Electric Fuel Pump Installation

#16

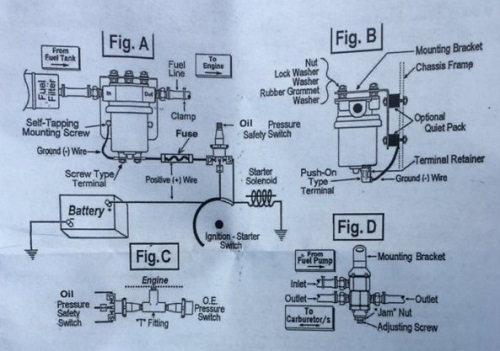

Here are the installation instructions from Carter. The oil pressure safety switch is designed to handle the full current of an electric fuel pump:

See figure A above for the oil pressure safety switch and how they recommend wiring it. They suggest Carter p/n A-68301, which is a slightly more complicated version of the NAPA OP6616 I used.

The Carter version is a SPDT switch. With no oil pressure present, terminal P is connected to S. This powers the pump when the starter is engaged. With oil pressure, terminal S is isolated and I is now connected to P. This runs the pump as long as oil pressure is present.

I ended up going with the simpler OP6616 switch instead. It is SPST. Years ago, when I first installed an electric pump, my local parts store was out of stock on the A-68301. The counterman suggested OP6616 instead, since I wasn't planning to automatically power the pump during start. He looked up the application and not only was it used as a safety switch, but also to control the electric choke heater on some vehicles. No idea of that amp draw, but that's going to be substantially more than a light bulb. I've run an electric pump with this particular switch (no relay) for over 10 years with no problems. Besides, if the switch should fail, I've got my spring-loaded override switch I can hold to limp home.

So basically I've wired the pump almost exactly as the manufacturer recommended. My version doesn't run the pump during start, that's all. I'm fine with that, and prefer the manual override.

You had previously asked about the extra filter I added at the pump inlet. I was trying to remember why I did that. Then I found the following per Carter, and remembered I was just following the manufacturer's instructions:

"To prevent fuel pump failure, installation of a high quality fuel filter on the inlet side is required."

Respectfully submitted.

Last edited by kr98664; 10-30-2018 at 07:30 PM. Reason: Removed dead link, added photos of Carter instruction manual

#17

Here are the installation instructions from Carter. The oil pressure safety switch is designed to handle the full current of an electric fuel pump:

http://carterfuelsystems.com/fuelpum...ec_FP_Inst.pdf

Scroll down to page 3 to see the oil pressure safety switch and how they recommend wiring it. They suggest Carter p/n A-68301, which is a slightly more complicated version of the NAPA OP6616 I used.

The Carter version is a SPDT switch. With no oil pressure present, terminal P is connected to S. This powers the pump when the starter is engaged. With oil pressure, terminal S is isolated and I is now connected to P. This runs the pump as long as oil pressure is present.

I ended up going with the simpler OP6616 switch instead. It is SPST. Years ago, when I first installed an electric pump, my local parts store was out of stock on the A-68301. The counterman suggested OP6616 instead, since I wasn't planning to automatically power the pump during start. He looked up the application and not only was it used as a safety switch, but also to control the electric choke heater on some vehicles. No idea of that amp draw, but that's going to be substantially more than a light bulb. I've run an electric pump with this particular switch (no relay) for over 10 years with no problems. Besides, if the switch should fail, I've got my spring-loaded override switch I can hold to limp home.

So basically I've wired the pump almost exactly as the manufacturer recommended. My version doesn't run the pump during start, that's all. I'm fine with that, and prefer the manual override.

You had previously asked about the extra filter I added at the pump inlet. I was trying to remember why I did that. Then I found this on page 4, and remembered I was just following the manufacturer's instructions:

"To prevent fuel pump failure, installation of a high quality fuel filter on the inlet side is required."

Respectfully submitted.

http://carterfuelsystems.com/fuelpum...ec_FP_Inst.pdf

Scroll down to page 3 to see the oil pressure safety switch and how they recommend wiring it. They suggest Carter p/n A-68301, which is a slightly more complicated version of the NAPA OP6616 I used.

The Carter version is a SPDT switch. With no oil pressure present, terminal P is connected to S. This powers the pump when the starter is engaged. With oil pressure, terminal S is isolated and I is now connected to P. This runs the pump as long as oil pressure is present.

I ended up going with the simpler OP6616 switch instead. It is SPST. Years ago, when I first installed an electric pump, my local parts store was out of stock on the A-68301. The counterman suggested OP6616 instead, since I wasn't planning to automatically power the pump during start. He looked up the application and not only was it used as a safety switch, but also to control the electric choke heater on some vehicles. No idea of that amp draw, but that's going to be substantially more than a light bulb. I've run an electric pump with this particular switch (no relay) for over 10 years with no problems. Besides, if the switch should fail, I've got my spring-loaded override switch I can hold to limp home.

So basically I've wired the pump almost exactly as the manufacturer recommended. My version doesn't run the pump during start, that's all. I'm fine with that, and prefer the manual override.

You had previously asked about the extra filter I added at the pump inlet. I was trying to remember why I did that. Then I found this on page 4, and remembered I was just following the manufacturer's instructions:

"To prevent fuel pump failure, installation of a high quality fuel filter on the inlet side is required."

Respectfully submitted.

The Federal motor vehicle saftey regs stipulate the installation of an inertia disconnect on all passenger vehicles fitted with elec fuel pumps. This is even more critical if you are using a return line where you can rupture the return line and still feed the motor fuel. An oil pressure cut out is certainly better than nothing, But an inertia cut out is a much better option. After some digging it seems GM used an Inertia cut out on the FP feed negating the need for a relay. Since they can be got for nothing from the wreckers as every single fuel injected vehicle has one it is a much better option. All the inertia cut outs have a reset button on them if they are tripped. Every single fuel injected passenger vehicle made since the mid 80's has been fitted with one.

If you do have to have to use a pre-filter a better choice would be a filter from a fuel injected application as they have much higher flow capabilities finer filtering and since they are moving a lot more fuel (having a return line) they can hold many many times more crud before plugging up. Something like Motorcraft G8018 which is not overly large is a good option. In your application it would likely be a life time filter.

#18

#19

You would have to look when the Inertia cut off switch started being used. I would guess when EFI came out as the motor will keep running upside down.

Still don't see why they could not use the oil psi switch but guess the sooner you can stop the pump the better?

With a carb I would go with just the psi switch because if upside down or motor stopped no psi no pump running.

If you want to install the Inertia switch ok but if it went off you would have a lot more to worry about than the pump in my book, besides motor most likely stopped any way.

Dave - - - -

Still don't see why they could not use the oil psi switch but guess the sooner you can stop the pump the better?

With a carb I would go with just the psi switch because if upside down or motor stopped no psi no pump running.

If you want to install the Inertia switch ok but if it went off you would have a lot more to worry about than the pump in my book, besides motor most likely stopped any way.

Dave - - - -

#20

#21

You would have to look when the Inertia cut off switch started being used. I would guess when EFI came out as the motor will keep running upside down.

Still don't see why they could not use the oil psi switch but guess the sooner you can stop the pump the better?

With a carb I would go with just the psi switch because if upside down or motor stopped no psi no pump running.

Still don't see why they could not use the oil psi switch but guess the sooner you can stop the pump the better?

With a carb I would go with just the psi switch because if upside down or motor stopped no psi no pump running.

Weren't there some vehicles during the 70s that used electric pumps and oil pressure safety switches? I'm thinking some smaller cars like the Vega or Capri, but am not sure. Or if they did have electric pumps, was it always an inertia switch only?

For anybody interested in adding an inertia switch, I found several new aftermarket options. There are many others, these are just two examples:

https://www.amazon.com/Standard-Moto...ct_top?ie=UTF8

https://www.amazon.com/gp/product/B0...Q32GNBY13BBK5S

A new part might be a better option than a junkyard find, plus these include a wiring pigtail.

If installing an inertia switch, you'd definitely want to connect it via a relay.

#22

#23

Weren't there some vehicles during the 70s that used electric pumps and oil pressure safety switches? I'm thinking some smaller cars like the Vega or Capri, but am not sure. Or if they did have electric pumps, was it always an inertia switch only?

For anybody interested in adding an inertia switch, I found several new aftermarket options. There are many others, these are just two examples:

https://www.amazon.com/Standard-Moto...ct_top?ie=UTF8

https://www.amazon.com/gp/product/B0...Q32GNBY13BBK5S

A new part might be a better option than a junkyard find, plus these include a wiring pigtail.

If installing an inertia switch, you'd definitely want to connect it via a relay.

For anybody interested in adding an inertia switch, I found several new aftermarket options. There are many others, these are just two examples:

https://www.amazon.com/Standard-Moto...ct_top?ie=UTF8

https://www.amazon.com/gp/product/B0...Q32GNBY13BBK5S

A new part might be a better option than a junkyard find, plus these include a wiring pigtail.

If installing an inertia switch, you'd definitely want to connect it via a relay.

The early common fuel injected vehicles in the 70's (VW's Mercedes BMW) has no provision for cutting out the fuel pump in the event of an accident. It was in the early 80's that they mandated the Inertia cut out on fuel injected vehicles.

As i stated earlier there are applications where the Inertia switch is in the fuel pump feed. It seems ford even did this. See below For 02 F250 fuel pump circuit.

As for wrecking yard ones. The inertia switches are not a dynamic part the only time they trigger is in an impact. The ford ones at least adhere to the KISS principle in construction and there really is nothing in them that could fail. They work or don't work. See below for a cut away of a Ford Inertia switch. The Ford switch is widely used by the hot rod crowd when adding Fuel injection or an Elec pump due to it's simplicity reliability and ease of installation.

#24

I've also added a fuel pressure regulator. When I first installed the pump, I noticed the output ranging up to about 12 psi on occasion, although it's only supposed to put out 6-8 psi. I wasn't sure if this was just a normal variation of the pump or if it was defective, but the engine ran fine regardless. Just to be safe, I added a fuel pressure regulator and now the output range is very tight.

I've since deleted the pressure regulator for simplicity. The pump itself was the cause of the pressure variations. A new pump fixed that, so the regulator was no longer needed.

#25

Of course this is already an old thread, but it should be a sticky! Great writeup kr98664!

Noticed the link to the Carter instructions is outdated. Try this one.

https://carterfuelsystems.com/resour...n-instructions

Also wanted to add a drawing of a control system that I have used successfully.

Noticed the link to the Carter instructions is outdated. Try this one.

https://carterfuelsystems.com/resour...n-instructions

Also wanted to add a drawing of a control system that I have used successfully.

#26

Of course this is already an old thread, but it should be a sticky! Great writeup kr98664!

Noticed the link to the Carter instructions is outdated. Try this one.

https://carterfuelsystems.com/resour...n-instructions

Also wanted to add a drawing of a control system that I have used successfully.

Noticed the link to the Carter instructions is outdated. Try this one.

https://carterfuelsystems.com/resour...n-instructions

Also wanted to add a drawing of a control system that I have used successfully.

1) Created a link to this thread in the Sticky in the carb & fuel injection section.

2) Moved his entire thread into the HOWTOS subforum.

Congratulations, Karl, I think this is Thread #2 you have stuck up there.

#27

#28

Update Time:

When I purchased my P4600HP about 5 years ago, the specs showed 6-8psi. I remember this very clearly, as I wanted to match the pressure specs for the stock mechanical pump. After installation, I verified the pressure was correct with a mechanical gauge. I've also added an electric gauge and that continues to show the desired 6-8psi.

However, I just went to the Carter website and it now shows 2.0-4.5psi:

https://carter.opticatonline.com/par...00HP&ctx_iam=1

Oddly enough, some online vendors show 6-8psi and others vendors show the the lower range. Heck if I know what is going on. I find it hard to believe that Carter would change the specs so drastically and keep the same part number. I wonder if that is a recent typo on Carter's part, and some vendors used that info. If so, a vendor that hasn't updated their listing may still have the (hopefully) correct values. If you were to purchase a P4600HP today, I can't verify exactly what you would get.

When I purchased my P4600HP about 5 years ago, the specs showed 6-8psi. I remember this very clearly, as I wanted to match the pressure specs for the stock mechanical pump. After installation, I verified the pressure was correct with a mechanical gauge. I've also added an electric gauge and that continues to show the desired 6-8psi.

However, I just went to the Carter website and it now shows 2.0-4.5psi:

https://carter.opticatonline.com/par...00HP&ctx_iam=1

Oddly enough, some online vendors show 6-8psi and others vendors show the the lower range. Heck if I know what is going on. I find it hard to believe that Carter would change the specs so drastically and keep the same part number. I wonder if that is a recent typo on Carter's part, and some vendors used that info. If so, a vendor that hasn't updated their listing may still have the (hopefully) correct values. If you were to purchase a P4600HP today, I can't verify exactly what you would get.

#29

However, I just went to the Carter website and it now shows 2.0-4.5psi:

https://carter.opticatonline.com/par...00HP&ctx_iam=1

Oddly enough, some online vendors show 6-8psi and others vendors show the the lower range. Heck if I know what is going on. I find it hard to believe that Carter would change the specs so drastically and keep the same part number. I wonder if that is a recent typo on Carter's part, and some vendors used that info. If so, a vendor that hasn't updated their listing may still have the (hopefully) correct values. If you were to purchase a P4600HP today, I can't verify exactly what you would get.

https://carter.opticatonline.com/par...00HP&ctx_iam=1

Oddly enough, some online vendors show 6-8psi and others vendors show the the lower range. Heck if I know what is going on. I find it hard to believe that Carter would change the specs so drastically and keep the same part number. I wonder if that is a recent typo on Carter's part, and some vendors used that info. If so, a vendor that hasn't updated their listing may still have the (hopefully) correct values. If you were to purchase a P4600HP today, I can't verify exactly what you would get.

#30

When a guy asks for help, isn't that considered a sign of weakness?

Oh, anyways, I did ask the tech helpline at Carter. Straight from the horse's mouth, a rep from Carter confirmed the P4600HP is still rated for 6-8psi.

I'll be curious to see if/when their website ever shows the correct specs.

Oh, anyways, I did ask the tech helpline at Carter. Straight from the horse's mouth, a rep from Carter confirmed the P4600HP is still rated for 6-8psi.

I'll be curious to see if/when their website ever shows the correct specs.

Thread

Thread Starter

Forum

Replies

Last Post

fmc400

1973 - 1979 F-100 & Larger F-Series Trucks

41

09-29-2023 09:46 AM

bigbird189

1980 - 1986 Bullnose F100, F150 & Larger F-Series Trucks

7

06-05-2016 11:49 AM