88' 2.3L - My head will NOT come off.

#1

Alright engine guys give me a hand here with this one. I have never seen a head stuck this bad. My original thread is in the Ranger forum:

https://www.ford-trucks.com/forums/s...d.php?t=443150

The short of the story if you skim through that thread is that I started leaking compression due to a HG leak. The cause was the head bolt on the exhaust side between cyl 2 & 3 broke. The pic should be in that thread but it basically broke 1/2" - 1" down in the head so removing it is not an option. I finally got a hoist to try "popping" the head and all that did was lift the front of the truck. So I pulled the entire engine so I could fix some minor oil leaks while I was at it. So on to the 1 burning question:

How do I remove a head that will not come off the block on an 88' 2.3L FI Ranger engine?

https://www.ford-trucks.com/forums/s...d.php?t=443150

The short of the story if you skim through that thread is that I started leaking compression due to a HG leak. The cause was the head bolt on the exhaust side between cyl 2 & 3 broke. The pic should be in that thread but it basically broke 1/2" - 1" down in the head so removing it is not an option. I finally got a hoist to try "popping" the head and all that did was lift the front of the truck. So I pulled the entire engine so I could fix some minor oil leaks while I was at it. So on to the 1 burning question:

How do I remove a head that will not come off the block on an 88' 2.3L FI Ranger engine?

#2

All of the other head bolts came out ok? Was there water leaking at the broken head bolt. If so you'll need to soak it with something to eat at the rust. Not trying to offend, however there are 10 headbolts. I have seen this happen. You can use a 1/2" extension about 12" long and work the try to rock the head. Unlikely to work, but has, put the plugs back in and remove the exhaust rockers. With starter spin the engine over. Lots of elbow grease may be needed. Don't drive a chisel between the head and block untill you're sure you've exhausted all other avenues. You will be decking block and head if you do.

#3

IDK if you saw my other thread, that I tried cranking it over to pop the head and that didn't work. I also tried using an air compressor to fill the cyl, that didn't work either. If you saw the pics I got all 10 bolts (well, 9.25 bolts in my case).

Based on the looks of the other exhaust side bolts there is A LOT of carbon build -up on the shaft of the bolt and in the bolt hole.

What do you recommend I use to eat the carbon/rust down the hole where the broken one is? DrainO for bolts?

Based on the looks of the other exhaust side bolts there is A LOT of carbon build -up on the shaft of the bolt and in the bolt hole.

What do you recommend I use to eat the carbon/rust down the hole where the broken one is? DrainO for bolts?

#4

Join Date: May 2004

Location: The hills of No. Calif.

Posts: 12,169

Likes: 0

Received 5 Likes

on

4 Posts

Wow, you're still fighting that thing? I hadn't heard anymore about it from you so I assumed (wrongly, obviously) that you'd gotten it.

Muriatic acid eats the hell out of rust, but you most likely don't want it getting down into the engine as it eats a lot of other things as well...

I don't know what to tell you at this point that hasn't already been covered in either of the earlier threads on the subject...dynamite?

Muriatic acid eats the hell out of rust, but you most likely don't want it getting down into the engine as it eats a lot of other things as well...

I don't know what to tell you at this point that hasn't already been covered in either of the earlier threads on the subject...dynamite?

#5

Try soaking the hole with WD40 or Liquid Wrench?

I would have left it in the truck and if it was that hard to pop loose, get a long pry bar (automotive or construction type) find a safe place like maybe the exhaust port or under the cam (?) to help pry upwards...but no gaurantee. Make sure you don't damage anything else....

Just make sure you already have remove the timing belt and anything else holding it too....

I would have left it in the truck and if it was that hard to pop loose, get a long pry bar (automotive or construction type) find a safe place like maybe the exhaust port or under the cam (?) to help pry upwards...but no gaurantee. Make sure you don't damage anything else....

Just make sure you already have remove the timing belt and anything else holding it too....

#6

TigerDan - Yes, I am still fighting it. I didn't have much $$$ during the holidays, and just recently another member let me borrow his hoist.

jamnjm - I did leave it in the truck for months. I tried almost every trick in the book to get that sucker off. Prybar, hammer, soaking the bolt hole, cranking to build compression, using an air compressor in the cyl, and I even tried to pull it off with the hoist while the block was still bolted in! All that did was lift the front of the truck up a bit.

jamnjm - I did leave it in the truck for months. I tried almost every trick in the book to get that sucker off. Prybar, hammer, soaking the bolt hole, cranking to build compression, using an air compressor in the cyl, and I even tried to pull it off with the hoist while the block was still bolted in! All that did was lift the front of the truck up a bit.

#7

Join Date: May 2004

Location: The hills of No. Calif.

Posts: 12,169

Likes: 0

Received 5 Likes

on

4 Posts

It's too bad we're on opposite coasts. I've got some heavy equipment here that I'm sure would work to get it off. Let's see...first, we remove the hood, then we chain the truck down to a couple of 2-ton (each) steel beams and chain that pesky head to our 8000lb. forklift and let 'er rip! Something's gotta give!

Trending Topics

#8

From the sounds of it, it would be the fork lift. Be carfull with that acid as it will eat alum and etch the steel. In forty years, I've never had a head I couldn't get off. It sounds like a real challange. You've got a female engine. Stuborn. I wonder if you could put some dynamite in the cylinders and set them all off at the same time. Not too much though.

In all seriousness the only other thing I can think of, is work the head in a rotational manner around that bolt. I know alignment dowels will loosen up if worked as the are just thin tubing. Can you center punch the end of the broken bolt and then progressivley drill down thru it, till it's almost gone. That will eliminate most of it and the remainder would break off. You might also use some drill busings to help keep it centered and straight.

In all seriousness the only other thing I can think of, is work the head in a rotational manner around that bolt. I know alignment dowels will loosen up if worked as the are just thin tubing. Can you center punch the end of the broken bolt and then progressivley drill down thru it, till it's almost gone. That will eliminate most of it and the remainder would break off. You might also use some drill busings to help keep it centered and straight.

#9

If you see pg5 of my original post there were some new details given & suggested.

I have thought about drilling it, but that is a fairly long bolt to be drilling into. Anyone ever see the movie Armageddon when they were drilling on the asteroid. That was the first thing that came to mind.

I will try working it side to side. I figure if I lay a 2x4 on the exhaust ports and then on the intake ports I can use a BFH to persuade it loose.

I have thought about drilling it, but that is a fairly long bolt to be drilling into. Anyone ever see the movie Armageddon when they were drilling on the asteroid. That was the first thing that came to mind.

I will try working it side to side. I figure if I lay a 2x4 on the exhaust ports and then on the intake ports I can use a BFH to persuade it loose.

#13

I would try the bar in the ports deal, I have used that a lot. I also have used on occasion a piece of a 5/16 wide flat screwdriver blade cut off about 3" long and ground to a very thin end. I don't like a chisle because they are hard and the vay

they are ground you dont have a wedge effect unless you change

them. I think you'll be suprised at how how little it takes to pop it loose.

When doing anything like this caution is the word you don't need a heavy

hammer 8 oz. will do, get to an easy access spot on one corner.

While we are on the subject of stuck heads I saw a Lincoln Zepher

V12 on a hot rod show the other evening looked like factory aluminum

heads, of course you all realize Henry senior had a love for studs. Figure

a half a day a side to get one off after it was soaked for a number of days.

Some guys used Iodine.

they are ground you dont have a wedge effect unless you change

them. I think you'll be suprised at how how little it takes to pop it loose.

When doing anything like this caution is the word you don't need a heavy

hammer 8 oz. will do, get to an easy access spot on one corner.

While we are on the subject of stuck heads I saw a Lincoln Zepher

V12 on a hot rod show the other evening looked like factory aluminum

heads, of course you all realize Henry senior had a love for studs. Figure

a half a day a side to get one off after it was soaked for a number of days.

Some guys used Iodine.

#14

Ok guys, this thing is really getting to me. The engine is out, all the bolts are removed (the broken piece is still in there), and the engine is mounted to a stand. I tried soaking the hole, I remove all the other accessories on the head and engine, and there is just nowhere to get leverage to pry up. I tried the only hard plastic wedge I could find (a tent stake that I ground a flat edge into), I'll let you guess what happened.  I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.

I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.

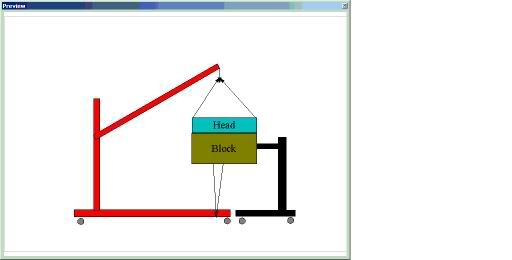

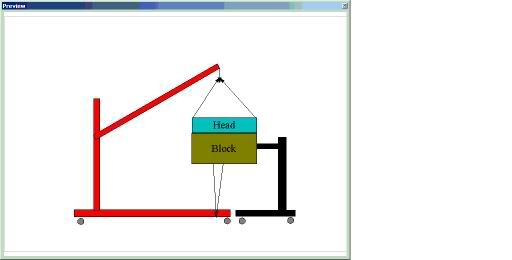

So now I have a new idea. I have never tried this but I think it could work, see what you think. Take a look at this simple pic I made to describe what I want to do. The black arrows are supposed to be chains. The crane has an 8 ton ram on it and I will use the strongest chain I can find. I was thinking of using the biggest bolts on the block like maybe where the mounts bolt to. What do you think????? Am I just crazy?

I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.

I even tried using an old head bolt set on some of the "over casting" edges, and smack it with a hammer...... nothing.So now I have a new idea. I have never tried this but I think it could work, see what you think. Take a look at this simple pic I made to describe what I want to do. The black arrows are supposed to be chains. The crane has an 8 ton ram on it and I will use the strongest chain I can find. I was thinking of using the biggest bolts on the block like maybe where the mounts bolt to. What do you think????? Am I just crazy?

#15

Join Date: May 2004

Location: The hills of No. Calif.

Posts: 12,169

Likes: 0

Received 5 Likes

on

4 Posts

No, not crazy, it looks do-able. Just go slow, increasing pressure gadually and watching for any signs of overloading/overstressing in the chains, fasteners, and even the ram on the hoist (not to mention the hoist itself) and put head bolts back in at the corners loosely so that it won't fly apart if it breaks loose suddenly.

First I would apply a moderate tension and then smack the side of the head/block right near the joint with a heavy brass hammer, or a piece of 2x4 endwise and beat on it with a hand-held sledge (singlejack) to try and send shock waves through that could break it loose.

First I would apply a moderate tension and then smack the side of the head/block right near the joint with a heavy brass hammer, or a piece of 2x4 endwise and beat on it with a hand-held sledge (singlejack) to try and send shock waves through that could break it loose.