Forscan Misfire Questions

#16

Actually I'm in Texas, need to check why my location doesn't show. That's why I drive these trucks so long, 93 had 240k when it got totaled and a 2000 in the driveway has 287k on the 2.5, I'm almost ready to push it in the garage and toy with an engine swap.

What do you suggest on the threads on these sensors ?

What do you suggest on the threads on these sensors ?

#17

Use the above homebrew rust buster mix to get them out if rusted in place. If your asking about anti-seize compound, most sensors now come with some already applied on the threads. I used a tad more on my Taurus because space doesn't permit me to get a long breaker bar in there if needed. I used a little additional Permatex high temp Nickel loaded anti-seize. https://www.permatex.com/products/lubricants/specialty-lubricants-anti-seize/permatex-nickel-anti-seize-lubricant/, Careful Not to get any past the threads onto the sensor innards so you don't contaminate it. Doesn't require much on the threads, so don't glob it on, just enough to fill the threads in a narrow vertical line up the threads 2-3 places around the threads circumference is plenty & torque the sensor in to spec, no need to over do the tightening either.

On the salted roads, I think I confused this thread with another up in RI that I was posting to??? Anyway, you might find the simple home brew rust buster recipe handy to have around your shop too!!!

On the salted roads, I think I confused this thread with another up in RI that I was posting to??? Anyway, you might find the simple home brew rust buster recipe handy to have around your shop too!!!

#19

With the mileage on those O2 sensors, who knows what's going on. The O2 sensors are just supposed to read/report on what they see coming to them from up stream, but with the mileage on them who knows how sound their sensitivity & reporting ability really is.

I'd install the new O2 sensors, wipe the computer KAM by disconnecting the battery B- cable during the sensor swap, or use the ELM/FORScan combo to clear KAM, which clears the corrupt fuel trim tables, so the computer can begin building new tables using the new O2 sensors input.

Then perform a base cold/warm idle strategy relearn routine as outlined here. https://www.ford-trucks.com/forums/showpost.php?p=9080519&postcount=12

Then go for a drive until all the emissions counters reset, or do the Ford drive cycle routine here Ford Motor OBD-II Driving Cycle | Car OBD Diagnostics, ECU Chip Tuning & Auto Repair Support, to hurry up their reset if you can't wait.

Then go for another drive with the A/C & OD turned Off, the ELM & FORScan running, to see how the O2 sensors switching profile & fuel trim for both cyl banks looks, capture that & post up That info, as it would take a lot of speculation out of what your seeing. With the A/C & OD off, note if the hesitation/miss is still there? If it is, under what driving conditions does it seem to occur?

More thoughts for consideration, let us know what you do & how it goes.

I'd install the new O2 sensors, wipe the computer KAM by disconnecting the battery B- cable during the sensor swap, or use the ELM/FORScan combo to clear KAM, which clears the corrupt fuel trim tables, so the computer can begin building new tables using the new O2 sensors input.

Then perform a base cold/warm idle strategy relearn routine as outlined here. https://www.ford-trucks.com/forums/showpost.php?p=9080519&postcount=12

Then go for a drive until all the emissions counters reset, or do the Ford drive cycle routine here Ford Motor OBD-II Driving Cycle | Car OBD Diagnostics, ECU Chip Tuning & Auto Repair Support, to hurry up their reset if you can't wait.

Then go for another drive with the A/C & OD turned Off, the ELM & FORScan running, to see how the O2 sensors switching profile & fuel trim for both cyl banks looks, capture that & post up That info, as it would take a lot of speculation out of what your seeing. With the A/C & OD off, note if the hesitation/miss is still there? If it is, under what driving conditions does it seem to occur?

More thoughts for consideration, let us know what you do & how it goes.

#20

#21

Ok, lets review a little & think about this some more. Is the problem still as described in your first post, a little rough on the idle & hesitation on moving off at throttle up?

If so, have you seen any improvement after adding the Techron?

Is the idle roughness when your at "P" or "N" & if so does it improve, or go away when you put the tranny in "D"?

On the hesitation at throttle up, check the air filter to see if its really dirty & make sure the filter is fully seated & the air box is fully buttoned up & the air tube is properly fastened.

EDIT: Also, seeing as how you say the rough idle occurs after warm up, keep in mind the difference in fuel trim is its Leaner at warm idle, so keep that in mind as you progress through the testing.

When last was the fuel filter replaced & was it replaced on time as called out in our scheduled maintenance list?

If the filter is due but hasn't been replaced, have you checked fuel pressure & delivery rate lately?

With the mileage on this vehicle, with your Analog multi-meter, check the TPS resistance range & for smoothness in resistance change, as you slowly go from closed to wide open throttle & for drop-outs as you begin to open the throttle.

In all those miles have you ever removed & cleaned the MAF sensor with non residual CRC MAF spray cleaner?

In all these miles, has the PCV valve ever been changed?

If so, have you seen any improvement after adding the Techron?

Is the idle roughness when your at "P" or "N" & if so does it improve, or go away when you put the tranny in "D"?

On the hesitation at throttle up, check the air filter to see if its really dirty & make sure the filter is fully seated & the air box is fully buttoned up & the air tube is properly fastened.

EDIT: Also, seeing as how you say the rough idle occurs after warm up, keep in mind the difference in fuel trim is its Leaner at warm idle, so keep that in mind as you progress through the testing.

When last was the fuel filter replaced & was it replaced on time as called out in our scheduled maintenance list?

If the filter is due but hasn't been replaced, have you checked fuel pressure & delivery rate lately?

With the mileage on this vehicle, with your Analog multi-meter, check the TPS resistance range & for smoothness in resistance change, as you slowly go from closed to wide open throttle & for drop-outs as you begin to open the throttle.

In all those miles have you ever removed & cleaned the MAF sensor with non residual CRC MAF spray cleaner?

In all these miles, has the PCV valve ever been changed?

#22

I haven't done the Techron yet, running low on cash after paying for front end work then having to fix it myself anyway. I'm to old to roll around in the driveway anymore, hurt for days afterwards. (I replaced lower control arm twice)

Fuel filter is months old, same with air filter, cleaned the MAF sensor and the throttle body. This was all trying to solve the hesitation problem which is gone. The miss I feel is at idle in drive sitting still,sometimes worse than others. I am doing what I can as $ comes in.

Fuel filter is months old, same with air filter, cleaned the MAF sensor and the throttle body. This was all trying to solve the hesitation problem which is gone. The miss I feel is at idle in drive sitting still,sometimes worse than others. I am doing what I can as $ comes in.

#23

Ok good feedback, so the hesitation is gone, but the miss is at idle in "D". Is the miss worse at warm idle, or cold idle, or when the engine is under load, like pulling a grade, or when you go smartly at throttle up?

When the miss occurs, can you hear any under hood valve ticking in time with the miss?

EDIT: Have you used, or rigged a stethoscope to listen to each of the cylinders for a valve noise & fuel injectors, listening to both long enough for the idle miss to occur, so to see if one sounds different & in time with the miss?

When the miss occurs, can you hear any under hood valve ticking in time with the miss?

EDIT: Have you used, or rigged a stethoscope to listen to each of the cylinders for a valve noise & fuel injectors, listening to both long enough for the idle miss to occur, so to see if one sounds different & in time with the miss?

#25

#26

I've got a DY-1093 F85Z-9G444-BA

and a DY-1081 F85Z-9G444-AB

These are the rears and one has the wrong connector and doesn't match what's on the truck. The alignment pins on the side are in different positions.

I'm going to have to soak the fronts to break them loose. I hope they gave me the right ones for that. DY-835 XL3Z-9F472-AA

and a DY-1081 F85Z-9G444-AB

These are the rears and one has the wrong connector and doesn't match what's on the truck. The alignment pins on the side are in different positions.

I'm going to have to soak the fronts to break them loose. I hope they gave me the right ones for that. DY-835 XL3Z-9F472-AA

#27

Rock Auto shows the DY1401 as the downstream sensors which matches neither one I have. The DY835 upstream ones I have show to be correct. Still need to get those out.

DY1093 and the DY1081 say their the same as the DY1401: https://www.rockauto.com/en/moreinfo...88&jsn=3&jsn=3

Still one has the alignment pins on the connector wrong, I can't remember where I bought these. Shoot me, but I cut the two pins off and stuck it in there. I hope it's wired correct ? Truck is runn9ing

For the DY1401 it says this:

Alternate/OEM Part Number(s): DY1005, DY1013, DY1034, DY1038, dy1039, DY1040, DY1053, DY1057, DY1060, DY1063, DY1081, DY1086, DY1087, DY1089, DY1091, DY1093, DY1104, DY649, DY661, DY703, DY731, DY761, DY800, DY831, DY832, DY834, DY850, F0SF9F472AA, F0SF9F472BA, F4SF9F472AB, F4UF9F472AA, F5MF9F472AA, F77F9F472BA, F88F9F472AB, F88F9F472BA, GP7441, PF9B511AA, TRM715F48, XC2F9F472AA, XC2Z9F472AA, XC2Z9F472BA

DY1093 and the DY1081 say their the same as the DY1401: https://www.rockauto.com/en/moreinfo...88&jsn=3&jsn=3

Still one has the alignment pins on the connector wrong, I can't remember where I bought these. Shoot me, but I cut the two pins off and stuck it in there. I hope it's wired correct ? Truck is runn9ing

For the DY1401 it says this:

Alternate/OEM Part Number(s): DY1005, DY1013, DY1034, DY1038, dy1039, DY1040, DY1053, DY1057, DY1060, DY1063, DY1081, DY1086, DY1087, DY1089, DY1091, DY1093, DY1104, DY649, DY661, DY703, DY731, DY761, DY800, DY831, DY832, DY834, DY850, F0SF9F472AA, F0SF9F472BA, F4SF9F472AB, F4UF9F472AA, F5MF9F472AA, F77F9F472BA, F88F9F472AB, F88F9F472BA, GP7441, PF9B511AA, TRM715F48, XC2F9F472AA, XC2Z9F472AA, XC2Z9F472BA

#29

you might want to check for exact parts from ford and match to yours here

These guys are best for checking: https://www.oemfordpartsjackyjones.com/

https://parts.ford.com/en.html

These guys are best for checking: https://www.oemfordpartsjackyjones.com/

https://parts.ford.com/en.html

#30

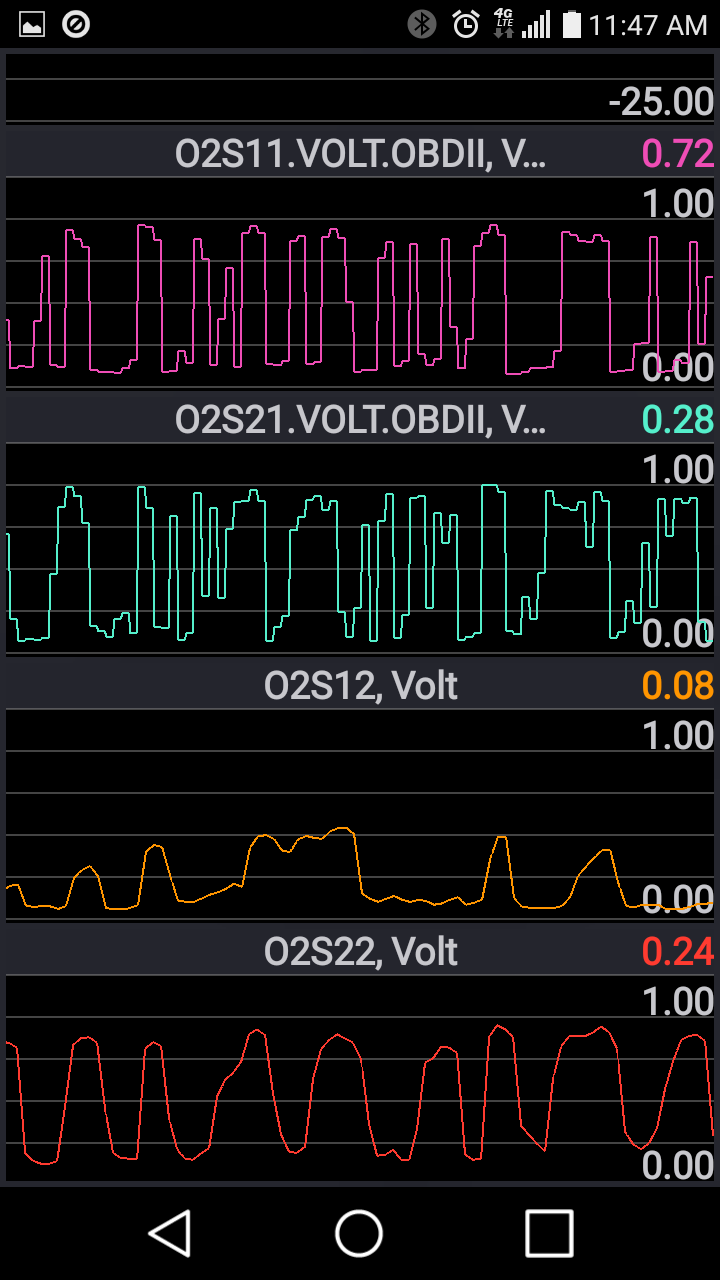

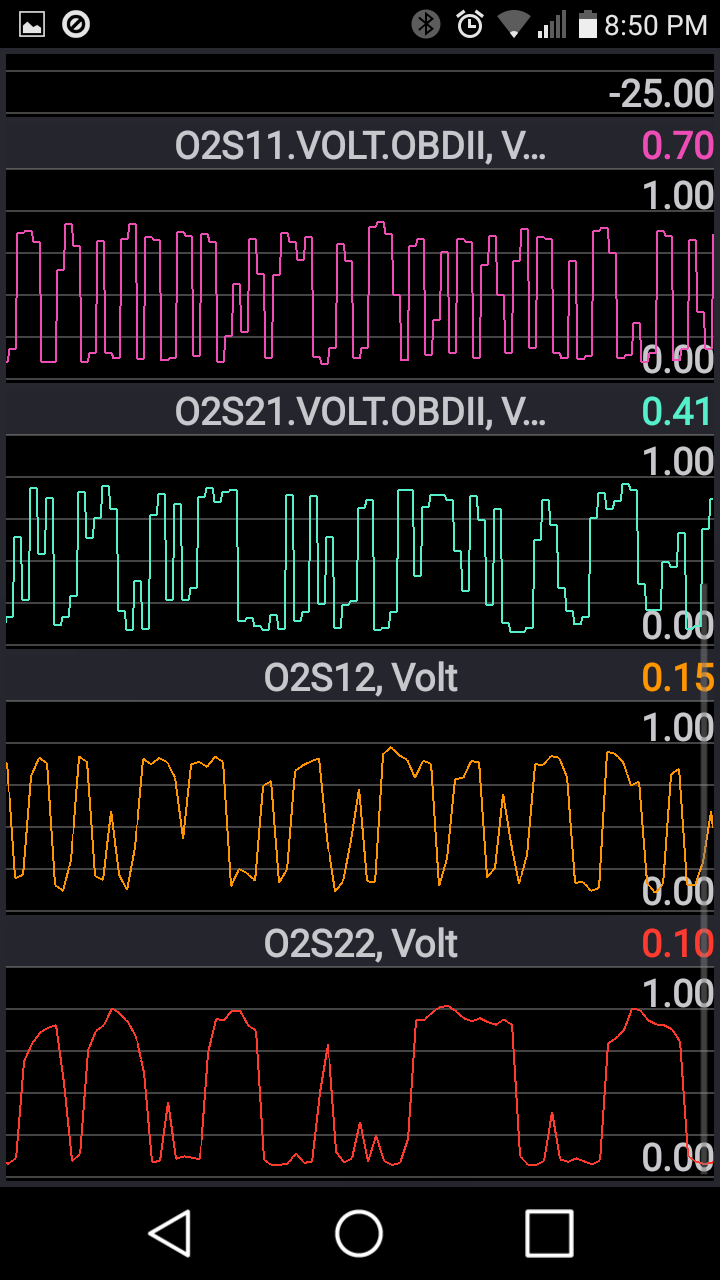

Is the above upstream O2 sensors plot still the old ones??? The trace looks similar to the initial posted plots. Bank-1 switching looks better than Bank-2, but bank-2 seems to be improved a tad bit from the initial plot posting but still isn't what it needs to look like, so maybe the Techron is doing some fuel injector tidy up such that the fuel injector spray pattern is better & that's improved combustion a little????

Fuel injector spray pattern, cylinder compression, spark quality, O2 sensor age, MAF Sensor sensitivity, all play a part in how things will look for the O2 sensor switching plot. Older O2 sensors are usually slower to respond & begin to switch, so their plot peaks will be less pointed, more square & the trace will be wider. A fresh O2 sensor plot is typically more pointed at the top, as it responds/switches faster, so the top of trace it more pointed & the traces are narrower & closer together/faster response/quicker switching, which is Good & what we're looking for, as it keeps fuel trim in tighter control & that'll improve MPG & drive-ability, cold & hot starts, lower emissions, etc.

The down stream/After cat converter O2 sensors show how the cat converters are doing trying to process what's being dumped into them.

^+1 on going to the Motorcraft, or Ford web sites & checking the O2 sensors part numbers for your engine. There are links to those sites atop the Oil & Lubrication forum in the Tech Info thread.

Fuel injector spray pattern, cylinder compression, spark quality, O2 sensor age, MAF Sensor sensitivity, all play a part in how things will look for the O2 sensor switching plot. Older O2 sensors are usually slower to respond & begin to switch, so their plot peaks will be less pointed, more square & the trace will be wider. A fresh O2 sensor plot is typically more pointed at the top, as it responds/switches faster, so the top of trace it more pointed & the traces are narrower & closer together/faster response/quicker switching, which is Good & what we're looking for, as it keeps fuel trim in tighter control & that'll improve MPG & drive-ability, cold & hot starts, lower emissions, etc.

The down stream/After cat converter O2 sensors show how the cat converters are doing trying to process what's being dumped into them.

^+1 on going to the Motorcraft, or Ford web sites & checking the O2 sensors part numbers for your engine. There are links to those sites atop the Oil & Lubrication forum in the Tech Info thread.