Cranks but only sparks when i let off the key

#46

Hold on hold on, lets take a step back here and not jump the gun, this truck was running just fine, now, no spark while cranking the engine, on this different engine thats apperently in here, what controls the spark, i have replaced the ignition module the ignition coil, the switch, the solenoid what else could cause the sparky problem?

See previous post.

#47

this was one of my buddies trucks it was running 2 months ago. Now, when i put the plugs and wires in i used the 5.8 351 firing order, could that be the problem? I got the 5.8w from the vin. But i guess its been swapped out now from what you guys are telling me so for my engine what is the proper firing order?

If it is a 351W then the 351 Firing order will be correct. You have a rather rare beast with this iteration of the EEC III system on it it was used for one year only 1983...... Again you should include your location in your sig as some of these cali emissions trucks used oddball stuff (case in point). Check that the dist cap you replaced is correct and the box you replaced was/is the brown strain relief one.

The crankshaft position sensor is likely the culprit...

Give me few here and I will scratch up the specs for testing it ....

#49

#53

Sorry I can not tell from the pic it is too close with nothing for perspective. But that looks to be the oil pressure switch, the crankshaft position sensor will been near the crank on the bottom at the front of the motor . Refer back to post 40 for it's approximate location.

This is what it looks like see below pic

Go back and reread my posts if you have not as there is information in them you will need.

As for replacing the crank position sensor it would not hurt, it likely is the original, and if it is I think after 35 years it's due to be replaced. .

Also did you have the right new DS II box and Dist cap ? Pics of the correct components were posted.

These systems need to be diagnosed in a methodical step by step manner otherwise you will just chase your tail, and continue to throw parts at it, and never get it to run.

Test your components to verify if they have failed or not even if you are replacing them,.. Also be sure to get EEC components the much more common Duraspark ones look the same but are different.

#54

#57

No it will not start without it. This what tells the box to fire the coil..... There is no bypassing anything in this set up all the parts have to be the correct ones , installed properly and with functional wiring.

And again is your replacement cap and box the correct ones.

If you want to get this running you need to follow the step by step. Otherwise you are just going to beat your head against a brick wall.

First step is we need to know if the box and dist cap installed are the right ones....

And again is your replacement cap and box the correct ones.

If you want to get this running you need to follow the step by step. Otherwise you are just going to beat your head against a brick wall.

First step is we need to know if the box and dist cap installed are the right ones....

#58

I was reading up on the duraspark III system a little bit. The crankshaft sensor sends a signal to a EECIII computer you have mounted somewhere in the truck, more than likely under the dash somewhere. The computer under the dash sends a signal to the ignition module (module in the picture in a previous post) which looks much like a duraspark II module, and that fires the coil.

No way no how can you set the timing on this engine, it is preset by the position of the crankshaft sensor. But you do have to align the distributor rotor, there is a special procedure to do this. You will have to do this procedure since you have the dist out of the engine. In other words, a regular distributor has two duties, to fire the coil and to distribute the spark to the proper cylinder. Your dist does not generate the spark, it only distributes the spark to the correct cylinder.

In a regular dist, the little pickup wheel is keyed to the dist shaft and the rotor that distributes the spark in the cap is also keyed to the shaft. So you never have to worry about aligning the rotor, once you set the timing the rotor is automatically aligned because of the keys in the shaft. But on your setup, the timing is set by the crank sensor. But you can still twist the dist around in different locations, so it has to be aligned properly. My 99 Chevy Tahoe has a system much like this.

#59

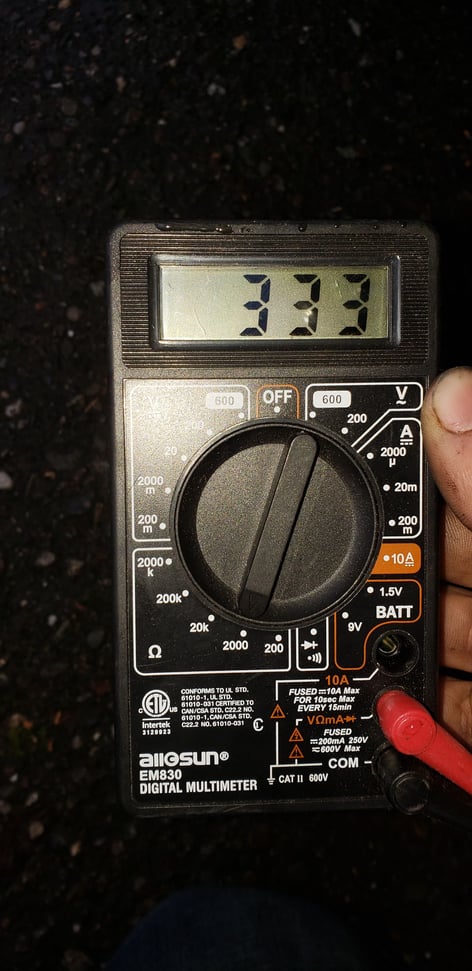

According to this his crankshaft sensor is good?

I was reading up on the duraspark III system a little bit. The crankshaft sensor sends a signal to a EECIII computer you have mounted somewhere in the truck, more than likely under the dash somewhere. The computer under the dash sends a signal to the ignition module (module in the picture in a previous post) which looks much like a duraspark II module, and that fires the coil.

No way no how can you set the timing on this engine, it is preset by the position of the crankshaft sensor. But you do have to align the distributor rotor, there is a special procedure to do this. You will have to do this procedure since you have the dist out of the engine. In other words, a regular distributor has two duties, to fire the coil and to distribute the spark to the proper cylinder. Your dist does not generate the spark, it only distributes the spark to the correct cylinder.

In a regular dist, the little pickup wheel is keyed to the dist shaft and the rotor that distributes the spark in the cap is also keyed to the shaft. So you never have to worry about aligning the rotor, once you set the timing the rotor is automatically aligned because of the keys in the shaft. But on your setup, the timing is set by the crank sensor. But you can still twist the dist around in different locations, so it has to be aligned properly. My 99 Chevy Tahoe has a system much like this.

I was reading up on the duraspark III system a little bit. The crankshaft sensor sends a signal to a EECIII computer you have mounted somewhere in the truck, more than likely under the dash somewhere. The computer under the dash sends a signal to the ignition module (module in the picture in a previous post) which looks much like a duraspark II module, and that fires the coil.

No way no how can you set the timing on this engine, it is preset by the position of the crankshaft sensor. But you do have to align the distributor rotor, there is a special procedure to do this. You will have to do this procedure since you have the dist out of the engine. In other words, a regular distributor has two duties, to fire the coil and to distribute the spark to the proper cylinder. Your dist does not generate the spark, it only distributes the spark to the correct cylinder.

In a regular dist, the little pickup wheel is keyed to the dist shaft and the rotor that distributes the spark in the cap is also keyed to the shaft. So you never have to worry about aligning the rotor, once you set the timing the rotor is automatically aligned because of the keys in the shaft. But on your setup, the timing is set by the crank sensor. But you can still twist the dist around in different locations, so it has to be aligned properly. My 99 Chevy Tahoe has a system much like this.

Yes the sensor tests as good.

Yes the computer controls all the timing. EEC-III automatically adjusts the distributor advance. You can't set the timing by rotating the distributor. If the procedure is needed I have it handy.

Also there is a procedure to get EEC III to output trouble codes this was normally read at the break out box, but I suppose it could be done with a meter at the tab tad solenoids similar to how it is done on EEC IV systems.

For now he needs to verify that he has the right bits installed..

Then we can move on to reinstalling the dist and setting it up.

And then pull some codes to see what is up....