Generator Charge and Discharge on Cluster

#1

Generator Charge and Discharge on Cluster

I don't think my generator is working, probably safe bet after 26 years of sitting.

I've done some voltage tests as people have recommended, high idle, low idle. Lights on. My voltage drops with lights on, but never < 6 volts. It sits around 6.3 at idle. High idle doesn't seem to change anything. I'm using a cheapo volt meter though, not a digital. So, it's all +/- .1 volt that i can read anyway. It never increases to 7 volts like I read. I don't have a ammeter. If I'm supposed to hear it start charging, I don't.

When going down road with lights on it goes to CHARGE on my gauge. Obviously that's not right. And with key in ignition and turning lights on it goes to CHARGE. So, I have wiring wrong somehow? Looking at the schematic, there isn't even a wire going to the charge/discharge, only the big yellow being held there. Is there some kind of induction thing going on (right word?), magnet, etc? Now I'm confused... lol I wired it as stated in the wiring diagram with the wire going from right to left when looking at back, but my picture before shows it was previously wired left to right...

I was going to eventually replace with an alternator (from MACs probably). Maybe I should just do that?

Should I jump the Field and Battery and "reset" or "re-polorize" like other state in some posts?

I've done some voltage tests as people have recommended, high idle, low idle. Lights on. My voltage drops with lights on, but never < 6 volts. It sits around 6.3 at idle. High idle doesn't seem to change anything. I'm using a cheapo volt meter though, not a digital. So, it's all +/- .1 volt that i can read anyway. It never increases to 7 volts like I read. I don't have a ammeter. If I'm supposed to hear it start charging, I don't.

When going down road with lights on it goes to CHARGE on my gauge. Obviously that's not right. And with key in ignition and turning lights on it goes to CHARGE. So, I have wiring wrong somehow? Looking at the schematic, there isn't even a wire going to the charge/discharge, only the big yellow being held there. Is there some kind of induction thing going on (right word?), magnet, etc? Now I'm confused... lol I wired it as stated in the wiring diagram with the wire going from right to left when looking at back, but my picture before shows it was previously wired left to right...

I was going to eventually replace with an alternator (from MACs probably). Maybe I should just do that?

Should I jump the Field and Battery and "reset" or "re-polorize" like other state in some posts?

#2

Use the procedures in the manuals and online flow charts etc, for troubleshooting, polarization, and testing for a Ford or "B" type generator only. Where people run into trouble is getting information thirdhand and they either don't understand what they are doing or they are using the testing procedures for a GM, they are different. Using the wrong method will damage the regulator.

Generators are VERY simple. Often it's the brushes, make sure they are fully seated against the commutator, they can hang up in the holders sometimes as they wear.

To test a FORD type "B" circuit generator, disconnect the wires at the generator and connect a jumper wire from ARM terminal to FLD terminal. Start the engine and spool it up to 1500 or 2000 RPM briefly, only perform this test long enough to verify it's working as there is no regulation, this is known as "full fielding" a generator. Connect a voltmeter between ARM and the GND terminal, voltage should spool up smoothly to several volts, probably around 8 to 10+ on a 6 volt generator. If the generator is on the bench you can "motor" the generator by connecting a battery in the same way. It should spool up smoothly to a good clip and run as a motor.

Generators are VERY simple. Often it's the brushes, make sure they are fully seated against the commutator, they can hang up in the holders sometimes as they wear.

To test a FORD type "B" circuit generator, disconnect the wires at the generator and connect a jumper wire from ARM terminal to FLD terminal. Start the engine and spool it up to 1500 or 2000 RPM briefly, only perform this test long enough to verify it's working as there is no regulation, this is known as "full fielding" a generator. Connect a voltmeter between ARM and the GND terminal, voltage should spool up smoothly to several volts, probably around 8 to 10+ on a 6 volt generator. If the generator is on the bench you can "motor" the generator by connecting a battery in the same way. It should spool up smoothly to a good clip and run as a motor.

#3

#4

As for you ammeter reading backwards, yes, it is dependent on the direction of current flow in the wire and reversing the direction that the wire passes through the loop will reverse the operation of the guage. If you have it wired in the direction that is called out in the manual, then verify that the battery has a positive ground just as it would have originally. Running a negative ground on an original 6 volt system will cause the ammeter to read backwards - and it also could cause your charging system to quit working unless you repolarize the generator field to match.

#5

As for you ammeter reading backwards, yes, it is dependent on the direction of current flow in the wire and reversing the direction that the wire passes through the loop will reverse the operation of the guage. If you have it wired in the direction that is called out in the manual, then verify that the battery has a positive ground just as it would have originally. Running a negative ground on an original 6 volt system will cause the ammeter to read backwards - and it could cause your charging system to quit working also unless to repolarize the generator field to match.

#6

#7

To test a FORD type "B" circuit generator, disconnect the wires at the generator and connect a jumper wire from ARM terminal to FLD terminal. Start the engine and spool it up to 1500 or 2000 RPM briefly, only perform this test long enough to verify it's working as there is no regulation, this is known as "full fielding" a generator. Connect a voltmeter between ARM and the GND terminal, voltage should spool up smoothly to several volts, probably around 8 to 10+ on a 6 volt generator. If the generator is on the bench you can "motor" the generator by connecting a battery in the same way. It should spool up smoothly to a good clip and run as a motor.

I did this and I get 0.0 volts. Perfect! lol I was actually kindof expecting this as nothing was happening at the battery when it was at high idle, 1500rpm, etc...

So clearly the generator is doing nothing. I'll take it apart and look, but will most likely just replace with alternator. I've been going around town with just the battery, works fine for the 20 miles or so I've been driving, just charge it overnight.

Thanks for the help guys!

Trending Topics

#8

Brushes were really worn, so I'll replace. ANd one spring was broken, so the brush wasn't even connecting. I cleaned out all the dirt, including a dirt dobber nest! I sanded the armature and commutator too and cleaned up metal on the outside of the coils.

Any tests I can do for continuity? On a video for a tractor i saw i shouldn't have continuity between the field or ground and the metal housing... but i have continuity with both. BUT, the tractor only had 2 connections, i also have an "ARM" and there isn't continuity to that.

Any tests I can do for continuity? On a video for a tractor i saw i shouldn't have continuity between the field or ground and the metal housing... but i have continuity with both. BUT, the tractor only had 2 connections, i also have an "ARM" and there isn't continuity to that.

#9

The manual has some tests for field coils and generator output in terms of amps. You'll have to have an ammeter that can measure more than 10 amps for that. Usually in service the whole endplate would get swapped out w/ new brushes. This can be done quickly without removing the generator. Make sure the brush spring assemblies are serviceable.

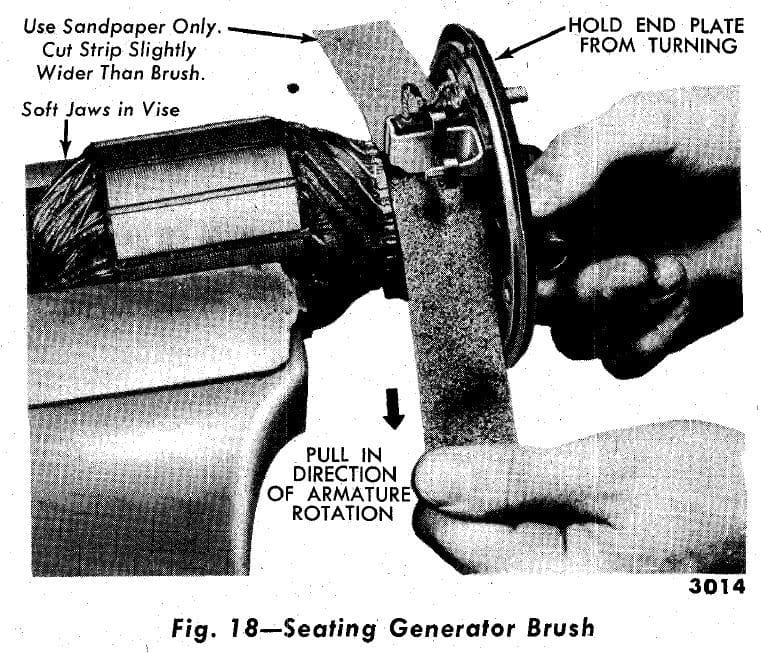

Be sure to seat the new brushes to the commutator before running it so they present a full contact patch. If you dig around the net you should be able to find some .PDF scans of Ford generator checks & services that illustrate this. Since you had the generator disassembled don't forget to polarize.

This page talks a little about seating brushes in general. It's easy and doesn't take very long, but it's easier when removed and on the bench. Put the armature in a vise. Hold the endplate steady so it doesn't turn, and pull a strip of garnet sandpaper through several times. The brushes will conform to the commutator surface before run-in. If this is not done they will be noisy, arc & burn and won't last for $h!@. Ask me how I know.

http://www.practicalmachinist.com/vb...rushes-318444/

Be sure to seat the new brushes to the commutator before running it so they present a full contact patch. If you dig around the net you should be able to find some .PDF scans of Ford generator checks & services that illustrate this. Since you had the generator disassembled don't forget to polarize.

This page talks a little about seating brushes in general. It's easy and doesn't take very long, but it's easier when removed and on the bench. Put the armature in a vise. Hold the endplate steady so it doesn't turn, and pull a strip of garnet sandpaper through several times. The brushes will conform to the commutator surface before run-in. If this is not done they will be noisy, arc & burn and won't last for $h!@. Ask me how I know.

http://www.practicalmachinist.com/vb...rushes-318444/

#10

Be sure to seat the new brushes to the commutator before running it so they present a full contact patch.

This page talks a little about seating brushes in general. It's easy and doesn't take very long, but it's easier when removed and on the bench. Put the armature in a vise. Hold the endplate steady so it doesn't turn, and pull a strip of garnet sandpaper through several times. The brushes will conform to the commutator surface before run-in. If this is not done they will be noisy, arc & burn and won't last for $h!@. Ask me how I know.

This page talks a little about seating brushes in general. It's easy and doesn't take very long, but it's easier when removed and on the bench. Put the armature in a vise. Hold the endplate steady so it doesn't turn, and pull a strip of garnet sandpaper through several times. The brushes will conform to the commutator surface before run-in. If this is not done they will be noisy, arc & burn and won't last for $h!@. Ask me how I know.

#11

#12

Yes, that's how it's done. The brushes need to have a full contact patch conforming to the commutator before being run. Normally brushes should last a long time. They can arc and burn if this is not done, as up to 30 amps goes through them. It doesn't take long, the carbon brush material is soft.

#13

Yes. And when they say sandpaper, they mean SANDPAPER (although sand isn't commonly used anymore). Not aluminum oxide, not silicone carbide, not emery paper, you know why? Garnet is the paper of choice because it is non-conductive. So even if a micro sized dust remains between the comm bars after dressing and seating, you're still good to go.

#15

I have charge! Can't believe it works, I'm pretty sure it wasn't working for years because one of the brushes was worn down a bunch more than the other, and the longer one's spring was broke (probably the reason it wasn't working). So, it probably ran for years with no generator working.

I'm getting 7.6 volts at idle... and just under 7.0 volts when I turn lights on. Is this ok or too much?

Should I be checking to make sure it stops charging after a while? I guess that would mean the voltage regulator needs adjusting if it doesn't?

I'm getting 7.6 volts at idle... and just under 7.0 volts when I turn lights on. Is this ok or too much?

Should I be checking to make sure it stops charging after a while? I guess that would mean the voltage regulator needs adjusting if it doesn't?