Dual tank/pump reservoir

#46

I have a short somewhere and I can't find it. When it shorts (which is about all the time now) the amp meter goes way down, the temp and oil pressure gauges goes way up. When the truck is just getting warmed up so the needle just starts comeing up it reads on the upper half of normal. When fully warmed it is pegged at hot. the head lights go dim.

It is now bouncing when it gets warm, the amp meter, so somewhere the shorting wire has become loose enough when warm to either bounce off to run normal or if it is a loose ground it is make contact. I have been told both is possible. I am not sure if the short and fuel are related.

At one time when the short was intermideate the truck ran better. the worse the short got the worse it ran. Now I can be sitting with out it shorted and the truck still runs kind of rough. Hard to tell since I am not moving to put under load.

I have a repair book. Of course no help with this problem but it was confusing a bit on testing the injectors. So I will try your link and see if it helps.

thank you for the responses from everyone. I get more help here then I was from the mechanic that was suppose to be helping to diagnose. All he did was tell me things that were wrong that had nothing to do with the problem.

It is now bouncing when it gets warm, the amp meter, so somewhere the shorting wire has become loose enough when warm to either bounce off to run normal or if it is a loose ground it is make contact. I have been told both is possible. I am not sure if the short and fuel are related.

At one time when the short was intermideate the truck ran better. the worse the short got the worse it ran. Now I can be sitting with out it shorted and the truck still runs kind of rough. Hard to tell since I am not moving to put under load.

I have a repair book. Of course no help with this problem but it was confusing a bit on testing the injectors. So I will try your link and see if it helps.

thank you for the responses from everyone. I get more help here then I was from the mechanic that was suppose to be helping to diagnose. All he did was tell me things that were wrong that had nothing to do with the problem.

Last edited by gr_ywolf001; 03-01-2012 at 09:38 AM. Reason: left out some information

#47

I have a short somewhere and I can't find it. When it shorts (which is about all the time now) the amp meter goes way down, the temp and oil pressure gauges goes way up. When the truck is just getting warmed up so the needle just starts coming up it reads on the upper half of normal. When fully warmed it is pegged at hot. the head lights go dim.

What engine and trans?

When the Check Engine light comes on, the computer should store the code

in memory.

Using a OBD 1 code reader it's very easy to pull codes.

Doing the wire jumper method and counting the blinking Check Engine light

does the same thing but can be confusing. It could help narrow down

one of your problems.

If no code is stored even though the light comes on and then goes off

the computer could be loosing power and reseting.

Take some time and read the link.

#48

I have had the obd 1 connected to it and it shows no codes. The truck is a 90 f250 with a 5.0 5 Sp. I have owned the truck for about 9 months. So I really don't know the history before me.

I only know that Ihave worked on it to get it right. It didn't run bad when I got it, just a tune up what I was thinking. I changed plugs, wires, cap, rotor, timing. The timing was way off when I set it. I would say it was about 25 instead of 10 I have it now at 8.

It has headers on it. from the headers it is 3 inch back. I don't know why 5.0 needed a 3 inch exhaust but that's what was done. the cat convert is not there was taken out I guess when the headers installed. I do know from lookin gat it some things were jerry rigged in it. I was told by someone that knew who I bought the truck from that he always took it to a mechanic around here.

I live in Benson AZ and have heard nothing good about the mechanics here, so I am very leary of taking it in to have it looked at. I went to Sierra Vista and that is when I had a mechanic that didn't want to look at it. So now I don't want anyone looking at around here. I trust me but I have never come across this before.

I have to say that this is the first ford I have owned. I changed to ford because of the poor designs of GM. they have had some problems for a while now. So my choices were Ford and Dodge. Ford come up first. I am not knowledgable on ford but I know mechanics of how things work are the same, just the details are sometimes different.

I am trying to stay with ford but htis problem is making it hard to do. lol

I only know that Ihave worked on it to get it right. It didn't run bad when I got it, just a tune up what I was thinking. I changed plugs, wires, cap, rotor, timing. The timing was way off when I set it. I would say it was about 25 instead of 10 I have it now at 8.

It has headers on it. from the headers it is 3 inch back. I don't know why 5.0 needed a 3 inch exhaust but that's what was done. the cat convert is not there was taken out I guess when the headers installed. I do know from lookin gat it some things were jerry rigged in it. I was told by someone that knew who I bought the truck from that he always took it to a mechanic around here.

I live in Benson AZ and have heard nothing good about the mechanics here, so I am very leary of taking it in to have it looked at. I went to Sierra Vista and that is when I had a mechanic that didn't want to look at it. So now I don't want anyone looking at around here. I trust me but I have never come across this before.

I have to say that this is the first ford I have owned. I changed to ford because of the poor designs of GM. they have had some problems for a while now. So my choices were Ford and Dodge. Ford come up first. I am not knowledgable on ford but I know mechanics of how things work are the same, just the details are sometimes different.

I am trying to stay with ford but htis problem is making it hard to do. lol

#49

#51

#52

It's bolted to the side of the throttle body.

There are 3 wires at the connector of the TPS.

To check for the 5 DC volt reference voltage.

Disconnect the TPS connector.

If you have a volt meter stick the red probe into the Orange/White wire

connector end. Place the Black probe into the Black/White wire connector

end.

Turn the ignition On. Should read 5 volts DC.

To check the TPS itself by measuring its resistance.

With the plug disconnected. Ignition off.

Place Red probe into the TPS where the Brown/Light Green wire was.

Place the Black probe into the TPS where the Black/White wire was.

Set the meter to read resistance (ohms). Manually move the throttle linkage

from closed to wide open throttle. The resistance value should smoothly

increase or decrease with no jumping as you move the throttle body linkage.

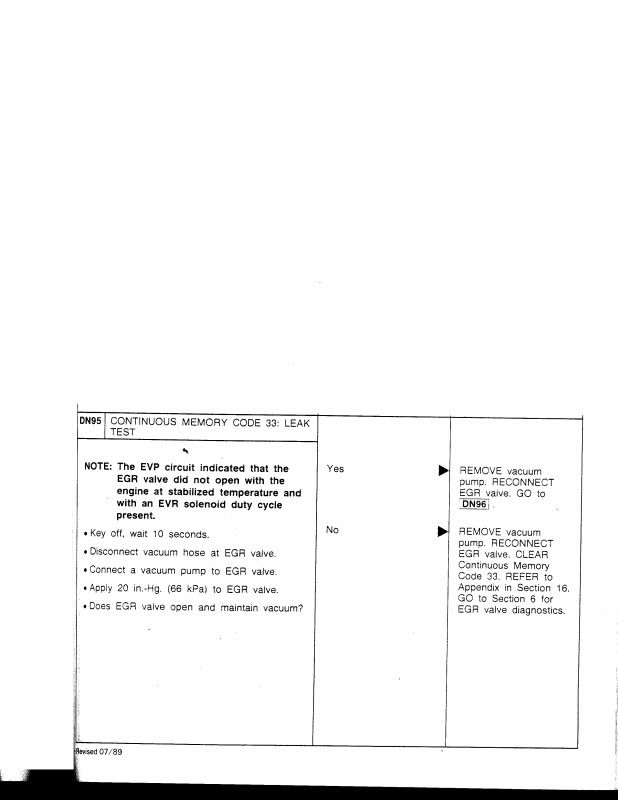

Code 53 EGR valve not opening.

To test the EGR valve itself.

Disconnect the vacuum hose going to it.

Rent a hand vacuum pump from Autozone or Advance auto if you can.

Start the engine and let it idle.

Use the vacuum pump and pump it up to 20 hg.

This will cause the valve to open. It should stay open as long as the vacuum is applied.

The engine should stumble and then stall as the valve is opening.

If it won't hold vacuum or engine doesn't stall or run rough, replace the EGR valve.

(The EGR valve exhaust passage could be clogged. Only way to tell would be to

remove it and inspect the passage).

Also inspect the vacuum hose going to the EGR valve solenoid for leaks.

The small unit bolted on the back of the EGR valve is what

senses the movement of the EGR diaphragm.

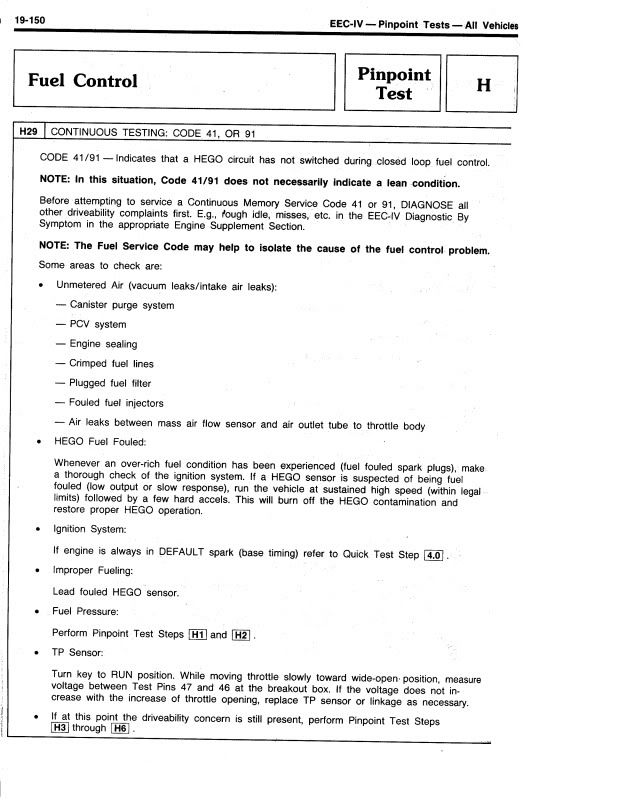

Code 41 indicates the fuel system was lean for more than 15 seconds

when the fuel system should have been in closed loop fuel control.

When under closed loop, the computer will continuously change the fuel mixture.The oxygen sensor output voltage should indicate that is happening in the exhaust gas.

In your situation for some unknown reason the oxygen sensor is always showing a lean condition.

************************************************** *********************

You mentioned you installed a new oxygen sensor and rewired it.

Can you explain how you wired it?

************************************************** *********************

Read what could cause a lean condition below.

#53

Because of my work schedule I haven't been able to test. I will post when I get it done.

With the o2 senson the previous own had put a one wire senson in so there was 3 wires not connected. And the wiring looked a mess. so when I replace the senson with the correct one and had to rewire from the o2 connector back to the engine to the next connector. It is a section of wire abor 2 ft. long. that is what I replaced. It was cheaper then trying to tract down that little section of wiring.

With the o2 senson the previous own had put a one wire senson in so there was 3 wires not connected. And the wiring looked a mess. so when I replace the senson with the correct one and had to rewire from the o2 connector back to the engine to the next connector. It is a section of wire abor 2 ft. long. that is what I replaced. It was cheaper then trying to tract down that little section of wiring.

#54

Ok tested the tps and heres what I got there is 4.88 volts. Is that a lttle low or ok. And I got no movement on restistance with the sensor itself. I got a messurement of 3.84 all the way thru so I will replace that.

What effect does the egr have if it does not open. My air pump locked up and I by passed it (took the pulley off) so there is no vacume created from it now. And the egr is gets its vacume from that as far as I could trace. I have alot of those vacume lines broken but figured since the air pump not connected didn't make a difference. Maybe I was really wrong.

Would that cause the engine to surge? I just read somewhere taht someone said it can be like having your cruise control on all the time. I don't know myself. By the way I do not have the cat conv. It was removed before I got it.

What effect does the egr have if it does not open. My air pump locked up and I by passed it (took the pulley off) so there is no vacume created from it now. And the egr is gets its vacume from that as far as I could trace. I have alot of those vacume lines broken but figured since the air pump not connected didn't make a difference. Maybe I was really wrong.

Would that cause the engine to surge? I just read somewhere taht someone said it can be like having your cruise control on all the time. I don't know myself. By the way I do not have the cat conv. It was removed before I got it.

Last edited by gr_ywolf001; 03-03-2012 at 01:22 PM. Reason: for got a comment

#55

#56

I reliezed as I said that how dumb that was I know the air pump blows not vacume. It appears that the vacume line go to it tho. Sorry was not thinking when I said that. lol I had three others conversations going at that time.

I am not that great on the emissions systems I prefer to go back to the early 70s and beyond when engines ran and you didn't have a computer tell it to run and how. lol

so if I left the egr vacume off I would be ok. I don't live in an emission testing area.

By the way thank you so much for your help and input. You have been a great help to me on this as has others on this site.

I am not that great on the emissions systems I prefer to go back to the early 70s and beyond when engines ran and you didn't have a computer tell it to run and how. lol

so if I left the egr vacume off I would be ok. I don't live in an emission testing area.

By the way thank you so much for your help and input. You have been a great help to me on this as has others on this site.

#57

#59