Starts for 2 secs then dies, Now With Video

#31

I believe applying voltage to the IPR closes it.

Have you tried pushing the go pedal some when it does start?

EDIT: The amount of fuel injected depends on HPO pressure and injection pulse width. If the pressure is too high then the pulse width would have to be shorter. Once the pulse width gets too short it probably just dies. If ICP is higher than the PCM is calling for it should set the CEL though.

Have you tried pushing the go pedal some when it does start?

EDIT: The amount of fuel injected depends on HPO pressure and injection pulse width. If the pressure is too high then the pulse width would have to be shorter. Once the pulse width gets too short it probably just dies. If ICP is higher than the PCM is calling for it should set the CEL though.

Last edited by cowmilker08; 02-03-2015 at 11:32 AM. Reason: Added info

#32

Have you repaired the vcwh yet. I just noticed the pictures and that's where I would start. That's some kinda nasty. Although it doesn't really explain why your icp spikes so high. It may not be a bad idea to yank the fuel bowl and check the wires under it. When I pulled mine the insulation was all melted into a nice mess. Exposing wires and begging for a issue.

#33

Yes, I believe that is correct. I'm waiting for parts in the mail so I've been killing time by reading and taking notes.

1. The Injector Pressure Regulator valve is normally open.

2. It is closed with a 12V pulse width modulated signal

3. With the key on, there should be a steady 12V at the red wire.

4. The red/yellow wire is the ground. It is modulated by the PCM.

5. The key on duty cycle is 14.8%

6. For a short time the valve can be forced closed by applying 12V directly from the battery.

7. The IPR Solenoid coil resistance should be 10.1-10.5 ohms.

8. If the 12V key on reference voltage is missing, check fuse #113

I get zero throttle response. That's partly why I believe that there is no signal to the injectors. With 3,000psi to the heads, any signal at all should keep it running. Unfortunately I don't have the means to monitor injector pulse width. I'm seriously thinking of buying Autoenginuity.

This makes sense and it does trigger a CEL but I have no way to analyze it. Another good argument for owning Autoenginuity.

I just placed my order with Riff Raff this morning. I'm upgrading to the Super Duty style.

It could if one of the melted wires is to the IPR. After doing some reading, I wonder if my IPR control wire hasn't gone to ground causing 100% duty cycle. Would that cause the PCM to interrupt signal to the injectors?

I no longer have a fuel bowl but this is looking more and more like an electronic/wiring problem.

The only thing left of my fuel bowl is the regulator.

My fuel filter is now mounted on the radiator bracket. I need to change the pressure gauge to a zero to thirty or even a 0-15psi gauge. What is the maximum pressure on the low pressure side of the fuel pump?

1. The Injector Pressure Regulator valve is normally open.

2. It is closed with a 12V pulse width modulated signal

3. With the key on, there should be a steady 12V at the red wire.

4. The red/yellow wire is the ground. It is modulated by the PCM.

5. The key on duty cycle is 14.8%

6. For a short time the valve can be forced closed by applying 12V directly from the battery.

7. The IPR Solenoid coil resistance should be 10.1-10.5 ohms.

8. If the 12V key on reference voltage is missing, check fuse #113

I get zero throttle response. That's partly why I believe that there is no signal to the injectors. With 3,000psi to the heads, any signal at all should keep it running. Unfortunately I don't have the means to monitor injector pulse width. I'm seriously thinking of buying Autoenginuity.

EDIT: The amount of fuel injected depends on HPO pressure and injection pulse width. If the pressure is too high then the pulse width would have to be shorter. Once the pulse width gets too short it probably just dies. If ICP is higher than the PCM is calling for it should set the CEL though.

It could if one of the melted wires is to the IPR. After doing some reading, I wonder if my IPR control wire hasn't gone to ground causing 100% duty cycle. Would that cause the PCM to interrupt signal to the injectors?

The only thing left of my fuel bowl is the regulator.

My fuel filter is now mounted on the radiator bracket. I need to change the pressure gauge to a zero to thirty or even a 0-15psi gauge. What is the maximum pressure on the low pressure side of the fuel pump?

#34

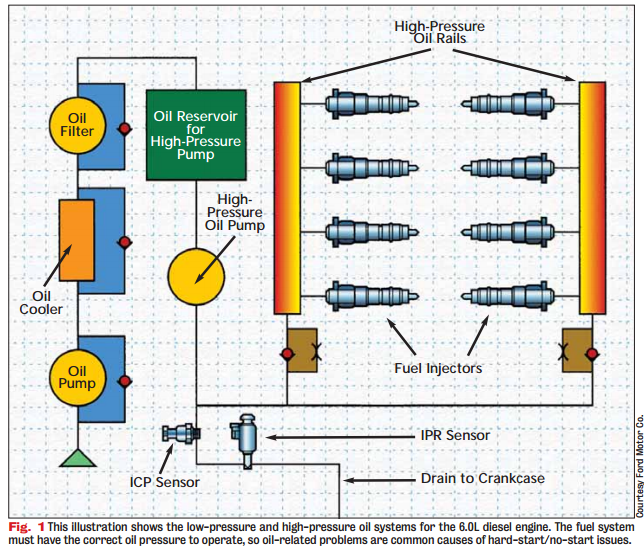

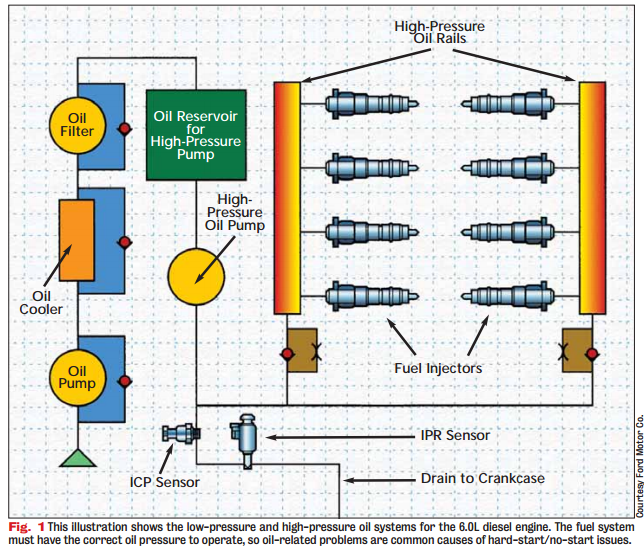

The 6.0 schematic below shows a symbol for quick dis-connects with one way check ***** at the end of each head galley. Does the 7.3 have any check valves between the HPOP and heads?

Link to wholestory

http://www.motor.com/magazine/pdfs/112011_09.pdf

Link to wholestory

http://www.motor.com/magazine/pdfs/112011_09.pdf

#35

#36

A cheaper alternative to autoenginuity is the Torque Pro app. It does most but not all things that AE can do. The down side is you have to buy a Bluetooth to OBD-II adapter for either $12 or $100. Plus you have to have an android device and buy the $5 app.

Low side pressure should be about 7 psi IIRC.

Low side pressure should be about 7 psi IIRC.

#37

A cheaper alternative to autoenginuity is the Torque Pro app. It does most but not all things that AE can do. The down side is you have to buy a Bluetooth to OBD-II adapter for either $12 or $100. Plus you have to have an android device and buy the $5 app.

Low side pressure should be about 7 psi IIRC.

Low side pressure should be about 7 psi IIRC.

#39

THE BEAST LIVES!

Thereís nothing worse than a thread that dies off with no conclusion. Iím always looking for the solution at the end of the problem but so often the OPís truck is running, theyíre happy and we get no conclusion.

Hereís the problemÖ I donít know what fixed it. Yes I found problems but I donít believe any of them would cause it to instantly die after starting.

Hereís what I found;

The ICP sending unit was leaking oil into the plug housing. I believe that it was still working correctly but even if it wasnít, the ECP would default to 750psi and the truck would still run. I installed a new ICP.

The UVCHís were all hosed up. Both sides had melted glow plug contacts. I also found one bad (open) glowplug. Surprisingly, as bad as the connectors look, none of the injector contacts ohmed out bad. The non-working glowplugs would contribute to hard starts but again would not cause it to instantly die. I replaced the UVCH,s with a new set of Super Dutyís and soldered in new Super Duty pigtails and installed all new Beru glowplugs. Surprisingly those were the original factory harnesses with 220K on them! I had this open at 120K to replace glowplugs and repair the pigtails but everything looked good under the valve covers at that time.

And just for kicks, a cross section of a glowplug. I always wanted to know what the windings looked like inside. This is the bad glowplug that ohmed out as open. I was hoping the cross section would reveal the falure but I donít see any.

The EBP (exhaust back pressure sensor) was thoroughly plugged top to bottom. I donít know how the ECP processes this info so Iím hoping someone can share this info here. I'm guessing it just effects minor fueling parameters? I removed the sensor, Sensor tube and even the fitting from the front of the passenger side exhaust manifold. They were all plugged. The tube was the hardest to clean but I was finally successful using a throttle cable from my sonís sprint-kart and lots of PB Blaster. Last, I flushed it with the garden hose. Lots of crud was flushed.

My top notch mechanics, Peanut and Plain helped me thoroughly inspect the engine wiring harness. There were no opens, shorts or crossovers of any kind, every single wire ohmed out pin for pin exactly according to the wiring schematic. I really thought I might find something here. Other than a melted seal around the IPR plug, it was perfect. I cleaned off all of the old tape, spliced in a new IPR plug, Spliced in Super Duty pigtails, re-taped every thing using vulcanizing rubber tape and re-installed the harness.

The breather needs new O-rings but thatís hardly an issue here. Since itís off, Iíll probably plumb it out the bottom and seal the intake hole. I always hate seeing engine oil going into my turbo.

Speaking of turboÖ I was happy to see that my wheel looked clean and un-dinged. End play was also tight.

So the bottom line isÖ I could find no cause. Yes, itís good that I was able to tidy up the miscellaneous maintenance issues and the truck is running but I really hate not knowing why.

I only have one speculation;

Is it possible that the incompatible ScangaugeII was the problem? I read elsewhere on this forum that trying to pull codes on our trucks with a ScangaugeII will kill the engine. I was messing with it the morning it died. I did all of the fixes mentioned above, unplugged the Scangauge and now it runs fine. And NO, Iím not willing to plug it back in and verify the theory.

Side note;

I inspected the fuel regulator for cleanliness and dropped (lost) the BB.

Now I'm down to 40 psi again

I think there is air in the oil galleys. It now takes 5-10 secs of cranking to pump up to the minimum start pressure but it fires easily and holds pressure once there. I've had both head galleys open to connect my pressure gauge so Maybe I just need to make a couple hard runs and clean the air out.

I also noticed that some of my injectors were barely pumping oil. could air in the galley be the cause. I unplugged each one individually and they were all contributing equally. I would really hate to have to replace them with some 200cc/30%

Thereís nothing worse than a thread that dies off with no conclusion. Iím always looking for the solution at the end of the problem but so often the OPís truck is running, theyíre happy and we get no conclusion.

Hereís the problemÖ I donít know what fixed it. Yes I found problems but I donít believe any of them would cause it to instantly die after starting.

Hereís what I found;

The ICP sending unit was leaking oil into the plug housing. I believe that it was still working correctly but even if it wasnít, the ECP would default to 750psi and the truck would still run. I installed a new ICP.

The UVCHís were all hosed up. Both sides had melted glow plug contacts. I also found one bad (open) glowplug. Surprisingly, as bad as the connectors look, none of the injector contacts ohmed out bad. The non-working glowplugs would contribute to hard starts but again would not cause it to instantly die. I replaced the UVCH,s with a new set of Super Dutyís and soldered in new Super Duty pigtails and installed all new Beru glowplugs. Surprisingly those were the original factory harnesses with 220K on them! I had this open at 120K to replace glowplugs and repair the pigtails but everything looked good under the valve covers at that time.

And just for kicks, a cross section of a glowplug. I always wanted to know what the windings looked like inside. This is the bad glowplug that ohmed out as open. I was hoping the cross section would reveal the falure but I donít see any.

The EBP (exhaust back pressure sensor) was thoroughly plugged top to bottom. I donít know how the ECP processes this info so Iím hoping someone can share this info here. I'm guessing it just effects minor fueling parameters? I removed the sensor, Sensor tube and even the fitting from the front of the passenger side exhaust manifold. They were all plugged. The tube was the hardest to clean but I was finally successful using a throttle cable from my sonís sprint-kart and lots of PB Blaster. Last, I flushed it with the garden hose. Lots of crud was flushed.

My top notch mechanics, Peanut and Plain helped me thoroughly inspect the engine wiring harness. There were no opens, shorts or crossovers of any kind, every single wire ohmed out pin for pin exactly according to the wiring schematic. I really thought I might find something here. Other than a melted seal around the IPR plug, it was perfect. I cleaned off all of the old tape, spliced in a new IPR plug, Spliced in Super Duty pigtails, re-taped every thing using vulcanizing rubber tape and re-installed the harness.

The breather needs new O-rings but thatís hardly an issue here. Since itís off, Iíll probably plumb it out the bottom and seal the intake hole. I always hate seeing engine oil going into my turbo.

Speaking of turboÖ I was happy to see that my wheel looked clean and un-dinged. End play was also tight.

So the bottom line isÖ I could find no cause. Yes, itís good that I was able to tidy up the miscellaneous maintenance issues and the truck is running but I really hate not knowing why.

I only have one speculation;

Is it possible that the incompatible ScangaugeII was the problem? I read elsewhere on this forum that trying to pull codes on our trucks with a ScangaugeII will kill the engine. I was messing with it the morning it died. I did all of the fixes mentioned above, unplugged the Scangauge and now it runs fine. And NO, Iím not willing to plug it back in and verify the theory.

Side note;

I inspected the fuel regulator for cleanliness and dropped (lost) the BB.

Now I'm down to 40 psi again

I think there is air in the oil galleys. It now takes 5-10 secs of cranking to pump up to the minimum start pressure but it fires easily and holds pressure once there. I've had both head galleys open to connect my pressure gauge so Maybe I just need to make a couple hard runs and clean the air out.

I also noticed that some of my injectors were barely pumping oil. could air in the galley be the cause. I unplugged each one individually and they were all contributing equally. I would really hate to have to replace them with some 200cc/30%

#41

Hey!! It's alive! Good deal man. I'd put my money on the SGII. It would have been nice to have known you had that on the truck when we were troubleshooting it.  Pulling that would have likely been one of the first things recommended.

Pulling that would have likely been one of the first things recommended.

At any rate, it doesn't matter much now. I'm glad you have it up and running again.

Pulling that would have likely been one of the first things recommended.

Pulling that would have likely been one of the first things recommended. At any rate, it doesn't matter much now. I'm glad you have it up and running again.

#42

I only have one speculation;

Is it possible that the incompatible ScangaugeII was the problem? I read elsewhere on this forum that trying to pull codes on our trucks with a ScangaugeII will kill the engine. I was messing with it the morning it died. I did all of the fixes mentioned above, unplugged the Scangauge and now it runs fine. And NO, Iím not willing to plug it back in and verify the theory.

Is it possible that the incompatible ScangaugeII was the problem? I read elsewhere on this forum that trying to pull codes on our trucks with a ScangaugeII will kill the engine. I was messing with it the morning it died. I did all of the fixes mentioned above, unplugged the Scangauge and now it runs fine. And NO, Iím not willing to plug it back in and verify the theory.

#43

#44

Glad I looked back up the thread.

I'd have checked the Tin nut on the IPR.

The ICP is easy to test just by unplugging it.

Looks like almost all your issue was in the wiring for the injectors.

That one burnout can make a huge difference.

These trucks can run on 7 cylinders, so you might have had an issue with both sides.

I'd have checked the Tin nut on the IPR.

The ICP is easy to test just by unplugging it.

Looks like almost all your issue was in the wiring for the injectors.

That one burnout can make a huge difference.

These trucks can run on 7 cylinders, so you might have had an issue with both sides.

Thread

Thread Starter

Forum

Replies

Last Post