pretty wiring on instrument panels

#1

Join Date: Jul 1997

Location: Beautiful Hueytown Alabam

Posts: 5,668

Received 727 Likes

on

259 Posts

pretty wiring on instrument panels

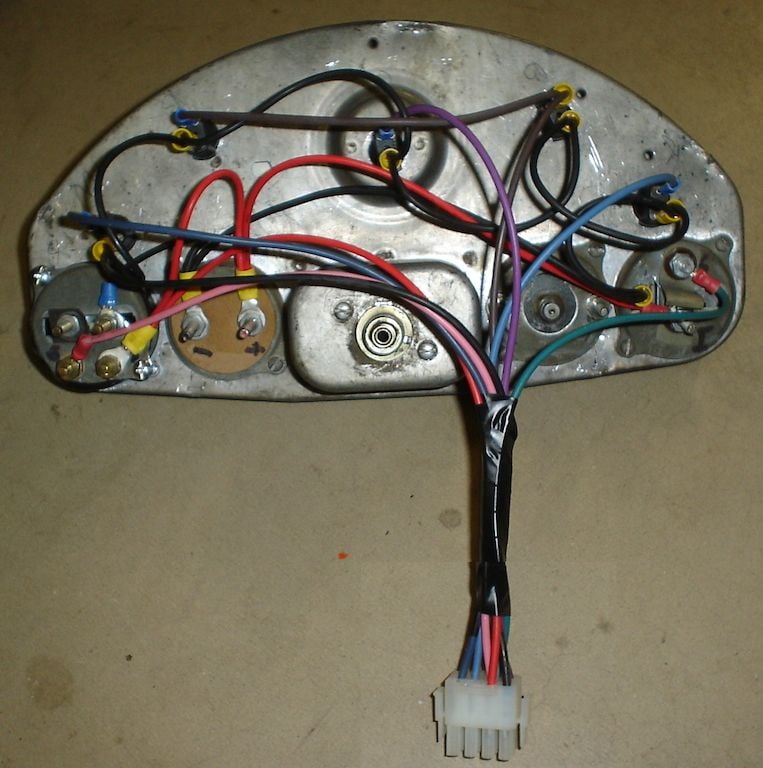

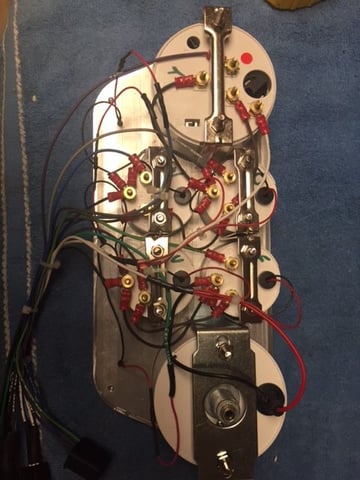

Ok guys, getting ready to start the instrument panel and looking for pretty work to copy... using a 6 gauge panel with dolphin gauges and want some examples, hints, suggestions and such.. wondering if I want to add a connector to the main group of wiring to make it easy to remove and work on if I need to.(hopefully not) but show me them pitures.

john

john

#2

Not sure if this helps but on my 56 I installed a Dakota Digital instrument cluster. I did not want the mounting screws to show from the front side of the bezel so I enclosed it all and mounted the control module on the back. I don't have a photo of the wires/cable leading to the control module but it was a fairly simple task to hook it up and enclose it in a wire loom.

#4

#5

#7

Join Date: Jul 1997

Location: Beautiful Hueytown Alabam

Posts: 5,668

Received 727 Likes

on

259 Posts

Trending Topics

#10

I just learned about these new type butt splices. Self soldering and self sealing with waterproof sleeves. Very cool. Hopefully they will add wire ends to this product line. I'm in France at the 24 hour race in Le Mans, but will try these as soon as I get home.

Parts Bin: NTE Self-Solder Butt Splice Connectors - OnAllCylinders

Parts Bin: NTE Self-Solder Butt Splice Connectors - OnAllCylinders

#11

In the early 70's I used those splices extensively when I worked at the Naval Air Rework Facility here in San Diego. We were upgrading the F-4B Phantoms to the F-4J configuration and there were a lot of splices needed per aircraft. We used specialized heat guns that had a slotted tip that focused the heat in one small area. Wire was jacketed with Teflon, not sure how this would work with other types of jacket material.

Thread

Thread Starter

Forum

Replies

Last Post

vonhef

1948 - 1956 F1, F100 & Larger F-Series Trucks

18

12-07-2021 09:07 PM