Bought new heads for my 2000 3.0 Ranger

#1

Bought new heads for my 2000 3.0 Ranger

I have been battling misfires, lean codes and a stumble that gets worse after the engine heats up or gets run hard for a while. This has me thinking exhaust valves acting up once they good and hot. The compression is all over the place on cylinders 4, 5 and 6 so I went ahead and bought a set of rebuilt heads on ebay that have the hardened valve seats installed already. I didn't do a leak down test to see where the compression is going. I'm currently betting the issue is on the top end and not rings.

I will hopefully do the swap here in the next week or so depending on when they arrive and document the process to see what went wrong. This should be fun........

I will hopefully do the swap here in the next week or so depending on when they arrive and document the process to see what went wrong. This should be fun........

#2

I am getting to start thinking "while I am at it......" I am considering pulling the valves out of the new heads to polish the combustion chamber and exhaust port before installing them. No port work or shaping, just a polish to get rid of rough casting to help the pinging.

Are there any bumps in the combustion chamber or exhaust ports that need to be left in place? I plan to remove any big casting flakes in the intake, but leave the casting rough for turbulence to mix the fuel.

I'm guessing it's wise to put in valves from the heads coming out to protect the seats while doing any grinding work.

Are there any bumps in the combustion chamber or exhaust ports that need to be left in place? I plan to remove any big casting flakes in the intake, but leave the casting rough for turbulence to mix the fuel.

I'm guessing it's wise to put in valves from the heads coming out to protect the seats while doing any grinding work.

#3

Well, as of right now, the original guy I bought from off of ebay, MS Pros, a machine shop in California took my money on the 30th and has yet to give me a tracking number or reply to any contact I have tried to make through ebay. They were supposed to arrive by today, so tomorrow I can get my money back. I ordered another set from a machine shop in West Virginia yesterday and they shipped today and gave me a tracking number.

I have the head bolts and gasket kit already here and am going to borrow a friends dremel tool with the flexible wand.

I'll take pics as I go. I am going to try my hand at polishing the combustion chambers and removing any big casting flash from the ports and runners. I also plan to gasket match the upper and lower intakes together and remove any big casting flash from the intake runners that I can get to.

I have the head bolts and gasket kit already here and am going to borrow a friends dremel tool with the flexible wand.

I'll take pics as I go. I am going to try my hand at polishing the combustion chambers and removing any big casting flash from the ports and runners. I also plan to gasket match the upper and lower intakes together and remove any big casting flash from the intake runners that I can get to.

#4

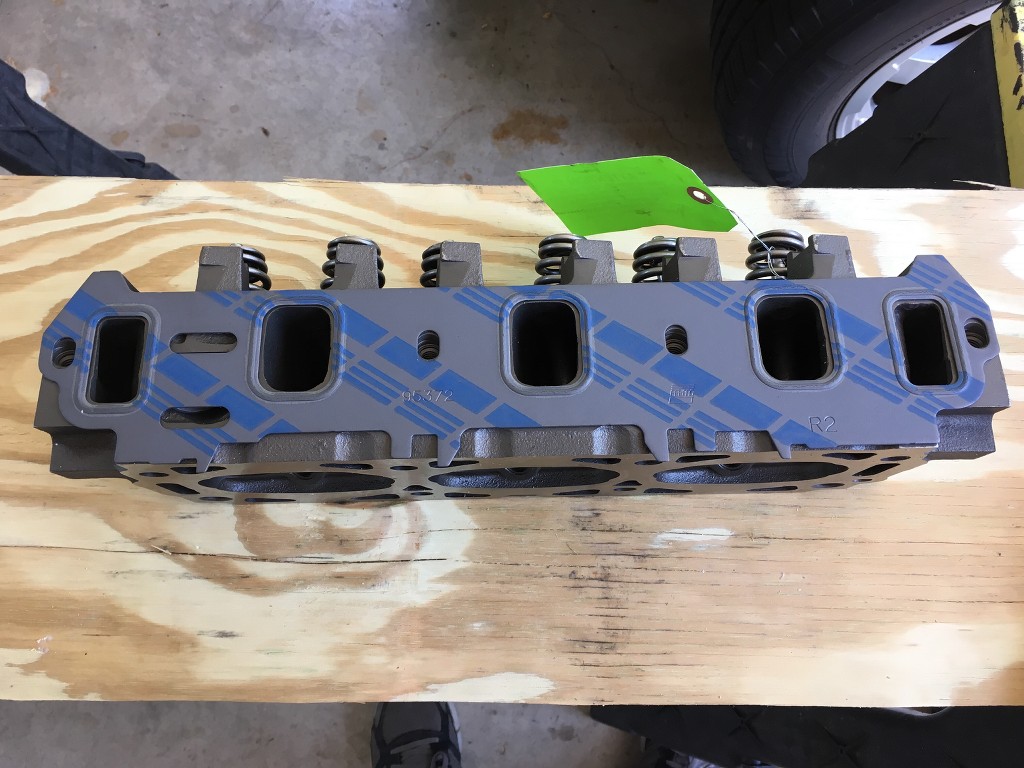

Got the heads yesterday. UPS said "delivery by 8 PM" and they showed up at 7:55 PM. And also, around 10PM last night, I got my full refund from the first machine shop in California.

Upon inspection, I am most likely not going to go through the hassle of taking them apart, grinding, cleaning and reassembling. They showed up in much better shape than I was expecting. There isn't much room for port matching to the intake manifold gasket, the valves could be unshrouded a little, but not very much, and there is no casting flash in the runners. I ran my finger through all of them and there are no sharp edges, no flakes sticking off the walls and and all the turns are rounded over already.

I am going to go around the lip where the heads were surfaced and knock off that knife edge where it transitions from deck surface to combustion chamber to help with pinging. I don't see any other sharp edges that would make detonation a problem.

The most work to do would be smoothing the valve guides over to a more rounded tip and like I said, I am not pulling them apart since they are so well assembled right now.

I am going to look over the intake while it off and see how bad it might be.

Upon inspection, I am most likely not going to go through the hassle of taking them apart, grinding, cleaning and reassembling. They showed up in much better shape than I was expecting. There isn't much room for port matching to the intake manifold gasket, the valves could be unshrouded a little, but not very much, and there is no casting flash in the runners. I ran my finger through all of them and there are no sharp edges, no flakes sticking off the walls and and all the turns are rounded over already.

I am going to go around the lip where the heads were surfaced and knock off that knife edge where it transitions from deck surface to combustion chamber to help with pinging. I don't see any other sharp edges that would make detonation a problem.

The most work to do would be smoothing the valve guides over to a more rounded tip and like I said, I am not pulling them apart since they are so well assembled right now.

I am going to look over the intake while it off and see how bad it might be.

#5

Today was disassembly. No broken bolts!!!!

Once the heads were off, my guess on the drivers side head having issues was confirmed by looking at the #4 and #6 exhaust valves:

Then I laid the heads flat and filled the combustion chambers with brake parts cleaner and had 5 out of 6 exhaust valves leaking by:

Then I tried to get some better shots at how the valves are sitting in the heads. You can see that they have somewhat shifted in the seat to one side:

One thing I am happy to see is that the cylinder wall still have a cross hatch after 180,000 miles and no detectable ridge at the top of the cylinder:

Now I am off to Autozone for oil, filter, coolant, scrapers, etc to do the cleaning tonight and be ready for reassembly tomorrow.

Between my house, my brothers house and various friends houses, I managed to gather up 8 old batteries and exchanged them for $80 in store credit gift cards at autozone so I should be able to do all my shopping without spending any money today.

Once the heads were off, my guess on the drivers side head having issues was confirmed by looking at the #4 and #6 exhaust valves:

Then I laid the heads flat and filled the combustion chambers with brake parts cleaner and had 5 out of 6 exhaust valves leaking by:

Then I tried to get some better shots at how the valves are sitting in the heads. You can see that they have somewhat shifted in the seat to one side:

One thing I am happy to see is that the cylinder wall still have a cross hatch after 180,000 miles and no detectable ridge at the top of the cylinder:

Now I am off to Autozone for oil, filter, coolant, scrapers, etc to do the cleaning tonight and be ready for reassembly tomorrow.

Between my house, my brothers house and various friends houses, I managed to gather up 8 old batteries and exchanged them for $80 in store credit gift cards at autozone so I should be able to do all my shopping without spending any money today.

#6

Got it all back together and running. After looking at the heads some more and seeing that cylinder #4's spark plug had a cracked porcelain, the head gaskets on the drivers side were shot. I looks like the metal by the water passage has rusted some and that probably pushed the surface apart to let coolant into the combustion chamber once it pressurized:

I didn't get any more pictures because it was full steam ahead with reassembly.

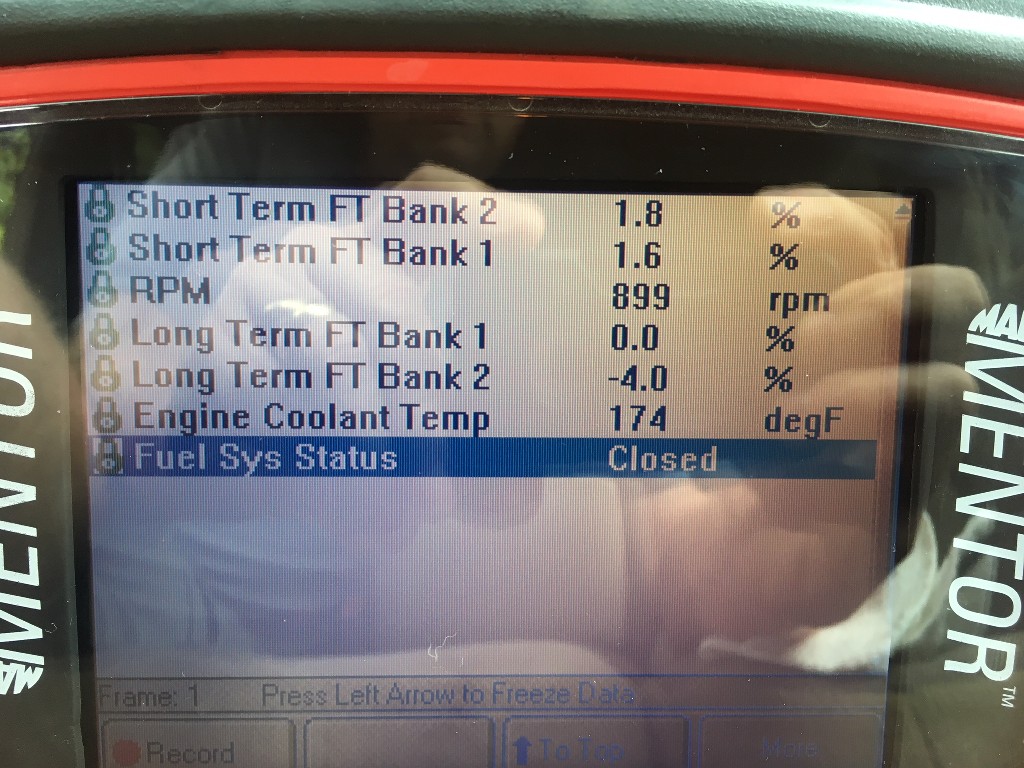

I am still getting a lean bank 1 code after a while of driving. The short term fuel trims start around 0.90 and the long terms start at 1.00, then as it idles, the short terms slowly come up to 1.00 and the long terms start to climb up to 1.25 until the code gets thrown.

I need to hook up my big scanner and look at the graph of the O2 sensors and see if it is time to replace them.

I didn't get any more pictures because it was full steam ahead with reassembly.

I am still getting a lean bank 1 code after a while of driving. The short term fuel trims start around 0.90 and the long terms start at 1.00, then as it idles, the short terms slowly come up to 1.00 and the long terms start to climb up to 1.25 until the code gets thrown.

I need to hook up my big scanner and look at the graph of the O2 sensors and see if it is time to replace them.

#7

Trending Topics

#8

Okay, got some time to work on the fuel trims today. The truck has been holding steady with a +24% on bank 1 and +17% on bank 2. I have hosed the engine down with water and brake parts cleaner trying to find a vacuum leak to no avail. I was worried the intake gaskets to the heads were leaking and I was going to gave to pull it all off again.

Today, after much video watching about fuel trims, I found one that helped a lot from Pine Hollow Auto Diagnostics. I unplugged my Jet after market MAF and the truck instantly idled better and the fuel trims went diving immediately.

I amazingly found my OEM MAF sensor and housing and reinstalled them. After starting and letting it run for a while, the LTFT's settled down to bank 1 bouncing between +6 and 7% and bank 2 boucing between 0 and +1%.

I'm hoping the new O2 sensors that are on the way can get them closer to agreeing and Bank 1 being closer to 0.

Also, other good news is that the coolant and oil have both stayed completely full and in their respective parts of the engine. No mixing on vital fluids!!!!

Today, after much video watching about fuel trims, I found one that helped a lot from Pine Hollow Auto Diagnostics. I unplugged my Jet after market MAF and the truck instantly idled better and the fuel trims went diving immediately.

I amazingly found my OEM MAF sensor and housing and reinstalled them. After starting and letting it run for a while, the LTFT's settled down to bank 1 bouncing between +6 and 7% and bank 2 boucing between 0 and +1%.

I'm hoping the new O2 sensors that are on the way can get them closer to agreeing and Bank 1 being closer to 0.

Also, other good news is that the coolant and oil have both stayed completely full and in their respective parts of the engine. No mixing on vital fluids!!!!

#9

#10

Going though exactly the same thing got everything but the heads off fueltrime is high 25% bank 1,2 lean I put intake gaskets on it was better did it again it got worse I've replaced every part on it but I think the parts are junk from o really and auto zone now I have junk New parts on Truck getting ready to oder heads the price on them I see big difference in anywhere from 350 to 1200 a set that's a big difference but the trucks doing exactly what you said yours was doing it would warm up start running like **** I thought I had a cracked intake or something when it warmed up I thought maybe it would open up a Crack I check for leaks with a full can brake cleaner nothing full can nothing hope heads do it

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]Thread

Thread Starter

Forum

Replies

Last Post

Schuyles

335 Series- 5.8/351M, 6.6/400, 351 Cleveland

7

09-20-2015 08:19 AM

johnsf

Big Block V8 - 385 Series (6.1/370, 7.0/429, 7.5/460)

3

01-15-2007 09:33 PM

Annihilator

FE & FT Big Block V8 (332, 352, 360, 390, 406, 410, 427, 428)

14

04-09-2004 07:56 PM