Need quick help that local dealerships can't handle

#16

Is that one rod journal or all of them?

Wouldn't be impossible someone had one or a couple journals machined to correct for damage to only those that required it, from what I understand some of the cheaper engine re mans do that sort of thing.

Even if that one rod required a undersized bearing due to the journal machining, the journal diameter being reduced nothing else done to the rod, the crank would have still rotated with a standard bearing in its place there would be excessive play/clearance because of it.

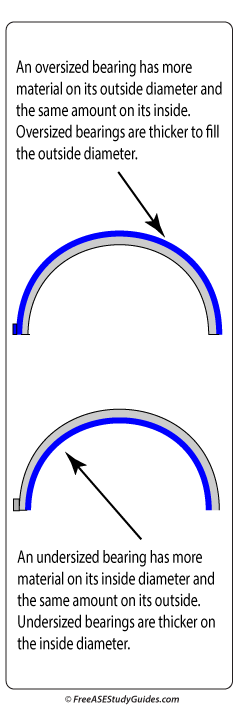

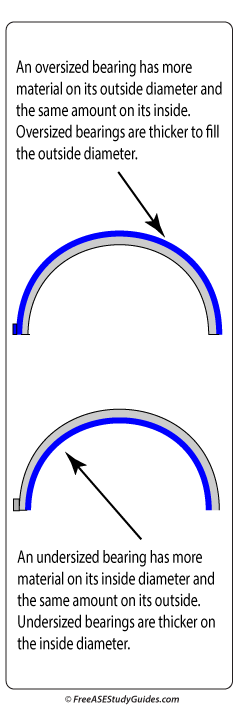

As you can see in the picture a undersized bearing would be thicker over all than a standard sized bearing.

If needed a undersize on one or more it'd be a good thing to find it as it would knock the first time ran due to being loose.

You need to get the rod clear of the main then put its cap on with no bearing in it, then measure the inner diameter of the assembled end.

In your original post you stated the crank wouldn't turn after completing the main bearings, like you had not started the rods.

In a later post stated you started to torque a couple rods you had already done after torquing the mains to find you could no longer rotate the crank. Took that as you never did get to torque those couple rods due to not being able to rotate the crank to do so.

Just trying to be clear as you can see your new update really doesn't "fit".

Oh and yea your math works but you'd be putting in more bearing material, thicker, in where you can't rotate the shaft now with less in that same space.

Wouldn't be impossible someone had one or a couple journals machined to correct for damage to only those that required it, from what I understand some of the cheaper engine re mans do that sort of thing.

Even if that one rod required a undersized bearing due to the journal machining, the journal diameter being reduced nothing else done to the rod, the crank would have still rotated with a standard bearing in its place there would be excessive play/clearance because of it.

As you can see in the picture a undersized bearing would be thicker over all than a standard sized bearing.

If needed a undersize on one or more it'd be a good thing to find it as it would knock the first time ran due to being loose.

You need to get the rod clear of the main then put its cap on with no bearing in it, then measure the inner diameter of the assembled end.

In your original post you stated the crank wouldn't turn after completing the main bearings, like you had not started the rods.

In a later post stated you started to torque a couple rods you had already done after torquing the mains to find you could no longer rotate the crank. Took that as you never did get to torque those couple rods due to not being able to rotate the crank to do so.

Just trying to be clear as you can see your new update really doesn't "fit".

Oh and yea your math works but you'd be putting in more bearing material, thicker, in where you can't rotate the shaft now with less in that same space.

#17

#18

DanR1,

That was a rushed update on my part. What actually happened was we replaced the mains and torqued, then rods and torqued. Nothing moved, so then I removed main caps and checked them, and checked rod caps, then replaced main caps and tightened and torqued, then turned the crank with great compression. Then I just tightened not even to torque specs on the rod caps and tried again, crank wouldn't move with same force.

I'm going to recheck the rod bearing seating and make sure it's all where it should be and correct then try re-torque and turn crank again. I'm gonna take some pictures of what I'm looking at tonight and post in the morning to avoid any obvious mistakes.

The graphic was really helpful understanding all that bearing stuff DanR1, Thank you.

Thanks everyone for the help and advice.

That was a rushed update on my part. What actually happened was we replaced the mains and torqued, then rods and torqued. Nothing moved, so then I removed main caps and checked them, and checked rod caps, then replaced main caps and tightened and torqued, then turned the crank with great compression. Then I just tightened not even to torque specs on the rod caps and tried again, crank wouldn't move with same force.

I'm going to recheck the rod bearing seating and make sure it's all where it should be and correct then try re-torque and turn crank again. I'm gonna take some pictures of what I'm looking at tonight and post in the morning to avoid any obvious mistakes.

The graphic was really helpful understanding all that bearing stuff DanR1, Thank you.

Thanks everyone for the help and advice.

#19

Yea I wasn't suggesting subterfuge or anything of the sort on your part just wanted to be sure everyone is clear on the order of events.

Don't recall if has been asked and didn't look, you guys are using assembly lube of some sort on the bearings correct?

The arrows point front and as pointed out they all must go back from where they where removed, both main and rod caps do not mix them around as that could be very bad.

Don't recall if has been asked and didn't look, you guys are using assembly lube of some sort on the bearings correct?

The arrows point front and as pointed out they all must go back from where they where removed, both main and rod caps do not mix them around as that could be very bad.

#20

Yes we're lubing the inside of the bearings as we're installing them. I'm 99.9% sure everything is replaced where it came from, but I was tool gophering a couple times and can't be 100%. Is there anywhere to get a picture of a stock untouched bottom end on a 302 to compare and make sure? I know that's a naive question and I know I should have taken a picture or marked them to start, but I was trusting an older family friend who has done this many times before on the same motor, or so he says so I was kind of pushed to the side in the beginning.

#21

Bearings have a tang to prevent spinning with the shaft and a corresponding slot in the block/cap rod end/cap for them to index into, correction those go to the same side.

Other than that detail without markings there is no way to know which cap came from which rod unless marked from a previous rebuild.

From what you've told us about the guy I would think he knows the importance of keeping them straight, if have doubts why not ask him? Again not accusing him but its something you're gonna need to know, that might be the reason it doesn't rotate once most or all of them are torqued he forgot or never knew that little detail.

If so he should man up and admit it, do the best he can to figure out what goes were and get it to spin.

Could be an impossible task or maybe its just the first two he swapped with each other and will know that once you put the question to him.

Other than that detail without markings there is no way to know which cap came from which rod unless marked from a previous rebuild.

From what you've told us about the guy I would think he knows the importance of keeping them straight, if have doubts why not ask him? Again not accusing him but its something you're gonna need to know, that might be the reason it doesn't rotate once most or all of them are torqued he forgot or never knew that little detail.

If so he should man up and admit it, do the best he can to figure out what goes were and get it to spin.

Could be an impossible task or maybe its just the first two he swapped with each other and will know that once you put the question to him.

#22

This is just a curiosity question...When you thought you had bad bearings and decided to replace them what did they look like? Were they showing any copper or were they scored? Was the motor knocking? It sounds like your oil pressure gauge is working ok. High at high engine speed and low at low engine speed but unless you installed a good quality gauge I would not trust the needle to be dead on the number for pressure.

#24

So... I have an update. It took a few weeks, but.... Here it goes:

So turns out a rod bearing shifted while we were installing it, which we figured out after using the plasti-gauge to determine clearances. So we corrected the bearing and the truck started fine... Unfortunately I had no oil pressure, so I shut her down, pulled the pan again and re-checked the new oil pump, screen, and rod... Sure enough one of my "helpers" missed the hole for the rod, so after re-seating the rod in it's correct hole and bolting everything back up the truck runs great with OP in the 60psi range at start-up and about 5psi over the 10psi/1000rpm at normal operating conditions. I've been very happy with THAT.

The idle problem I solved by replacing the idle air bypass.

Then the distributor-to-coil wire&plug had a wire burn/break somehow so I pulled the wire, replaced it and re-fed it through the plug and re-soldered the connection. Problem solved.

Then my rear end blew up, so I had one off a parts truck and slapped it in, Problem Solved.

NOW... I have a couple new issues. My CEL comes on and stays off and on randomly while driving. But none of the shops with OBD I scanners have had time to check the codes for me... I havent been too worried about it because it was on before and I assume it's a sensor, although my throttle response could be the indicator too.

When in low idle or from takeoff occassionally I'm forced to pat the gas pedal a few times to get a response and some actual revving. Once it's going it's not an issue, just from take off. It has cut off twice in the last couple weeks randomly at low RPM idle, just cuts off and I just crank it back up.

Took it to a hunting dog field trial this weekend, drove an hour each way, primarily highway miles. No problem. Came home and parked at my kennels to unload the dogs and left the truck running for 5 minutes tops. Drove the truck 50 ft uphill to my house and parked and cut it off. I walked inside and my girlfriend was getting things out of the truck. She came in and told me she thought my radiator blew because it was bubbling and leaking anti-freeze. I went outside and found the radiator overflow leaking and boiling over.

I let the truck cool down, re-filled the radiator and tried to watch for leaks. I can't see any. I let the truck run with cap off for 5 minutes, heat on. Heat blew nice and hot. Temp gauge was on nOrmal and so I put the cap on and drove around town. Came home and noticed my level was low. SO... I let it cool, topped it off and again let it run with cap off, topping off as needed. Then after 5-10 minutes with no problems I replaced the cap and let it keep running. 5 minutes later the overflow started boiling and so I shut it down, opened the overflow cap and cracked the radiator cap to relieve pressure.

I'm stumped. I just replaced the thermostat a month ago, and I had flushed the radiator/coolant system when I replaced the water pump in December..

My friend who is a Ford guy said he thinks it's either my radiator cap or my fan clutch. He recommended replacing the cap, and buying a fan from the scrap yard without a clutch and put that on instead of replacing the fan-clutch. I just want to do whatever I need to PROPERLY fix this problem. Any ideas? THANKS IN ADVANCE

Also, my driver-side power window is not wanting to come up, feels like the belt is slipping. Just curious if anyone knows how tricky this replacement is and how expensive the belt is.

I LOVE this group and it has been a lifesaver.

OHHHH and FYI to everybody... We did all the lower motor work, water pump, oil pump, timing chain cover gasket, thermostat, EVERYTHING with the motor in the truck. We jacked it up to get access, but we didn't pull the motor and although it was a little tricky at times, it was possible. So for anyone wondering if it is possible, it is! And that was with the larger hi-flow oil pump as well.

So turns out a rod bearing shifted while we were installing it, which we figured out after using the plasti-gauge to determine clearances. So we corrected the bearing and the truck started fine... Unfortunately I had no oil pressure, so I shut her down, pulled the pan again and re-checked the new oil pump, screen, and rod... Sure enough one of my "helpers" missed the hole for the rod, so after re-seating the rod in it's correct hole and bolting everything back up the truck runs great with OP in the 60psi range at start-up and about 5psi over the 10psi/1000rpm at normal operating conditions. I've been very happy with THAT.

The idle problem I solved by replacing the idle air bypass.

Then the distributor-to-coil wire&plug had a wire burn/break somehow so I pulled the wire, replaced it and re-fed it through the plug and re-soldered the connection. Problem solved.

Then my rear end blew up, so I had one off a parts truck and slapped it in, Problem Solved.

NOW... I have a couple new issues. My CEL comes on and stays off and on randomly while driving. But none of the shops with OBD I scanners have had time to check the codes for me... I havent been too worried about it because it was on before and I assume it's a sensor, although my throttle response could be the indicator too.

When in low idle or from takeoff occassionally I'm forced to pat the gas pedal a few times to get a response and some actual revving. Once it's going it's not an issue, just from take off. It has cut off twice in the last couple weeks randomly at low RPM idle, just cuts off and I just crank it back up.

Took it to a hunting dog field trial this weekend, drove an hour each way, primarily highway miles. No problem. Came home and parked at my kennels to unload the dogs and left the truck running for 5 minutes tops. Drove the truck 50 ft uphill to my house and parked and cut it off. I walked inside and my girlfriend was getting things out of the truck. She came in and told me she thought my radiator blew because it was bubbling and leaking anti-freeze. I went outside and found the radiator overflow leaking and boiling over.

I let the truck cool down, re-filled the radiator and tried to watch for leaks. I can't see any. I let the truck run with cap off for 5 minutes, heat on. Heat blew nice and hot. Temp gauge was on nOrmal and so I put the cap on and drove around town. Came home and noticed my level was low. SO... I let it cool, topped it off and again let it run with cap off, topping off as needed. Then after 5-10 minutes with no problems I replaced the cap and let it keep running. 5 minutes later the overflow started boiling and so I shut it down, opened the overflow cap and cracked the radiator cap to relieve pressure.

I'm stumped. I just replaced the thermostat a month ago, and I had flushed the radiator/coolant system when I replaced the water pump in December..

My friend who is a Ford guy said he thinks it's either my radiator cap or my fan clutch. He recommended replacing the cap, and buying a fan from the scrap yard without a clutch and put that on instead of replacing the fan-clutch. I just want to do whatever I need to PROPERLY fix this problem. Any ideas? THANKS IN ADVANCE

Also, my driver-side power window is not wanting to come up, feels like the belt is slipping. Just curious if anyone knows how tricky this replacement is and how expensive the belt is.

I LOVE this group and it has been a lifesaver.

OHHHH and FYI to everybody... We did all the lower motor work, water pump, oil pump, timing chain cover gasket, thermostat, EVERYTHING with the motor in the truck. We jacked it up to get access, but we didn't pull the motor and although it was a little tricky at times, it was possible. So for anyone wondering if it is possible, it is! And that was with the larger hi-flow oil pump as well.

#25

Join Date: Feb 2002

Location: Greater Austin, Texas

Posts: 7,300

Likes: 0

Received 355 Likes

on

285 Posts

There is no belt in the power window. The plastic gears in your motor are shot. You can get a kit to replace them on Amazon. You will need to R&R the motor. If it's never been done before, you will need to drill two 1/2" holes in the door frame to access 2 of the bolts. The other is exposed enough to get it without drilling. The door frame is already dimpled where you are supposed to drill. Three 5/16" bolts hold the motor to the window regulator.

#26

#27

That was a mouth! You may have air in the system still. Get the front end up higher than it sits on the ground and see if you can burp any air out of it. The air always rises to the top in the system and sometimes just plain gets stuck for whatever reason. That's a simple thing to look at first.

#28

Bird-Dog, I'm going to try to jack up the front end and let it run and add water as needed, but after letting it run for 20 min just awhile ago, it got to normal temp and was running fine, WITH THE RAD CAP OFF. As soon as I cut it off she gurgled up some, leading me to believe my cap is bad and not holding pressure, but releasing all the coolant into the overflow, hence the overflow-overflowing and bubbling out of the overflow. I'm picking up a new cap to try but I'll definitely try the burping first just to be sure.

***I swear it's always something. Took the wheel off to replace the bearing and I cant get the last two locker screws out. The star/torks ones. Broke one star bit head off in one and cant get the other to budge... Looks like I'm going to be drilling out the heads to pull the locker cap. But I sadly think that's when I'll discover the REAL work. Haha****

***I swear it's always something. Took the wheel off to replace the bearing and I cant get the last two locker screws out. The star/torks ones. Broke one star bit head off in one and cant get the other to budge... Looks like I'm going to be drilling out the heads to pull the locker cap. But I sadly think that's when I'll discover the REAL work. Haha****

#29

What brand t-stat did you install?

If not Motorcraft, then I suspect it.

Was the t-stat installed correctly?

Is the water pump new?

If your driving around and it's fine, but then it's starting to boil over just after shutting down, really points me to a stuck closed t-stat or it is failing and not allowing it to open properly. That would coincide when just driving it and then shutting down and shortly after, it's dumping out the overflow tank.

If not Motorcraft, then I suspect it.

Was the t-stat installed correctly?

Is the water pump new?

If your driving around and it's fine, but then it's starting to boil over just after shutting down, really points me to a stuck closed t-stat or it is failing and not allowing it to open properly. That would coincide when just driving it and then shutting down and shortly after, it's dumping out the overflow tank.