Idle issue nightmare

#61

OK You need to plug it back in, pull the spout, start it and rotate distributor. Once timing is set, turn it off, plug the spout back in, and tighten the distributor hold down bolt. At that point, whatever it does is where you stand. If it is not a good idle, you must at that point run codes to see where to proceed..

#62

I wouldn't think they do. I'll go out on a limb and A$$-ume that EECV = OBDII, in which case my 1996 doesn't require that

#63

Intake Air Temperature/Air Charge Temperature sensor: Fuel Injection Technical Library » Air Charge Temperature (ACT)

Engine Coolant Temperature sensor:Fuel Injection Technical Library » Engine Coolant Temperature Sensor (ECT)

Engine Coolant Temperature sensor:Fuel Injection Technical Library » Engine Coolant Temperature Sensor (ECT)

#64

OK You need to plug it back in, pull the spout, start it and rotate distributor. Once timing is set, turn it off, plug the spout back in, and tighten the distributor hold down bolt. At that point, whatever it does is where you stand. If it is not a good idle, you must at that point run codes to see where to proceed..

#66

Join Date: Feb 2002

Location: Greater Austin, Texas

Posts: 7,295

Likes: 0

Received 351 Likes

on

282 Posts

it goes up a little if you retard and down if you advance.

Once the timing is set, you should disconnect the IAC and then adjust the idle stop screw on the TB to 400 RPM for manual trans. This is called your "base idle speed". Sometimes people monkey around with that screw and jack up the idle. If the base idle speed is too high, it freaks out the ECU because it cannot control the idle speed to it's satisfaction via the IAC valve.

#67

You have that backwards. Advancing the timing will raise the idle speed.

Once the timing is set, you should disconnect the IAC and then adjust the idle stop screw on the TB to 400 RPM for manual trans. This is called your "base idle speed". Sometimes people monkey around with that screw and jack up the idle. If the base idle speed is too high, it freaks out the ECU because it cannot control the idle speed to it's satisfaction via the IAC valve.

Once the timing is set, you should disconnect the IAC and then adjust the idle stop screw on the TB to 400 RPM for manual trans. This is called your "base idle speed". Sometimes people monkey around with that screw and jack up the idle. If the base idle speed is too high, it freaks out the ECU because it cannot control the idle speed to it's satisfaction via the IAC valve.

#68

Join Date: Feb 2002

Location: Greater Austin, Texas

Posts: 7,295

Likes: 0

Received 351 Likes

on

282 Posts

I know what you are saying but I have always heard on the forum that the idle screw should never be turned. Unless the previous owner moved it as indicated by the paint. This is just what I have heard from this forum.. I do not have the knowledge to really discuss it. Ford has a sticker on there saying to never adjust it. So I don't know. I did try it ONCE. Sandy

#69

One word of caution on adjusting the throttle stop screw. Yes, I agree someone previously may have jacked with it so I highly suggest you inspect the screw to see if the factory thread locker is still there. If no signs of tampering and the idle RPM is too high, IAC unplugged, then you may have a vacuum leak and/or the throttle blades-bore may be worn. If you start backing out the throttle stop screw to lower the idle RPM you could induce the very problem the screw adjuster was designed for: preventing the throttle blades from closing too far then sticking in the bore.

As far as this thread is concerned I think the OP has two issues. One is electronic that is causing the intermittent high idle with the IAC plugged in. The other is mechanical causing the high idle RPM with the IAC unplugged. As others have noted the idle RPM should be very low or the engine stalls with the IAC unplugged.

As far as this thread is concerned I think the OP has two issues. One is electronic that is causing the intermittent high idle with the IAC plugged in. The other is mechanical causing the high idle RPM with the IAC unplugged. As others have noted the idle RPM should be very low or the engine stalls with the IAC unplugged.

#70

Join Date: Feb 2002

Location: Greater Austin, Texas

Posts: 7,295

Likes: 0

Received 351 Likes

on

282 Posts

If you start backing out the throttle stop screw to lower the idle RPM you could induce the very problem the screw adjuster was designed for: preventing the throttle blades from closing too far then sticking in the bore.

I don't get why some folks think this is some kind of magical screw that must never be touched. It's an adjustment, just like any other.

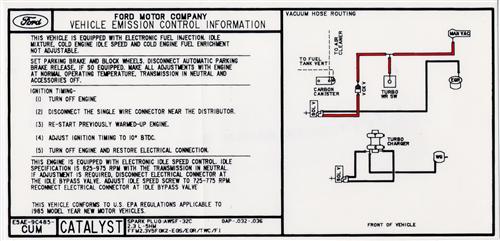

Look towards the bottom where it says to disconnect the IAC valve and adjust the screw:

#71

I don’t read anywhere in this thread where anyone states for this OP not to adjust the Throttle Body Stop Screw. Ford never intended for folks unfamiliar with the EFI system to adjust this screw to change the idle because once it was factory set, other component failures caused a change to the idle. But there is a time and place in the troubleshooting process to make these adjustments.

Old carburetor guys adjusted this screw when the Air Bypass Valve failed, and when the TPS failed or the replacement was not adjusted properly, etc. So, yes previous owners did foolishly adjust this screw, and it is prudent to ask the OP the question as I did in post #10. There are multiple instructions available to adjust this screw, some are mechanical and some are electronic. I suggest the OP perform a mechanical one first.

So, Will, to clear up this part of the discussion, insert a 0.025 inch feeler gauge in-between the screw tip and the throttle stop, the feeler gauge should fit snug and be able to slide in and out with slight difficulty. Adjust the screw to achieve this. This will baseline the mechanical stop adjustment. Please report back for additional guidance.

This adjustment also changes the TPS voltage output, so as recommended in post # 20, make these measurements when you get the chance and report back with the reading to continue the process of elimination. Adjustments to this screw can cause the TPS output voltage to be out of range at closed idle.

Check your Throttle Plates for deformities, and do your plates have any holes drilled in them? Maybe with plugs in the holes? Feel free to upload photos.

Check your Timing sooner than later.

Check your Codes sooner than later.

Old carburetor guys adjusted this screw when the Air Bypass Valve failed, and when the TPS failed or the replacement was not adjusted properly, etc. So, yes previous owners did foolishly adjust this screw, and it is prudent to ask the OP the question as I did in post #10. There are multiple instructions available to adjust this screw, some are mechanical and some are electronic. I suggest the OP perform a mechanical one first.

So, Will, to clear up this part of the discussion, insert a 0.025 inch feeler gauge in-between the screw tip and the throttle stop, the feeler gauge should fit snug and be able to slide in and out with slight difficulty. Adjust the screw to achieve this. This will baseline the mechanical stop adjustment. Please report back for additional guidance.

This adjustment also changes the TPS voltage output, so as recommended in post # 20, make these measurements when you get the chance and report back with the reading to continue the process of elimination. Adjustments to this screw can cause the TPS output voltage to be out of range at closed idle.

Check your Throttle Plates for deformities, and do your plates have any holes drilled in them? Maybe with plugs in the holes? Feel free to upload photos.

Check your Timing sooner than later.

Check your Codes sooner than later.

#73

There are several references to not turn the throttle stop screw counter-clockwise and the reason why: " (do not turn it counter-clockwise as this may cause the throttle plate to stick at idle).

My personal preference is to remove the throttlebody and verify the blades are just barely cracked open. If they are and the idle RPM is still too high...time to start diagnosing where the unmtered air is coming from.

Think about it - if this was what Ford wanted, they could have just formed a stop in the body of the TB. No, they needed it to be adjustable because there are clearance tolerances and such that can affect idle speed. This thing was always intended be adjustable, it's just that, after the fact, Ford decided they wanted to be the only ones adjusting it.

I don't get why some folks think this is some kind of magical screw that must never be touched. It's an adjustment, just like any other.

I don't get why some folks think this is some kind of magical screw that must never be touched. It's an adjustment, just like any other.

Will the world end if you do move it? No, but doing so is masking another issue IMHO.

Enough of this subject for now. The OP has other items to check before going down this path.

#74

Thread

Thread Starter

Forum

Replies

Last Post