What transmission should I use?

#1

What transmission should I use?

My rig is a 1973 P-400, essentially a 2-ton truck chassis with an aluminum delivery van body on top. It weighed 5720lb when I stripped it to convert to a motorhome, and I expect it to approach its 10k GVWR by the time the conversion is done. On top of that, I also want to be able to tow up to ~6000lb. It has a 300 six and an NP435. The transmission has two problems:

1. Not enough gears. The spread is too wide for the engine's powerband, hills are a problem, and with a 4.56 rear it screams near redline on the highway (3k RPM at 60mph). I could change the rear but that'd make the spread even wider.

2. It's making increasingly ominous noises.

I've done some reading and the Mazda 5-speed is out. The ZF 5-speed seems to be the default choice, but is it strong enough for this medium-duty beast? A 6-speed would be my top choice but I can't find any info; are there any that'll bolt to a 300? What other options do I have that don't involve custom work (an off-the-shelf adapter kit would be ok)?

1. Not enough gears. The spread is too wide for the engine's powerband, hills are a problem, and with a 4.56 rear it screams near redline on the highway (3k RPM at 60mph). I could change the rear but that'd make the spread even wider.

2. It's making increasingly ominous noises.

I've done some reading and the Mazda 5-speed is out. The ZF 5-speed seems to be the default choice, but is it strong enough for this medium-duty beast? A 6-speed would be my top choice but I can't find any info; are there any that'll bolt to a 300? What other options do I have that don't involve custom work (an off-the-shelf adapter kit would be ok)?

#2

The ZF would be fine for your application. The 6 speeds are going to have a different bell to engine pattern. The ZF will require a hydraulic clutch.

There are other options, from moving to a T19 with a Gear Vendors OD, to a NV4500, to later T56. All have some compromise to be dealt with.

You can search out the gear ratios for each and see what you'd be getting for the money. Gear Vendors lists all the ratios:

https://www.gearvendors.com/fdrive.html

You could even put a GV unit behind your NP435. They offer, as far as I know, a stand-alone version that is mounted as a divorced unit behind the transmission.

Ranger OD is another one, it mounts between the bell and transmission:

https://high-impact.net/product/ford-ranger-overdrive

There are other options, from moving to a T19 with a Gear Vendors OD, to a NV4500, to later T56. All have some compromise to be dealt with.

You can search out the gear ratios for each and see what you'd be getting for the money. Gear Vendors lists all the ratios:

https://www.gearvendors.com/fdrive.html

You could even put a GV unit behind your NP435. They offer, as far as I know, a stand-alone version that is mounted as a divorced unit behind the transmission.

Ranger OD is another one, it mounts between the bell and transmission:

https://high-impact.net/product/ford-ranger-overdrive

#3

I've already got a hydraulic clutch... were there cable clutches for some of these?

Something that's proving hard to research: most 300 setups have two motor mounts and two transmission mounts. I've got two mounts at the trans bellhousing, one at the very front of the engine, and that's it. Will a ZF for a regular truck work with this setup?

Also, are all NP435 the same, for fitment purposes (specifically, shifter location)?

Thanks for the link to that Ranger box. I would have thought it applied to, well, Ford Rangers, a much lighter-duty rig than mine. It'd let me keep my driveline brake, but my shifter is already quite far back... well, it's an option. More reading to do...

Something that's proving hard to research: most 300 setups have two motor mounts and two transmission mounts. I've got two mounts at the trans bellhousing, one at the very front of the engine, and that's it. Will a ZF for a regular truck work with this setup?

Also, are all NP435 the same, for fitment purposes (specifically, shifter location)?

Thanks for the link to that Ranger box. I would have thought it applied to, well, Ford Rangers, a much lighter-duty rig than mine. It'd let me keep my driveline brake, but my shifter is already quite far back... well, it's an option. More reading to do...

#4

No cables for ZF. Some (BBF, maybe Diesel) had external slave cylinders. SBF pattern is internal. Carefully note the year and model of any trans you get, get everything even if it's trashed, and get the EXACT replacements.

NP435/T19 are, from what I see, direct swap. More on them here. Not sure about the brake.

https://www.novak-adapt.com/knowledg...anual/t18-t19/

Your engine mounting is typical for older trucks and for your model in particular. By using your current trans and an od or the closer ratio'd T19 and an od, you preserve your bell and mounting system. Any trans that has a separate bell does the same, such as the expensive T56 or NV4500 options.

Afaik, the ZF never incorporated such mounts. Being an aluminum trans, the bell would be fairly weak compared to the cast iron monster bell you have now.

NP435/T19 are, from what I see, direct swap. More on them here. Not sure about the brake.

https://www.novak-adapt.com/knowledg...anual/t18-t19/

Your engine mounting is typical for older trucks and for your model in particular. By using your current trans and an od or the closer ratio'd T19 and an od, you preserve your bell and mounting system. Any trans that has a separate bell does the same, such as the expensive T56 or NV4500 options.

Afaik, the ZF never incorporated such mounts. Being an aluminum trans, the bell would be fairly weak compared to the cast iron monster bell you have now.

#5

The custom work I want to avoid is anything I'd have to farm out to a machine shop - flywheel and bellhousing adapters - because I seem to have the worst luck paying others to do work, in general. Fabricating new mounting brackets is within my abilities though, so changing the tricycle mounts to conventional ones for the purpose of fitting a ZF is an option. Turns out they have available driveline brakes, too. But an internal slave cylinder is a dealbreaker. All SBF ZF were internal, no exceptions, no way around it?

Does the tricycle mount mean that my block is different from a normal one, either in its mounting holes or bellhousing?

The OD boxes have merits, but my shifter is already too far back.

Does the tricycle mount mean that my block is different from a normal one, either in its mounting holes or bellhousing?

The OD boxes have merits, but my shifter is already too far back.

#6

I finished installing a ZF5 behind my 300 a few months ago, and really like it. The NP-435 was great, but it did have it's gearing issues. It was begging for more gears.

If you have an 11" clutch, you should be able to reuse your current one. If you already have a hydraulic clutch, it should be a pretty easy swap too.

The bellhousing will bolt right up with no issues.

You just need to look for one behind a 300 or 351, and be sure to get either the 2x4 or 4x4 version, depending on what you currently have.

As far as durability, transmissions are rated by the torque of the engine they're behind, as opposed to the size of the vehicle they're in. ZFs came in many big, heavy F-350s.

The ZF is rated for either 420 or 470tq, depending on which model you get.

#7

The custom work I want to avoid is anything I'd have to farm out to a machine shop - flywheel and bellhousing adapters - because I seem to have the worst luck paying others to do work, in general. Fabricating new mounting brackets is within my abilities though, so changing the tricycle mounts to conventional ones for the purpose of fitting a ZF is an option. Turns out they have available driveline brakes, too. But an internal slave cylinder is a dealbreaker. All SBF ZF were internal, no exceptions, no way around it?

Does the tricycle mount mean that my block is different from a normal one, either in its mounting holes or bellhousing?

The OD boxes have merits, but my shifter is already too far back.

Does the tricycle mount mean that my block is different from a normal one, either in its mounting holes or bellhousing?

The OD boxes have merits, but my shifter is already too far back.

There is no way around the internal slave with a smallblock/300 ZF. The bellhousing is part of the transmission case and can't be changed. The ZF is a good transmission but it has it's own issues too. They have a tendency to pop out of gear. This mainly happens in reverse and either 3rd or 5th. They also like to break the tailshaft housings at the mount ears. Add that to the internal slaves which I personally can't stand ( I've had to replace them a few times ) and having to completely change the engine mount design. I just don't think the ZF is the best choice.

The 300's engine block wasn't different for that style mounting. It just used a front mount and special bellhousing.

Forget about the T-19, they were mainly geared towards big blocks. They don't do any thing for the need of more gears.

First let's cover the noise you are hearing with your NP435. Is it happening with the clutch pedal stepped down or released? If it makes the noise with the clutch pedal stepped down then it's most likely just a throw out bearing. If that's the case it's a good time to replace the clutch set/kit. If the noise is when you are off the clutch pedal then it's most likely a input shaft bearing going bad. You can rebuild the NP435 for less then $250.00.

Or you should be able to find a replacement NP435 for cheap. But if you are going to replace it you need to find the same version. There were at least 5 variances, maybe more, of the NP435 that I know of.

There were 3 different 2wd versions:

1. Long tailshaft that used a slip yoke.

2. Short tailshaft housing with a fixed yoke out put.

3. Short tailshaft fixed yoke HD version used in 1-ton and heavier trucks.

there are some other differences like drum drivetrain parking brakes, etc. But the mounting bosses for that stuff should be on them all, as long as it's the correct tailshaft design.

There were two 4x4 versions:

1. Short tailshaft with a fixed yoke out put. Basically like the 2wd one but it has a transfer case shifter mount on the tailshaft housing. This was the transmission for a divorced transfercase.

2. The other is the standard 4x4 version for the married transfer case set up.

All that being said I would fix the one you have. You know it works. And they are pretty simple to fix/rebuild.

Now to fix the gear spacing issue and lack of OD I see 3 fairly easy options. I'll break them into two groups.

1. Advance Adapters Ranger OD/gear splitter. - This is my favorite option, this is what I want for my vehicles -

It's the easiest install. It just bolts in between the bellhousing and transmission. It does move the transmission and transmission crossmember back 7 1/2". This will require modifying/extending your shifter and having the driveshaft shortened & rebalanced or a new one built.

It also will add another shifter to operate it. They are tough! It's all mechanical, no electronics to fail. It would take doing something pretty stupid to break one.

The main down side to this is the cost. They will run around $1,700. But they are all brand new. Forget about trying to find a used one. I've been looking for the last 10 years with no luck!

2. The Spicer/Brownie 3 spd auxiliary transmission, Model: 5831b - This is the strongest option and what will probably end up in my 89 E350 build -

These were used in medium and HD trucks from the I believe the 50's - the late 70's. This is a fairly heavy divorced 3spd auxiliary transmission. This will require fabricating a mount/crossmember set up to mount it. then you will need a short driveshaft made for joining it to the transmission and then one for going from it to the diff/axle. You also need to mount a remote shifter and linkages to operate it. These usually cost around $700-$1000 used. And you may need to rebuild it, depending on it's condition. This set up let's you keep your original shifter location. You don't need to change anything dealing with your transmission or engine. You are just adding behind it. If you go this way try to get the unit with all the shifter parts. You may have to modify some of them on your install but you'll have something to work with.

Now the other group would be the electronically controlled aftermarket add on OD units. These would include stuff like Gear Vendors, US gear and some other brands. They either mount on the tailshaft housing or are divorce mounted ( the option you would need ) . These are smaller units so they are easier to mount and don't need another shifter to operate them. These are electronically controlled with a dash/shifter button. And they aren't as strong as the AA Ranger or Spicer/Browine set ups. I have seen plenty of these units break or have electrical issues. You will need to fabricate a mount/X-member and have a couple driveshafts made up for them too.

Those will give you a few more options to consider that won't require changing motor mount set ups, clutch linkage/pedal set up, etc.

Trending Topics

#8

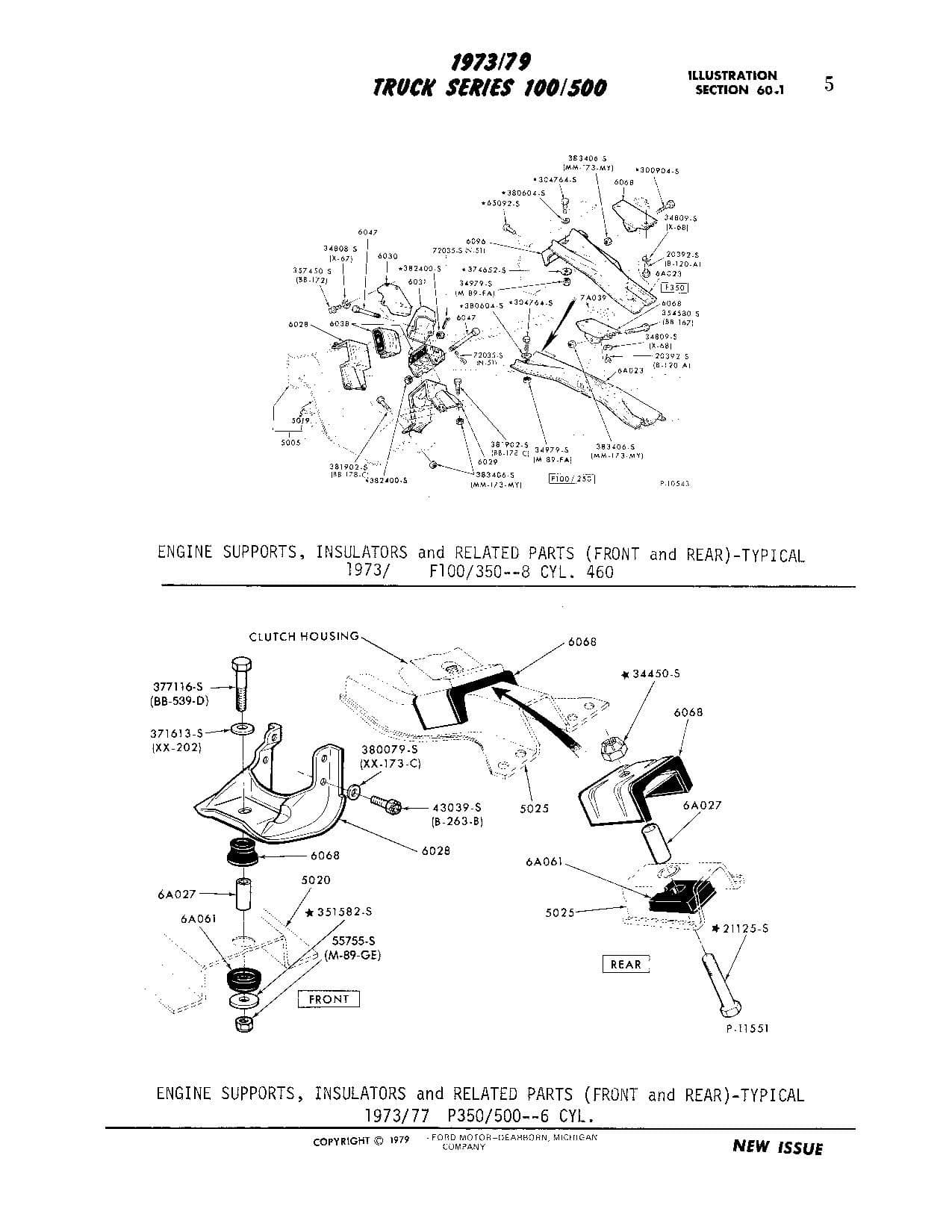

L shaped bracket bolts to the front of the engine, has 1 center lower rubber insulator below the cross member, 1 center upper insulator above the cross member, below the L shaped bracket.

All these trucks have "ears" on the bell housing. There's 1 rubber insulator per side below the cross member, 1 per side above the cross member, below the ears.

So, that's 2 front insulators and 4 rear insulators.

See lower pic below:

#9

Thank you for taking the time to type all that up! You gave me some new ideas and I'm looking into them.

Are there SBF-to-BBF adapters, so I could use a diesel/BBF one?

A T-19 would not be a perfect solution, but it'd help somewhat just being closer-ratio. Mine is basically a three-speed with a crawler gear.

There's a bit of noise in neutral, just the internals turning over, but the big noises are when driving: 1. a low-pitched hum that varies with output/vehicle speed, which in all but fourth is drowned out by 2. a medium-heavy grinding/rattling-type noise in second and third that varies with load, accompanied by a significant vibration when really loaded, and 3. a lighter rattle in third, especially but not exclusively during on/off load transitions. All three are quite loud to my ears. I've driven a 76 F250 and late-80's F150, both 4wd 300 sixes with a 3+granny (not sure what type) and both were far quieter.

I flat-towed this rig about two miles some time ago. I just now read that this can kill an NP435. Before, I had noise #1 and a little of #2. After, #1 stayed the same, #2 got a lot worse, and #3 started.

I've rebuilt manuals and can do it again, I just want different gearing.

That's a bigger problem than in an F-series. Not only is my shifter too far back already, but this is a motorhome and the new location would eat into the front doorway. Below is a pre-conversion photo, but the basic dimensions are the same. If I did find a good deal on a used box, I'd consider it, but my feeling is that $1700+driveshaft+435 rebuild kit is a lot of money to pay for worse ergonomics.

Thanks for bringing this to my attention; I'm reading further and so far so good. I have the skills to lengthen a few shift rods, not so much to fab my own (to fit an NP435 shifter, for instance).

Couldn't I bolt it directly (with some adapters) to the transmission?

I can fix electrical issues on the side of the road, but weak mechanicals I'd prefer to avoid.

Honestly, for the cost and amount of work that most of these solutions require... if I'm paying that much up-front, I'd rather not have compromises to live with later. The Spicer box is an option but I'm going to look further into adapting a modern 5-speed or 6-speed.

Question: I know the 300 boltpattern is the same as other SBF, but what about other dimensions for engine-to-transmission fitment purposes (disregarding shifter, crossmember, driveshaft) - flywheel depth, starter location, pilot bearing size, clutch splines...? If I find, say, a plug-and-play kit to fit a 6-speed to a 351, will it also fit my 300?

Ok, to be precise, there are three powertrain mounting points, each with two mounts. Is there any benefit to this system over the more typical four-mount style?

Forget about the T-19, they were mainly geared towards big blocks. They don't do any thing for the need of more gears.

First let's cover the noise you are hearing with your NP435. Is it happening with the clutch pedal stepped down or released? If it makes the noise with the clutch pedal stepped down then it's most likely just a throw out bearing. If that's the case it's a good time to replace the clutch set/kit. If the noise is when you are off the clutch pedal then it's most likely a input shaft bearing going bad. You can rebuild the NP435 for less then $250.00.

I flat-towed this rig about two miles some time ago. I just now read that this can kill an NP435. Before, I had noise #1 and a little of #2. After, #1 stayed the same, #2 got a lot worse, and #3 started.

I've rebuilt manuals and can do it again, I just want different gearing.

It does move the transmission and transmission crossmember back 7 1/2". This will require modifying/extending your shifter

2. The Spicer/Brownie 3 spd auxiliary transmission, Model: 5831b - If you go this way try to get the unit with all the shifter parts. You may have to modify some of them on your install but you'll have something to work with.

Couldn't I bolt it directly (with some adapters) to the transmission?

Now the other group would be the electronically controlled aftermarket add on OD units....I have seen plenty of these units break or have electrical issues.

Honestly, for the cost and amount of work that most of these solutions require... if I'm paying that much up-front, I'd rather not have compromises to live with later. The Spicer box is an option but I'm going to look further into adapting a modern 5-speed or 6-speed.

Question: I know the 300 boltpattern is the same as other SBF, but what about other dimensions for engine-to-transmission fitment purposes (disregarding shifter, crossmember, driveshaft) - flywheel depth, starter location, pilot bearing size, clutch splines...? If I find, say, a plug-and-play kit to fit a 6-speed to a 351, will it also fit my 300?

Ok, to be precise, there are three powertrain mounting points, each with two mounts. Is there any benefit to this system over the more typical four-mount style?

#10

Do you think an NV3550 can handle this kind of weight? It otherwise seems an excellent solution: $320 adapter to my bellhousing means no clutch or mount customization, 300ft-lb input torque rating should have no trouble with the ~225 of my 4.9, and the ratios are perfect especially with a slightly shorter rear (like the 5.11 on a junked F450 I saw recently).

#11

No, that gets into the whole area that you said you didn't want to go there in post # 5. And it's not just adapting the bellhousing pattern. you also have to adapt the big block flywheel, starter, clutch, etc. You get into spending a bunch of money to use a transmission that isn't that great, just ok. I have a 91 F-super Duty 7.3L IDI diesel with the ZF 5spd.

There's a bit of noise in neutral, just the internals turning over, but the big noises are when driving: 1. a low-pitched hum that varies with output/vehicle speed, which in all but fourth is drowned out by 2. a medium-heavy grinding/rattling-type noise in second and third that varies with load, accompanied by a significant vibration when really loaded, and 3. a lighter rattle in third, especially but not exclusively during on/off load transitions. All three are quite loud to my ears. I've driven a 76 F250 and late-80's F150, both 4wd 300 sixes with a 3+granny (not sure what type) and both were far quieter.

I flat-towed this rig about two miles some time ago. I just now read that this can kill an NP435. Before, I had noise #1 and a little of #2. After, #1 stayed the same, #2 got a lot worse, and #3 started.

I've rebuilt manuals and can do it again, I just want different gearing.

I flat-towed this rig about two miles some time ago. I just now read that this can kill an NP435. Before, I had noise #1 and a little of #2. After, #1 stayed the same, #2 got a lot worse, and #3 started.

I've rebuilt manuals and can do it again, I just want different gearing.

That's a bigger problem than in an F-series. Not only is my shifter too far back already, but this is a motorhome and the new location would eat into the front doorway. Below is a pre-conversion photo, but the basic dimensions are the same. If I did find a good deal on a used box, I'd consider it, but my feeling is that $1700+driveshaft+435 rebuild kit is a lot of money to pay for worse ergonomics.

The Spicer/ Brownie box is a nice unit. Since it goes behind the transmission it allows you to mount it just about anywhere in line between the rear axle and transmission. It will take a fairly substantial crossmember to mount it from. You want it to be strong enough so you don't have the Spicer fall out while driving down the road.

Keep searching on them and you can get some ideas on how others have mounted them.

Keep searching on them and you can get some ideas on how others have mounted them.If you wanted to spend thousands of dollars have a machine shop fabricate a tailshaft housing for the transmission and then a drive sleeve adapter to join the two sure. You could mount it directly to the transmission. But you would still need another crossmember to support it's weight. I'm pretty sure it weighs more then the NP435 does. But just divorce mounting it and installing a short driveshaft to join the transmission and Brownie would be a whole lot cheaper.

Question: I know the 300 boltpattern is the same as other SBF, but what about other dimensions for engine-to-transmission fitment purposes (disregarding shifter, crossmember, driveshaft) - flywheel depth, starter location, pilot bearing size, clutch splines...? If I find, say, a plug-and-play kit to fit a 6-speed to a 351, will it also fit my 300?

The main thing to know is the balance is different between the 240/300's and the SBF V8's. The 300 is a neutral/ 0 imbalance. The small block V8's will be either 28 oz. or 50 oz. imbalance depending on the engine and the age. So if going with a V8 flywheel you need an aftermarket neutral balance one designed for stroker engines. You'll need a bell housing that is designed to work with whatever transmission you use. That will give you the correct depth for the input shaft. You'll need the correct flywheel to match the bellhousing ( 157 tooth or 164 tooth ) . And you 'll also need the matching block spacer plate to match the bell housing and flywheel. Because that's what locates the starter for correct engagement.

If you want to spend money you could contact one of the places that specialize in manual transmission swaps. And buy a complete Tremec TKO 5spd or Tremec T-56 6 speed, Richmond, liberty or whatever. It will work if you get the neutral balance flywheel. But it will be a car transmission not a truck one. They will have good ratios for driving but aren't designed for heavy vehicles or towing. And the other down side to a car transmission is most if not all will locate the shifter even farther back then you currently have it. The NP435 has the shifter right in the center of the main case cover. Car transmissions almost always have the shifter located somewhere in the tailshaft housing.

No matter what you do there is going to be a compromise of some kind. You are just going to have to decide for yourself what you can live with and what you can't. Sorry looks like I wrote novel for a reply.

#12

The more I read about shifter relocation, the more acceptable that compromise becomes. I can live with a small hump. It's about as (mildly) inconvenient as having two shifters. Heck, depending on what trans I end up with, there may be enough room under the floor to clear the shifter linkage. The photo doesn't make it obvious, but I have a *lot* more room than a typical vehicle's transmission tunnel.

I should clarify my stance on custom work. If it's paying someone to figure out a new widget - they get paid before I see something that works - I strongly hesitate. If it's paying someone to just spit out a copy of a widget they long ago figured out - I first see (and, ideally, read good reviews about) something that works, then I buy it - that's fine by me. The latter tends to be a lot cheaper, too.

Novak makes a $320 widget to fit an NV3550 to my bellhousing. I'm doing my homework on their products, but unless reviews suggest otherwise, that kind of custom solution is perfectly ok.

I should clarify my stance on custom work. If it's paying someone to figure out a new widget - they get paid before I see something that works - I strongly hesitate. If it's paying someone to just spit out a copy of a widget they long ago figured out - I first see (and, ideally, read good reviews about) something that works, then I buy it - that's fine by me. The latter tends to be a lot cheaper, too.

Novak makes a $320 widget to fit an NV3550 to my bellhousing. I'm doing my homework on their products, but unless reviews suggest otherwise, that kind of custom solution is perfectly ok.

#13

The more I read about shifter relocation, the more acceptable that compromise becomes. I can live with a small hump. It's about as (mildly) inconvenient as having two shifters. Heck, depending on what trans I end up with, there may be enough room under the floor to clear the shifter linkage. The photo doesn't make it obvious, but I have a *lot* more room than a typical vehicle's transmission tunnel.

I should clarify my stance on custom work. If it's paying someone to figure out a new widget - they get paid before I see something that works - I strongly hesitate. If it's paying someone to just spit out a copy of a widget they long ago figured out - I first see (and, ideally, read good reviews about) something that works, then I buy it - that's fine by me. The latter tends to be a lot cheaper, too.

Novak makes a $320 widget to fit an NV3550 to my bellhousing. I'm doing my homework on their products, but unless reviews suggest otherwise, that kind of custom solution is perfectly ok.

I should clarify my stance on custom work. If it's paying someone to figure out a new widget - they get paid before I see something that works - I strongly hesitate. If it's paying someone to just spit out a copy of a widget they long ago figured out - I first see (and, ideally, read good reviews about) something that works, then I buy it - that's fine by me. The latter tends to be a lot cheaper, too.

Novak makes a $320 widget to fit an NV3550 to my bellhousing. I'm doing my homework on their products, but unless reviews suggest otherwise, that kind of custom solution is perfectly ok.

Can't be much help on the dodge and gm transmissions. I don't use them. Is the NV3550 the dodge 5spd? If it is I believe there was an issue with 5th gear on some of them. I remember something about a the gear breaking free from the shaft or something like that. If it's the one I'm thinking of the fix was something like welding the gear to the shaft or something like that. Just double check that. Like I said I don't really deal with them.So I might be thinking of a different one. If the NV3550 will work for you just remember there is more to it then just the adapter. You'll have to use the correct clutch for it, figure out the correct pilot bearing and then the correct length driveshaft. But if you can use your current bell housing/clutch linkage set up that would save a bunch of work,

#15

With any of the swaps I am seeing you will need to over come the motor / bell housing mounting unless you stay with what you have and add the OD unit on the back side.

I have not heard anything on the Gear Vender units having issues and have looked into it for my project. I have also looked at the AA range splitter and in my case I think it is a better fit as you can split any gear where the GV you have to be going over 30 MPH before you can use OD so limits the gear slitting.

Have you looked into how hard it is to find a used Brownie? I hear they can be hard as they don't make them any more.

Now what I have not heard of any one say is of the autos that can be used. You would not have a shifter in the middle of the floor, a cable type can be mounted anywhere.

They make C6 that bolt to the 300 and being anon-OD trany you would need to bolt the GV unit on the back side and once over 30 MPH you can split gears.

You also have the AOD and AODE both have over drive the "E" being electric and needs a controller box to run it but is used it heaver trucks.

Just something to think about.

Dave ----

I have not heard anything on the Gear Vender units having issues and have looked into it for my project. I have also looked at the AA range splitter and in my case I think it is a better fit as you can split any gear where the GV you have to be going over 30 MPH before you can use OD so limits the gear slitting.

Have you looked into how hard it is to find a used Brownie? I hear they can be hard as they don't make them any more.

Now what I have not heard of any one say is of the autos that can be used. You would not have a shifter in the middle of the floor, a cable type can be mounted anywhere.

They make C6 that bolt to the 300 and being anon-OD trany you would need to bolt the GV unit on the back side and once over 30 MPH you can split gears.

You also have the AOD and AODE both have over drive the "E" being electric and needs a controller box to run it but is used it heaver trucks.

Just something to think about.

Dave ----