82' Electrical Battery/Alternator Help!

#16

Installing a new 4 gauge charge cable and changing a pulley is still a bolt on deal. Oh, might be getting crazy as you'll have to crimp or solder a wire on the new harness off the alternator as well. Get an alternator already clocked correctly for your application and you won't have to loosen and tighten those 3 case bolts either. 3g is a bolt on swap. heck for that matter a 10si or 12si is a bolt on swap.

To OP, personally I wouldn't bother with the small case 95 amp 3g, the cost difference is negligible and it takes the same time to install either one.

A 42 amp 1g will work and be adequate for the electrical load these trucks have. The advantage of going with a 3g is a simple internally regulated alternator, less wiring, and mainly increased output at idle for full voltage. No more dimming lights or slow defroster at idle, less runtime required to charge battery after starting.

To OP, personally I wouldn't bother with the small case 95 amp 3g, the cost difference is negligible and it takes the same time to install either one.

A 42 amp 1g will work and be adequate for the electrical load these trucks have. The advantage of going with a 3g is a simple internally regulated alternator, less wiring, and mainly increased output at idle for full voltage. No more dimming lights or slow defroster at idle, less runtime required to charge battery after starting.

#17

So,

Tested the alternator thoroughly, like you guys guessed, it was shot. Pretty sure its the original 30+ year old alternator(surprised it lasted this long). Anyway, picked up a 70amp exact copy remanufactured model from the local autopart, stuck with the external regulator, cleaned up all connections, new harness, etc. After about an hour of work, and a recharged battery, she fired up perfectly on the first turn.

Thanks for all the help!

Tested the alternator thoroughly, like you guys guessed, it was shot. Pretty sure its the original 30+ year old alternator(surprised it lasted this long). Anyway, picked up a 70amp exact copy remanufactured model from the local autopart, stuck with the external regulator, cleaned up all connections, new harness, etc. After about an hour of work, and a recharged battery, she fired up perfectly on the first turn.

Thanks for all the help!

#18

#20

I don't bother on alternator pulleys though, never had one give me a lick of trouble. Be careful using antiseize on any threads for rotating things that are not positively locked in place, you don't want it coming loose from spinning or stopping motions.

#21

Reviving the thread! Lol

So, truck worked great for about a week, and then started having the same issue. Finally realized the problem was the aftermarket radio, which was wired in a funky way. Left it unplugged for about a week, testing battery every day, and you guessed it, that was it.

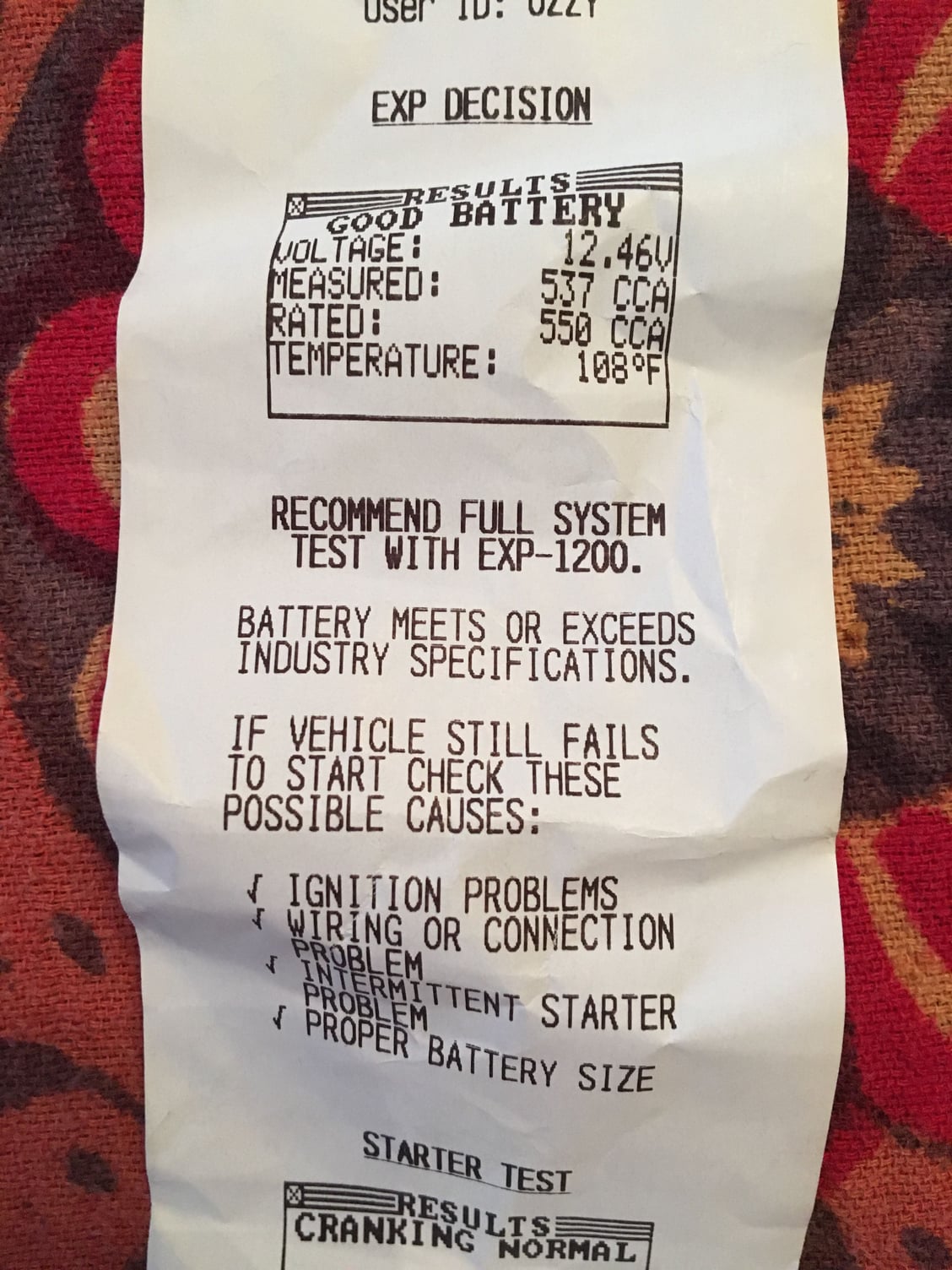

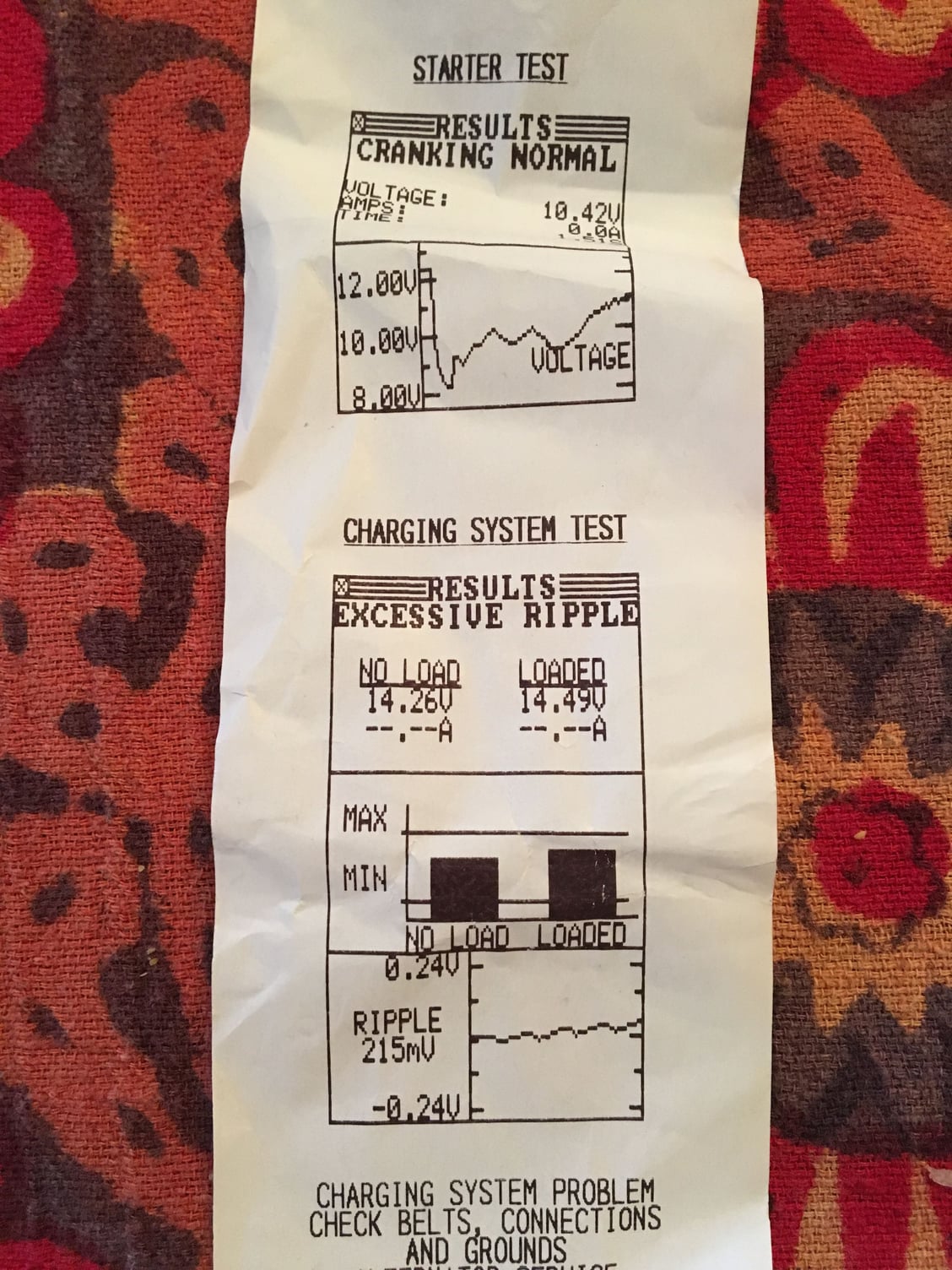

So, after correctly wiring, the new alternator, new voltage regulator, truck is working fine. But.... went to auto part today to use their tester and still getting an “excessive ripple” reading. Albeit, the voltages are much more stable than with the shot alternator, what does this mean?

#22

#23

http://www.aa1car.com/library/voltage_drop_testing.htm

Read the link, it's easy to do and no special tools required nor disconnecting anything.

To perform a voltage drop test a load is placed across the circuit (parallel) or connection that's being tested. Measure the drop across the live connection while it is under load. Voltage follows the path of least resistance so the voltage lost due to circuit resistance will be displayed as a positive number on the meter. Ideally "Zero" voltage drop but there will always be some.

Read the link, it's easy to do and no special tools required nor disconnecting anything.

To perform a voltage drop test a load is placed across the circuit (parallel) or connection that's being tested. Measure the drop across the live connection while it is under load. Voltage follows the path of least resistance so the voltage lost due to circuit resistance will be displayed as a positive number on the meter. Ideally "Zero" voltage drop but there will always be some.

#24

By design, any alternator will put out minor AC ripple.

#25

When you increase other loads, the regulator (somewhat mistakenly) interprets this as a higher voltage needed to maintain the same level of battery charge. Perfect? Not really, but still adequate. That’s why we always stress to start with a fully charged battery for any electrical troubleshooting.

#26

Voltage Drop Testing

Read the link, it's easy to do and no special tools required nor disconnecting anything.

Read the link, it's easy to do and no special tools required nor disconnecting anything.

#27

#28

You are correct, the problem has been resolved, just wanted to know what you guys thought about that ripple. Not very familiar with these older electrical systems, so just wanted to make sure there wasn’t a hidden/underlying problem there. Thanks for the input and help!

Also there are 6 diodes in the Alt 2 For each phase (3 phases in the alt) one blocking the neg side of the sine wave and one blocking the positive side of the sine wave.

Thread

Thread Starter

Forum

Replies

Last Post

SMDT LLC.

1987 - 1996 F150 & Larger F-Series Trucks

10

08-09-2019 09:00 PM

mmcrorey

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

5

08-04-2003 03:20 PM