Electric Fan Direction Pusher or Puller

#16

I never said it shuts off ( THAT IS THE PROBLEM ) it goes to 200 degrees on gauge the fan relay turns it on like it should at 200 degrees fan is at a very high speed but the temp keeps going up on the gauge went to 240 fan never brought it down to 185 degrees where it will shut off--- supplier is telling me this set-up should work I tell them to much shroud and hole should be 18" with fan or ? ? -- shroud and surrounding sheet metal is hot to touch--

#17

This sounds like a water flow problem to me. Either wrong impeller rotation, head gaskets on the wrong sides, or -?-. You didn't answer Mixer's question on whether this is happening while driving, idling in the garage, or what? If this is in the garage, definitely a water flow problem. Try leaving the radiator cap off, and watching for flow.

#18

#19

Fan

As an aside, you can actually overheat an engine by removing the thermostat altogether, because the coolant doen't spend enough time in residence in the radiator core to transfer heat fast enough, and will eventually become thermally saturated with only convection for cooling.

------- So hopefully I explained what I got and what happened to all of you that are helping and giving me advise--- this is the first rest-o-rod I had that I ever used a shroud like this one always just used fan and worked -------

?

#20

That's odd that the lower hose blew because that's (supposedly) the suction side of the coolant pump, and would have the lowest Δt and Δp . Apparently your radiator and expansion reservoir caps aren't working/relieving either. The symptoms you describe now lead to thermal saturation. Did you change the coolant pump for your build? Another thing to consider is air pockets in the cooling system (the pump could be air bound). The truest way to eliminate air pockets is how you fill the system - fill it from the bottom up, the lowest point. Usually the radiator drain. Use a hand or drill pump with the radiator top tank cap removed.

Edit: Fill until there is no air space around the neck and it overflows onto the coolant recovery reservoir, and then one-third full.

Edit: That spring in the bottom radiator hose is to keep it from collapsing under the coolant pump suction (very low Δp).

Edit: Fill until there is no air space around the neck and it overflows onto the coolant recovery reservoir, and then one-third full.

Edit: That spring in the bottom radiator hose is to keep it from collapsing under the coolant pump suction (very low Δp).

#21

Fan

That's odd that the lower hose blew because that's (supposedly) the suction side of the coolant pump, and would have the lowest Δt and Δp . Apparently your radiator and expansion reservoir caps aren't working/relieving either. The symptoms you describe now lead to thermal saturation. Did you change the coolant pump for your build? Another thing to consider is air pockets in the cooling system (the pump could be air bound). The truest way to eliminate air pockets is how you fill the system - fill it from the bottom up, the lowest point. Usually the radiator drain. Use a hand or drill pump with the radiator top tank cap removed.

Edit: Fill until there is no air space around the neck and it overflows onto the coolant recovery reservoir, and then one-third full.

Edit: That spring in the bottom radiator hose is to keep it from collapsing under the coolant pump suction (very low Δp).

Edit: Fill until there is no air space around the neck and it overflows onto the coolant recovery reservoir, and then one-third full.

Edit: That spring in the bottom radiator hose is to keep it from collapsing under the coolant pump suction (very low Δp).

#22

#23

A picture of the lower hose set up might help. Respectfully, At this point, I suggest you go back thru this thread, read every word, answer every question that has been asked of you.

What is the build level on that engine?

Is it a new rebuild or has it been in any service before?

Have you used an infrared thermometer to view temperatures at various locations of the assembly?

Is the radiator heating up at the top first?

Are you absolutely certain the water pump rotation is correct?

What is the build level on that engine?

Is it a new rebuild or has it been in any service before?

Have you used an infrared thermometer to view temperatures at various locations of the assembly?

Is the radiator heating up at the top first?

Are you absolutely certain the water pump rotation is correct?

#24

Later!

Mr. Ed

#25

#26

ENGINE-- complete rebuild--was a 93 Mustang GT 42K engine I converted over to a carb engine

Know engine temp by water dash gauge-- it does work goes to 200 fan comes on

Heating top of rad first--

UNKNOWN - Pump rotation when I order it was to be a clockwise rotation--

Know engine temp by water dash gauge-- it does work goes to 200 fan comes on

Heating top of rad first--

UNKNOWN - Pump rotation when I order it was to be a clockwise rotation--

#27

I have been reading through this post and tend to agree with Mixerman. I would certainly check the flow at the radiator with the cap off and observe the flow through the radiator. I would also check the air flow in front of the radiator with a piece of paper to make sure air is being moved at all areas of the front of the core, not just the area where the fan is situated in relation to the total are of the core.

#28

Exactly. That is why a deep conical shaped shroud is the most desirable. It will draw air from the far corners as well.

#29

Join Date: Aug 2002

Location: Saskatoon SK Canada

Posts: 6,682

Likes: 0

Received 11 Likes

on

8 Posts

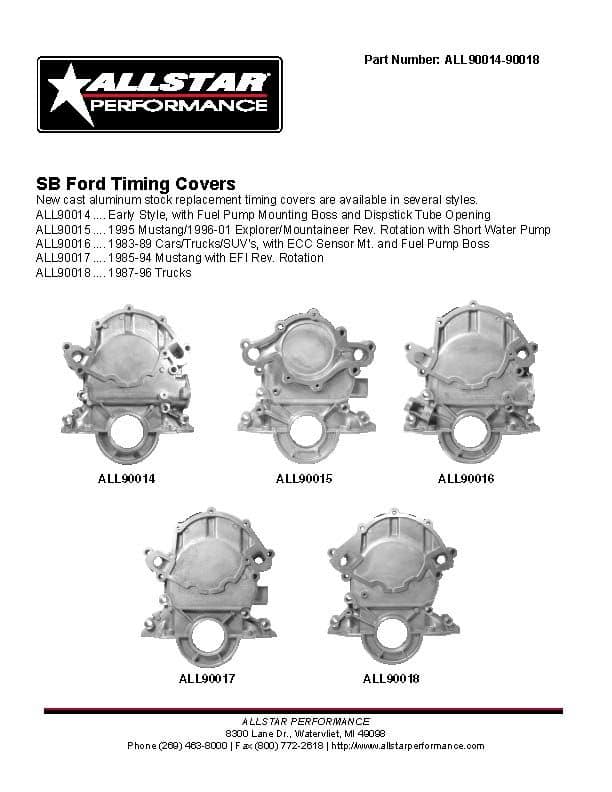

I would like to note that standard rotation and reverse rotation water pumps have different pulley bolt patterns. The cover doesn't really matter for flow. From factory Ford put reverse rotation pumps on normal covers in the Mustangs. Only the trucks got the proper reverse rotation timing cover.

#30

Tried it this morning at idle fan went on at 200 degrees got it down to 185 BUT no heat in cab and it was on HIGH and another problem I was not happy with was went out to grill see how fan was pulling put paper up to the grill did not suck fast to grill-- Put it up against AC condenser not even a little pull in--- but inside engine bay area blowing lots of air back towards firewall---