4.9L Camshaft Bearing Oil Supply

#1

4.9L Camshaft Bearing Oil Supply

Hello all,

I originally posted this question in my build thread in the "bullnose" section. A member suggested that I post it here for some help.

I recently had my 4.9L 300 from an 81 F100 rebuilt at a shop, but not re-assembled. They did, however, install the camshaft bearings for me.

After I got the block home, I noticed that some of the camshaft bearings partially block the oil supply hole.

Of the 4 camshaft bearing oil supply holes, 2 are partially blocked and 2 are 100% open. I've attached a picture which is representative of the 2 partially blocked holes and a picture of an un-blocked hole.

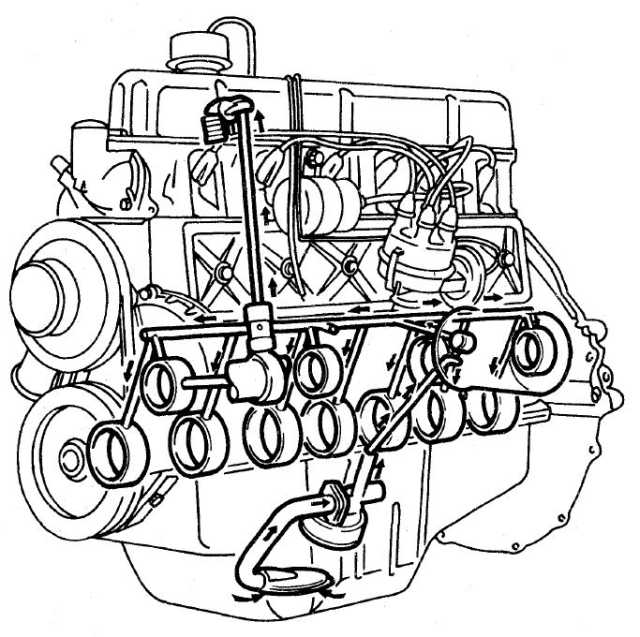

Also, the Factory Service Manual explains that the lifters/pushrods and crankshaft are supplied oil separate from the camshaft bearings. Meaning, a partial restriction should only affect the camshaft and nothing else. Picture below:

My question: does this need to be addressed or can the camshaft be installed with the bearing positioning as-is, without concern? Thank you all!

I originally posted this question in my build thread in the "bullnose" section. A member suggested that I post it here for some help.

I recently had my 4.9L 300 from an 81 F100 rebuilt at a shop, but not re-assembled. They did, however, install the camshaft bearings for me.

After I got the block home, I noticed that some of the camshaft bearings partially block the oil supply hole.

Of the 4 camshaft bearing oil supply holes, 2 are partially blocked and 2 are 100% open. I've attached a picture which is representative of the 2 partially blocked holes and a picture of an un-blocked hole.

Also, the Factory Service Manual explains that the lifters/pushrods and crankshaft are supplied oil separate from the camshaft bearings. Meaning, a partial restriction should only affect the camshaft and nothing else. Picture below:

My question: does this need to be addressed or can the camshaft be installed with the bearing positioning as-is, without concern? Thank you all!

#2

there's a reason the hole in the bearing resembles the same size of the supply hole in the block. they are supposed to be lined up...period. Will it effect the longevity of the engine? maybe or maybe not. I wouldn't think that it'd effect the rest of the bearings and/ or components, directly.

on top of my soapbox for a moment...

you paid for a proper install on a freshly machined block. I'd ask that they do the install of the bearings again.

have you had this shop do work for you before? is this a first time occurrence? I'd wonder if this is indicative of the type of work they produce in general? maybe even get another opinion on the block from a different shop. check the dimensions against the specs listed on the receipt from the original shop. the longevity of your engine is dependent upon the level of precision and tolerance standards the machinist considers acceptable.

sorry to be all doom and gloom. bottom line though...the build starts with a quality block. no amount of wrenching, tuning, or cool parts will be able to iron out poor machining practices. Really hoping it works out for you though. Please post back with your findings. This thread holds valuable info for members...past, present, and future.

on top of my soapbox for a moment...

you paid for a proper install on a freshly machined block. I'd ask that they do the install of the bearings again.

have you had this shop do work for you before? is this a first time occurrence? I'd wonder if this is indicative of the type of work they produce in general? maybe even get another opinion on the block from a different shop. check the dimensions against the specs listed on the receipt from the original shop. the longevity of your engine is dependent upon the level of precision and tolerance standards the machinist considers acceptable.

sorry to be all doom and gloom. bottom line though...the build starts with a quality block. no amount of wrenching, tuning, or cool parts will be able to iron out poor machining practices. Really hoping it works out for you though. Please post back with your findings. This thread holds valuable info for members...past, present, and future.

#4

Hi guys,

Thank you for the replies. I have emailed the shop with the same picture I shared here, asking for their help. Let's see what they come back with.

I have not used this shop before. It was recommended to me by a friend who has rebuilt many motors and used this shop several times. He highly recommended them to me. When I met them, they were very friendly and helpful. They are a very small shop with only a few employees, but they seem to have a ton of work (I would hope that is a good sign of their craftsmanship).

Rechecking their measurements is probably not a bad idea. I agree with you 100%. The whole reason I paid the money to have the block and head rebuilt is so that I can start with a good foundation to build upon.

I will definitely keep this thread updated.

Regarding the #1 bearing with 2 holes: Do you mean that the bearing should also have a second oil hole? Or that there is a second hole in the block to supply oil to the gear?

I ask because the bearing they installed in #1 only has 1 oil hole. I honestly don't know if the block has a second hole because I never saw it without bearings. And I can't remember if any of the original bearings had 2 oil holes.

I went out and looked at the block and found a hole which might be an oil supply hole for the cam gear (see picture below). But I really don't know if it is fed from the main oil gallery or from the #1 bearing? The FSM doesn't say anything about the oiling of the gears (only about the distributor gear).

I'm sorry if I'm asking stupid questions. I'm definitely not an expert on the 300 but I'm trying to learn as much as my brain can hold.

Thank you all again!

Thank you for the replies. I have emailed the shop with the same picture I shared here, asking for their help. Let's see what they come back with.

I have not used this shop before. It was recommended to me by a friend who has rebuilt many motors and used this shop several times. He highly recommended them to me. When I met them, they were very friendly and helpful. They are a very small shop with only a few employees, but they seem to have a ton of work (I would hope that is a good sign of their craftsmanship).

Rechecking their measurements is probably not a bad idea. I agree with you 100%. The whole reason I paid the money to have the block and head rebuilt is so that I can start with a good foundation to build upon.

I will definitely keep this thread updated.

Regarding the #1 bearing with 2 holes: Do you mean that the bearing should also have a second oil hole? Or that there is a second hole in the block to supply oil to the gear?

I ask because the bearing they installed in #1 only has 1 oil hole. I honestly don't know if the block has a second hole because I never saw it without bearings. And I can't remember if any of the original bearings had 2 oil holes.

I went out and looked at the block and found a hole which might be an oil supply hole for the cam gear (see picture below). But I really don't know if it is fed from the main oil gallery or from the #1 bearing? The FSM doesn't say anything about the oiling of the gears (only about the distributor gear).

I'm sorry if I'm asking stupid questions. I'm definitely not an expert on the 300 but I'm trying to learn as much as my brain can hold.

Thank you all again!

#5

OP, you may find help in these threads. Its long and I don't have time to read them but its along the lines of this thread and may answer some questions.

https://www.ford-trucks.com/forums/1365059-300-4-9-cam-bearing-tip-oil-holes-for-timing-gears.html

https://www.ford-trucks.com/forums/324779-please-help-cam-bearing-oil-hole-alignment.html

I would question the machine shop if the holes and bearings don't align perfectly....

https://www.ford-trucks.com/forums/1365059-300-4-9-cam-bearing-tip-oil-holes-for-timing-gears.html

https://www.ford-trucks.com/forums/324779-please-help-cam-bearing-oil-hole-alignment.html

I would question the machine shop if the holes and bearings don't align perfectly....

#7

Hi FTF. Thank you for your reply. The guys over on the 'bullnose' forum explained that you are the guru here, and that they trust your knowledge.

Hearing from you makes me feel a bit better.

One additional question: the #1 bearing does NOT have a second hole, which would feed the cam gear oil squirter. The shop supplied an engine kit with a phenolic cam gear. However, it appears that the cam bearings (Enginetech CC445G) DO have an external groove. Perhaps this external groove would also help feed the oil squirter from #1? Do you see any issues with the oil squirter not being fed directly by a hole on the #1 bearing, but rather by the bearing exterior groove?

FYI - the machine shop called me this morning to tell me not to worry about the cam bearings. In principle, I'm still a bit annoyed that they didn't do a better job of lining everything up in the first place. But if it really isn't something to lose sleep over, then I will move on.

Thank you all again.

-Adam

Hearing from you makes me feel a bit better.

One additional question: the #1 bearing does NOT have a second hole, which would feed the cam gear oil squirter. The shop supplied an engine kit with a phenolic cam gear. However, it appears that the cam bearings (Enginetech CC445G) DO have an external groove. Perhaps this external groove would also help feed the oil squirter from #1? Do you see any issues with the oil squirter not being fed directly by a hole on the #1 bearing, but rather by the bearing exterior groove?

FYI - the machine shop called me this morning to tell me not to worry about the cam bearings. In principle, I'm still a bit annoyed that they didn't do a better job of lining everything up in the first place. But if it really isn't something to lose sleep over, then I will move on.

Thank you all again.

-Adam

Trending Topics

#9

I am not familiar with the external groove type of bearing, but I'll bet it will be fine.

The 4.9 crossflow head came with two 1/8 feed holes to supply the rocker shaft / arms and oil the valves. I asked the head engineers if that was enough and they said one would have been enough, but given the history of the Y-block problems with getting lube to the top end they decided to put in two. I have subsequently put .050 restrictors in mine since not much is needed to keep oil in the rocker shaft. 50 psi of oil pressure blows an amazingly large volume out a .050 hole.

Thanks for the kudos.

The 4.9 crossflow head came with two 1/8 feed holes to supply the rocker shaft / arms and oil the valves. I asked the head engineers if that was enough and they said one would have been enough, but given the history of the Y-block problems with getting lube to the top end they decided to put in two. I have subsequently put .050 restrictors in mine since not much is needed to keep oil in the rocker shaft. 50 psi of oil pressure blows an amazingly large volume out a .050 hole.

Thanks for the kudos.

Thread

Thread Starter

Forum

Replies

Last Post

OrangeJuice

FE & FT Big Block V8 (332, 352, 360, 390, 406, 410, 427, 428)

8

05-28-2009 01:20 AM

FordEdselFanatic

FE & FT Big Block V8 (332, 352, 360, 390, 406, 410, 427, 428)

19

02-13-2009 12:12 PM

andy_547

Ford Inline Six, 200, 250, 4.9L / 300

8

12-31-2004 04:31 PM

BackwoodsBum

FE & FT Big Block V8 (332, 352, 360, 390, 406, 410, 427, 428)

4

11-30-2001 05:50 PM