Tomahawk's F100

#991

Ya some times over building stuff is not always the best. This is usually only the case when dynamic loading forces are at play. Some times stuff needs to be able to flex or absorb shock loading to prevent fatigue cracking.

This is one of the reasons hot riveting lasted so long in certain applications and is still even used today on certain structures like steel truss bridges. Rivets or bolting allow the structure to flex where as welding although stronger for static capacity with repeated flexing such as steel truss bridges see the welds would eventually fail.

Usually once a person understands how frame mount receiver hitches work it makes sense and it is actually quite surprising the amount of the engineering calculations that go in to something as simple as a frame mount receiver hitch to make it strong enough to handle the loads encountered yet flexible enough to prevent shock loads being transmitted to the attachment points to prevent fatigue cracking. This comes in to play even more when it is being built to a price point.

#992

The receiver directly welded to the 2x2 cross member would be a better setup.

I wanted to reuse the old bumper so I had to mount the receiver out on the edge of the 1/2" steel plate. That makes a big moment arm, over 14" from the 2x2 tube to the hitch ball. That's about double the normal moment arm of an OEM hitch. I'm not sure how happy that 1/2" steel plate would be with a trailer ball hanging out over 14" so welding the plate to the bumper was an easy decision.

I wanted to reuse the old bumper so I had to mount the receiver out on the edge of the 1/2" steel plate. That makes a big moment arm, over 14" from the 2x2 tube to the hitch ball. That's about double the normal moment arm of an OEM hitch. I'm not sure how happy that 1/2" steel plate would be with a trailer ball hanging out over 14" so welding the plate to the bumper was an easy decision.

Not all hitches have the receiver tube welded directly to the cross tube.

Most off the shelf ones do just for cost considerations during fabrication.

The only thing that would need to be changed is a chunk of angle welded to the plate and the cross tube to help distribute the stress so it is not all on the

welds on the plate. This is also for saftey reasons, If a group of welds fail there is not just one group of material welds keeping things attached but 2 separate groups of material welds.

Most off the shelf receiver hitches are built this way that have tube mounted under or on the cross tube. See below. Some do away with it by having the receiver tube integral to the cross tube. .

#993

. Personal miles doesn't matter.

. Personal miles doesn't matter.

#994

Your set up is fine even with the 1/2" plate extension the cross tube would just need to be sized appropriately to accommodate the extra distance (or torque) from it being placed so far away.

Not all hitches have the receiver tube welded directly to the cross tube.

Most off the shelf ones do just for cost considerations during fabrication.

The only thing that would need to be changed is a chunk of angle welded to the plate and the cross tube to help distribute the stress so it is not all on the welds on the plate.

Not all hitches have the receiver tube welded directly to the cross tube.

Most off the shelf ones do just for cost considerations during fabrication.

The only thing that would need to be changed is a chunk of angle welded to the plate and the cross tube to help distribute the stress so it is not all on the welds on the plate.

LOL J/K Sorry I couldn't resist.

LOL J/K Sorry I couldn't resist.

Good stuff Matt.

#995

Interesting information from someone in the engineering field. This falls into the "overbuild it" category. Sometimes that is not a good thing.

Nice work Gavin.......as usual.

I took ol blue to a BBQ last weekend. It was with a bunch of racing/gearhead buddies that go back 20+ years. Many hadn't seen the truck in lots years. I told them how much loving it needs, but they say "no it doesn't". It still looks the same, though the driver is getting rough

Nice work Gavin.......as usual.

I took ol blue to a BBQ last weekend. It was with a bunch of racing/gearhead buddies that go back 20+ years. Many hadn't seen the truck in lots years. I told them how much loving it needs, but they say "no it doesn't". It still looks the same, though the driver is getting rough

It looks even better with the bumper.

From the cab to the bumper is complete! Now on to the engine compartment.

#996

#997

#998

#999

Join Date: Nov 2005

Location: La Ribera, Baja, Mexico

Posts: 2,694

Likes: 0

Received 43 Likes

on

25 Posts

OMG Matt, now you have me going out to crawl under 'Ol Ralph and photographing my home made bumper and hitch... All welded solid, to the 4" pipe bumper, which hangs from 5/8" plates, bolted with 6, 5/8" grade 8 bolts, washers, and lock nuts to the rear of the frame. Just a bit of over injunearing. My 'Baja' injunearing manual sez... "If 1 will do, 2 has to be better and more secure." The manual guarantees me that it will hold until it breaks... photo soon...

Sorry for jumping in on this Gavin, but your bumper looks so clean, and Matt's engineering obviously so correct, and its true, that you never know when you will need to pull 10K...

Baja

Sorry for jumping in on this Gavin, but your bumper looks so clean, and Matt's engineering obviously so correct, and its true, that you never know when you will need to pull 10K...

Baja

#1000

Join Date: Nov 2005

Location: La Ribera, Baja, Mexico

Posts: 2,694

Likes: 0

Received 43 Likes

on

25 Posts

Well amigos, I do not remember getting so carried away with bolts when I put this bumper on 4 or 5 years ago... but I hope Matt sees this, and makes some comments engineering wise... and humor is always good

dangme, for some reason my photos won't post at this time??? oh well,, another try later...

Baja

dangme, for some reason my photos won't post at this time??? oh well,, another try later...

Baja

#1002

Sorry just seen this I was miss stuff when threads jumps to the next page DOH and I do not mean to hi jack but.

Your set up should be fine. You have the bumper/hitch mounted to the frame on on 2 axis's the side of the frame and the bottom of the channel the bottom bolting will prevent the side plate from flexing in the vertical plane this will for all intense purposes make the bumper structurally integral (one piece) with the frame. Plus the Bumper is a cross tube and believe it or not that tube will flex a bit.

It will transfer shock loading to the frame of the vehicle but not the attachment points and could potentially lead to fatigue cracking in the frame at other locations but I think this is unlikely as Ford truck frames are fairly flexible and should be able absorb most of the shock loading. Occasional frame inspections ( like once a year) at transition points ( depth of frame or width changes) and at the first cross member in front of the attachment point (that area I would inspect closely) it would be cheap insurance if you are towing above class 3 regularly. Do check the welds on the crosstube also when you inspect this just as a matter of fact.

In all likely hood you will never have issue,

Now if you are constantly towing 10K plus then a more conventional torsion tube receiver would be advisable.

If this was a newer box style frame then all bets would off and in time fatigue cracking would be inevitable. There are too many places to start stress risers from on modern boxed truck frames with all the dimensional changes along the length of the frame.

#1003

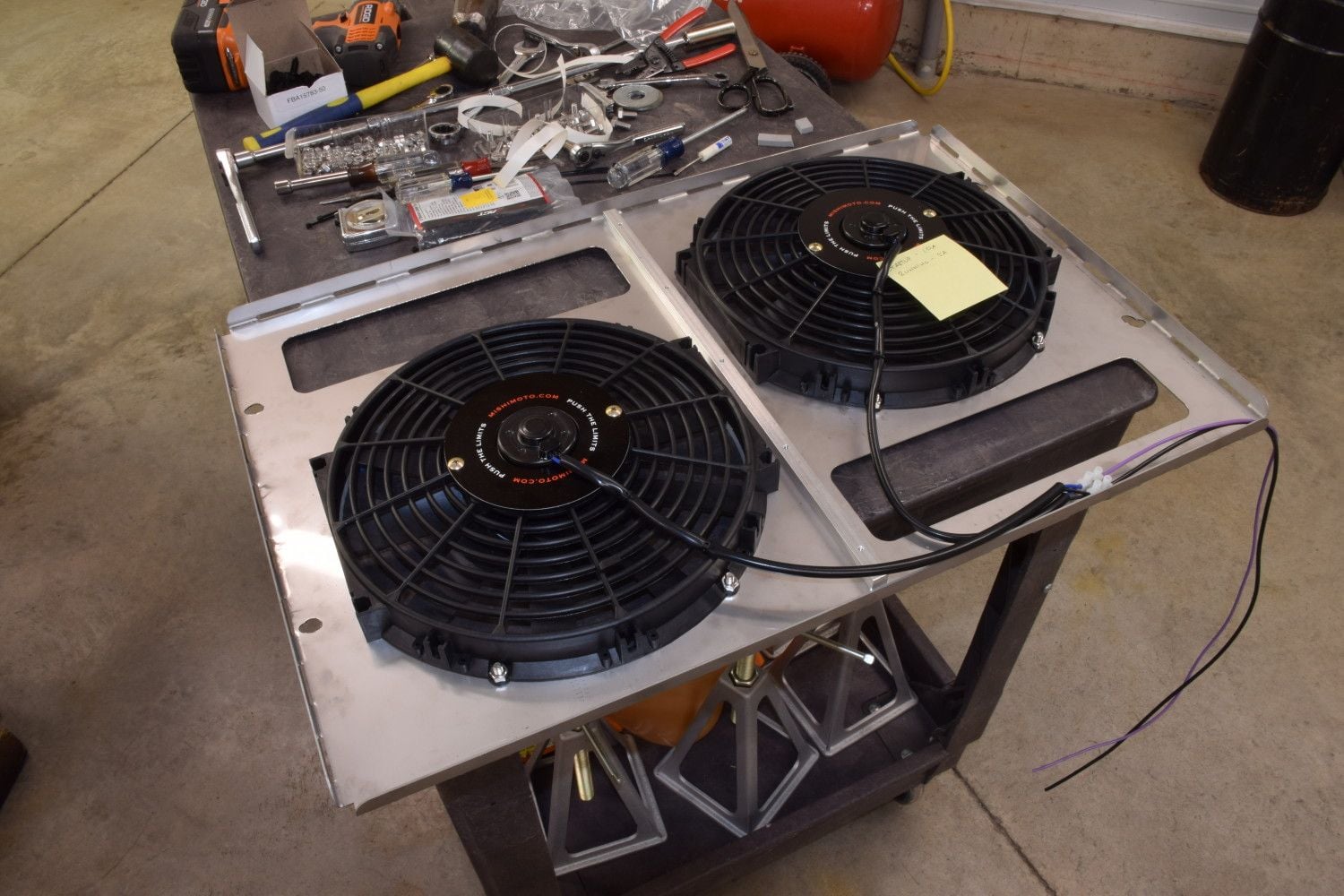

I got my electric fans working tonight.

I ran the engine for 15-20 minutes tonight at 1800-2200 RPM finishing up breaking in the cam.

The fans work great!

#1005