slowly (be careful if hot).

Use 3/4" wrench to losen radiator drain valve (bottom left-hand driver's side). Drain into suitable container. Expect at least a 5-gallon bucket-full.

Remove lower radiator hose (at radiator) and drain any sediment and/or coolant from radiator and hose into container.

Remove driver's side block plug with 1/4" socket wrench driver, and drain coolant into suitable container.

Remove passenger's side block plug with 1/4" socket wrench driver, and drain coolant into suitable container.

*Tip* This is best done without an extension on the wrench, working under the truck from the top rear side of starter - no need to remove starter.

Re-install both block plugs finger-tight.

Re-install lower radiator hose temporarily.

Close radiator drain valve.

Remove thermostat housing and thermostat.

Re-install thermostat housing without thermostat, using old gasket (it's ok if it leaks a little while flushing and running engine).

Remove heater hose at passenger's side coming off the engine (just below intercooler tube).

Install that heater hose to one end of the 5/8" flush "T".

Install 1 1/2 foot of 5/8" hose to other end of flush "T", Like this.

Install the remaining end of the 5/8" hose to fitting where the original hose was removed from the engine.

*Tip* You could permanently install the flushing "T" in the heater hose if desired. The heater hose removed in this procedure is the one consistent with what you'll find on the flush "T" directions. However, you could install the "T" on either heater hose.

Install garden hose onto flush "T", noting the direction of flow stamped on the "T".

Turn garden hose on until clear water (no green tint) runs (backflushes) out of top of degas bottle. This will take several minutes.

With hose still on, start and run engine for a couple of minutes, again until water coming out of degas bottle is clear (no green tint). Minor water leaks and spray from fan are normal.

Turn engine off. Turn garden hose off.

Drain radiator at drain valve, remove both block plugs, remove lower radiator hose.

Remove flushing "T", the extra 5/8" hose, and reinstall the original heater hose back onto engine.

Close radiator drain valve, reinstall and finger-tighten both block plugs, reinstall lower radiator hose (permanently).

Fill system with distilled water until the degas bottle is full.

Run engine a couple of minutes.

Drain radiator at drain valve, remove both block plugs.

Close radiator drain, reinstall and finger-tighten both block plugs.

Again, fill degas bottle with distilled water.

Run engine a couple of minutes.

Drain radiator at drain valve, remove both block plugs.

*Tip* You may decide to flush with distilled water one more time if your tap water is extremely bad.

Close radiator drain valve permanently. Do not over-tighten.

Install both block plugs and tighten permanently and firmly. Sealant can be used on the plugs sparingly, but it is not necessary.

Install thermostat and new thermostat gasket. If reusing the thermostat housing, use emery cloth to clean any rust/corrosion before installing.

Carefully torque the thermostat housing bolts to a maximum 15 ft-lbs. Do not over-tighten.

Add 4 gallons of anti-freeze concentrate to the degas bottle.

If using SCA, add it to cooling system per SCA manufacturer's instructions (usually 3-4 pints). Do not use SCA's if you're using an Organic Acid Technology Extended Life Coolant meeting CAT EC-1 specifications.

Add distilled water to finish filling the system until the degas bottle indicates between min/max.

Replace degas bottle cap.

Rinse off any coolant from engine and underbody of vehicle.

Turn in-cab heater valve all the way to "hot". This will help you determine if the thermostat is operating or if there is air left in the system.

Run engine (or drive truck for faster heating), until thermostat opens and hot air is felt through heater in cab. Periodically check coolant level adding distilled water as necessary. If heater does not get hot (or stay hot), it may be necessary to rev engine or purge air from the cooling system.

Add distilled water until level equalizes (min/max mark) in degas bottle (this may take several days).

Use test strip to test and add SCA if applicable. Again, not applicable if using an OAT ELC.

This method will yield approximately a 50/50 mixture of coolant/distilled water. It is always best to have the freeze/boil protection tested with a quality refractometer. Most shops will do this free.

Write down date and mileage of coolant maintenance for future use.

--------------------------------------------------------------------------------------------------------------------------

Additional coolant info to follow.

Stewart

EDIT: For clarity sake, obviously if you're gonna replace the coolant with an OAT ELC meeting CAT EC-1 specs, ignore the parts referring to SCA's

Last edited by Stewart_H; 07-19-2015 at 12:26 AM. Reason: Added some ELC language for clarity

#4

The following is an excerpt from a thread regarding questions that arose in the thread, where Gooch addressed those questions and issues. Keep this in mind when you see references to other people and topics that haven't been addressed in this thread.

The reason I post Gooch's response in its entirety is because I do not want to edit anything and possibly change how the information is meant to be applied.

As you can see, the info taken by and of itself is easily understandable without the "backstory" regarding the reason for the post.

-----------------------------------------------------------------------------------------------------------------------------------

Some errors and corrections...

I've been getting lots of PM's about Bob's coolant/SCA article (the sticky that was closed), and I would like to address a few things to help folks better understand. I think Bob realizes that much of his information is out-dated, pertains to certain engines other than our Powerstrokes, and is just plain wrong.

To give you a little background, first let me say that I've had extensive training and education in the field of coolants, some by the coolant manufacturers themselves. I worked with International during their cavitation crisis of the 6.9L and 7.3L IDI, helping to write bulletins, provide technical field data, and testing several different types of coolants, SCA's and mixtures thereof. I've operated and maintained a large fleet (100+ vehicles) of International/Ford 7.3L Powerstrokes. I am also a Mechanical Engineer with a background in Materials Science who has studied cavitation in cylinder walls and water pumps. Coolants are my specialty.

Where diesel cylinder cavitation is concerned, the bubbles are formed by the rapid flexing of the cylinder wall liners as the high compression, high energy diesel combustion process takes place. Much like if you filled a plastic liter pop bottle up with water and rapidly flexed the sides of the bottle back and forth with your hand. Bubbles form without any heat present. The bubbles in diesel cylinder wall cavitation don't explode, they implode due to pressure. It is this implosion against the metal surface that causes the pitting to form in the outside of the cylinder wall. Eventually the prolonged pitting become a hole. Water/coolant enters the cylinder, and thus we have engine failure (usually via hydrolock). Unlike gasoline engines, all diesel engines experience some level of inherent cavitation, some worse than others. FWIW, the Ford 6.9L and 7.9L IDI's originally had serious cavitation issues because Ford did not initially require (or add) SCA to the coolant. Ford later issued a bulletin to address that, and problems decreased dramatically.

As Bob stated, SCA's are one method of inhibiting cavitation by providing a barrier on the coolant side of the cylinder wall. However, I would like to say that it is not necessarily the SCA's displaced layer that can cause scale and coolant system plugging, but the components in the SCA itself, particularly when mixed with H2O or glycol. The use of conventional SCA is effective, but it requires testing, careful dosing, and frequent flushing. It will reduce heat transfer, and exacerbate water pump and other engine component failure.

One thing that importantly needs to be corrected, and a mistake than many misinformed people make, is that not all OAT coolants are like what GM uses. GM typically uses a "Dexcool" formulation, which is specifically not recommended for your diesel engine. Dexcool type coolants were never intended for diesel applications. There are many modern Heavy Duty Extended Life Coolants specifically designed for diesels. Delo ELC, Rotella ELC, International's Fleetrite ELC, CAT ELC, Mobil 1 ELC, and a host of others. They will address diesel cavitatation, provide superior metal corrosion protection, provide better heat transfer, require no testing and maintenance, be free of harmful abrasive silicates, borates, and phosphates, and have an operating life up to 1 million miles (Delo ELC). In fact International, who made your engine, recommends and factory-fills with these Heavy Duty Extended Life Coolants (Fleetrite ELC/Shell Rotella ELC). And in fact almost all heavy duty diesel manufacturers use Heavy Duty ELC's meeting the most strict requirements in the industry...Caterpillar's EC-1. Very little to do with GM's OAT coolant.

No where has Ford said you can not use a heavy duty ELC in your Powerstroke due to seal incompatibility. That is simply more misinformation. As we know International makes the engine and uses the HD ELC coolant, generally in more harsh, commercial applications. Seals are fine. The only coolants in the Owner's Manual Ford recommends you don't use are Dexcool and Ford's Specialty Orange. Owners and fleets have been using HD ELC successfully, and in fact with better success, for many, many years.

Another correction...Ford's Gold (G-05) coolant is nothing like a Heavy Duty ELC coolant. Thus is will not meet the more strict specs of other Heavy Duty ELC coolants, or provide the higher level of protection. The Gold is simply a universal hybrid, one-size-fits-all coolant that Ford uses in its entire line up that, with the exception of the Powerstroke, are all gasoline engines. Ford simply uses the Gold in your diesel out of convenience, simplicity, cost, and uniformity throughout it's product line and dealerships. The Gold coolant contains conventional (green coolant) components like silicate, which eventually form microscopic abrasives that eat water pump seals. It provides a lower level of cavitation protection using traditional SCA's like Nitrite, it has a shorter life, it reduces heat transfer compared to HD ELC's, and it in fact does require testing and SCA maintenance if you are an enthusiast about protecting your engine. In fact Ford recommends you add SCA to the Gold in certain F-Series applications. Caterpillar and John Deere also recommend adding SCA if it is going to be used in their diesels. Ironically, Ford's Gold will not meet International's heavy duty diesel B-1 spec. HD ELC's will. The Gold will work, but it's not the best.

For the record, adding SCA to a HD ELC will not produce anything close to "mud" or "goop". That is more misinformation. HD ELC's and SCA's are completely compatible, although not recommended only because you will lose the long-life properties of the HD ELC. There is no need to add SCA to HD ELC's. "Extenders" are available to add to HD ELC's if you want to further extend their life from the 300K, 500K, or 750K mile mark, depending on brand.

I have no intention of discrediting Bob's comments about the Evans and RMI-25, only to inform you. Evans is a good product, although expensive and hard to find. Less expensive, easier to find modern HD ELC's provide similar operating lives and similar (or better) protection. And the Evans does require modification of your cooling system to run low pressure, when your water pump seal is designed to run (and seal) under higher pressure, as documented by Ford. I have not used RMI-25 and don't plan to for reasons I won't discuss here. I would not recommend putting anything into your cooling system other than coolant and SCA.

Additionally, these days it is not appropriate to identify coolants by color. Color means nothing. A "green" coolant could be anything from a conventional, to a pre-charged, to a G-05, to an ELC. Same with red, purple, pink, gold, etc. You have to know what type of coolant it is.

There are 4 choices for your Powerstroke....

Conventional coolant (usually green) with the addition of SCA at initial fill. Frequent SCA testing and maintenance there after.

Pre-charged coolant (usually purple or pink). Comes with an initial dose of SCA. Frequent SCA testing and maintenance required thereafter.

G-05 coolants. Comes pre-charged with SCA package. Flush required at 50K miles. Semi-annual SCA testing and maintenance recommended.

Heavy Duty Extended Life Coolants. Come pre-charged with carboxylate inhibitors. No testing or maintenance. Super protection. Super long life.

Specialty coolants. Evans. Waterless, pressureless. Long life. No maintenance or testing. Expensive.

Not to be used - Dexcool, Universal coolants, All-makes-all-models, etc.

I use Chevron's Delo HD ELC. Good for 750K miles/8 years or 1M miles with addition of an extender.

-----------------------------------------------------------------------------------------------------------------------------------

Stewart

The reason I post Gooch's response in its entirety is because I do not want to edit anything and possibly change how the information is meant to be applied.

As you can see, the info taken by and of itself is easily understandable without the "backstory" regarding the reason for the post.

-----------------------------------------------------------------------------------------------------------------------------------

Some errors and corrections...

I've been getting lots of PM's about Bob's coolant/SCA article (the sticky that was closed), and I would like to address a few things to help folks better understand. I think Bob realizes that much of his information is out-dated, pertains to certain engines other than our Powerstrokes, and is just plain wrong.

To give you a little background, first let me say that I've had extensive training and education in the field of coolants, some by the coolant manufacturers themselves. I worked with International during their cavitation crisis of the 6.9L and 7.3L IDI, helping to write bulletins, provide technical field data, and testing several different types of coolants, SCA's and mixtures thereof. I've operated and maintained a large fleet (100+ vehicles) of International/Ford 7.3L Powerstrokes. I am also a Mechanical Engineer with a background in Materials Science who has studied cavitation in cylinder walls and water pumps. Coolants are my specialty.

Where diesel cylinder cavitation is concerned, the bubbles are formed by the rapid flexing of the cylinder wall liners as the high compression, high energy diesel combustion process takes place. Much like if you filled a plastic liter pop bottle up with water and rapidly flexed the sides of the bottle back and forth with your hand. Bubbles form without any heat present. The bubbles in diesel cylinder wall cavitation don't explode, they implode due to pressure. It is this implosion against the metal surface that causes the pitting to form in the outside of the cylinder wall. Eventually the prolonged pitting become a hole. Water/coolant enters the cylinder, and thus we have engine failure (usually via hydrolock). Unlike gasoline engines, all diesel engines experience some level of inherent cavitation, some worse than others. FWIW, the Ford 6.9L and 7.9L IDI's originally had serious cavitation issues because Ford did not initially require (or add) SCA to the coolant. Ford later issued a bulletin to address that, and problems decreased dramatically.

As Bob stated, SCA's are one method of inhibiting cavitation by providing a barrier on the coolant side of the cylinder wall. However, I would like to say that it is not necessarily the SCA's displaced layer that can cause scale and coolant system plugging, but the components in the SCA itself, particularly when mixed with H2O or glycol. The use of conventional SCA is effective, but it requires testing, careful dosing, and frequent flushing. It will reduce heat transfer, and exacerbate water pump and other engine component failure.

One thing that importantly needs to be corrected, and a mistake than many misinformed people make, is that not all OAT coolants are like what GM uses. GM typically uses a "Dexcool" formulation, which is specifically not recommended for your diesel engine. Dexcool type coolants were never intended for diesel applications. There are many modern Heavy Duty Extended Life Coolants specifically designed for diesels. Delo ELC, Rotella ELC, International's Fleetrite ELC, CAT ELC, Mobil 1 ELC, and a host of others. They will address diesel cavitatation, provide superior metal corrosion protection, provide better heat transfer, require no testing and maintenance, be free of harmful abrasive silicates, borates, and phosphates, and have an operating life up to 1 million miles (Delo ELC). In fact International, who made your engine, recommends and factory-fills with these Heavy Duty Extended Life Coolants (Fleetrite ELC/Shell Rotella ELC). And in fact almost all heavy duty diesel manufacturers use Heavy Duty ELC's meeting the most strict requirements in the industry...Caterpillar's EC-1. Very little to do with GM's OAT coolant.

No where has Ford said you can not use a heavy duty ELC in your Powerstroke due to seal incompatibility. That is simply more misinformation. As we know International makes the engine and uses the HD ELC coolant, generally in more harsh, commercial applications. Seals are fine. The only coolants in the Owner's Manual Ford recommends you don't use are Dexcool and Ford's Specialty Orange. Owners and fleets have been using HD ELC successfully, and in fact with better success, for many, many years.

Another correction...Ford's Gold (G-05) coolant is nothing like a Heavy Duty ELC coolant. Thus is will not meet the more strict specs of other Heavy Duty ELC coolants, or provide the higher level of protection. The Gold is simply a universal hybrid, one-size-fits-all coolant that Ford uses in its entire line up that, with the exception of the Powerstroke, are all gasoline engines. Ford simply uses the Gold in your diesel out of convenience, simplicity, cost, and uniformity throughout it's product line and dealerships. The Gold coolant contains conventional (green coolant) components like silicate, which eventually form microscopic abrasives that eat water pump seals. It provides a lower level of cavitation protection using traditional SCA's like Nitrite, it has a shorter life, it reduces heat transfer compared to HD ELC's, and it in fact does require testing and SCA maintenance if you are an enthusiast about protecting your engine. In fact Ford recommends you add SCA to the Gold in certain F-Series applications. Caterpillar and John Deere also recommend adding SCA if it is going to be used in their diesels. Ironically, Ford's Gold will not meet International's heavy duty diesel B-1 spec. HD ELC's will. The Gold will work, but it's not the best.

For the record, adding SCA to a HD ELC will not produce anything close to "mud" or "goop". That is more misinformation. HD ELC's and SCA's are completely compatible, although not recommended only because you will lose the long-life properties of the HD ELC. There is no need to add SCA to HD ELC's. "Extenders" are available to add to HD ELC's if you want to further extend their life from the 300K, 500K, or 750K mile mark, depending on brand.

I have no intention of discrediting Bob's comments about the Evans and RMI-25, only to inform you. Evans is a good product, although expensive and hard to find. Less expensive, easier to find modern HD ELC's provide similar operating lives and similar (or better) protection. And the Evans does require modification of your cooling system to run low pressure, when your water pump seal is designed to run (and seal) under higher pressure, as documented by Ford. I have not used RMI-25 and don't plan to for reasons I won't discuss here. I would not recommend putting anything into your cooling system other than coolant and SCA.

Additionally, these days it is not appropriate to identify coolants by color. Color means nothing. A "green" coolant could be anything from a conventional, to a pre-charged, to a G-05, to an ELC. Same with red, purple, pink, gold, etc. You have to know what type of coolant it is.

There are 4 choices for your Powerstroke....

Conventional coolant (usually green) with the addition of SCA at initial fill. Frequent SCA testing and maintenance there after.

Pre-charged coolant (usually purple or pink). Comes with an initial dose of SCA. Frequent SCA testing and maintenance required thereafter.

G-05 coolants. Comes pre-charged with SCA package. Flush required at 50K miles. Semi-annual SCA testing and maintenance recommended.

Heavy Duty Extended Life Coolants. Come pre-charged with carboxylate inhibitors. No testing or maintenance. Super protection. Super long life.

Specialty coolants. Evans. Waterless, pressureless. Long life. No maintenance or testing. Expensive.

Not to be used - Dexcool, Universal coolants, All-makes-all-models, etc.

I use Chevron's Delo HD ELC. Good for 750K miles/8 years or 1M miles with addition of an extender.

-----------------------------------------------------------------------------------------------------------------------------------

Stewart

#5

The following information from Gooch pertains to why ELC's are not recommended for use in early '99 7.3L PSD's.

-------------------------------------------------------------------------------------------------------------------------------

Mostly it's the injector cups. International, who made the engine, found some compatibility issues with the older injector cup material, sensors, front cover, seals, gaskets, o-rings, and probably some other stuff when using coolants that contained organic acid technology (OAT). Coolants like ELC's (usually Red) and G-05 (usually Gold) will have these OAT's. Conventional coolants (usually Green) will not.

So International revised those components on all 2/2/99-up build engines (SN 940614-up), and began recommending and factory filling with HD ELC coolants mid-year 2000. Never looked back.

You could use HD ELC's in the older engines, but you run the risk of having to replace the cups and maybe some other stuff. I always try to recommend conventional coolant meeting ASTM D4985 with SCA or a pre-charged conventional coolant meeting ASTM D6210 for those. But it's your call, and some owners use the ELC in their older engine successfully. For the 2/2/99-up builds I would highly recommend upgrading to HD ELC.

BTW, if you need to check the build date of your engine, you can find it on the valve-cover tag (driver's side), or stamped on a machined surface on the underside of the engine, behind the oil filter and just ahead of the bell-housing cover. You may need to wire brush/clean it to read it.

-------------------------------------------------------------------------------------------------------------------------------

Stewart

-------------------------------------------------------------------------------------------------------------------------------

Mostly it's the injector cups. International, who made the engine, found some compatibility issues with the older injector cup material, sensors, front cover, seals, gaskets, o-rings, and probably some other stuff when using coolants that contained organic acid technology (OAT). Coolants like ELC's (usually Red) and G-05 (usually Gold) will have these OAT's. Conventional coolants (usually Green) will not.

So International revised those components on all 2/2/99-up build engines (SN 940614-up), and began recommending and factory filling with HD ELC coolants mid-year 2000. Never looked back.

You could use HD ELC's in the older engines, but you run the risk of having to replace the cups and maybe some other stuff. I always try to recommend conventional coolant meeting ASTM D4985 with SCA or a pre-charged conventional coolant meeting ASTM D6210 for those. But it's your call, and some owners use the ELC in their older engine successfully. For the 2/2/99-up builds I would highly recommend upgrading to HD ELC.

BTW, if you need to check the build date of your engine, you can find it on the valve-cover tag (driver's side), or stamped on a machined surface on the underside of the engine, behind the oil filter and just ahead of the bell-housing cover. You may need to wire brush/clean it to read it.

-------------------------------------------------------------------------------------------------------------------------------

Stewart

#6

The above warning about early 99's and ELC is why I have new injector cups intalled with Loctite 620 Retaining Compound. Never had a problem I could definitively blame on OTA ELC, but I was replacing the injectors and did the cups as well. Peace of mind kind of thing. Just another reason among many that my sig says "Not So Early 99".

Thanks for the post Stewart.

Thanks for the post Stewart.

#7

More of Gooch's info regarding ELC's:

-------------------------------------------------------------------------------------------------------------------------------

I would recommend a silicate-free, maintenance-free, Heavy Duty ELC. Heavy Duty Extended Life Coolants (HD ELC's - usually "Red") require no such SCA. These are the types of coolants International recommends for all 2/2/99-up engines.

Here is a list of ELC's that would work:

Chevron DELO ELC is the bomb!

Fleetrite / Rotella ELC : The Rotella is the same exact stuff as the Fleetrite, just in different bottles and it's the best type of coolant to use. Just make sure you do a proper flush and use distilled water.

Zerez Extreme Duty (RED)...you can get it at Napa. It is already pre charged and doesn't require any monitoring or additives.

FYI, there are two types of SCA. DCA-2 and DCA-4.

NapaKool is a DCA-2 SCA.

DCA-2 is a Nitrite-only based SCA. Nitrite is the primary and most effective cavitation inhibitor in any SCA. DCA-2 usually contains potassium buffers, free of phosphate.

DCA-2 was the first SCA, and it remains the most popular. It can be tested with any test strip that shows Nitrite levels, either a 2-way or 3-way strip.

DCA-4 is a Molybdate/Nitrite based SCA. It uses both Molybdate and Nitrite "synergy" as a cavitation inhibitor. DCA-4 usually has sodium buffers and phosphates.

DCA-4 is somewhat harder to find, maintain, and optimize. It can be tested with a 3-way test strip, although conversions are available for using 2-way strips.

-------------------------------------------------------------------------------------------------------------------------------

Stewart

-------------------------------------------------------------------------------------------------------------------------------

I would recommend a silicate-free, maintenance-free, Heavy Duty ELC. Heavy Duty Extended Life Coolants (HD ELC's - usually "Red") require no such SCA. These are the types of coolants International recommends for all 2/2/99-up engines.

Here is a list of ELC's that would work:

- CAT HD ELC

- Fleetrite HD ELC (International's brand)

- Rotella HD ELC

- Prestone HD ELC

- Zerex Extreme HD ELC

- Chevron/Texaco/Delo ELC

The latest formulation of the Delo ELC has a maintenance-free change interval of 750K miles/8 years or 1M miles with an extender.

Chevron DELO ELC is the bomb!

Fleetrite / Rotella ELC : The Rotella is the same exact stuff as the Fleetrite, just in different bottles and it's the best type of coolant to use. Just make sure you do a proper flush and use distilled water.

Zerez Extreme Duty (RED)...you can get it at Napa. It is already pre charged and doesn't require any monitoring or additives.

FYI, there are two types of SCA. DCA-2 and DCA-4.

NapaKool is a DCA-2 SCA.

DCA-2 is a Nitrite-only based SCA. Nitrite is the primary and most effective cavitation inhibitor in any SCA. DCA-2 usually contains potassium buffers, free of phosphate.

DCA-2 was the first SCA, and it remains the most popular. It can be tested with any test strip that shows Nitrite levels, either a 2-way or 3-way strip.

DCA-4 is a Molybdate/Nitrite based SCA. It uses both Molybdate and Nitrite "synergy" as a cavitation inhibitor. DCA-4 usually has sodium buffers and phosphates.

DCA-4 is somewhat harder to find, maintain, and optimize. It can be tested with a 3-way test strip, although conversions are available for using 2-way strips.

-------------------------------------------------------------------------------------------------------------------------------

Stewart

Trending Topics

#8

Here is what Gooch has to say about using tap water, versus distilled water, in our engines.

The following information was compiled from several posts in a single thread, by Gooch.

------------------------------------------------------------------------------------------------------------------------------

Even some of the best tap water will contain undesirable minerals, dissolved salts, and acids. Those components, like calcium, iron, magnesium, carbonates, hydroxides, nitrates, and so on, not only reduce the life of the coolant, but they reduce its ability to protect the cooling system. Those of us experienced with cooling systems know that tap water undoubtedly leads to exacerbated cooling system failures.

Since tap water is not pH neutral, it changes the desired alkalinity of the coolant formulation when mixed with the coolant. Distilled water, although not always completely mineral-free, is generally more neutral than reverse osmosis and purified water.

By using proper cooling system maintenance, you won't need to worry about having your radiator rodded or replaced.

You could flush with tap water, as long as your tap water was exceptional. Otherwise it is best to make your final flush(es) with distilled water. Always fill with distilled water.

It doesn't matter what conditions you operate your vehicle under. Coolant with distilled water will always protect your cooling system better and longer than tap water.

Using tap water for coolant maintenance...is second-rate maintenance. That is not opinion, but a well-known fact.

Where coolants are concerned, the facts are the facts. Using tap water will have consequences down the road...reduced protection, reduced coolant life, increased maintenance, and premature repair. Using tap water is sloppy, second-rate work.

------------------------------------------------------------------------------------------------------------------------------

Stewart

The following information was compiled from several posts in a single thread, by Gooch.

------------------------------------------------------------------------------------------------------------------------------

Even some of the best tap water will contain undesirable minerals, dissolved salts, and acids. Those components, like calcium, iron, magnesium, carbonates, hydroxides, nitrates, and so on, not only reduce the life of the coolant, but they reduce its ability to protect the cooling system. Those of us experienced with cooling systems know that tap water undoubtedly leads to exacerbated cooling system failures.

Since tap water is not pH neutral, it changes the desired alkalinity of the coolant formulation when mixed with the coolant. Distilled water, although not always completely mineral-free, is generally more neutral than reverse osmosis and purified water.

By using proper cooling system maintenance, you won't need to worry about having your radiator rodded or replaced.

You could flush with tap water, as long as your tap water was exceptional. Otherwise it is best to make your final flush(es) with distilled water. Always fill with distilled water.

It doesn't matter what conditions you operate your vehicle under. Coolant with distilled water will always protect your cooling system better and longer than tap water.

Using tap water for coolant maintenance...is second-rate maintenance. That is not opinion, but a well-known fact.

Where coolants are concerned, the facts are the facts. Using tap water will have consequences down the road...reduced protection, reduced coolant life, increased maintenance, and premature repair. Using tap water is sloppy, second-rate work.

------------------------------------------------------------------------------------------------------------------------------

Stewart

The following users liked this post:

#9

Nice Stewart, if this doesn't answer the question with folks doing this procedure nothing will. I changed mine out at 100,000 as you know with the CAT ELC, 40,000 miles now with a coolant bypass and all is good.. Are you going to run a coolant filtration system on yours?? Not sure if you mentioned that earlier..

#10

I have it on my Excursion, but I haven't yet ordered it for my F250.

Joe (Izzy) has several times posted a picture of silicate drop out and it sure looks a lot like the "casting sand" caught by the coolant bypass filters.

I'll probably still get a bypass setup for my truck in the future, but right now I'm trying to make sure I have enough money for a Detroit Truetrac for my rig. I'm really tired of trying to offset my one-wheel-peel at the drag strip by staggering the air pressure in the rear tires. Trying to find that sweet spot where both wheels grab with the same traction is difficult at the track with a limited slip diff that no longer works.

Plus, I want a set of Caltracs along with the Truetrac before my next trip to Redding for the next NHRDA Division 2 points race.

Stewart

Joe (Izzy) has several times posted a picture of silicate drop out and it sure looks a lot like the "casting sand" caught by the coolant bypass filters.

I'll probably still get a bypass setup for my truck in the future, but right now I'm trying to make sure I have enough money for a Detroit Truetrac for my rig. I'm really tired of trying to offset my one-wheel-peel at the drag strip by staggering the air pressure in the rear tires. Trying to find that sweet spot where both wheels grab with the same traction is difficult at the track with a limited slip diff that no longer works.

Plus, I want a set of Caltracs along with the Truetrac before my next trip to Redding for the next NHRDA Division 2 points race.

Stewart

#11

#12

Joe (Izzy) has several times posted a picture of silicate drop out and it sure looks a lot like the "casting sand" caught by the coolant bypass filters.

I would say that is is not "casting sand" but drop-out from SCA. JMHO

Plus, I want a set of Caltracs along with the Truetrac before my next trip to Redding for the next NHRDA Division 2 points race.

Stewart

I would say that is is not "casting sand" but drop-out from SCA. JMHO

Plus, I want a set of Caltracs along with the Truetrac before my next trip to Redding for the next NHRDA Division 2 points race.

Stewart

What is/are Caltracs? Never mind I googled it. Traction bars.

#13

Mike, that's not derailing bud. All that info is relevant to the thread!

Stewart

#14

The following users liked this post:

#15

He sure didn't mince words when discussing the use of tap water, did he.

Last edited by Stewart_H; 08-14-2015 at 03:03 AM.

Ahh, yes, the Tru-Trac, sweet.

Ahh, yes, the Tru-Trac, sweet.