King Pin Help, 71 f100 with disc conversion

#1

King Pin Help, 71 f100 with disc conversion

Okay guys I feel dumb for even asking but I havent been able to find the answer, and ive been searching.

Im working on a 71 f100 ranger that was factory 4 wheel power drums. I have a disc conversion kit for the 67-72 f100 from lmc and the parts are going on djm dream beams. The kit came with new spindles, discs, calpiers, lines and a king pin set for the spindles. Here is where my question comes in.

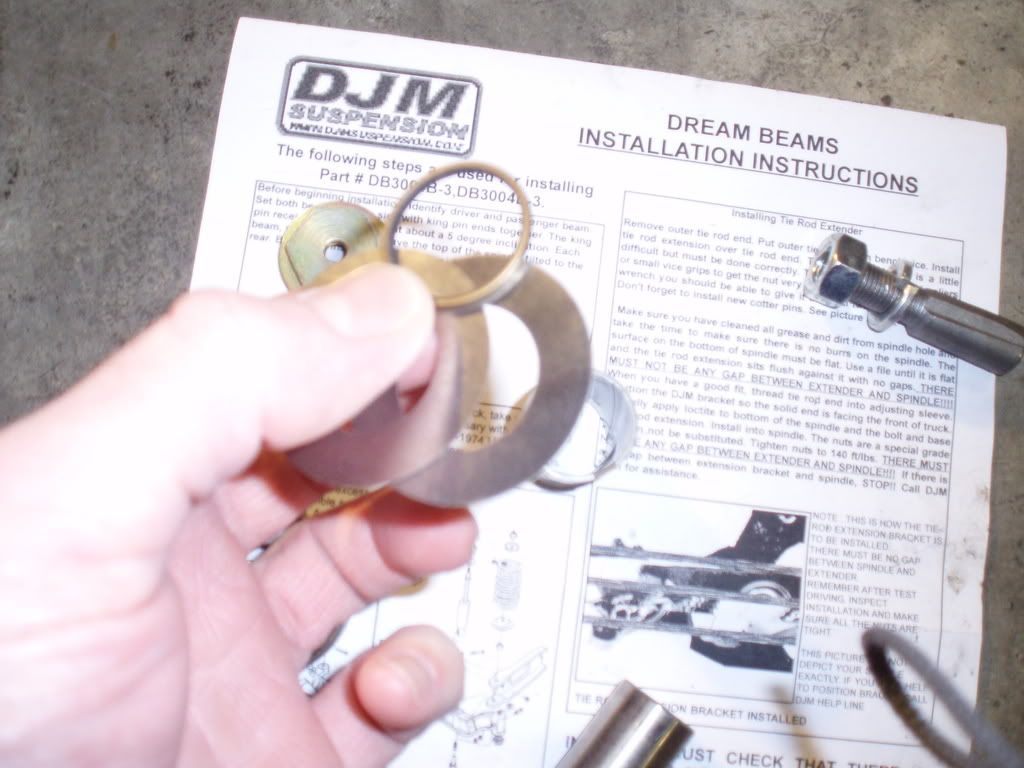

Its obvious where most of the parts go but there are a few that im not 100% on and cant find any diagram that shows them. I know the bearing goes between the spindle and beam on the bottom side of the beam. The kit included two thrust washers(for each side) and another very small washer that looks to be a combination between a crush copper washer and a rubber liner. This washer seems like it seals to the kingpin and the OD is just barely over that of the king pin. The kit only had two of these so there is 1 for each side.

So where do these thrust washers go and where does this smaller washer go? It was hard to get a pic of them so here they are.

I was thinking a thrust washer went between the bearing/spindle on the bottom and between the beam/spindle on top, but im not sure and i cant find a breakdown that shows these parts. Typically you will have a couple thrust washers next to each other so im also thinking these will both go between the beam/spindle on the top side(would make more sense) and the smaller washer would go with the bearing.

thanks

Im working on a 71 f100 ranger that was factory 4 wheel power drums. I have a disc conversion kit for the 67-72 f100 from lmc and the parts are going on djm dream beams. The kit came with new spindles, discs, calpiers, lines and a king pin set for the spindles. Here is where my question comes in.

Its obvious where most of the parts go but there are a few that im not 100% on and cant find any diagram that shows them. I know the bearing goes between the spindle and beam on the bottom side of the beam. The kit included two thrust washers(for each side) and another very small washer that looks to be a combination between a crush copper washer and a rubber liner. This washer seems like it seals to the kingpin and the OD is just barely over that of the king pin. The kit only had two of these so there is 1 for each side.

So where do these thrust washers go and where does this smaller washer go? It was hard to get a pic of them so here they are.

I was thinking a thrust washer went between the bearing/spindle on the bottom and between the beam/spindle on top, but im not sure and i cant find a breakdown that shows these parts. Typically you will have a couple thrust washers next to each other so im also thinking these will both go between the beam/spindle on the top side(would make more sense) and the smaller washer would go with the bearing.

thanks

#3

Matt,

The little washers are kinda like mini inner wheel bearing seals and they go into the bottom of the the top hole of the spindle, right above the axle. Be careful putting them in, as they are pretty flimsy and bend easily. I ended up having to re-use one of my old ones because I damaged one of the new ones try to get it in. I was told that the thrust washers/spacers went under the bearing and to put as many as would fit comfortably without forcing them. The TRW kit that I used had 8 or 10 in the box.

Have Fun,

Gene

The little washers are kinda like mini inner wheel bearing seals and they go into the bottom of the the top hole of the spindle, right above the axle. Be careful putting them in, as they are pretty flimsy and bend easily. I ended up having to re-use one of my old ones because I damaged one of the new ones try to get it in. I was told that the thrust washers/spacers went under the bearing and to put as many as would fit comfortably without forcing them. The TRW kit that I used had 8 or 10 in the box.

Have Fun,

Gene

#4

im not sure i follow you on that gene.

The mini washer/seal goes around the king pin between the spindle and the beam? There is no way it would fit there. I put the spindle on, both thrust washer on top of the beam and the bearing at the bottom and that was super tight. im going to take a pic of it and maybe you can point it out because im sure im missing what you are saying.

The mini washer/seal goes around the king pin between the spindle and the beam? There is no way it would fit there. I put the spindle on, both thrust washer on top of the beam and the bearing at the bottom and that was super tight. im going to take a pic of it and maybe you can point it out because im sure im missing what you are saying.

#5

okay, sorry the text is so small, but here is a pic.

its obvious that when the truck is on its 'feet' the lower bearing is going to be taking all of the load(or most of it). If i didnt install both shim/thrust washers on the top of the beam it would be metal on metal on there. I couldnt imagine this being right.

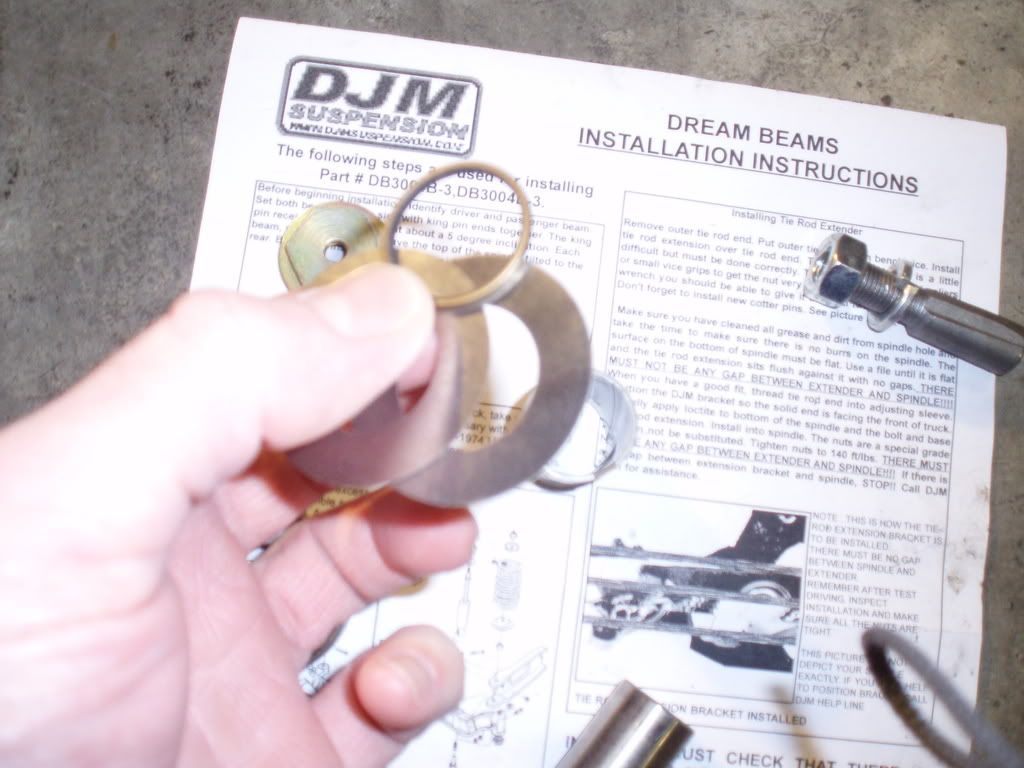

here is maybe a better picture of the small seal/washer still in question.

im holding it up to the top cap to show its size. Because the od seems to be the same as the bushings. Does this go between one of the bushings and the spindle? if so which one?

I think when you were saying axle you may have confused me. the small washer i have is far from flimsy. its really stout. Only thing i can think is its there to keep the grease above beam where the lower one doesnt have this issue.

I just want to be absolutely sure before i put all this together and before i start the other side.

Thanks!!!!

its obvious that when the truck is on its 'feet' the lower bearing is going to be taking all of the load(or most of it). If i didnt install both shim/thrust washers on the top of the beam it would be metal on metal on there. I couldnt imagine this being right.

here is maybe a better picture of the small seal/washer still in question.

im holding it up to the top cap to show its size. Because the od seems to be the same as the bushings. Does this go between one of the bushings and the spindle? if so which one?

I think when you were saying axle you may have confused me. the small washer i have is far from flimsy. its really stout. Only thing i can think is its there to keep the grease above beam where the lower one doesnt have this issue.

I just want to be absolutely sure before i put all this together and before i start the other side.

Thanks!!!!

#6

Matt, as 68horses said the little washer isn't a washer at all. It's a grease seal. It goes into the spindle just under the upper bushing.

Your setup of the thrust bearing and shims is correct. The weight sits on the bearing. The shims control the up/down play in the spindle. I try to shim them to have .010 to .015 thrust play. Too tight and it can cause binding. A little more play really won't hurt anything.

Also if you ever see a king pin that doesn't have room for shims don't worry. Although rare I've seen a couple that didn't need shimmed. The grease keeps the spindle and axle from damaging each other.

Your setup of the thrust bearing and shims is correct. The weight sits on the bearing. The shims control the up/down play in the spindle. I try to shim them to have .010 to .015 thrust play. Too tight and it can cause binding. A little more play really won't hurt anything.

Also if you ever see a king pin that doesn't have room for shims don't worry. Although rare I've seen a couple that didn't need shimmed. The grease keeps the spindle and axle from damaging each other.

#7

thanks redcat and 68!

This spindle was tight on the beam but i was affraid since the beam had wrinkle powder coat on it so i took a file and cleaned up the top and bottom mating surfaces. I was affraid the powdercoat would wear causing excess play. As it stands now there is really no play in the assembly but i didnt take all the powdercoat off so i think i may get it on wheels and and let it wear in a bit before i decide about the shims, or do you think im way off base with that one and i should just pull them back out now.

Thanks for the help guys. If this was my truck and i could check it periodically i wouldnt be so worried about it but once its done i may only see the truck once a year if that.

This spindle was tight on the beam but i was affraid since the beam had wrinkle powder coat on it so i took a file and cleaned up the top and bottom mating surfaces. I was affraid the powdercoat would wear causing excess play. As it stands now there is really no play in the assembly but i didnt take all the powdercoat off so i think i may get it on wheels and and let it wear in a bit before i decide about the shims, or do you think im way off base with that one and i should just pull them back out now.

Thanks for the help guys. If this was my truck and i could check it periodically i wouldnt be so worried about it but once its done i may only see the truck once a year if that.

Trending Topics

#8

Matt it takes many thousands of miles to wear the upper surface of the beam and spindle. As I mentioned in my last post if it's too tight it will bind. I would check for the .010 to .015" clearance, if it's in that range or even a bit more let it run as is. If the clearance is less remove the shims.

BTW, I would suggest that you pull it back apart and coat the pin, bore and lockbolt with anti sieze compound. It could save you a lot of grief sometime in the distant future. I've fought my share of siezed king pins. It's no fun.

BTW, I would suggest that you pull it back apart and coat the pin, bore and lockbolt with anti sieze compound. It could save you a lot of grief sometime in the distant future. I've fought my share of siezed king pins. It's no fun.

#9

yeah i certainly planned on it clay. I can still push the kingpin out with my pinky(bottom cap is keeping it from dropping out), i was just getting a feel for the parts and clearance. I will certainly hit those numbers you put up. I know im going to have to pull out at least one of the washers but honestly I think even with both out its more like .006-.008.

When i get to it(tomorrow some time) ill post back with the specs. Both the spindle and the beams had paint on them which is why i was worried but if you said a little on the loose side is fine and no washer up top is okay ill run with it. Im certainly not an expert on this suspension so any advice I get is taken to heart.

thanks!

When i get to it(tomorrow some time) ill post back with the specs. Both the spindle and the beams had paint on them which is why i was worried but if you said a little on the loose side is fine and no washer up top is okay ill run with it. Im certainly not an expert on this suspension so any advice I get is taken to heart.

thanks!

#10

Thread

Thread Starter

Forum

Replies

Last Post

dmack91

1948 - 1956 F1, F100 & Larger F-Series Trucks

35

02-19-2022 10:39 PM

f100today

1967 - 1972 F-100 & Larger F-Series Trucks

37

01-24-2017 10:22 AM

1965GTFB

1961 - 1966 F-100 & Larger F-Series Trucks

12

07-10-2013 04:58 PM

junkrider

1987 - 1996 F150 & Larger F-Series Trucks

3

11-07-2009 11:29 AM