Oil leak at dipstick tube flange fixed -with pics!

#151

#152

I was nervous about this repair. I have read all about it, I read this whole thread and more. It sounded harder than it was!

I got the dipstick tube O-ring, dipstick tube adapter O-ring, and new flange nut from the local Ford Dealer (what a rip-off at $47). Then last Sunday I went and got some needle nose Vise Grips and made a Widget. I disconnected the batteries and took off the starter. Then took the dipstick tube and flange nut off, removed the old O-ring's from the tube and adapter. Cleaned things up with rag and Q-tips. Put every thing back together using the new parts and using a little Loctite on the threads.

I figured the original O-ring's lasted 16 years and 280000 miles, I was happy with that! And If a second set of original type O-rings lasted that long I would be doing good. If not, It will be easier to repair a second time if it wasn't all gooped up with sealers.

After repair, I started the engine. About 10 minutes later I was disappointed to see a drip of oil on the flange nut. I carefully tightened the flange nut as much as I dared.

On Monday morning, after my 30+ mile drive to work, I was very disappointed to see oil all over the bottom of the truck. I was not looking forward to trying this repair again! After the drive home, the oil mess didn't look much worse. It seemed the leak had sealed some. So I hosed the oil off. Tuesday morning after driving to work, there was just a little oil that ran from the flange nut to the bottom of the oil pan. I hosed it off and it has not leaked since.

While making the repair, I did notice that the O-ring didn't protrude very much from the grove in the adapter. As mentioned in earlier posts, the O-ring swells in oil. I think the O-ring is designed to easily fit in the adaptor grove for ease of assembly, then swell to tightly fill the grove and mating surface sealing the assembly.

The moral to this story is; I don't believe the extra seal and RTV gooped all over are necessary. And if it leaks a little after repair, DO NOT PANNIC!!! It will probably seal after a day or two of driving.

IMHO This is an easy repair. Be prepared, but don't over think it.

I got the dipstick tube O-ring, dipstick tube adapter O-ring, and new flange nut from the local Ford Dealer (what a rip-off at $47). Then last Sunday I went and got some needle nose Vise Grips and made a Widget. I disconnected the batteries and took off the starter. Then took the dipstick tube and flange nut off, removed the old O-ring's from the tube and adapter. Cleaned things up with rag and Q-tips. Put every thing back together using the new parts and using a little Loctite on the threads.

I figured the original O-ring's lasted 16 years and 280000 miles, I was happy with that! And If a second set of original type O-rings lasted that long I would be doing good. If not, It will be easier to repair a second time if it wasn't all gooped up with sealers.

After repair, I started the engine. About 10 minutes later I was disappointed to see a drip of oil on the flange nut. I carefully tightened the flange nut as much as I dared.

On Monday morning, after my 30+ mile drive to work, I was very disappointed to see oil all over the bottom of the truck. I was not looking forward to trying this repair again! After the drive home, the oil mess didn't look much worse. It seemed the leak had sealed some. So I hosed the oil off. Tuesday morning after driving to work, there was just a little oil that ran from the flange nut to the bottom of the oil pan. I hosed it off and it has not leaked since.

While making the repair, I did notice that the O-ring didn't protrude very much from the grove in the adapter. As mentioned in earlier posts, the O-ring swells in oil. I think the O-ring is designed to easily fit in the adaptor grove for ease of assembly, then swell to tightly fill the grove and mating surface sealing the assembly.

The moral to this story is; I don't believe the extra seal and RTV gooped all over are necessary. And if it leaks a little after repair, DO NOT PANNIC!!! It will probably seal after a day or two of driving.

IMHO This is an easy repair. Be prepared, but don't over think it.

Was it a constant leak that you could see right away or was it more of a seaping kind of leak

Thanks for the all the helpful information

#153

I did this repair except I replaced with the stock o ring that sits on the inside of the pan on the flange...Did it in 1 hour and it looks great(no leaks and none of that mess on the outside}If you need help pm me and I can tell you exactly how I did it without dropping flange into pan....3.27 for the o-ring from ford and 1 hour to do...

Can you send instructions on how you replaced your dip stick o-ring in 1 hour ?

Thanks,

sds

#154

#155

I need help. We went to do this change yesterday. But we cannot get the dipstick tube out of the flange. Yes we undid the bolt to the valve cover. We pulled, we twisted, yet it would not come out. I'm thinking I will have to probably get a new tube tomorrow when the dealer opens, but I have to get the old tube out first.

Is all that is holding the tube into the flange is an o-ring?

BTW it's an E-99, not that it should matter.

Is all that is holding the tube into the flange is an o-ring?

BTW it's an E-99, not that it should matter.

#157

#158

Any new users?

Has anyone installed one of these and have pictures of the process? Would you go this route again ($300)? Are there any new products that address the dipstick tube leak?

A little backstory.....I recently acquired a 7.3 Excursion and after changing the oil (T6 synthetic) I noticed a slight oil leak originating at what looks like the point where the dipstick enters the pan. No, I haven't touched the retainer nut since I read that usually makes things worse. I just would like to fix the problem before it gets too bad. Right now it is a few drops per day.

#159

I had some weepage around the flange. Several factors (time, money, cajones, and reading that it may not fix the problem) drove me to another alternative. I bought a new o-ring for the dipstick tube and then had at the flange with Motorcraft TA-31. You can get it here:

Motorcraft TA31 RTV Silicone Sealant

It comes out very tacky (you need a caulking gun) and reminds me is designed for use specifically on our engines. It's not pretty (I do not have any certifications to slather goop) but it has been effective (tube is back in but the starter is still out):

Motorcraft TA31 RTV Silicone Sealant

It comes out very tacky (you need a caulking gun) and reminds me is designed for use specifically on our engines. It's not pretty (I do not have any certifications to slather goop) but it has been effective (tube is back in but the starter is still out):

#160

I had some weepage around the flange. Several factors (time, money, cajones, and reading that it may not fix the problem) drove me to another alternative. I bought a new o-ring for the dipstick tube and then had at the flange with Motorcraft TA-31. You can get it here:

Motorcraft TA31 RTV Silicone Sealant

It comes out very tacky (you need a caulking gun) and reminds me is designed for use specifically on our engines. It's not pretty (I do not have any certifications to slather goop) but it has been effective (tube is back in but the starter is still out):

Motorcraft TA31 RTV Silicone Sealant

It comes out very tacky (you need a caulking gun) and reminds me is designed for use specifically on our engines. It's not pretty (I do not have any certifications to slather goop) but it has been effective (tube is back in but the starter is still out):

How long has your repair been in place? Did it stop the leak completely?

#161

I did the same thing. New oring and flange were a failure so I Just slathered it in " the right stuff(permatex product)" and it has been dry as a bone ever since. 5 years, 150k and holding.

#163

#164

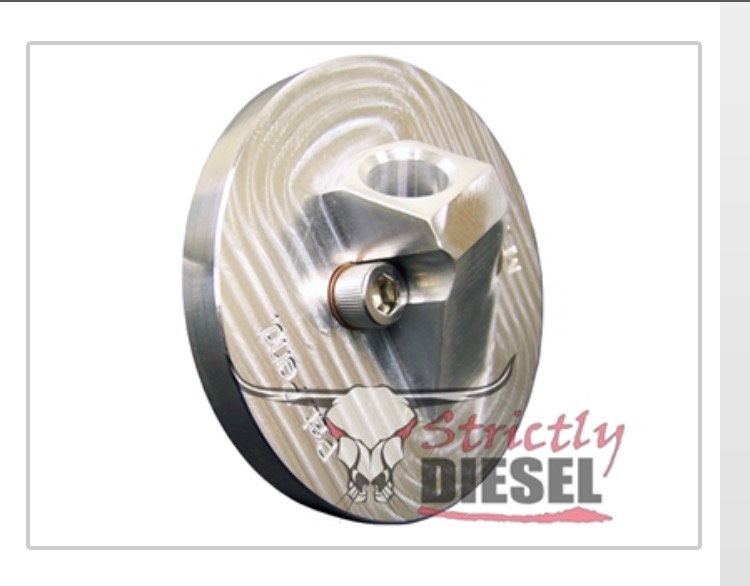

I bought this kit bout 2 yrs ago when i noticed the leak on mine. It sat in the corner until about 3 mths ago when the leak was bad enough that I said, damn, i gotta fix that, its pretty damn bad now. Took a little time, but pretty straight forward and no leaks after about 10k miles.

Oil Level Gauge Adapter Repair Kit for 1994 - 2003

Oil Level Gauge Adapter Repair Kit for 1994 - 2003

#165