Bucking / Power loss at Full Throttle

#181

I installed the Duraspark first and got the same thin spark with signs of yellow.

Then I plugged the MSD 6AL directly into the Duraspark distributor, added the MSD coil and the spark became very bright, thick, loud and no signs of yellow.

The only problem was the timing changed and went advanced so moving the distributor to correct the timing put the rotor phasing too far out.

The Duraspark box triggers when the magnetic based signal crosses zero and the MSD must trigger when the signal begins to rise.

So I hooked the Duraspark back into the system and let the Duraspark box trigger the MSD and the Duarspark is there as a backup in case of an MSD failure.

Timing back to normal.

Ported head 232 .050" duration cam (288 advertised duration), Quick Fuel HR650 carb, Hedman header, 1977 2WD pickup, T18 tranny.

Rear tires break loose as soon as the engine hits 1200 rpm in second gear and gets 17+ MPG at 70 mph highway @ 2400 rpm. 15 mpg around town.

Then I plugged the MSD 6AL directly into the Duraspark distributor, added the MSD coil and the spark became very bright, thick, loud and no signs of yellow.

The only problem was the timing changed and went advanced so moving the distributor to correct the timing put the rotor phasing too far out.

The Duraspark box triggers when the magnetic based signal crosses zero and the MSD must trigger when the signal begins to rise.

So I hooked the Duraspark back into the system and let the Duraspark box trigger the MSD and the Duarspark is there as a backup in case of an MSD failure.

Timing back to normal.

Ported head 232 .050" duration cam (288 advertised duration), Quick Fuel HR650 carb, Hedman header, 1977 2WD pickup, T18 tranny.

Rear tires break loose as soon as the engine hits 1200 rpm in second gear and gets 17+ MPG at 70 mph highway @ 2400 rpm. 15 mpg around town.

#182

I installed the Duraspark first and got the same thin spark with signs of yellow.

Then I plugged the MSD directly into the Duraspark distributor and the spark became very bright, thick, loud and no signs of yellow.

I had a different spark tester but the MSD spark would jump the 40k distance on yours.

The only problem was the timing changed and went advanced so moving the distributor to correct the timing put the rotor phasing too far out.

The Duraspark box triggers when the magnetic based signal crosses zero and the MSD must trigger when the signal begins to rise.

So I hooked the Duraspark back into the system and let the Duraspark box trigger the MSD and the Duarspark is there as a backup in case of an MSD failure.

Timing back to normal.

Ported head 232 .050" duration cam (288 advertised duration), Quick Fuel HR650 carb, Hedman header, 1977 2WD pickup, T18 tranny.

Rear tires break loose as soon as the engine hits 1200 rpm in second gear and gets 17+ MPG at 70 mph highway @ 2400 rpm. 15 mpg around town.

Ask 250-restorer about his MSD experience.

Then I plugged the MSD directly into the Duraspark distributor and the spark became very bright, thick, loud and no signs of yellow.

I had a different spark tester but the MSD spark would jump the 40k distance on yours.

The only problem was the timing changed and went advanced so moving the distributor to correct the timing put the rotor phasing too far out.

The Duraspark box triggers when the magnetic based signal crosses zero and the MSD must trigger when the signal begins to rise.

So I hooked the Duraspark back into the system and let the Duraspark box trigger the MSD and the Duarspark is there as a backup in case of an MSD failure.

Timing back to normal.

Ported head 232 .050" duration cam (288 advertised duration), Quick Fuel HR650 carb, Hedman header, 1977 2WD pickup, T18 tranny.

Rear tires break loose as soon as the engine hits 1200 rpm in second gear and gets 17+ MPG at 70 mph highway @ 2400 rpm. 15 mpg around town.

Ask 250-restorer about his MSD experience.

#183

Am I understanding right that the MSD didn't work properly with your application, and you had to revert to the DS box?

Maybe I'm not following.

Still, your gas mileage makes me scratch my head.

I'm averaging 11 in town, maybe 13 - 14 on the highway.

70mph is 2000 RPMs.

I mean, I know I have 32" A/T tires, which makes a difference, but it shouldn't be that much.

Did you see my question about what voltage range I should be looking for on my tester? I know what results I'm getting, but I don't know what I'm shooting for, or what I'm comparing against.

Maybe I'm not following.

Still, your gas mileage makes me scratch my head.

I'm averaging 11 in town, maybe 13 - 14 on the highway.

70mph is 2000 RPMs.

I mean, I know I have 32" A/T tires, which makes a difference, but it shouldn't be that much.

Did you see my question about what voltage range I should be looking for on my tester? I know what results I'm getting, but I don't know what I'm shooting for, or what I'm comparing against.

#184

#185

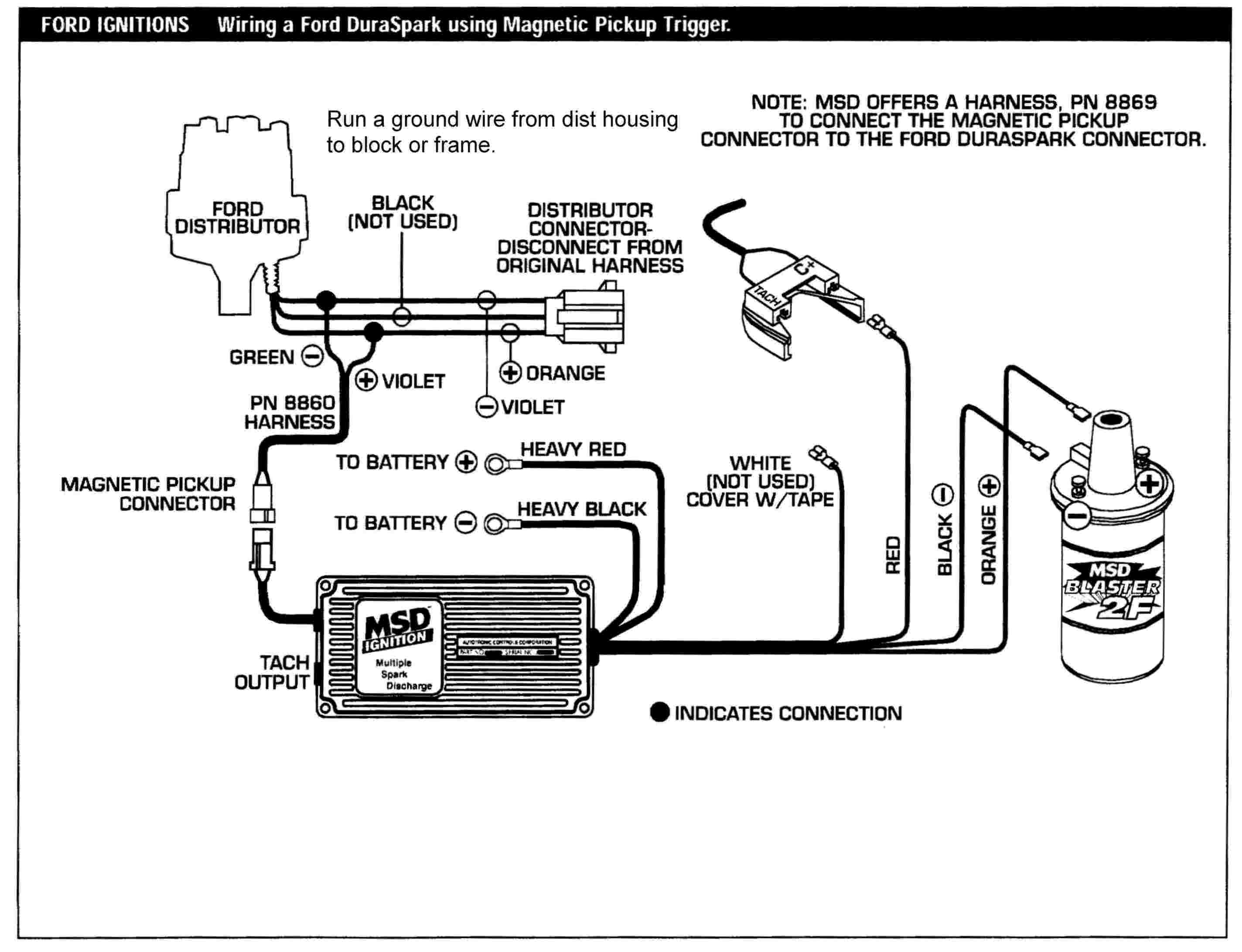

Here are the MSD 6AL instructions. https://www.jegs.com/InstallationIns...1/121-6425.pdf

I started with the wiring shown on the bottom of page 15 using the PN 8869 adapter cable.

When I found the timing change I changed to the wiring shown on the top of page 15.

You can also wire the MSD into the HEI system as shown on page 14.

I started with the wiring shown on the bottom of page 15 using the PN 8869 adapter cable.

When I found the timing change I changed to the wiring shown on the top of page 15.

You can also wire the MSD into the HEI system as shown on page 14.

#186

I see what you mean.

Yeah, it looks like the MSD install is pretty straight forward and easy to do, with either the DSII or HEI.

If I went this route, though, I'm not sure I'd see much use in keeping the HEI, except that it's curved to my engine. Dunno.

Still, though, I contacted DUI about this. This isn't a stock HEI system, but a high output performance version, so it shouldn't be "weak"

Maybe something internally is wrong?

Yeah, it looks like the MSD install is pretty straight forward and easy to do, with either the DSII or HEI.

If I went this route, though, I'm not sure I'd see much use in keeping the HEI, except that it's curved to my engine. Dunno.

Still, though, I contacted DUI about this. This isn't a stock HEI system, but a high output performance version, so it shouldn't be "weak"

Maybe something internally is wrong?

#189

#190

#191

First big problem is assuming the EFI throttle body doesn't need manifold heat. It needs MORE heat than a carb. It does NOT "atomize" fuel better than a carb. It does not emulsify fuel at all, which a carb does, and it merely tries to squirt small streams of fuel into the air stream to be sheared. For that reason, when sheared across throttle blades, it will do a better job of "atomizing" than at full throttle, with worse air velocity and no vacuum to help with phase change, etc.

Second thing I see is the VE map is majorly over compensating for what looks like a poorly tuned acceleration enrichment. Problem is that the acceleration enrichment can't be properly tuned if it's causing a missfire from not having manifold heat. The system is definitely chasing it's tail adding way too much fuel when it isn't needed, and in my opinion you're fighting a rich miss. Cyl 6 plug is evident of it and is the first to miss from being overly rich and fuel dropout.

Second thing I see is the VE map is majorly over compensating for what looks like a poorly tuned acceleration enrichment. Problem is that the acceleration enrichment can't be properly tuned if it's causing a missfire from not having manifold heat. The system is definitely chasing it's tail adding way too much fuel when it isn't needed, and in my opinion you're fighting a rich miss. Cyl 6 plug is evident of it and is the first to miss from being overly rich and fuel dropout.

#192

I installed the Duraspark first and got the same thin spark with signs of yellow.

Then I plugged the MSD 6AL directly into the Duraspark distributor, added the MSD coil and the spark became very bright, thick, loud and no signs of yellow.

The only problem was the timing changed and went advanced so moving the distributor to correct the timing put the rotor phasing too far out.

The Duraspark box triggers when the magnetic based signal crosses zero and the MSD must trigger when the signal begins to rise.

So I hooked the Duraspark back into the system and let the Duraspark box trigger the MSD and the Duarspark is there as a backup in case of an MSD failure.

Timing back to normal.

P

Then I plugged the MSD 6AL directly into the Duraspark distributor, added the MSD coil and the spark became very bright, thick, loud and no signs of yellow.

The only problem was the timing changed and went advanced so moving the distributor to correct the timing put the rotor phasing too far out.

The Duraspark box triggers when the magnetic based signal crosses zero and the MSD must trigger when the signal begins to rise.

So I hooked the Duraspark back into the system and let the Duraspark box trigger the MSD and the Duarspark is there as a backup in case of an MSD failure.

Timing back to normal.

P

Everything was reset [timing & carburetion] and this system has worked well for years.

#193

First big problem is assuming the EFI throttle body doesn't need manifold heat. It needs MORE heat than a carb. It does NOT "atomize" fuel better than a carb. It does not emulsify fuel at all, which a carb does, and it merely tries to squirt small streams of fuel into the air stream to be sheared. For that reason, when sheared across throttle blades, it will do a better job of "atomizing" than at full throttle, with worse air velocity and no vacuum to help with phase change, etc.

From my reading, a TBI atomized fuel just as well, if not better, than a carburetor. Why wouldn't it? A carb squirt fuel into the air stream at low pressure, whereas the TBI injects in a high pressured mist that's already partially dispersed.

The Sniper system also has about 10 different holes it comes out of that circle around the venturi to aid in this even more.

After an hour or so of research, I can't find anything that says that a TBI setup requires the intake floor to be heated, but plenty of resources stating that a carburetor does.

Also, this isn't necessarily at wide open throttle, but full cylinder fill, and more so at lower RPMs. At lower RPMs, full cylinder pressure can easily be achieved with only 40 - 50% throttle, leaving the fuel sheared by the throttle blades.

Again, not saying it's not true, and if that's simply the case, I'd gladly look into it. But, I can't find anything to confirm it.

Second thing I see is the VE map is majorly over compensating for what looks like a poorly tuned acceleration enrichment. Problem is that the acceleration enrichment can't be properly tuned if it's causing a missfire from not having manifold heat. The system is definitely chasing it's tail adding way too much fuel when it isn't needed, and in my opinion you're fighting a rich miss. Cyl 6 plug is evident of it and is the first to miss from being overly rich and fuel dropout.

I'm definitely not shooting down your ideas, because I need an answer to this issue, and you sound like you know what you're talking about. I am just prodding for more info, since I can't confirm any of it elsewhere.

I don't know if this will help any, but my truck has a Duraspark distributor with MSD box. When first installed, the engine would fire off immediately and idled well with sparkplugs gapped @ .050". However, when driven, it would buck violently under light throttle when it approached ~1800 RPMs. It would run a little better with the vacuum advance blocked off. I had made a wiring mistake. Look at the diagram [below] and the violet colored distributor wire had been connected to the violet colored wire of the MSD ignition box [backwards!!!]. This advanced the timing quite a bit, such that as Mr. Muller has stated that the rotor phasing was too far out. When the wiring was corrected, the ~650 RPM idle immediately dropped to a struggling, but maintaining, ~350 RPMs!!

Everything was reset [timing & carburetion] and this system has worked well for years.

Everything was reset [timing & carburetion] and this system has worked well for years.

#194

Research some on carburetor emulsification and why TBI fuel injection cannot match the power production of a carburetor, even at the same fuel ratios. You can also search for slow motion videos on YouTube of Fitech and Holly Sniper TBI systems in operation, as well as carburetors. The only time you would not need manifold heat is without a "wet manifold" - port injection. In port injection, fuel vaporizes by injecting on a hot intake valve instead.

Throttle percentage does not necessarily equate to "wide open throttle". MAP/vacuum readings do moreso. Throttle readings are more used for rate of change acceleration enrichment calculations, just like a carb accelerator pump. Just because the throttle is open 50% doesn't mean the air velocity is 50% more than at 100% throttle, especially when the throttle body is oversized for the application. This can be seen easily by watching the MAP vs TPS relationships over the RPM range.

Look at the large hot spot in the VE map. It shouldn't be there. The VE map should mimic the engine torque curve, while the acceleration enrichment settings should cover the throttle changes. It may take more than just manifold heat to overcome the problems associated with auto learn tuning, it may also take changes to the acceleration enrichment settings and auto learn settings as well. Of course, it's always best to have professional tuning instead. Here's a video that explains the relationships some: https://youtu.be/Xou5u9DaH2Q

Throttle percentage does not necessarily equate to "wide open throttle". MAP/vacuum readings do moreso. Throttle readings are more used for rate of change acceleration enrichment calculations, just like a carb accelerator pump. Just because the throttle is open 50% doesn't mean the air velocity is 50% more than at 100% throttle, especially when the throttle body is oversized for the application. This can be seen easily by watching the MAP vs TPS relationships over the RPM range.

Look at the large hot spot in the VE map. It shouldn't be there. The VE map should mimic the engine torque curve, while the acceleration enrichment settings should cover the throttle changes. It may take more than just manifold heat to overcome the problems associated with auto learn tuning, it may also take changes to the acceleration enrichment settings and auto learn settings as well. Of course, it's always best to have professional tuning instead. Here's a video that explains the relationships some: https://youtu.be/Xou5u9DaH2Q

#195

Research some on carburetor emulsification and why TBI fuel injection cannot match the power production of a carburetor, even at the same fuel ratios. You can also search for slow motion videos on YouTube of Fitech and Holly Sniper TBI systems in operation, as well as carburetors. The only time you would not need manifold heat is without a "wet manifold" - port injection. In port injection, fuel vaporizes by injecting on a hot intake valve instead.

Do you have any links/reading material that supports this? I'd be interested.

I'll keeping looking information on heating the intake, because yeah, they supply fuel the same way by mixing at the source, instead of at the head right before it enters the cylinder.

Throttle percentage does not necessarily equate to "wide open throttle". MAP/vacuum readings do moreso. Throttle readings are more used for rate of change acceleration enrichment calculations, just like a carb accelerator pump. Just because the throttle is open 50% doesn't mean the air velocity is 50% more than at 100% throttle, especially when the throttle body is oversized for the application. This can be seen easily by watching the MAP vs TPS relationships over the RPM range.

I was mentioning that above in your response about the shearing by the throttle blades. It can happen when the throttle blades aren't fully open (and often does), even though the MAP has reached "100%", since the TPS and MAP aren't a 1:1 ratio.

No worries, I'm used to how different sized carbs require different amounts of throttle for the same cylinder pressure / vacuum.

Look at the large hot spot in the VE map. It shouldn't be there. The VE map should mimic the engine torque curve, while the acceleration enrichment settings should cover the throttle changes. It may take more than just manifold heat to overcome the problems associated with auto learn tuning, it may also take changes to the acceleration enrichment settings and auto learn settings as well. Of course, it's always best to have professional tuning instead. Here's a video that explains the relationships some: https://youtu.be/Xou5u9DaH2Q

Yes, the "hot spot" in the VE map bugs me and any time I've reset the table and started relearning from scratch, it comes back immediately.

There are numerous acceleration enrichment settings available.

AE vs. TPS rate of change

AE vs. TPS vs Coolant temp (boost for cold engine)

AE Correction vs TPS (this one I don't understand what it does)

AE vs. MAP rate of change

MAP AE decay vs. coolant temp

MAP AE vs. coolant temp

The only reason I don't see it being an AE issue is that the only common factor is manifold pressure. Not TPS, not TPS rate of change, not MAP rate of change, just MAP. But, again, I'm fairly new to EFI and learning, so am all ears.

This is the current VE table:

Large View: https://www.supermotors.net/getfile/...iginal/afr.jpg

Lastly, for what it's worth, I recently posted this issue over on the Sniper forums, and about 5 or 6 responses all came back saying the same thing in that it's ignition related.

So, I'm quite confused.