Truck bucks and stutters at idle after reaching normal operating temps.

#16

#17

I checked the pigtail connections for the EBP sensor since both the old and new sensors show the exact same readings. Connections looked good as well as the pigtail itself. I went ahead and ordered another EBPS as well as the IPR and o-ring kit for the fuel bowl assembly from Riffraff's since now that I think about it, the previous EBP sensor I bought for it only cost me around $20. So I'm thinking I may have gotten some knockoff version of it. I figured at least I can hope to get a good reading with a new OEM sensor and go from there. Btw, any idea what your EBP readings are at idle and no load?

My buddy was generous enough to allow me to try his ICP sensor as well to rule out if my came DOA. Unfortunately his did the same. It's still interesting that once I pull the ICP it smoothes out as I figured it would and shows 700psi from the HPOP. However changing it out at least with a known good sensor as well as the recent sensor I bought makes no difference. Pigtail and connectors appear to look okay as well. No cuts or loose connections that I can see.

So at this point would it be safe to assume my IPR is on it's way out? I would hate to have to rip everything out right now just to get to the IPR since there doesn't appear to be any other way to take it out with all the CA emission crap attached to the fuel bowl. Other than that I am at a total loss...

#18

#19

#20

Ok so I got my replacement IPR, ICP, EBPS, fuel bowl reseal kit and turbo intake boot from Riffraff's on Saturday. All parts appear to be OEM minus the intake boot since Ford discontinued the original orange accordian boot. Everything appeared to go on without issues and now can officially say at least all sensors are back to OEM.

Unfortunately I am still have the bucking and stuttering issues.

So at this point here is what I have replaced...

EBP Sensor, Tube and 45 Degree elbow that connects tube and sensor

IPR

ICP

Fuel Filter

CMP (Tried three different IH units and one Motorcraft which all appear to be the same dark bluish gray with purple o-ring. Part# is 1876736C91)

Oil Change (Delo 15W40 with Motorcraft Filter)

Lift Pump (Changed previously due to the original leaking, although issue originated before hand)

Up Pipe Gaskets

All sensor pigtails appear to look ok as well as the valve cover harnesses. I don't see any chaffing or frayed wiring either.

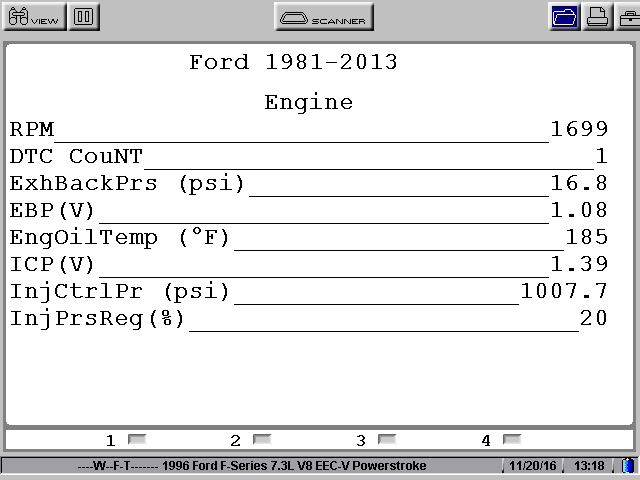

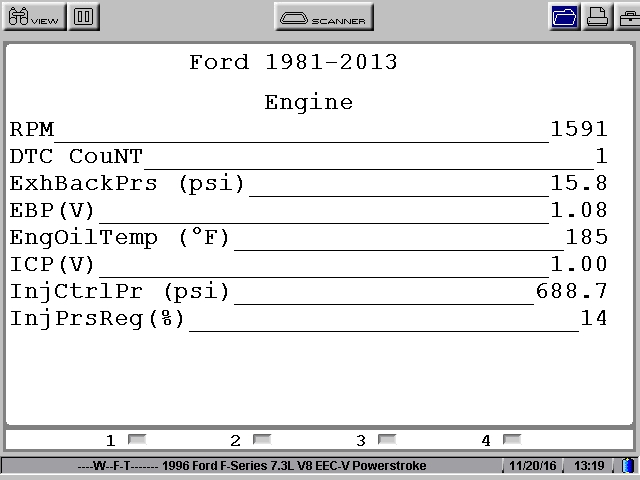

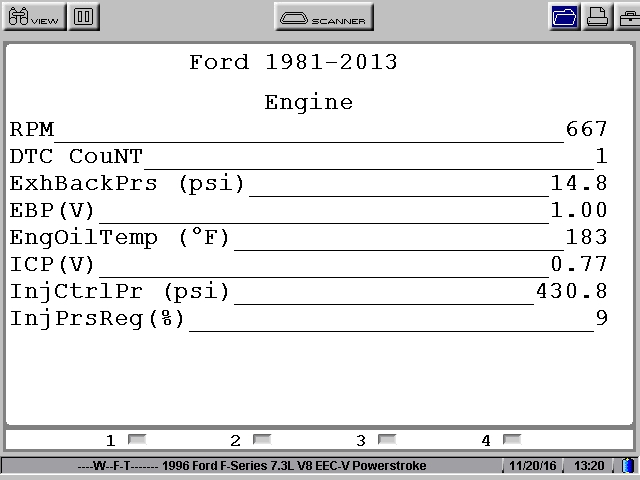

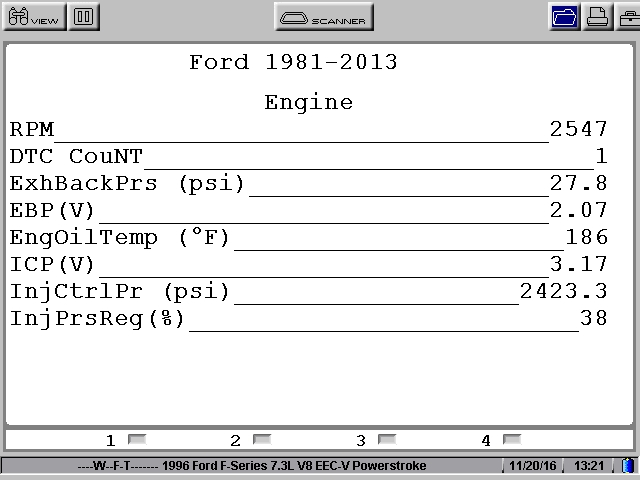

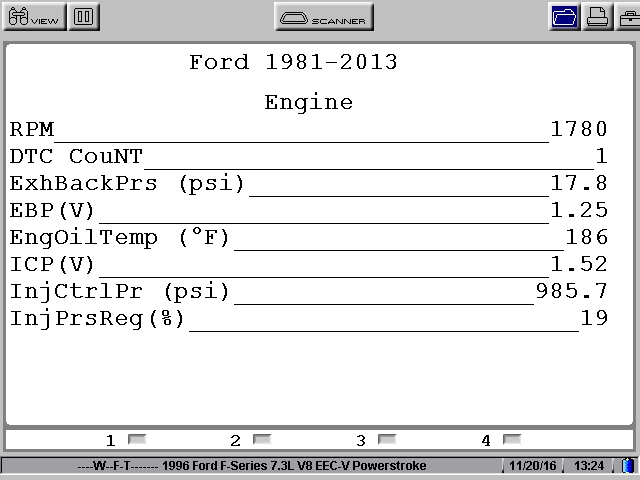

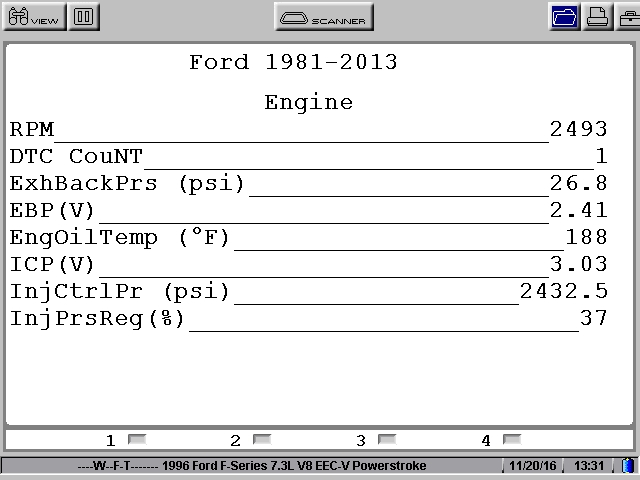

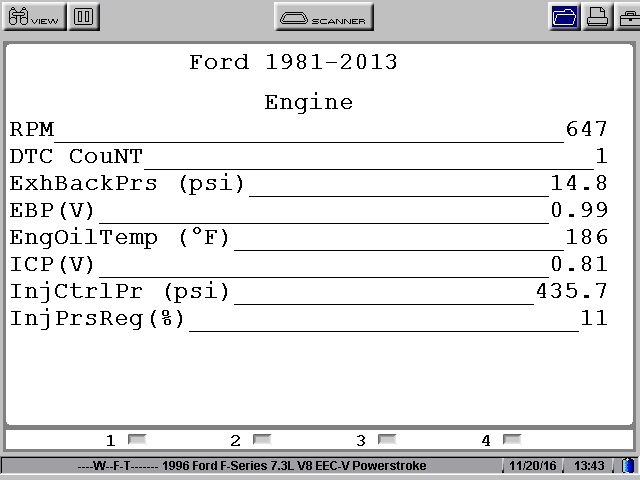

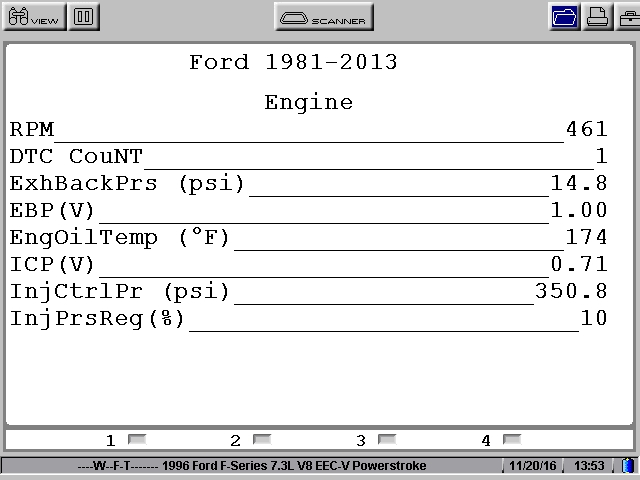

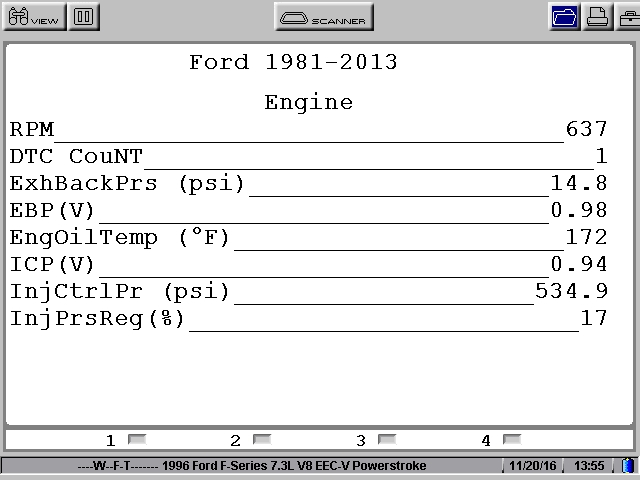

Here are some additional screen shots from the Modis on the last test run I took it on after everything has been replaced...

1) Accelerating to 50mph...

2) Holding speed at 50mph...

3) Idle at stop sign...

4) WOT up to 70mph...

5) Holding speed at 60mph...

6) WOT up to 75mph...

7) Idle again at stop sign...

8) Engine starts to cutout...

9) Engine regains normal, smooth idle speed...

The one thing I did notice again was when I pulled the ICP harness off the sensor ICP PSI went back to 700 and truck would no longer buck and stumble. I let it idle for a good 15 minutes at normal operating temp. Once I plugged the sensor back in is when the bucking and stumbling came back. There doesn't appear to be any pattern on when it will do it other than the fact it does it when the oil temp is up to operating temp and so far I cant see anything on the scanner that would indicate otherwise.

At this point I am completely at a loss on where to go from here. It appears to smooth out when the ICP is disconnected but both it and the IPR have been replaced. I find it hard to believe that two ICP's, both the original Standard Ignition part and the new Motorcraft sensor seem to be acting the same way.

At this point it appears to be electrical related but could it be coincidence I have to bad ICP's or is there something else I am over looking?

Unfortunately I am still have the bucking and stuttering issues.

So at this point here is what I have replaced...

EBP Sensor, Tube and 45 Degree elbow that connects tube and sensor

IPR

ICP

Fuel Filter

CMP (Tried three different IH units and one Motorcraft which all appear to be the same dark bluish gray with purple o-ring. Part# is 1876736C91)

Oil Change (Delo 15W40 with Motorcraft Filter)

Lift Pump (Changed previously due to the original leaking, although issue originated before hand)

Up Pipe Gaskets

All sensor pigtails appear to look ok as well as the valve cover harnesses. I don't see any chaffing or frayed wiring either.

Here are some additional screen shots from the Modis on the last test run I took it on after everything has been replaced...

1) Accelerating to 50mph...

2) Holding speed at 50mph...

3) Idle at stop sign...

4) WOT up to 70mph...

5) Holding speed at 60mph...

6) WOT up to 75mph...

7) Idle again at stop sign...

8) Engine starts to cutout...

9) Engine regains normal, smooth idle speed...

The one thing I did notice again was when I pulled the ICP harness off the sensor ICP PSI went back to 700 and truck would no longer buck and stumble. I let it idle for a good 15 minutes at normal operating temp. Once I plugged the sensor back in is when the bucking and stumbling came back. There doesn't appear to be any pattern on when it will do it other than the fact it does it when the oil temp is up to operating temp and so far I cant see anything on the scanner that would indicate otherwise.

At this point I am completely at a loss on where to go from here. It appears to smooth out when the ICP is disconnected but both it and the IPR have been replaced. I find it hard to believe that two ICP's, both the original Standard Ignition part and the new Motorcraft sensor seem to be acting the same way.

At this point it appears to be electrical related but could it be coincidence I have to bad ICP's or is there something else I am over looking?

#21

what Is lift pump that you replaced?

IPC went below 500, that's why it dies

How high is oil level? How much oil do you put in when doing an oil change?

What is dipstick length to full mark?

Do you know low oil pressure when this happens?

You could have a chaffed IPR wire that cuts out the IPR

IPC went below 500, that's why it dies

How high is oil level? How much oil do you put in when doing an oil change?

What is dipstick length to full mark?

Do you know low oil pressure when this happens?

You could have a chaffed IPR wire that cuts out the IPR

#22

what Is lift pump that you replaced?

IPC went below 500, that's why it dies

How high is oil level? How much oil do you put in when doing an oil change?

What is dipstick length to full mark?

Do you know low oil pressure when this happens?

You could have a chaffed IPR wire that cuts out the IPR

IPC went below 500, that's why it dies

How high is oil level? How much oil do you put in when doing an oil change?

What is dipstick length to full mark?

Do you know low oil pressure when this happens?

You could have a chaffed IPR wire that cuts out the IPR

Lift pump I went with was the OEM Motorcraft Mechanical Fuel Pump. I changed it previously due to the original leaking. I had this issue before replacing it. I also changed out all the hoses attaching it and the fuel bowl.

Oil Level is at the full mark on this dip stick, checked onlevel ground. I typically put in about 14 or 15 quarts. I even sucked out what was in the HPOP before the recent change to pull out as much of the old oil out as possible. I checked the HPOP level and it's about 1/8 to 1/4" from the top.

If I am idling in the driveway or at a stop sign after the engine has reached operating temp, I usually am seeing around 430 to 500 PSI. At this point truck seems to be idling great. When it starts to buck or "hiccup" as I am seeing others use that term, the scanner shows around 380 to 400 PSI. The only thing I have not determined yet is if the scanner is seeing the lower oil pressure before is stumbles or afterwards as a result of the engine wanting to cut out.

The only thing I have been able to determine so far through out this whole ordeal is the truck runs great with no hiccups at all with the ICP unplugged. As far as chaffing goes, all connections to the ICP, IPR, CMP seem to be good and wiring seems to be intact.

I'm hoping to rule out one theory that my HPOP is getting weak and from what I can tell it seems to be ok. Other than the fact that oil pressure drops when it wants to stumble, do you see any concern with the pressures from the HPOP and IPR duty cycles from the various screenshots?

#23

#24

I'll have to put a gauge on it and see. Haven't looked at the LPOP pressure yet. Not sure if my scanner will give me at least an idea or not but I will check. Correct me if I am wrong here but if my LPOP pressure was low, would it also have a hard time filling up the HPOP reservoir? I know the idiot gauge on the panel doesn't say so but you can't rely soley on that. One of the things I checked early on, sorry forgot to mention it, was right after it started to hiccup, I shut it off and immediately checked the level in the HPOP and it was still near the top. Not sure if that would have told me anything but at least wanted to see if I was suffering from a low HPOP volume...

#25

Oh yeah, one more thing I forgot to mention....I hooked up my scanner to my buddies truck who I had borrowed the ICP from and checked his HPOP pressure at warm idle and it almost ball parked exactly where mine is. I've also read elsewhere that other users have verified there warm idle pressure to be similar to mine. With that low of a duty cycle, idling or WOT, could it still be said that my HPOP is on it's way out?

#26

the HPOP reservoir is sealed up so no pressure from LPOP could cause it to cavitate and no oil loss, I am not an expert on this part but pumps are pumps.

Get a gauge on the LPOP, there is no analog input to PCM for a scanner to read

When it does dies, IPR% goes up a bit and that looks more like a leaking oring on an injector

Get a gauge on the LPOP, there is no analog input to PCM for a scanner to read

When it does dies, IPR% goes up a bit and that looks more like a leaking oring on an injector

#27

the HPOP reservoir is sealed up so no pressure from LPOP could cause it to cavitate and no oil loss, I am not an expert on this part but pumps are pumps.

Get a gauge on the LPOP, there is no analog input to PCM for a scanner to read

When it does dies, IPR% goes up a bit and that looks more like a leaking oring on an injector

Get a gauge on the LPOP, there is no analog input to PCM for a scanner to read

When it does dies, IPR% goes up a bit and that looks more like a leaking oring on an injector

Ok I put a gauge on the LPOP and this is what I saw...

Cold start and idleing (700rpm).....................47psi

Oil temp at 180F and idleing (700rpm)...........27psi

Oil temp at 180F and holding at 1500rpm...........58psi

I looked at Fords specs and they are calling their minimum's out 12psi @ 700rpm, 24psi @ 1200 rpm and 45psi @ 1800rpm, all at normal operating temps. So I would think my LPOP would be ok, right?

I haven't done the injector O-rings yet but at this point I am about out of remaining options here. Everything I have read so far has pretty much pointed to everything I have either checked or already replaced so far but still not seeing any changes....

#28

IPR% goes from 9 to 17% at idle at times, to me that would be injector orings since LPOP is with in spec. For under 60 bucks you can be sure they are new. Alliant Injector O-rings - Ford 7.3L Powerstroke (94-03)

You don't even need valve cover gasket since they are reusable.

instructions I followed

https://www.ford-trucks.com/forums/9...ml#post8610883

Also might want to do this as well while you are in there

http://dieselpro.ca/Poppet%20Valve.pdf

INTERNATIONAL T444E / DT466e / 1530E injector tune up SHIM KIT w/ IP Tools | eBay

You don't even need valve cover gasket since they are reusable.

instructions I followed

https://www.ford-trucks.com/forums/9...ml#post8610883

Also might want to do this as well while you are in there

http://dieselpro.ca/Poppet%20Valve.pdf

INTERNATIONAL T444E / DT466e / 1530E injector tune up SHIM KIT w/ IP Tools | eBay

#29

Thanks again for your help. I studied a bit more how the entire high pressure oil system works as far as firing the injectors and I see what you mean now about possibly have leaky injector O-rings and it more than likely being the cause of my low hpop pressure after warming up. The IPR has been replaced as well with new O-rings so it seems that my hpop is working well within spec and yeah this appears to be the last bit in the equation.

The one thing I'm still a bit confused on and haven't found any info detailing my concern is this....When I cold start the engine in the morning, I'll notice that my oil pressure seems to be hovering around 650psi +/-. As the engine builds up temp, the oil pressure drops as I assume it would since it's seems to start leaking through the injectors but what I don't get it after the engine warms up and it hovers around 430 psi +/-, the engine will stay running but then it does its bucking and occasionally will cut out. Is there some mode that the ECM gets in that after seeing that low pressure for a certain time it will act like it wants to cut out? I get now that my injectors are leaking and that it's causing the low pressure but still don't get what is causing the occasional bucking. It still seems like an electrical glitch given the symptoms I'm having...

The one thing I'm still a bit confused on and haven't found any info detailing my concern is this....When I cold start the engine in the morning, I'll notice that my oil pressure seems to be hovering around 650psi +/-. As the engine builds up temp, the oil pressure drops as I assume it would since it's seems to start leaking through the injectors but what I don't get it after the engine warms up and it hovers around 430 psi +/-, the engine will stay running but then it does its bucking and occasionally will cut out. Is there some mode that the ECM gets in that after seeing that low pressure for a certain time it will act like it wants to cut out? I get now that my injectors are leaking and that it's causing the low pressure but still don't get what is causing the occasional bucking. It still seems like an electrical glitch given the symptoms I'm having...

#30

low pressure and injectors wont fire

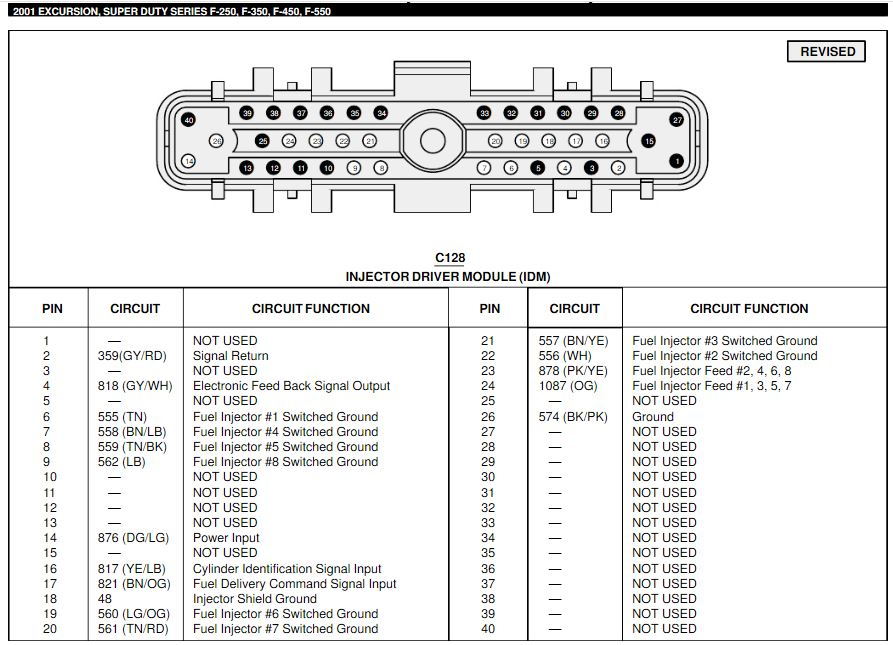

also could be the common for the injectors

Best to ohm out the 42 pin connector at the IDM and sometimes the pin for the common gets corroded or wire gets chaffed on the drivers side valve cover

but high IPR% make it look like injector o rings and as the oil warms up it gets thinner and leaks more