Towing a gooseneck with a truck that's got a service body

#1

Towing a gooseneck with a truck that's got a service body

I'm looking to trade my F-250 for a guy that's got an 01 F-450 with a 12' service body on it and i tow a gooseneck trailer fairly regularly. What would my best option be as far as installing a gooseneck on that truck? Reason i'm looking to trade is even with a B&W extended gooseneck ball i can't make the 90* turn i need to without getting uncomfortably close to my cab when backing the trailer into our new storage lot.

#2

#3

#4

I looked at the truck and it's 24" from the floor of the bed to the top of the boxes and 48" from the axle centerline to the back of the bed and my truck now is 21" from the floor to the top of the box. it'll leave about 7" from the top of the boxes to the gooseneck rails and the gooseneck rails are flat.

Hhowell1990...

Obviously you won't have to worry about clearance to the back of the cab window, for two reasons...1) the cab to axle distance is longer on any model of 2001 F-450 than on any model of pickup, and 2)your gooseneck rails do not have a deck over the neck... so no cab crush.

What is concerning though with the service body is box crush... and I don't mean top of box crush, but tail corner swing clearance crush between the back corner's of the service body and the triangular gussets supporting the gooseneck rails while you are in a compound angle turn heading down a driveway perpendicular to the road you were driving on.

Accordingly, I would run a tape from the anticipated hitch point that is directly over the center of your drive axle... stretching the tape diagonally over to each corner of the service box... especially the top corners. I'd be less concerned if the bumper sticks out more, because the bumper will always ride significantly below the triangular gussets.

I would then make a corresponding measurement on the gooseneck trailer... because that neck looks a little bit shorter than 8' from the photo... I've seen them as short as 6', although not commonly. Measure from the trailer's ball coupler to the triangular gussets on the uprights that support the neck rails. Visualize the tail corners of the service box swinging through the radius measured, while imaging the truck mid turn, tilting down, while the trailer is still level.

A cab chassis not only has a longer cab axle distance than any pickup, it also has a longer axle to rear bumper distance along the frame rails aft of the axle than any pickup. That distance is long enough to stuff a 40 gallon aft axle fuel tank. So the swing clearance between the tail of the cab chassis service body and the drop wall of a gooseneck or fiver trailer has to be considered.

A lot of dedicated 5th wheel hauler beds have the top rear corners of the enclosed box bodies chopped off at downward angle, to afford more truck to trailer articulation clearance. This is an extra thing to look out for in addition to the top of box to trailer overhang clearance you already measured to be 7".

As for hitches... there is no easy bolt up pre made solution. Any installation will require drilling and cutting, due to the variance in deck height of the service body. So if you like B&W, you either have to cut a trap door in the deck of the service body, or, fabricate a built up rail that enables the B&W receiver to mount flush up under the deck of the service body. But even then, you will have to cut the stiffening ribs out from underneath the deck of the service body, so that you can have the flush fit and just be able to drill that clean 4" round hole.

Oftentimes, the actual deck of the service body is about 4.5" above the top of the frame rails. A typical pickup bed deck height is only about half that high, or even less between the kick up of a pick up frame above the axle and the bed. The chassis cab rails are straight and flat, front to back, but on the Fords you do have to work around a couple of cross member rivets and an overload spring cleat, depending on the design of supporting structure fabricated to hold up the B&W receiver. B&W does not offer a cross rail kit for chassis cabs, because of their being so many different potential variations.

If you like Reese products, then Reese makes a puck and rail kit for 34" cab chassis rails that functions just like the factory prep puck kit that Ford introduced into the 2011 and up models. The difference is that the Reese rails are upside down U channel tubes that are designed to rest on top of the chassis cab rails, which again puts the puck height at about 2.625" above the frame rail, which could be as much as 2" below the deck height of the service body.

Once the pucks are in place, Reese sells an over the bed deck gooseneck hitch assembly that clicks into the four perimeter pucks. The disadvantage of this system is that the ball height will increase by about 5 to 8 inches over an embedded ball under a trap door or a retractable B&W Ball. If the adjustable coupler to your trailer doesn't run up that high, then the rear axle of your trailer might end up taking on more weight than the front axle, as the trailer would be nose high.

B&W isn't the only retractable or removable ball solution. Reese/Drawtite offer the "Remove-A-Ball", and there are similar designs that have the word "Flip" in them, since the ball is flipped down when not in use. I just can't remember their trade names at the moment I am typing this.

A simpler to install, but not nearly as strong, hitch solution is to install a traditional 5th wheel rail kit on top of the service body deck, and then use long L brackets to tie the ends of the hat channel fiver hitch rails to the web of the frame rails, bolted through the service deck, spaced about 22" apart (11" ahead of, and 11" behind the center axle). Then get one of those Reese or Curt Spyder type of gooseneck assemblies that J bolts into the surface mount fiver rails that you will otherwise have to trip over all the time when not towing. Without any under bed fabrication of cross rail support, this install would leaves a weak point in the center of each hat channel fiver hitch rail, right at the point where the pin pulls and pushes the hardest... in the center.

Lots of options... none of them are direct bolt in out of a box. All will require some sort of cutting or drilling. I did not say welding, because welding a gooseneck hitch to the frame is not recommended nowdays, even though that was commonly done on the horse ranch I spent my youth on many moons ago.

#5

#6

Hhowell1990...

Obviously you won't have to worry about clearance to the back of the cab window, for two reasons...1) the cab to axle distance is longer on any model of 2001 F-450 than on any model of pickup, and 2)your gooseneck rails do not have a deck over the neck... so no cab crush.

What is concerning though with the service body is box crush... and I don't mean top of box crush, but tail corner swing clearance crush between the back corner's of the service body and the triangular gussets supporting the gooseneck rails while you are in a compound angle turn heading down a driveway perpendicular to the road you were driving on.

Accordingly, I would run a tape from the anticipated hitch point that is directly over the center of your drive axle... stretching the tape diagonally over to each corner of the service box... especially the top corners. I'd be less concerned if the bumper sticks out more, because the bumper will always ride significantly below the triangular gussets.

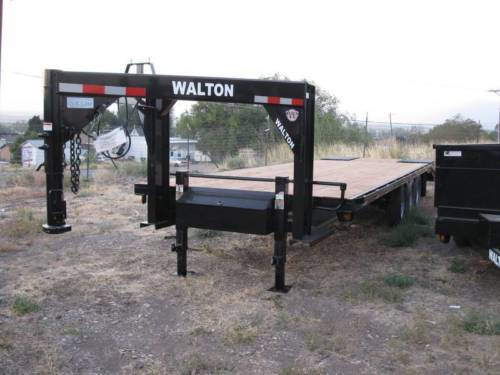

I would then make a corresponding measurement on the gooseneck trailer... because that neck looks a little bit shorter than 8' from the photo... I've seen them as short as 6', although not commonly. Measure from the trailer's ball coupler to the triangular gussets on the uprights that support the neck rails. Visualize the tail corners of the service box swinging through the radius measured, while imaging the truck mid turn, tilting down, while the trailer is still level.

A cab chassis not only has a longer cab axle distance than any pickup, it also has a longer axle to rear bumper distance along the frame rails aft of the axle than any pickup. That distance is long enough to stuff a 40 gallon aft axle fuel tank. So the swing clearance between the tail of the cab chassis service body and the drop wall of a gooseneck or fiver trailer has to be considered.

A lot of dedicated 5th wheel hauler beds have the top rear corners of the enclosed box bodies chopped off at downward angle, to afford more truck to trailer articulation clearance. This is an extra thing to look out for in addition to the top of box to trailer overhang clearance you already measured to be 7".

As for hitches... there is no easy bolt up pre made solution. Any installation will require drilling and cutting, due to the variance in deck height of the service body. So if you like B&W, you either have to cut a trap door in the deck of the service body, or, fabricate a built up rail that enables the B&W receiver to mount flush up under the deck of the service body. But even then, you will have to cut the stiffening ribs out from underneath the deck of the service body, so that you can have the flush fit and just be able to drill that clean 4" round hole.

Oftentimes, the actual deck of the service body is about 4.5" above the top of the frame rails. A typical pickup bed deck height is only about half that high, or even less between the kick up of a pick up frame above the axle and the bed. The chassis cab rails are straight and flat, front to back, but on the Fords you do have to work around a couple of cross member rivets and an overload spring cleat, depending on the design of supporting structure fabricated to hold up the B&W receiver. B&W does not offer a cross rail kit for chassis cabs, because of their being so many different potential variations.

If you like Reese products, then Reese makes a puck and rail kit for 34" cab chassis rails that functions just like the factory prep puck kit that Ford introduced into the 2011 and up models. The difference is that the Reese rails are upside down U channel tubes that are designed to rest on top of the chassis cab rails, which again puts the puck height at about 2.625" above the frame rail, which could be as much as 2" below the deck height of the service body.

Once the pucks are in place, Reese sells an over the bed deck gooseneck hitch assembly that clicks into the four perimeter pucks. The disadvantage of this system is that the ball height will increase by about 5 to 8 inches over an embedded ball under a trap door or a retractable B&W Ball. If the adjustable coupler to your trailer doesn't run up that high, then the rear axle of your trailer might end up taking on more weight than the front axle, as the trailer would be nose high.

B&W isn't the only retractable or removable ball solution. Reese/Drawtite offer the "Remove-A-Ball", and there are similar designs that have the word "Flip" in them, since the ball is flipped down when not in use. I just can't remember their trade names at the moment I am typing this.

A simpler to install, but not nearly as strong, hitch solution is to install a traditional 5th wheel rail kit on top of the service body deck, and then use long L brackets to tie the ends of the hat channel fiver hitch rails to the web of the frame rails, bolted through the service deck, spaced about 22" apart (11" ahead of, and 11" behind the center axle). Then get one of those Reese or Curt Spyder type of gooseneck assemblies that J bolts into the surface mount fiver rails that you will otherwise have to trip over all the time when not towing. Without any under bed fabrication of cross rail support, this install would leaves a weak point in the center of each hat channel fiver hitch rail, right at the point where the pin pulls and pushes the hardest... in the center.

Lots of options... none of them are direct bolt in out of a box. All will require some sort of cutting or drilling. I did not say welding, because welding a gooseneck hitch to the frame is not recommended nowdays, even though that was commonly done on the horse ranch I spent my youth on many moons ago.

Obviously you won't have to worry about clearance to the back of the cab window, for two reasons...1) the cab to axle distance is longer on any model of 2001 F-450 than on any model of pickup, and 2)your gooseneck rails do not have a deck over the neck... so no cab crush.

What is concerning though with the service body is box crush... and I don't mean top of box crush, but tail corner swing clearance crush between the back corner's of the service body and the triangular gussets supporting the gooseneck rails while you are in a compound angle turn heading down a driveway perpendicular to the road you were driving on.

Accordingly, I would run a tape from the anticipated hitch point that is directly over the center of your drive axle... stretching the tape diagonally over to each corner of the service box... especially the top corners. I'd be less concerned if the bumper sticks out more, because the bumper will always ride significantly below the triangular gussets.

I would then make a corresponding measurement on the gooseneck trailer... because that neck looks a little bit shorter than 8' from the photo... I've seen them as short as 6', although not commonly. Measure from the trailer's ball coupler to the triangular gussets on the uprights that support the neck rails. Visualize the tail corners of the service box swinging through the radius measured, while imaging the truck mid turn, tilting down, while the trailer is still level.

A cab chassis not only has a longer cab axle distance than any pickup, it also has a longer axle to rear bumper distance along the frame rails aft of the axle than any pickup. That distance is long enough to stuff a 40 gallon aft axle fuel tank. So the swing clearance between the tail of the cab chassis service body and the drop wall of a gooseneck or fiver trailer has to be considered.

A lot of dedicated 5th wheel hauler beds have the top rear corners of the enclosed box bodies chopped off at downward angle, to afford more truck to trailer articulation clearance. This is an extra thing to look out for in addition to the top of box to trailer overhang clearance you already measured to be 7".

As for hitches... there is no easy bolt up pre made solution. Any installation will require drilling and cutting, due to the variance in deck height of the service body. So if you like B&W, you either have to cut a trap door in the deck of the service body, or, fabricate a built up rail that enables the B&W receiver to mount flush up under the deck of the service body. But even then, you will have to cut the stiffening ribs out from underneath the deck of the service body, so that you can have the flush fit and just be able to drill that clean 4" round hole.

Oftentimes, the actual deck of the service body is about 4.5" above the top of the frame rails. A typical pickup bed deck height is only about half that high, or even less between the kick up of a pick up frame above the axle and the bed. The chassis cab rails are straight and flat, front to back, but on the Fords you do have to work around a couple of cross member rivets and an overload spring cleat, depending on the design of supporting structure fabricated to hold up the B&W receiver. B&W does not offer a cross rail kit for chassis cabs, because of their being so many different potential variations.

If you like Reese products, then Reese makes a puck and rail kit for 34" cab chassis rails that functions just like the factory prep puck kit that Ford introduced into the 2011 and up models. The difference is that the Reese rails are upside down U channel tubes that are designed to rest on top of the chassis cab rails, which again puts the puck height at about 2.625" above the frame rail, which could be as much as 2" below the deck height of the service body.

Once the pucks are in place, Reese sells an over the bed deck gooseneck hitch assembly that clicks into the four perimeter pucks. The disadvantage of this system is that the ball height will increase by about 5 to 8 inches over an embedded ball under a trap door or a retractable B&W Ball. If the adjustable coupler to your trailer doesn't run up that high, then the rear axle of your trailer might end up taking on more weight than the front axle, as the trailer would be nose high.

B&W isn't the only retractable or removable ball solution. Reese/Drawtite offer the "Remove-A-Ball", and there are similar designs that have the word "Flip" in them, since the ball is flipped down when not in use. I just can't remember their trade names at the moment I am typing this.

A simpler to install, but not nearly as strong, hitch solution is to install a traditional 5th wheel rail kit on top of the service body deck, and then use long L brackets to tie the ends of the hat channel fiver hitch rails to the web of the frame rails, bolted through the service deck, spaced about 22" apart (11" ahead of, and 11" behind the center axle). Then get one of those Reese or Curt Spyder type of gooseneck assemblies that J bolts into the surface mount fiver rails that you will otherwise have to trip over all the time when not towing. Without any under bed fabrication of cross rail support, this install would leaves a weak point in the center of each hat channel fiver hitch rail, right at the point where the pin pulls and pushes the hardest... in the center.

Lots of options... none of them are direct bolt in out of a box. All will require some sort of cutting or drilling. I did not say welding, because welding a gooseneck hitch to the frame is not recommended nowdays, even though that was commonly done on the horse ranch I spent my youth on many moons ago.

Thread

Thread Starter

Forum

Replies

Last Post

ERAUGrad04

Fifth Wheel & Gooseneck RV Towing

13

02-26-2018 06:46 PM

ToughestTruckBuilt

1973 - 1979 F-100 & Larger F-Series Trucks

2

07-19-2010 11:01 AM

swengle

Flatbed, Car, Boat, Utility, Horse & Misc. Trailer Towing

2

07-30-2008 12:18 AM

444

Other; Brakes, Electrical, Hitches, Weight Distribution & CDL Discussion

6

05-11-2008 06:28 PM